Thinner radiator?

#1

Hi guys,

I have an NB making about 190whp and it is having cooling issues. I'm running an ASI 52mm radiator with stock fans and shroud, a Flyin' Miata oil cooler kit and a Cooling Pro intercooler (550 x 140 x 65). The car still has A/C fitted but no power steering.

All the stock MSM shrouding is retained and I have added fitted adhesive-backed foam to seal up the little gaps around the radiator.

The coolant temp creeps up to 110C after a couple of hard laps on the track. If I put the heater on I can prolong the time it takes to hit this temp, I'm not prepared to push the car beyond this temperature. Oil temp is around 110C.

I was thinking such a thick radiator with the three cores (intercooler, A/C, radiator) stacked together may be causing the air to stall?

My next step is going to be measuring the temperature differential between the inlet and outlet of the radiator. The problem only presents itself on the track so I have limited possibilities to investigate.

Do you think it is worth trying a thinner core?

I have also considered venting the bonnet but I'd rather not do this if it isn't essential as the car is still occasionally driven on the street.

Cheers

I have an NB making about 190whp and it is having cooling issues. I'm running an ASI 52mm radiator with stock fans and shroud, a Flyin' Miata oil cooler kit and a Cooling Pro intercooler (550 x 140 x 65). The car still has A/C fitted but no power steering.

All the stock MSM shrouding is retained and I have added fitted adhesive-backed foam to seal up the little gaps around the radiator.

The coolant temp creeps up to 110C after a couple of hard laps on the track. If I put the heater on I can prolong the time it takes to hit this temp, I'm not prepared to push the car beyond this temperature. Oil temp is around 110C.

I was thinking such a thick radiator with the three cores (intercooler, A/C, radiator) stacked together may be causing the air to stall?

My next step is going to be measuring the temperature differential between the inlet and outlet of the radiator. The problem only presents itself on the track so I have limited possibilities to investigate.

Do you think it is worth trying a thinner core?

I have also considered venting the bonnet but I'd rather not do this if it isn't essential as the car is still occasionally driven on the street.

Cheers

#4

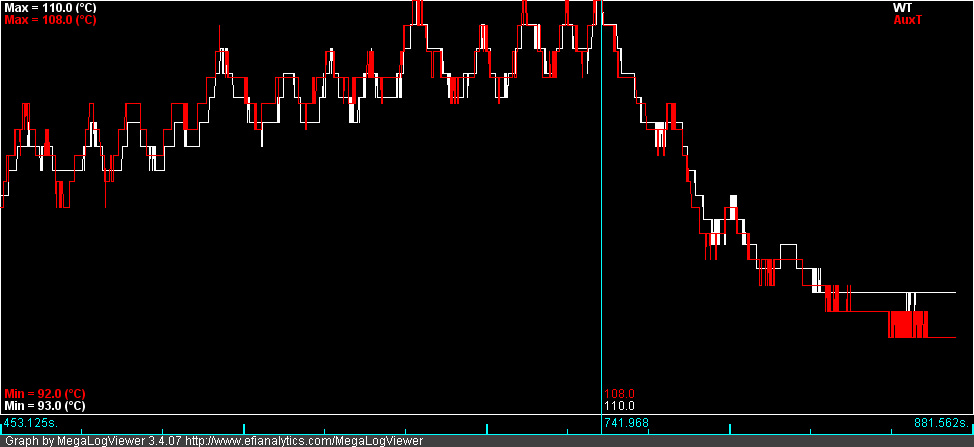

It's an MSM engine, so it has the same coolant passages and headgasket as the VVT engine. I have a Maruha thermostat housing spacer with an extra thermistor fitted, and from this log on the track the maximum delta between the front and back of the head was only 2 degrees C:

So the temperatures are even between the front and back, but I guess the reroute could provide additional flow? It would mean pulling the head (for an earlier gasket swap) which I'm not too keen on, but if it has to be done then sure.

Cheers

#8

Is the gap at the bottom of the radiator sealed? I use 40mil vinyl tub/shower liner (thanks genesplicer) to seal all around radiator (along the bottom, and along the brackets on the sides) to the plastic "mouth". When I had AC still on the car I had to cut a couple of reliefs in the vinyl for the AC lines. I then use foam to fill the gap between the side of the radiator and the brackets on either side.

I don't like FM's oil cooler kit due to how it affects pressure differentials between the front of the bumper and the engine bay. Ideally you want no air entering the engine bay except through the bumper opening and then through your heat exchangers.

I don't like FM's oil cooler kit due to how it affects pressure differentials between the front of the bumper and the engine bay. Ideally you want no air entering the engine bay except through the bumper opening and then through your heat exchangers.

Last edited by Mobius; 06-20-2014 at 02:41 AM. Reason: added image

#10

If you are going to have a stack of heat exchangers that think, you need to not only seal around them but duct to the front so the air is forced through them. Venting out the hood helps lower pressures behind but my sense is the air is stalling as you suggested. A pair of butch Spal fans might help pull but at the end of the day, you need to find a natural way to get more air through the stack.

#11

We have collected some data along these lines. The big FMIC makes far more a difference to total airflow than the change from say a 32, 37 or 55mm core. The A/C condenser has surprisingly small effect. The gains from a the fatter rad core are diminishing when you have so much stuff blocking airflow. IOW, the gains in cooling efficiency from the fatter core are greater when you have good airflow (no A/C, FMIC). The vented hood will gain you more than the bigger core. On some high hp track applications however, you need all of it. Ducting, venting, bigger core, crossflow radiator, 1.3bar cap, reroute and running almost straight distilled water with a splash of water wetter.

On our SuperMiata race series 140whp N/A cars the 32mm crossflow is more than enough to run 200° in a draft on a 100° day and shaves about 5 lbs off the front of the car.

On our SuperMiata race series 140whp N/A cars the 32mm crossflow is more than enough to run 200° in a draft on a 100° day and shaves about 5 lbs off the front of the car.

__________________

#12

That's awesome data Emilio.

I did have a big block of foam completely sealing up the gap between the bottom of the radiator and the undertray. I checked today and it looks to have disappeared, it's probably on the highway somewhere.

Needless to say I'll be installing another, and this time I'll Sikaflex it to the undertray, or go with something like Mobius' setup. The rest of the adhesive-backed foam is standing up OK and looks to be making a good seal.

Will report back after next track day. I'll also look into an uprated fan setup as suggested by mr_hyde.

Thanks for all the feedback and data!

Cheers

I did have a big block of foam completely sealing up the gap between the bottom of the radiator and the undertray. I checked today and it looks to have disappeared, it's probably on the highway somewhere.

Needless to say I'll be installing another, and this time I'll Sikaflex it to the undertray, or go with something like Mobius' setup. The rest of the adhesive-backed foam is standing up OK and looks to be making a good seal.

Will report back after next track day. I'll also look into an uprated fan setup as suggested by mr_hyde.

Thanks for all the feedback and data!

Cheers

#13

Big fans are neat for street cars in rush hour traffic in 110* ambient but if they are needed on a track car, other things should be addressed first. If you are working with a stock nose, look at this thread by Joey Reid who spent the extraordinary time necessary to fully duct up his MSM while retaining an OEM look from.

Radiator / Intercooler ducting

Radiator / Intercooler ducting

#17

I've seen good fans solve overheating problems at 75 mph constant airspeed. I think you may not realize how stagnant the air in the engine bay can be. Venting the hood - if allowed by your class regs - will have a pretty massive effect on your cooling capabilites. Much better than just adding more radiator core.

#18

#19

FWIW, I was given radiator core 101 by a custom radiator builder. I think I remember most of it.

Tubes are narrow and long. Wider tubes carry more water but not much more surface area, so they only help if you're being limited by flow rate.

Fins are where the efficiency differences are;

Basic fin (TX?) is a zig-zag form between the tubes. Lowest efficiency. Typical street design.

Next is the one piece fin that has holes for the tubes. I think it's brazed to the tubes. Higher fin count gives more heat transfer until you get to the point of impeding air flow. Typical performance design.

Max efficiency still uses the one piece fins, but now they have tiny louvers cut into them to increase heat exchange to the air. At the time (several years ago) these were the highest efficiency cores you could buy.

For heat transfer, copper > aluminum but of course there's a weight trade-off.

Tubes are narrow and long. Wider tubes carry more water but not much more surface area, so they only help if you're being limited by flow rate.

Fins are where the efficiency differences are;

Basic fin (TX?) is a zig-zag form between the tubes. Lowest efficiency. Typical street design.

Next is the one piece fin that has holes for the tubes. I think it's brazed to the tubes. Higher fin count gives more heat transfer until you get to the point of impeding air flow. Typical performance design.

Max efficiency still uses the one piece fins, but now they have tiny louvers cut into them to increase heat exchange to the air. At the time (several years ago) these were the highest efficiency cores you could buy.

For heat transfer, copper > aluminum but of course there's a weight trade-off.

#20

Awesome discussion! Bill, I expect the core to be whatever is cheapest to make, the radiator wasn't a high dollar item.

I picked up these goodies to measure the effectiveness of the radiator, I already have a sensor just before the radiator inlet so this sensor will be installed inline in an old bottom radiator hose:

All I have left is to drill and tap the thread in the sensor block to suit the OE sensor.

Cheers

I picked up these goodies to measure the effectiveness of the radiator, I already have a sensor just before the radiator inlet so this sensor will be installed inline in an old bottom radiator hose:

All I have left is to drill and tap the thread in the sensor block to suit the OE sensor.

Cheers