Oil priming procedure?

#1

Senior Member

Thread Starter

iTrader: (2)

Join Date: Nov 2015

Location: Seattle

Posts: 1,426

Total Cats: 266

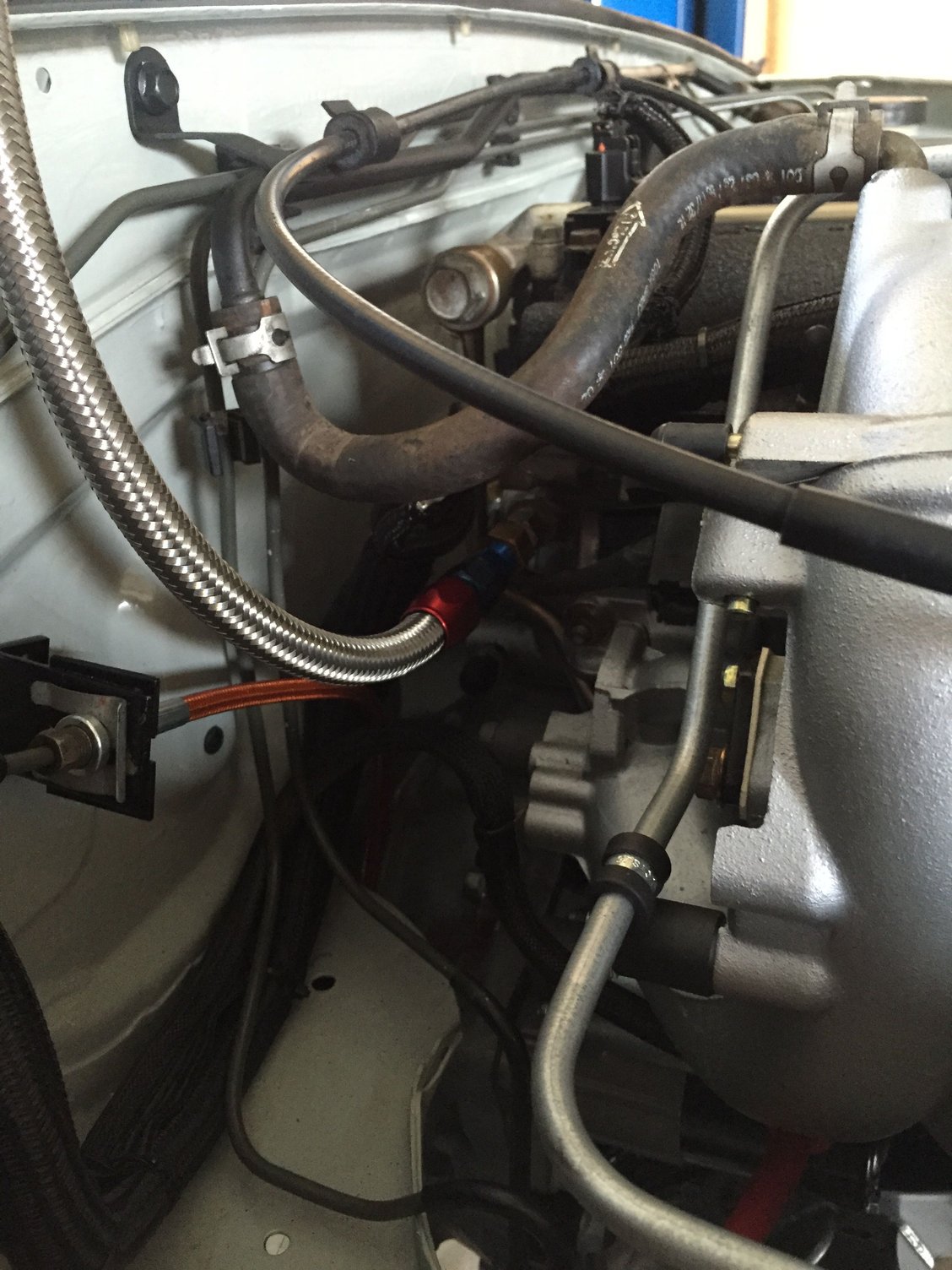

I'm just about ready to fire up the motor after a head rebuild & turbo install. I'd like to prime the oil pressure before I try to start it. I've never primed the oil before.

Is there an easy/preferred method? It seems like I might be able to just pull spark plugs so it turns over easily, and shut off spark & fuel from tunerstudio. MS3pro PNP FYI.

Is there an easy/preferred method? It seems like I might be able to just pull spark plugs so it turns over easily, and shut off spark & fuel from tunerstudio. MS3pro PNP FYI.

#2

SADFab Destructive Testing Engineer

iTrader: (5)

Join Date: Apr 2014

Location: Beaverton, USA

Posts: 18,642

Total Cats: 1,866

If you disconnect the crank/cam sensor it wont inject. Pull the plugs so theres no compression, and crank. My plan is to disconnect the oil drain on the turbo so I know oil is flowing through the turbo, and wait for pressure to build. Then reconnect the drain, hook up the sensors and go.

#3

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,188

Total Cats: 1,684

If you disconnect the crank/cam sensor it wont inject. Pull the plugs so theres no compression, and crank. My plan is to disconnect the oil drain on the turbo so I know oil is flowing through the turbo, and wait for pressure to build. Then reconnect the drain, hook up the sensors and go.