steering rack play

#1

Thread Starter

Elite Member

iTrader: (2)

Joined: May 2007

Posts: 2,608

Total Cats: 16

From: Cromwell, Connecticut

I have a depowered rack in my 96. I just drained the fluid , greased the gears, and looped the lines because 96's are different than the ones in flyinmiatas instructions and I couldn't get it all apart to take the seals out.

The rack has been depowered for a few thousand miles and there is a lot of slop in the steering now. You can hear the clunk back and forth when you move the wheel. I have tightened the adjuster all the way and it still has a lot of play in it.

Any suggestions? should I be looking for a new rack?

The rack has been depowered for a few thousand miles and there is a lot of slop in the steering now. You can hear the clunk back and forth when you move the wheel. I have tightened the adjuster all the way and it still has a lot of play in it.

Any suggestions? should I be looking for a new rack?

#2

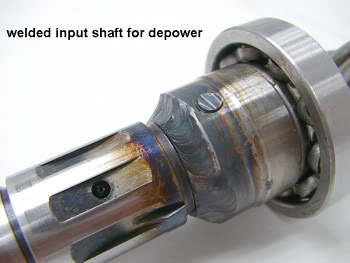

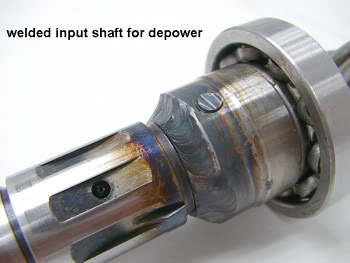

It might be your quill has too much play and may need to be welded. I'm not sure about the clunking though. It could be the valve/seals in the rack.

http://forum.miata.net/vb/showthread...ck#post3922065

http://forum.miata.net/vb/showthread...ck#post3922065

#11

Tightening the adjuster "all the way" isn't a solution; it has to be adjusted correctly or you'll either damage the rack and pinion gears, or you'll add excessive friction and accelerate wear of the rack and pinion gears. There's a sweet spot and anything out of that spot isn't good. Besides, it didn't seem to help you so there's something else amiss and there aren't really that many moving parts. To me everything points to a failed pinion.

You either need to replace the rack or take it apart and have a good look at the internals. I definitely wouldn't drive it that way.

#13

My bet it is the steering shaft. I’ve had 2 of them develop slop.

The shaft between the firewall and the rack is a splined slip shaft, you can see the step in it where its got outer tube connected to the firewall U-joint and an inner shaft connected to the rack U-joint. It is splined on the inside. To keep it from having slop in the splines it has plastic injected into it. A downpipe leak or just really hot exhaust like near a turbo can cause the plastic to melt and then you start feeling slop. Sort of a clunking feeling in the steering.

Get somebody to wiggle the steering wheel while you look down at the joint in the middle of the shaft in the engine bay. You can either see or feel the two parts of the shaft move relative to each other. when the plastic melts the thing can be slipped apart as well.

Bob

The shaft between the firewall and the rack is a splined slip shaft, you can see the step in it where its got outer tube connected to the firewall U-joint and an inner shaft connected to the rack U-joint. It is splined on the inside. To keep it from having slop in the splines it has plastic injected into it. A downpipe leak or just really hot exhaust like near a turbo can cause the plastic to melt and then you start feeling slop. Sort of a clunking feeling in the steering.

Get somebody to wiggle the steering wheel while you look down at the joint in the middle of the shaft in the engine bay. You can either see or feel the two parts of the shaft move relative to each other. when the plastic melts the thing can be slipped apart as well.

Bob

#15

I would say a replacement would be alot more expensive than just having the two welded. Even if you do replace that plastic is just going to melt again (if you're turboed and if that is what caused the problem in the first place).

I wonder if wrapping that joint with reflective heat wrap could extend it's lifetime. Just an idea.

I wonder if wrapping that joint with reflective heat wrap could extend it's lifetime. Just an idea.

Last edited by seraph; 08-31-2010 at 04:20 PM. Reason: ninja edit

#19

I would say a replacement would be alot more expensive than just having the two welded. Even if you do replace that plastic is just going to melt again (if you're turboed and if that is what caused the problem in the first place).

I wonder if wrapping that joint with reflective heat wrap could extend it's lifetime. Just an idea.

I wonder if wrapping that joint with reflective heat wrap could extend it's lifetime. Just an idea.

I would trust that more than a weld.

Bob