Delrin Control arm bushings... yay or nay?

#1

Thread Starter

Junior Member

iTrader: (1)

Joined: Jun 2014

Posts: 133

Total Cats: -7

From: Toronto, ON, Canada

Hey Miata turbo,

Tis the season for car overhauls... on my to-do list is new control arm bushings. I'm a machinist and I am able to make my own parts in my boss's shop as long as i'm punched out. So i'm debating if I should just make my own control arm bushings, or suck it up and buy poly.

What I like about delrin is that I don't have to re grease them like poly bushings. Also I really just have to pay for material costs.

But I'm not sure how much more harsh delrin bushings will be.

My car is pretty much a fun weekend street car that I take to the track. Not a daily driver...

I would love to hear opinions from people who have delrin control arm bushings!

Tis the season for car overhauls... on my to-do list is new control arm bushings. I'm a machinist and I am able to make my own parts in my boss's shop as long as i'm punched out. So i'm debating if I should just make my own control arm bushings, or suck it up and buy poly.

What I like about delrin is that I don't have to re grease them like poly bushings. Also I really just have to pay for material costs.

But I'm not sure how much more harsh delrin bushings will be.

My car is pretty much a fun weekend street car that I take to the track. Not a daily driver...

I would love to hear opinions from people who have delrin control arm bushings!

#3

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

You can run one poly in each lower control arm. My current plan is delrin everywhere except 4 polys in the lower control arms and sphericals the the upper rear.

You should still grease delrin, it will make it last longer.

Search for the rear upper sphericals thread.

You should still grease delrin, it will make it last longer.

Search for the rear upper sphericals thread.

#4

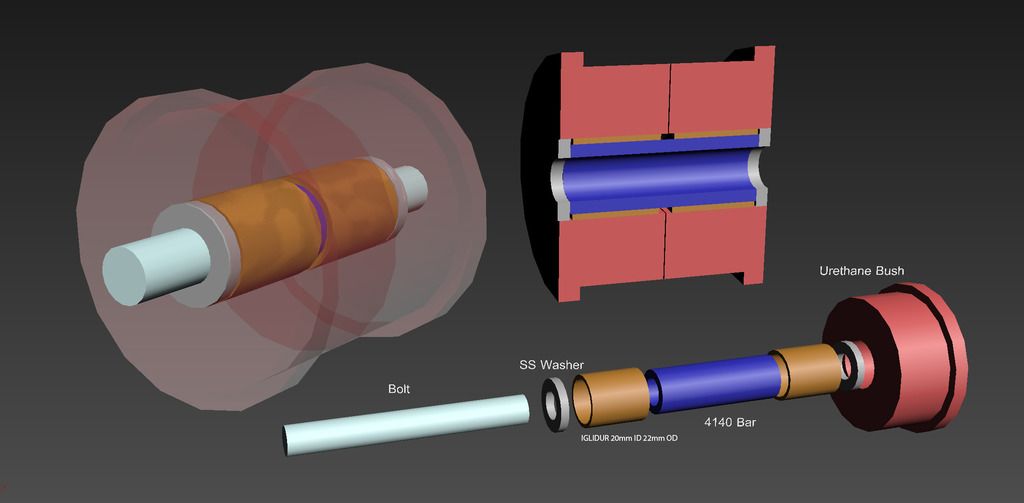

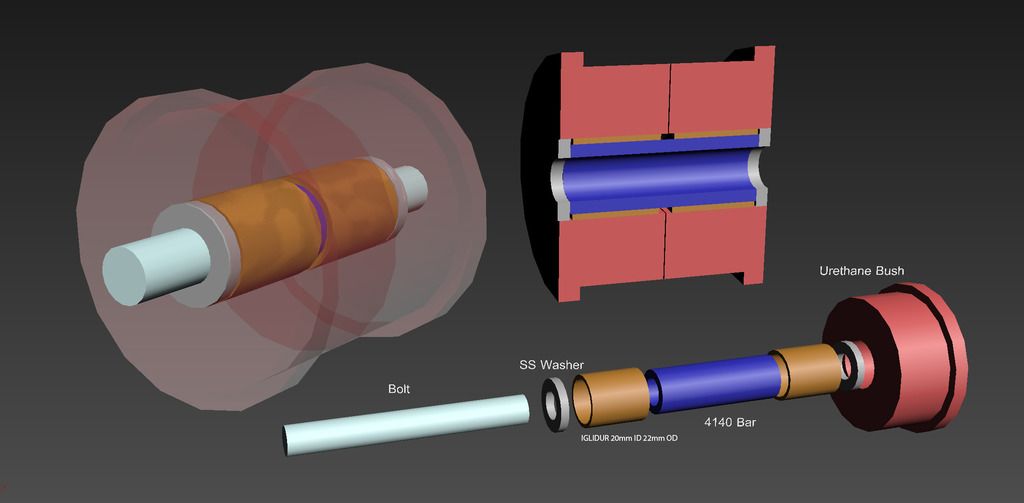

bbundy posted in the spherical thread about a way of using bronze bearings inside poly bushes. I've made my own version of this using machined 4140 sleeves and running thin plastic delrin bushings in between the sleeve and the poly bushing.

All up it works brilliantly. You get the benefit of the poly bushing with some give for alignment but with basically zero friction like a spherical.

I have no idea on how long the bearing surface will last, but I don't do lots of km. Also they are cheap @ around $1 each bearing. I think if you're worried about it you could run bronze instead but I think they are around $6 a bearing.

All up it works brilliantly. You get the benefit of the poly bushing with some give for alignment but with basically zero friction like a spherical.

I have no idea on how long the bearing surface will last, but I don't do lots of km. Also they are cheap @ around $1 each bearing. I think if you're worried about it you could run bronze instead but I think they are around $6 a bearing.

#5

So you just used the off the shelf poly kit, then cut down the 4140 bar? It all fits inside, just replaces the poly kit center pin?

That's pretty neat-o. My cheap poly bushing kit is oversized though, and I think most all of the play on the lower control arms comes from the large bushing face against the subframe pockets. Yours don't do that, I guess?

That's pretty neat-o. My cheap poly bushing kit is oversized though, and I think most all of the play on the lower control arms comes from the large bushing face against the subframe pockets. Yours don't do that, I guess?

#7

Yup, Energy suspension bushing kit. The only one that this doesn't work for is the upper rear, as the bushing is a different ID. You could probably order a special bearing to fit in this one, but I had to order a minimum of 20 of them from Germany and at that stage hadn't figured out that it was different.

It's all pretty solid when it's together, so the plastic bearing surface kinda squashes into the bushing. It's tight enough that it won't move against the poly surface once installed. It then slides over the 4140 sleeve with enough friction to turn easily with a thumb and finger inside the sleeve. I only used the washers on the end where there are the adjustment bolts for alignment. The washers probably aren't really needed but it helps stop the dirt getting in.

One issue I can see is that my car sits for a while between events and any moisture that gets in there might create some surface rust on the 4140 and then wear the bearing quicker. I've run like this for a few months now and pulled them apart the other day to check. It's all very clean in there and the bearing isn't wearing at all that I can see.

I used Iglidur bearings. 20mm ID, 22mm OD and they slide nicely into the poly bushings. I picked up a 3m 20mm OD peeled 4140 bar for $30 AUS. Bushings were like $1.50 AUS a piece (need 40 or so of them). Then you need about 6 hours of standing at a lathe drilling holes!

edit: there is a whole range of different composite bearing materials. I think I used G, but you can get ones that might be more suited with a high wear resistance and also strength. They cost more though. Also I'm not sure this setup would be suited to a street car. Life might really take a hit with daily use.

It's all pretty solid when it's together, so the plastic bearing surface kinda squashes into the bushing. It's tight enough that it won't move against the poly surface once installed. It then slides over the 4140 sleeve with enough friction to turn easily with a thumb and finger inside the sleeve. I only used the washers on the end where there are the adjustment bolts for alignment. The washers probably aren't really needed but it helps stop the dirt getting in.

One issue I can see is that my car sits for a while between events and any moisture that gets in there might create some surface rust on the 4140 and then wear the bearing quicker. I've run like this for a few months now and pulled them apart the other day to check. It's all very clean in there and the bearing isn't wearing at all that I can see.

I used Iglidur bearings. 20mm ID, 22mm OD and they slide nicely into the poly bushings. I picked up a 3m 20mm OD peeled 4140 bar for $30 AUS. Bushings were like $1.50 AUS a piece (need 40 or so of them). Then you need about 6 hours of standing at a lathe drilling holes!

edit: there is a whole range of different composite bearing materials. I think I used G, but you can get ones that might be more suited with a high wear resistance and also strength. They cost more though. Also I'm not sure this setup would be suited to a street car. Life might really take a hit with daily use.

Last edited by Madjak; 12-18-2015 at 03:39 AM. Reason: Noted

#9

Joined: Sep 2012

Posts: 4,560

Total Cats: 1,142

From: your mom's house phoenix, AZ

Myself, Adidan and Monkeywinkey (spelling?) have all wanted to start a master bushing thread with all this info, because who searches "upper spherical thing" when they want to find a better than poly solution?

I plan to very soon.

Aidan, tag monkeywinkey for me. I want to see if he ever got his set done ad the results...

edit- its monkeywinky

I plan to very soon.

Aidan, tag monkeywinkey for me. I want to see if he ever got his set done ad the results...

edit- its monkeywinky

#10

Thread Starter

Junior Member

iTrader: (1)

Joined: Jun 2014

Posts: 133

Total Cats: -7

From: Toronto, ON, Canada

Myself, Adidan and Monkeywinkey (spelling?) have all wanted to start a master bushing thread with all this info, because who searches "upper spherical thing" when they want to find a better than poly solution?

I plan to very soon.

Aidan, tag monkeywinkey for me. I want to see if he ever got his set done ad the results...

I plan to very soon.

Aidan, tag monkeywinkey for me. I want to see if he ever got his set done ad the results...

I guess no one... Because you don't know what you don't know.

#11

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

@monkeywinky

I have purchased the delrin, bushings just need to be made. I'm also doing an ABS swap at the same time so everything will be out of the car.

I have purchased the delrin, bushings just need to be made. I'm also doing an ABS swap at the same time so everything will be out of the car.

#12

Yea I've been using my bronze bushed poly for a year now they have worked flawlessly. Using Bronze bushings inside Poly. all the benefits of poly with friction similar to spherical and even lower wear rate than spherical.

Almost all the standard poly versions uses 7/8" sleeves. Low friction bushings with a 3/4" Id and 7/8" od of many different kinds and materials are readily available off the shelf. I used ĺ” 4340 bar to make new sleeves came with a mirrored surface finish already. madjaks picture describes what I made. I like the higher strength stuff so the thinner wall section and reduced bearing area doesn't squish when you over tighten the cam bolts to keep them from slipping.

Almost all the standard poly versions uses 7/8" sleeves. Low friction bushings with a 3/4" Id and 7/8" od of many different kinds and materials are readily available off the shelf. I used ĺ” 4340 bar to make new sleeves came with a mirrored surface finish already. madjaks picture describes what I made. I like the higher strength stuff so the thinner wall section and reduced bearing area doesn't squish when you over tighten the cam bolts to keep them from slipping.

#17

Yup, Energy suspension bushing kit. The only one that this doesn't work for is the upper rear, as the bushing is a different ID. You could probably order a special bearing to fit in this one, but I had to order a minimum of 20 of them from Germany and at that stage hadn't figured out that it was different.

It's all pretty solid when it's together, so the plastic bearing surface kinda squashes into the bushing. It's tight enough that it won't move against the poly surface once installed. It then slides over the 4140 sleeve with enough friction to turn easily with a thumb and finger inside the sleeve. I only used the washers on the end where there are the adjustment bolts for alignment. The washers probably aren't really needed but it helps stop the dirt getting in.

One issue I can see is that my car sits for a while between events and any moisture that gets in there might create some surface rust on the 4140 and then wear the bearing quicker. I've run like this for a few months now and pulled them apart the other day to check. It's all very clean in there and the bearing isn't wearing at all that I can see.

I used Iglidur bearings. 20mm ID, 22mm OD and they slide nicely into the poly bushings. I picked up a 3m 20mm OD peeled 4140 bar for $30 AUS. Bushings were like $1.50 AUS a piece (need 40 or so of them). Then you need about 6 hours of standing at a lathe drilling holes!

edit: there is a whole range of different composite bearing materials. I think I used G, but you can get ones that might be more suited with a high wear resistance and also strength. They cost more though. Also I'm not sure this setup would be suited to a street car. Life might really take a hit with daily use.

It's all pretty solid when it's together, so the plastic bearing surface kinda squashes into the bushing. It's tight enough that it won't move against the poly surface once installed. It then slides over the 4140 sleeve with enough friction to turn easily with a thumb and finger inside the sleeve. I only used the washers on the end where there are the adjustment bolts for alignment. The washers probably aren't really needed but it helps stop the dirt getting in.

One issue I can see is that my car sits for a while between events and any moisture that gets in there might create some surface rust on the 4140 and then wear the bearing quicker. I've run like this for a few months now and pulled them apart the other day to check. It's all very clean in there and the bearing isn't wearing at all that I can see.

I used Iglidur bearings. 20mm ID, 22mm OD and they slide nicely into the poly bushings. I picked up a 3m 20mm OD peeled 4140 bar for $30 AUS. Bushings were like $1.50 AUS a piece (need 40 or so of them). Then you need about 6 hours of standing at a lathe drilling holes!

edit: there is a whole range of different composite bearing materials. I think I used G, but you can get ones that might be more suited with a high wear resistance and also strength. They cost more though. Also I'm not sure this setup would be suited to a street car. Life might really take a hit with daily use.

#18

I pretty much gave up on Miata.net years ago after multiple discussions of the sort like proper alignment to achieve proper Miata balance required 1/2 degree more rear camber than front and your wheel bearings would explode in short order and your car would handle like crap if you didnít have between 40 and 45 mm offset on your wheels as Mazda intended. Sometimes I find Miataroadster.net entertaining and every now and then the out of the box moronic thinking that goes on there sparks ideas for something functional but not too often.

#19

22mm is basically 7/8" anyway with only 0.2mm difference. The larger metric bearings actually push into the poly nice and snuggly which is good I think. Over here it's directly opposite and trying to get non metric sizes is hard. You can basically replace 3/4" bar with 19mm too but the composite bearings don't come in that size.

Iglidur do imperial sizing so you could try using them instead of the bronze. They are nice and light!

With the thinner bearings there is a little more meat in the sleeve, enough I think to not need the washers on the adjustable links as they are only 2mm OD different to the standard sleaves. It would make them a bit easier to make and install without juggling the arms to keep the washers in place.

Iglidur do imperial sizing so you could try using them instead of the bronze. They are nice and light!

With the thinner bearings there is a little more meat in the sleeve, enough I think to not need the washers on the adjustable links as they are only 2mm OD different to the standard sleaves. It would make them a bit easier to make and install without juggling the arms to keep the washers in place.