Field testing negative lift of rear diffuser

#1

Not sure if this is viable...but it's something I've been thinking about.

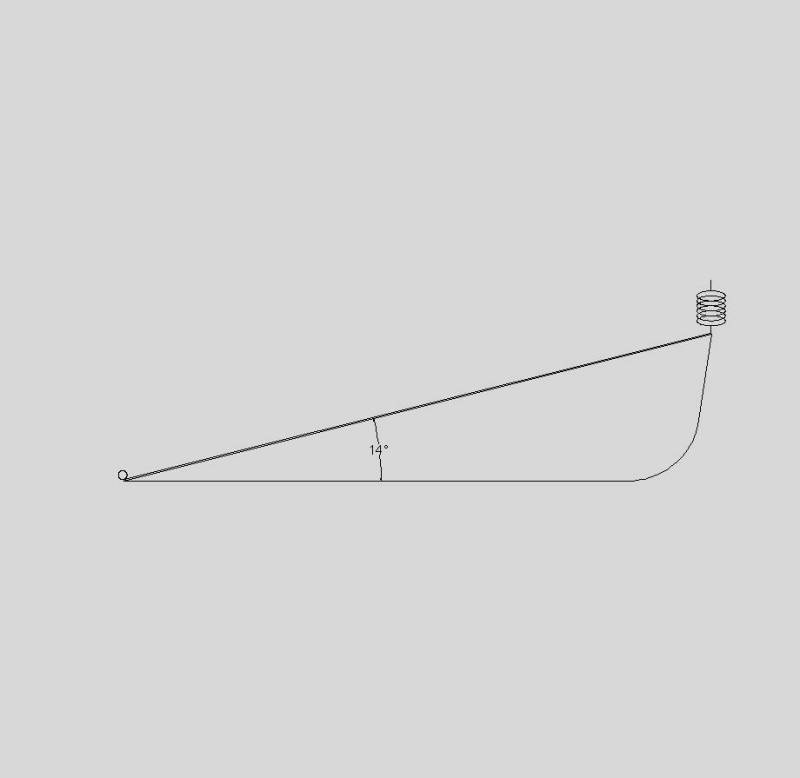

If you have a rear diffuser and it's mounted via hinge in front and springs with known rate of extension lb/in or whatever. Taping a ruler to the back of your car and a gopro, you could theoretically determine how much negative lift you are generating.

I would start off with 2 of these http://www.mcmaster.com/#9628K13 with 125 lb/in (effectively 250 lb/in) and use extra wires that'll limit maximum deflection to like, 3 inches. If it hardly moves, use weaker springs, if it maxes out, use more or stronger springs.

From a conceptual standpoint, would this be a valid testing method?

If you have a rear diffuser and it's mounted via hinge in front and springs with known rate of extension lb/in or whatever. Taping a ruler to the back of your car and a gopro, you could theoretically determine how much negative lift you are generating.

I would start off with 2 of these http://www.mcmaster.com/#9628K13 with 125 lb/in (effectively 250 lb/in) and use extra wires that'll limit maximum deflection to like, 3 inches. If it hardly moves, use weaker springs, if it maxes out, use more or stronger springs.

From a conceptual standpoint, would this be a valid testing method?

#2

Could be a good idea. The two issues I see are the momentum of the diffuser skewing the data over bumps and rises, and the fact that the diffuser's force relies upon the angle of the diffuser, which is obviously going to change as you lower it.

With a very light diffuser, a very high-resolution travel sensor, and fairly stiff springs, you might be able to get some good data, though.

The easier way to do it would be to figure out how to accurately measure ride height, and then take averages over one lap before the diffuser and after the diffuser. From there it's easy to figure out.

With a very light diffuser, a very high-resolution travel sensor, and fairly stiff springs, you might be able to get some good data, though.

The easier way to do it would be to figure out how to accurately measure ride height, and then take averages over one lap before the diffuser and after the diffuser. From there it's easy to figure out.

#5

Good point about the dynamic angle of attack. I suppose in concept it could work, but in real world testing, it'd be pretty difficult to get precise and accurate data. One thought though is that it sags, AOA would decrease, so you won't cause flow separation.

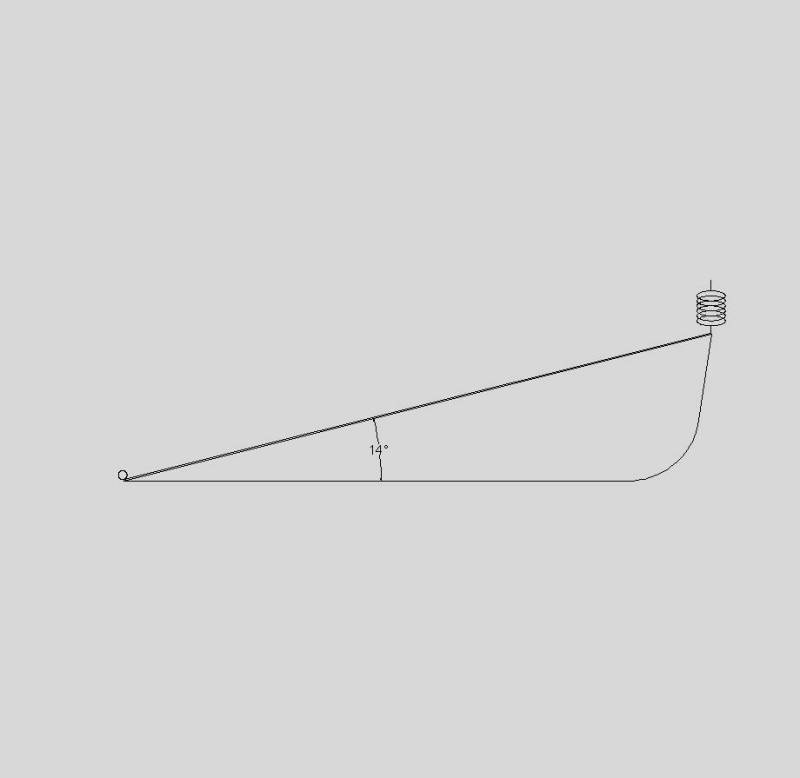

I'll think about it some more. I want to figure out a good way to test this so that when I do finish my diffuser design, I have a good way to test placement, AOA, etc. I started with 14 degrees because I read somewhere that any more than that and you start having flow separation.

In order to prevent bumps in the road from skewing the data, I was hoping to find some "really" flat surface and just go in a straight line. Record speed using trackmaster and a 5hz gps and sync it to the video of the diffuser to get an idea of how much negative lift you create at said speeds.

The problem I see with the ride height measurement idea is that since the springs are so stiff, it would have to be some REALLY precise measuring equipment. As such, using relatively weak extension springs and limiting the speed/deflection, you may be able to make some projections guesses as to how much force you are creating.

I guess it just depends what your goals are. If I can use this technique to create a RELATIVE level of negative lift in order to determine diffuser placement, I'll be happy.

Shrugs, if someone can figure out how to make this work or the ride height measurement idea work, do share.

I'll think about it some more. I want to figure out a good way to test this so that when I do finish my diffuser design, I have a good way to test placement, AOA, etc. I started with 14 degrees because I read somewhere that any more than that and you start having flow separation.

In order to prevent bumps in the road from skewing the data, I was hoping to find some "really" flat surface and just go in a straight line. Record speed using trackmaster and a 5hz gps and sync it to the video of the diffuser to get an idea of how much negative lift you create at said speeds.

The problem I see with the ride height measurement idea is that since the springs are so stiff, it would have to be some REALLY precise measuring equipment. As such, using relatively weak extension springs and limiting the speed/deflection, you may be able to make some projections guesses as to how much force you are creating.

I guess it just depends what your goals are. If I can use this technique to create a RELATIVE level of negative lift in order to determine diffuser placement, I'll be happy.

Shrugs, if someone can figure out how to make this work or the ride height measurement idea work, do share.

#6

I plan to cut out some curved fins with tabs, mount to some aluminum sheet.

curved vs. straight diffusers?

Man, I has the much to learn. Just trying to figure out ways to collect more data. Thanks for the input

#7

You've read 14*, I've read 12*.... along with many other numbers.

spoolin2bars noted he did around 5* with positive results in rear end grip.

I've tested 9.82* and 6.52* on a 3.75" pinch car with 1/4" rake-- with 75mm front airdam ground clearance, statistically (averages with many samples) it exhibits less drag with 6.52* (coast down tests), but negative lift differences between 6.52 vs 9.82 are difficult to notice at speeds 80-90mph. (judged by how "light" the rear end is at speed)

9.82* vs 6.52* just happened to be the two AOAs the two holes on the L brackets on my rear most diffuser mounts ended up.

If I moved it up to the upper hole, it coincidentally went to 9.82*.

I was shooting for a range of 7-10* based on what I read. Drag redux was the goal.

BTW monkey, aero is highly application specific.

FUN FACT: ground temp/ambient temp had more effect on drag than fuel levels in my test parameters.

spoolin2bars noted he did around 5* with positive results in rear end grip.

I've tested 9.82* and 6.52* on a 3.75" pinch car with 1/4" rake-- with 75mm front airdam ground clearance, statistically (averages with many samples) it exhibits less drag with 6.52* (coast down tests), but negative lift differences between 6.52 vs 9.82 are difficult to notice at speeds 80-90mph. (judged by how "light" the rear end is at speed)

9.82* vs 6.52* just happened to be the two AOAs the two holes on the L brackets on my rear most diffuser mounts ended up.

If I moved it up to the upper hole, it coincidentally went to 9.82*.

I was shooting for a range of 7-10* based on what I read. Drag redux was the goal.

BTW monkey, aero is highly application specific.

FUN FACT: ground temp/ambient temp had more effect on drag than fuel levels in my test parameters.

Last edited by greeenteeee; 02-28-2012 at 09:51 PM.

#8

You've read 14*, I've read 12*.... along with many other numbers.

spoolin2bars noted he did around 5* with positive results in rear end grip.

I've tested 9.82* and 6.52* on a 3.75" pinch car with 1/4" rake-- with 75mm front airdam ground clearance, statistically (averages with many samples) it exhibits less drag with 6.52* (coast down tests), but negative lift differences between 6.52 vs 9.82 are difficult to notice at speeds 80-90mph. (judged by how "light" the rear end is at speed)

spoolin2bars noted he did around 5* with positive results in rear end grip.

I've tested 9.82* and 6.52* on a 3.75" pinch car with 1/4" rake-- with 75mm front airdam ground clearance, statistically (averages with many samples) it exhibits less drag with 6.52* (coast down tests), but negative lift differences between 6.52 vs 9.82 are difficult to notice at speeds 80-90mph. (judged by how "light" the rear end is at speed)

How do you measure drag, or, a reduction thereof? engine load at different speeds w/ and w/o diffuser (or any other aero part for this matter)?

#10

if you just want to see if it's having an effect, why not put a small rubber ring around each shock where the strut enters the body, do a straight line run, mark the location of each ring, then do the same thing again with the aero attached? if the rings are above the previously marked lines then you're most likely generating some downforce. of course you'd have to make sure that you run the same length of road each time, and that it's a relatively smooth run. it won't tell you how much you're generating but it'll at least let you know its working.

#11

or even easier... mount a wooden rod or two along the front and rear bumpers that can slide up and down and place them so that they just touch the ground. The further up the stick gets pushed, the more of an effect you should be having. this way you'll be able to test different setups quickly as well.

#12

Finding a smooth road was beyond me, where traffic isn't an issue (or I wouldn't cause too much). I found 4x test spots, ran it at a starting speed, and depending on the test spot, there are 1 or 2 check points where I note the speed it reaches.

This was mainly because I would be changing the setup several times and these spots are roads I commute through regardless of if I was testing this or not. It is not a perfectly flat road, there is downhill of various inclines, one has an uphill segment at the end. One has a road side radar which I note the speed it clocks me at as well. (for example, before it'd clock me at 42... as development progressed, it is seeing 43... similar gains were found in my other car.)

Hit 40mph, pop it in neutral, let it coast-- for the most part, I'm always under speed limit. Pax window closed, driver always at 1/2 to 3/4 closed, fuel level measured initially (thinking it'd have an effect on speeds), tire psi constant, wheel setup constant, weight constant (aside from fuel). More recently started taking note of ground temps when I noticed speeds increased during hotter daytime temps.

I test different configurations (up to 8 different configs with the Miata now) and take the numbers and average them for each configuration. The idea is repeatable results, not one or two runs for data. This way I am not driving 3 hrs to find salt lake beds each new configuration.

My 75mm airdam/undertray added more drag than without, which was basically an added airdam with stock bumper at 115mm ground clearance, however neg. lift benefit of 75mm airdam/undertray at 80-90 is well worth any drag addition. Undertray and diffuser added most improvement for drag redux.

Overall now (aero is a total package), it reaches faster speeds than before.

Many variables, I just tried to limit the unknowns and went with quantity of data to find averages.

This is tested with two different cars, and there is consistency so it's good enough for me.

This was mainly because I would be changing the setup several times and these spots are roads I commute through regardless of if I was testing this or not. It is not a perfectly flat road, there is downhill of various inclines, one has an uphill segment at the end. One has a road side radar which I note the speed it clocks me at as well. (for example, before it'd clock me at 42... as development progressed, it is seeing 43... similar gains were found in my other car.)

Hit 40mph, pop it in neutral, let it coast-- for the most part, I'm always under speed limit. Pax window closed, driver always at 1/2 to 3/4 closed, fuel level measured initially (thinking it'd have an effect on speeds), tire psi constant, wheel setup constant, weight constant (aside from fuel). More recently started taking note of ground temps when I noticed speeds increased during hotter daytime temps.

I test different configurations (up to 8 different configs with the Miata now) and take the numbers and average them for each configuration. The idea is repeatable results, not one or two runs for data. This way I am not driving 3 hrs to find salt lake beds each new configuration.

My 75mm airdam/undertray added more drag than without, which was basically an added airdam with stock bumper at 115mm ground clearance, however neg. lift benefit of 75mm airdam/undertray at 80-90 is well worth any drag addition. Undertray and diffuser added most improvement for drag redux.

Overall now (aero is a total package), it reaches faster speeds than before.

Many variables, I just tried to limit the unknowns and went with quantity of data to find averages.

This is tested with two different cars, and there is consistency so it's good enough for me.

#15

The best way would be to use some kind of load cells that only measure pressure without any travel at all.

Or a modded luggage scale

http://www.oldwillknottscales.com/taylor-8120.html

Unsure if it extends under load though, but there must be hundreds of alternatives.

Or a modded luggage scale

http://www.oldwillknottscales.com/taylor-8120.html

Unsure if it extends under load though, but there must be hundreds of alternatives.

#17

You would have problems measuring like that, I suspect.

You aren't accounting for the possibility that at angle "a", most of the downforce might be generated near the fulcrum, while at angle "b", the downforce might be spread evenly across the plane; and finally, at angle "c", that downforce might be mostly generated furthest from the fulcrum.

While all three different scenarios might generate very nearly identical downforce, your measurement method will show that angle "c" provides measurably more downforce than angle "b", and substantially more downforce than angle "a".

A better and more repeatable method was suggested by someone in this thread already; measure, instead, the compression of your rear suspension at speed.

You aren't accounting for the possibility that at angle "a", most of the downforce might be generated near the fulcrum, while at angle "b", the downforce might be spread evenly across the plane; and finally, at angle "c", that downforce might be mostly generated furthest from the fulcrum.

While all three different scenarios might generate very nearly identical downforce, your measurement method will show that angle "c" provides measurably more downforce than angle "b", and substantially more downforce than angle "a".

A better and more repeatable method was suggested by someone in this thread already; measure, instead, the compression of your rear suspension at speed.

#18

Need to use a load cell and I suspect you will have to do some signal processing to get usefull data.

http://www.transducertechniques.com/mlp-load-cell.aspx

Bob

http://www.transducertechniques.com/mlp-load-cell.aspx

Bob

#20

if you just want to see if it's having an effect, why not put a small rubber ring around each shock where the strut enters the body, do a straight line run, mark the location of each ring, then do the same thing again with the aero attached? if the rings are above the previously marked lines then you're most likely generating some downforce. of course you'd have to make sure that you run the same length of road each time, and that it's a relatively smooth run. it won't tell you how much you're generating but it'll at least let you know its working.

Stiff rear springs would make the ride height change tiny.