NA Crank Trigger Wheel Setup

#1

Thread Starter

Elite Member

iTrader: (17)

Joined: Aug 2007

Posts: 2,949

Total Cats: 183

From: Knoxville, TN

I've been trying to get my '94 setup on a crank wheel and I'm getting no where. I'd really appreciate if a kind soul could explain it to me, very slowly, and using small words.

What I have:

'94 Miata

Supermiata Damper with 12+1 trigger wheel

MSPNP2 purchased from DIYAutotune

'99 Miata crank sensor

What I did:

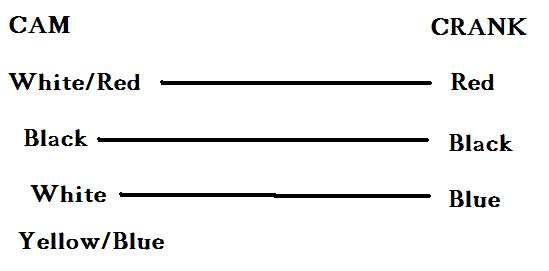

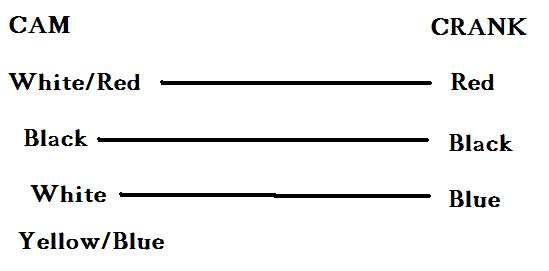

I removed the stock CAS and spliced in the '99 Crank sensor. From what I've read on the stock sensor Wht/Red = power, Black = ground, White = Crank signal, Yellow/Blue = Cam Signal. Using that I wired them to the crank sensor like:

The yellow/blue wire is currently unused.

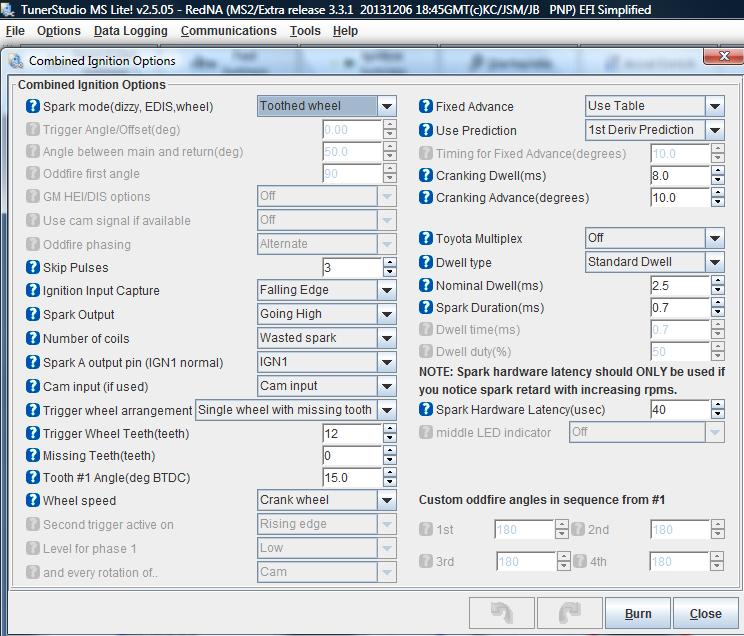

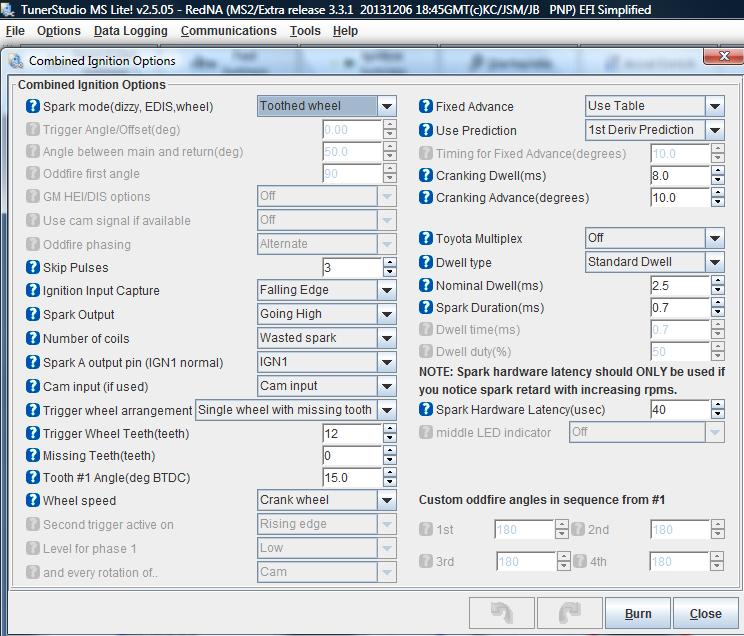

I then read that Megasquirt cannot comprehend the 12+1 wheel that I bought so I got out my dremmel and -1'd the wheel to make it a 12 tooth wheel, all equally spaced. I then opened Tunerstudio and changed my ignition options to "Toothed Wheel", "Single wheel with missing tooth", selected 12 teeth, missing 0, at 15 degrees BTDC (which I can find no documentation of, but it appears to be correct). All other settings were left the same.

While cranking, the car alternates reading rpms and showing zero, as well as sync and loss of sync. When I datalog I get "Reason 2: Missing tooth at wrong time". Datalog and MSQ are attached if someone wants to look it over.

I seriously have no clue what I'm doing here, if you have any suggestions I would really appreciate it. Is there another setting to use since the wheel is not missing any teeth? Should I try to add the stock CAS back in and use both wheels together (I'd planned on doing that eventually but didn't want to complicate things unnecessarily)?

What I have:

'94 Miata

Supermiata Damper with 12+1 trigger wheel

MSPNP2 purchased from DIYAutotune

'99 Miata crank sensor

What I did:

I removed the stock CAS and spliced in the '99 Crank sensor. From what I've read on the stock sensor Wht/Red = power, Black = ground, White = Crank signal, Yellow/Blue = Cam Signal. Using that I wired them to the crank sensor like:

The yellow/blue wire is currently unused.

I then read that Megasquirt cannot comprehend the 12+1 wheel that I bought so I got out my dremmel and -1'd the wheel to make it a 12 tooth wheel, all equally spaced. I then opened Tunerstudio and changed my ignition options to "Toothed Wheel", "Single wheel with missing tooth", selected 12 teeth, missing 0, at 15 degrees BTDC (which I can find no documentation of, but it appears to be correct). All other settings were left the same.

While cranking, the car alternates reading rpms and showing zero, as well as sync and loss of sync. When I datalog I get "Reason 2: Missing tooth at wrong time". Datalog and MSQ are attached if someone wants to look it over.

I seriously have no clue what I'm doing here, if you have any suggestions I would really appreciate it. Is there another setting to use since the wheel is not missing any teeth? Should I try to add the stock CAS back in and use both wheels together (I'd planned on doing that eventually but didn't want to complicate things unnecessarily)?

#3

Thread Starter

Elite Member

iTrader: (17)

Joined: Aug 2007

Posts: 2,949

Total Cats: 183

From: Knoxville, TN

Right now I am just trying to get it to run on the crank sensor on batch injection.

I know I need the cam sensor to run sequential, and that is my ultimate goal. I'm under the impression you have to cut up the stock CAS to get it to run sequential injection and I'd rather not do that until I'm confident the crank sensor is working properly. Right now everything is easily reversible with no money involved, if I botch the cam sensor and still can't get it running then I'm out a couple hundred bucks just to get back to my starting point of running on a crappy cam sensor.

I know I need the cam sensor to run sequential, and that is my ultimate goal. I'm under the impression you have to cut up the stock CAS to get it to run sequential injection and I'd rather not do that until I'm confident the crank sensor is working properly. Right now everything is easily reversible with no money involved, if I botch the cam sensor and still can't get it running then I'm out a couple hundred bucks just to get back to my starting point of running on a crappy cam sensor.

#5

Thread Starter

Elite Member

iTrader: (17)

Joined: Aug 2007

Posts: 2,949

Total Cats: 183

From: Knoxville, TN

If you have suggestions I'm certainly open to them, just trying to keep things as simple as possible.

I rewired the stock CAS today with power, ground, and cam signal and tried again with a dual wheel trigger arrangement. That gave me no RPM signal at all, but that was expected based on what I've read.

I feel like I need to cut another tooth off the crank wheel but I hate to aimlessly chop up a $125 crank wheel hoping I get lucky enough to hit something that works.

I rewired the stock CAS today with power, ground, and cam signal and tried again with a dual wheel trigger arrangement. That gave me no RPM signal at all, but that was expected based on what I've read.

I feel like I need to cut another tooth off the crank wheel but I hate to aimlessly chop up a $125 crank wheel hoping I get lucky enough to hit something that works.

#7

Thread Starter

Elite Member

iTrader: (17)

Joined: Aug 2007

Posts: 2,949

Total Cats: 183

From: Knoxville, TN

I like that idea and if you can suggest how to do it, I'll give it a try.

Right now I can't get the crank sensor to work by itself, I feel like adding a cam sensor just adds complexity to what I already can't find an answer to.

Right now I can't get the crank sensor to work by itself, I feel like adding a cam sensor just adds complexity to what I already can't find an answer to.

#8

You'd effectively running all '99-05 sensors. Find a 99 valvecover, camsensor, and probably a 99 camgear as I don't know if the NA gears have nubs for the sensor to read. Then splice ground, 12V and signal from the CAS connector to both the new cam and crank sensor and set it up as 99-05 instead of 'toothed wheel'. (Someone verify this for a 12 tooth wheel instead of the stock NB 4 tooth wheel.)

So GND and +12V from CAS to both crank and cam sensors, then the CMP wire from the CAS to the new cam sensor and the CKP to the crank sensor (which you already did).

Then again, maybe someone who knows what he's doing should chime in as well

So GND and +12V from CAS to both crank and cam sensors, then the CMP wire from the CAS to the new cam sensor and the CKP to the crank sensor (which you already did).

Then again, maybe someone who knows what he's doing should chime in as well

#10

Thread Starter

Elite Member

iTrader: (17)

Joined: Aug 2007

Posts: 2,949

Total Cats: 183

From: Knoxville, TN

I know it's not right, but I've got no idea how to fix it.

There isn't a "single wheel (no missing teeth)" option and it didn't like "dual wheel" when I tried to use it with the stock cam sensor in combination with the crank wheel.

Do you have any suggestions? Should I cut another tooth off the wheel (does it matter which one)? Should I cut a tooth off the cam sensor (does it matter which one)? Would Oscar's recommendation of converting to a '99-'00 cam sensor and running the 12 tooth wheel work?

There isn't a "single wheel (no missing teeth)" option and it didn't like "dual wheel" when I tried to use it with the stock cam sensor in combination with the crank wheel.

Do you have any suggestions? Should I cut another tooth off the wheel (does it matter which one)? Should I cut a tooth off the cam sensor (does it matter which one)? Would Oscar's recommendation of converting to a '99-'00 cam sensor and running the 12 tooth wheel work?

#11

Thread Starter

Elite Member

iTrader: (17)

Joined: Aug 2007

Posts: 2,949

Total Cats: 183

From: Knoxville, TN

I did stumble onto this site in the research I've done: Megasquirt-3 MS3 Trigger Wheel

I realize it's for MS3, but would those parameters generally apply to MS2 as well?

I realize it's for MS3, but would those parameters generally apply to MS2 as well?

#12

A 12-0 trigger wheel can not be used without a cam sync for ignition control of a 4 cylinder engine. This is not a MegaSquirt issue in particular, it wouldn't work with any normal EMS as there is no cylinder ID possible.

You have no sync currently because the MegaSquirt will not run your engine with your present trigger configuration to prevent engine damage.

You will need to remove a tooth to create a 12-1 trigger wheel, and then set your tooth #1 angle per the documentation.

You have no sync currently because the MegaSquirt will not run your engine with your present trigger configuration to prevent engine damage.

You will need to remove a tooth to create a 12-1 trigger wheel, and then set your tooth #1 angle per the documentation.

#17

Thread Starter

Elite Member

iTrader: (17)

Joined: Aug 2007

Posts: 2,949

Total Cats: 183

From: Knoxville, TN

A 12-0 trigger wheel can not be used without a cam sync for ignition control of a 4 cylinder engine. This is not a MegaSquirt issue in particular, it wouldn't work with any normal EMS as there is no cylinder ID possible.

You have no sync currently because the MegaSquirt will not run your engine with your present trigger configuration to prevent engine damage.

You will need to remove a tooth to create a 12-1 trigger wheel, and then set your tooth #1 angle per the documentation.

You have no sync currently because the MegaSquirt will not run your engine with your present trigger configuration to prevent engine damage.

You will need to remove a tooth to create a 12-1 trigger wheel, and then set your tooth #1 angle per the documentation.

MS2 trigger wheel info, for posterity: MS2-Extra Missing_Tooth

#18

How to make your trigger wheel work on MS3+MS3X with sequential injection and ignition

(assuming you wired your coils and injectors as fully sequential using MS3X board)

Part 1: Making your trigger wheel work

Congradulations, your car is now running in batch (e.g. not sequential) on just the trigger wheel

Part 2. Modifying and adding CAS, enabling full sequential

(assuming you wired your coils and injectors as fully sequential using MS3X board)

Part 1: Making your trigger wheel work

- Unplug the NA CAS/NB CAM sensor

- Make sure your trigger wheel has a missing tooth

- Figure out where the missing tooth comes in (e.g. angle)

Megasquirt-3 MS3 Trigger Wheel - Wire your crank sensor and mount the trigger wheel. The crank trigger has a single "signal" wire and that goes to MS3 trigger input (not MS3X)

- Change injection to "semi-sequential" (batch if not using sequential)

- Change ignition to "wasted COP" (wasted spark if not using sequential)

- Change ignition to "Single wheel with missing tooth"

- Try running the car. If it gets sync errors, you may have wired the crank sensor wrong. Or its too far away. Adjust until you have no sync errors and trigger log looks good.

- Verify the trigger angle with trigger light.

Congradulations, your car is now running in batch (e.g. not sequential) on just the trigger wheel

Part 2. Modifying and adding CAS, enabling full sequential

- Modify the cam signal so it only has one tooth

If your car is NA and you're using a CAS- Depending

- Take the CAS apart

- Modify your CAS to only have 1 tooth per camshaft revolution

If it's a "magnetic" cas and has metal rotors inside of it

- You need to cut off all the teeth except one.

- A magnetic CAS has 2 rotors inside - one with 2 teeth and one with 4.

- I cut the 2 teeth rotor off completely, and 3 teeth off the 4-tooth rotor. I have pictures somewhere - it has to be a specific tooth that you cut off.

If It's an optical cas and has disks with holes in them - you could either make a new trigger wheel with just the right holes, tape the ones you don't need or just get a magnetic CAS

- Wire the CAS so only one wire goes to the MS3X "cam" input. Depending which disk/rotor you used inside the CAS you either use SGT (you used larger, 4-tooth disk/rotor) or SGC (you used smaller, 2-tooth disk/rotor)

If your car is 99-00 NB, then you need to grind off the 2 "bumps" from the face of the intake cam wheel. No wiring changes need to be done

#20

Thread Starter

Elite Member

iTrader: (17)

Joined: Aug 2007

Posts: 2,949

Total Cats: 183

From: Knoxville, TN

Awesome writeup, thank you.

Do you know, are the '90-'93 CAS's are magnetic and '94-'97 optical? Or is it just a crapshoot? I think I've got a spare '90 cas that I'll pull apart when I get home.

Do you know, are the '90-'93 CAS's are magnetic and '94-'97 optical? Or is it just a crapshoot? I think I've got a spare '90 cas that I'll pull apart when I get home.