Oil pressure dip under brakes

#1

My oiling setup: Stock sump (no baffle) -> Stock oil pump (no pressure relief valve) -> Sandwich plate -> Peterson external oil pressure valve -> oil cooler -> sandwich plate - > engine

On the track I see a constant 60PSI which is what my external pressure valve is set to except for a short dip to approx 30PSI around 1 second after I first apply the brakes. I'll sometimes get a second dip another second or so later. I'm assuming this is the oil slopping around in the sump, moving forwards, back then forwards again.

Here is a video that clearly shows it. Oil gauge is on the A-pillar

I've read several threads about the issue and most people aren't concerned, however I don't think it's that great, given I'm often blipping the revs up to 8000 as I'm dropping through the gears probably right when this low oil pressure is there. Not only that but if the oil pressure is dropping, it must mean the oil pickup is getting air which means the bubbles will be going through the entire system, the engine and the bearings.

I'm surprised this isn't a bigger topic given that my engine is basically stock and I'm not even running big aero.

What's the best solution? Does baffling the sump fix it?

On the track I see a constant 60PSI which is what my external pressure valve is set to except for a short dip to approx 30PSI around 1 second after I first apply the brakes. I'll sometimes get a second dip another second or so later. I'm assuming this is the oil slopping around in the sump, moving forwards, back then forwards again.

Here is a video that clearly shows it. Oil gauge is on the A-pillar

I've read several threads about the issue and most people aren't concerned, however I don't think it's that great, given I'm often blipping the revs up to 8000 as I'm dropping through the gears probably right when this low oil pressure is there. Not only that but if the oil pressure is dropping, it must mean the oil pickup is getting air which means the bubbles will be going through the entire system, the engine and the bearings.

I'm surprised this isn't a bigger topic given that my engine is basically stock and I'm not even running big aero.

What's the best solution? Does baffling the sump fix it?

#3

It's less so the pressure I'm worried about because 30 PSI is probably still fine especially when the engine isn't under load, it's more the fact that if the pressure is dropping that much then the pickup would have to be sucking air. An accusump won't fix that. That air will go through the cooler and hit the engine when it's back under full load.

A swirl tank would probably fix the air issue, but still this must be a common enough problem for any track miata.

A swirl tank would probably fix the air issue, but still this must be a common enough problem for any track miata.

#4

The "solution" is to ignore it. Every track car, every SM, every hard-driven Miata has this issue. Nobody pulls torched bearings out of track cars on a regular basis. If it were a serious issue, everyone would be having issues.

If you still think it's an issue that you want to solve, an Accusump is what you want.

If you still think it's an issue that you want to solve, an Accusump is what you want.

#5

The "solution" is to ignore it. Every track car, every SM, every hard-driven Miata has this issue. Nobody pulls torched bearings out of track cars on a regular basis. If it were a serious issue, everyone would be having issues.

If you still think it's an issue that you want to solve, an Accusump is what you want.

If you still think it's an issue that you want to solve, an Accusump is what you want.

I did run a bit more oil in the sump for the run you can see in the video, however the dip was still there, just not quite as bad. I think my first step is a sump baffle and see how much helps, second step is Accusump, or alternatively just go for a dry sump and be done with it.

I must say I don't really like the Accusumps. More connections, more items to worry about, more weight. Goes against the grain of keeping everything simple and easy to maintain.

#6

I run an accusump on my car.

That said, I'd work on baffling too before doing an accusump for the reasons you mentioned. I did it just to have to be safe and to crank the motor with oil pressure every time (pretty sweet feature). I tested this before when my car lost pressure during braking. Running 3/4 quart above full helped a lot, but then it burned oil... I just run an accusump now.

That said, I'd work on baffling too before doing an accusump for the reasons you mentioned. I did it just to have to be safe and to crank the motor with oil pressure every time (pretty sweet feature). I tested this before when my car lost pressure during braking. Running 3/4 quart above full helped a lot, but then it burned oil... I just run an accusump now.

#7

If it is dropping pressure due to picking up air, then an accusump will only maintain the pressure but not fix the air. Given this dip is so common I can't see it being an oil pickup issue at all, otherwise there would be bearings going all over the place on any car that can brake hard.

Talking to the guys on MX5cartalk... do you think it could be an oil inertia effect similar to water hammering in a pipe? If the oil is flowing through the system at full speed (8300 rpm) then immediately the pump halves it's flow rate as the revs drop, the oil has to slow down causing a low pressure reading where my oil pressure sensor is. Fitment of an Accusump probably acts a bit like a damper for this effect, just like adding a damper into the fuel system.

I can test this in the workshop and see if I can get an oil pressure dip when the revs drop rapidly. If I get the effect to occur whilst the car is stationary it rules out oil surging in the sump. Also could a voltage drop from the alternator trick the oil pressure sender into dropping it's signal strength?

Talking to the guys on MX5cartalk... do you think it could be an oil inertia effect similar to water hammering in a pipe? If the oil is flowing through the system at full speed (8300 rpm) then immediately the pump halves it's flow rate as the revs drop, the oil has to slow down causing a low pressure reading where my oil pressure sensor is. Fitment of an Accusump probably acts a bit like a damper for this effect, just like adding a damper into the fuel system.

I can test this in the workshop and see if I can get an oil pressure dip when the revs drop rapidly. If I get the effect to occur whilst the car is stationary it rules out oil surging in the sump. Also could a voltage drop from the alternator trick the oil pressure sender into dropping it's signal strength?

#10

I just read your OP again. Pulling the pan to baffle it when you're only seeing 30psi in braking zones is a complete waste of time. When I see this issue, it's on cars that are stopping much harder than yours is, because I will see oil pressure drop to <10psi for 2-3 seconds at a time, typically through the entire braking zone. A dip to 30psi wouldn't even make me blink, and I certainly wouldn't pull the engine out of the car to try and rectify it. If you want to try a baffle, add it next time the engine is open for something else.

#11

I just read your OP again. Pulling the pan to baffle it when you're only seeing 30psi in braking zones is a complete waste of time. When I see this issue, it's on cars that are stopping much harder than yours is, because I will see oil pressure drop to <10psi for 2-3 seconds at a time, typically through the entire braking zone. A dip to 30psi wouldn't even make me blink, and I certainly wouldn't pull the engine out of the car to try and rectify it. If you want to try a baffle, add it next time the engine is open for something else.

When I did the big end last year I was lapping nearly 2 seconds a lap quicker than my previous PB as I was testing my rear wing, plus I was overly enthusiastic blipping down through the gears under brakes. I run fairly high revs (8500) so I think there is probably oil sitting up in the head, reducing oil in the pan. Hard on the brakes, oil sloshes forwards and a few high revs whilst the pickup is exposed and there goes a bearing.

I pulled the engine on Monday night to check the bearings and replace with ACL. It was a planned rebuild because when I built this engine ACL and Kings were out of stock so I had to use oem spec bearings. Plus I wasn't sure on the reason for the bearing failure. Upon inspection look fine and all measure to spec. As Sav points out this dip probably isn't much of an issue atm, but maybe it gets lots worse when I run my rear wing which is why that bearing died last year.

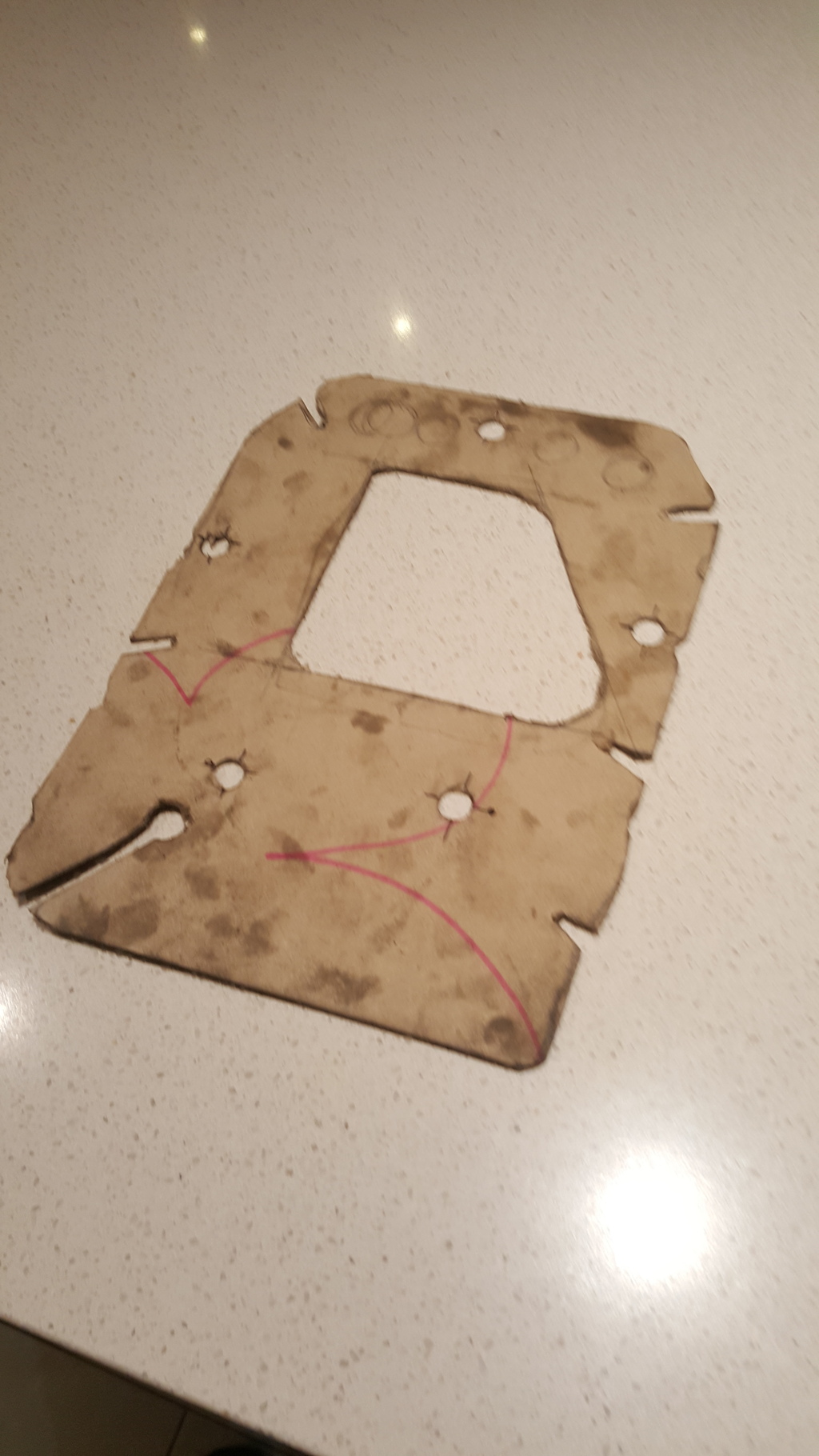

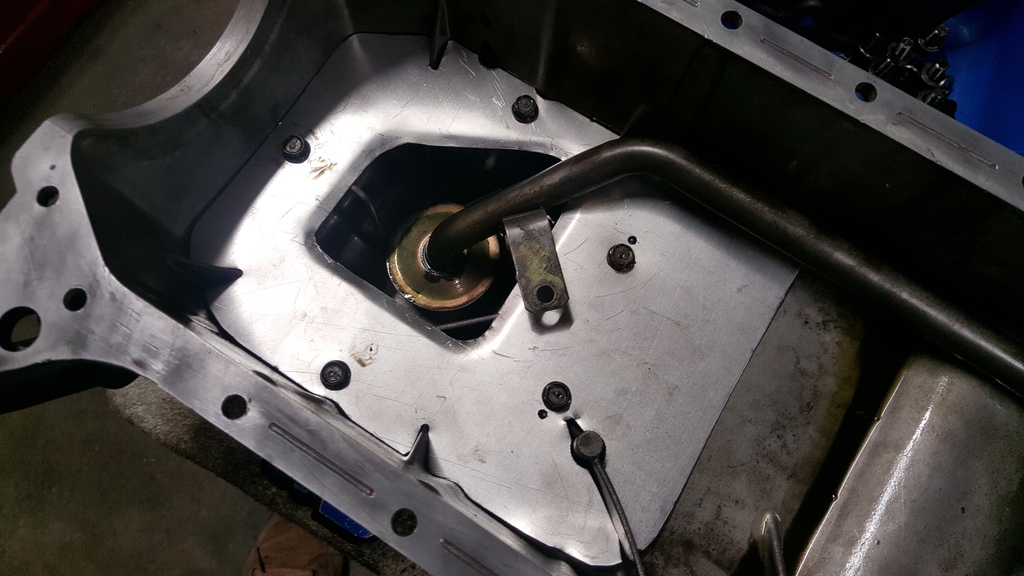

It's worth trying something whilst the engine is out anyway. Instead of the gated sumps, which I'm not sure really help that much I figured I'd install a flat plate across the entire sump and seal it up fairly well. I initially went to the workshop to make a paper template, but ended up making the entire baffle plate out of ally instead.

Another hour later and it's done.

It's fairly well sealed on the front edge and has a bit of a fall towards the sump pickup. I rounded the hole where the oil falls into the sump to give it some structural strength to stop it flapping about. It should work well to stop the oil moving forwards. I plan to test it before putting it back in the car by filling the pan with oil and seeing how long it takes to drain out.

I'll see if it stops the issue. I'll report back in 3 weeks after running my next event.

#14

Secondly, a high reving N/A engine (greater than 8500rpm) is putting far more load on the big end bearing than a 7500rpm turbo engine, making it more susceptible to failure due to air bubbles or pressure dips. I doubt we'll ever get good data on this due to the number of cars running under these conditions, but for such a simple solution it's well worth doing on any car that is seeing this pressure dip regardless of if it's doing bearings or not.