Erratic AFR values, AE Settings

#1

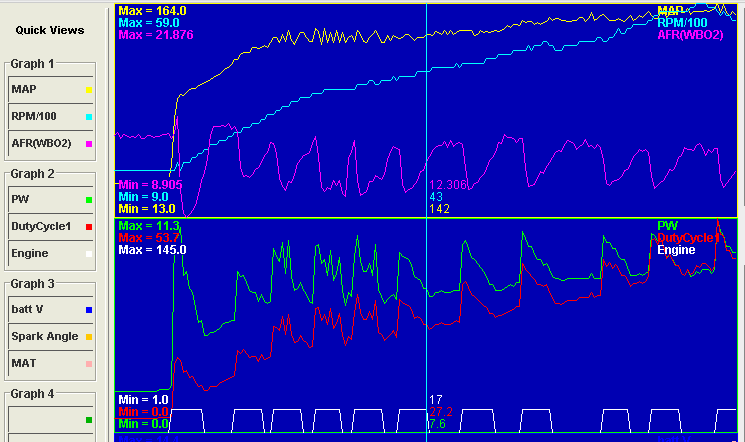

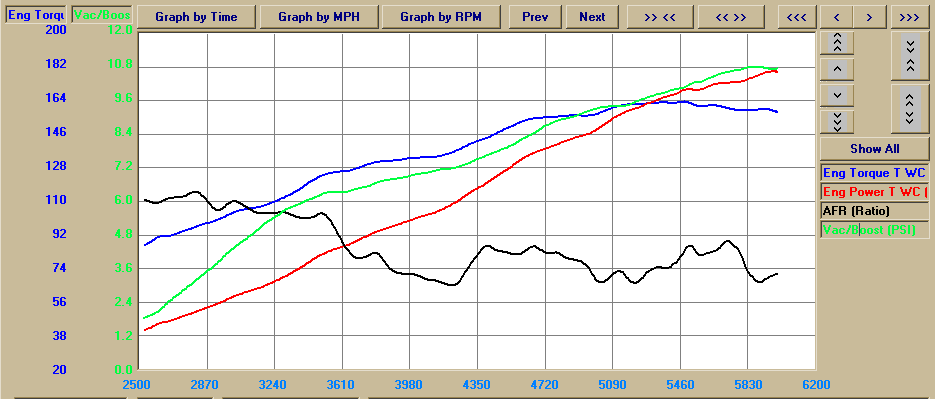

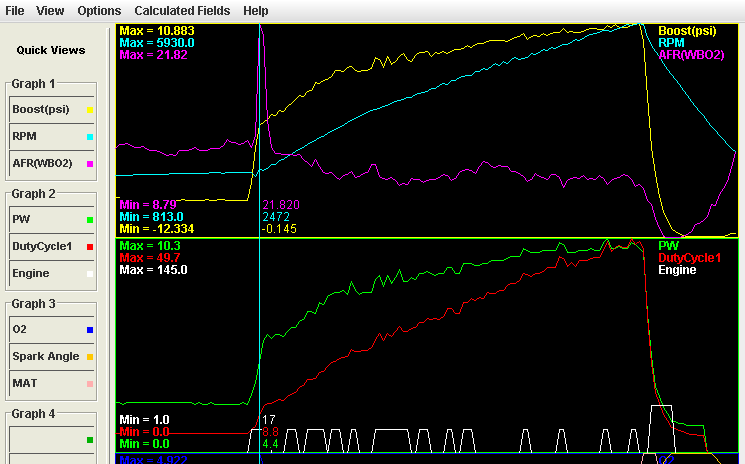

We've got a '90 with Flying Miata turbo and just installed MSPNP. Car runs just "ok" and we're working on the dyno to tune the VE table and eventually ignition. Right now we're getting AFR readings jumping all over during a power run. On the data log we can see the PW and Duty cyle jumping around. We turned on the "Engine Bits" channel and see the value stepping from 1 to 17. These pulses correspond exactly with the PW spikes.

From my reading/research, this indicates the Accel Enrichment is active when the Engine Bits = 16. So here are my questions:

> Is the AE being activated, decaying and then re-activated?

> Are the "Engine Bits" values additive - we saw a value of 31 at one point.

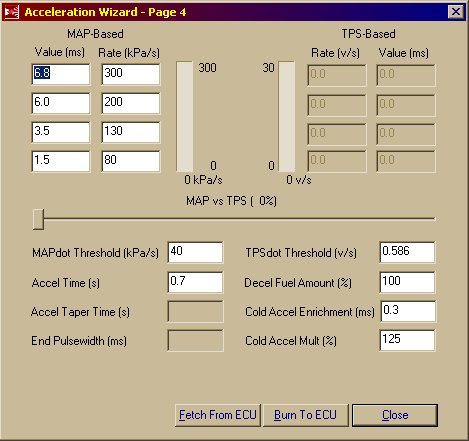

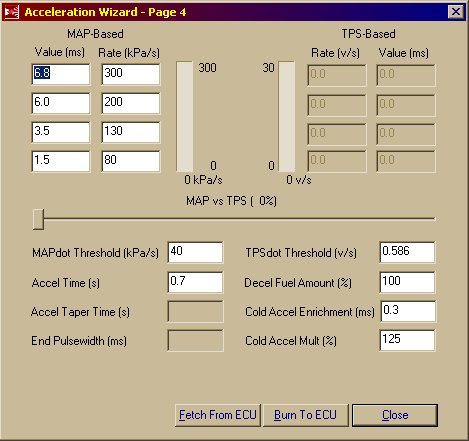

So I'm thinking our AE settings are completely wrong. Here is the set up.

OR have we got some other problem?

datalog200812051518.zip

From my reading/research, this indicates the Accel Enrichment is active when the Engine Bits = 16. So here are my questions:

> Is the AE being activated, decaying and then re-activated?

> Are the "Engine Bits" values additive - we saw a value of 31 at one point.

So I'm thinking our AE settings are completely wrong. Here is the set up.

OR have we got some other problem?

datalog200812051518.zip

#2

Joined: Sep 2005

Posts: 33,556

Total Cats: 6,933

From: Chicago. (The less-murder part.)

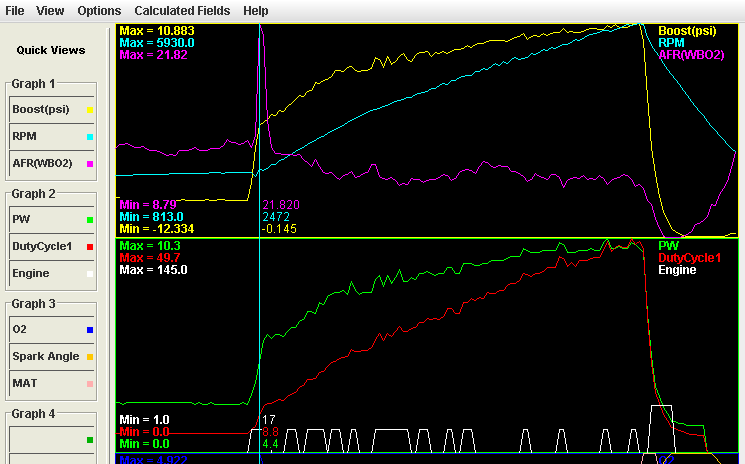

It does appear that accel enrichment is to blame here. Take a look at this plot, where I've shown Accel as the white line in the #2 strip. Each jump in injector PW and drop in AFR is accompanied by some activity in the Accel enrichment. It doesn't look very dramatic here, because the plot is scaled down owing to the min and max Accel values in the log being quite amazingly large.

In fact, take a look here:

See how accel went to 1,066 for a moment? That suggests that the values are way too big.

Unfortunately I can't give you specific advice here as I use TPS rather than MAP, but definately look at scaling those down.

In fact, take a look here:

See how accel went to 1,066 for a moment? That suggests that the values are way too big.

Unfortunately I can't give you specific advice here as I use TPS rather than MAP, but definately look at scaling those down.

#5

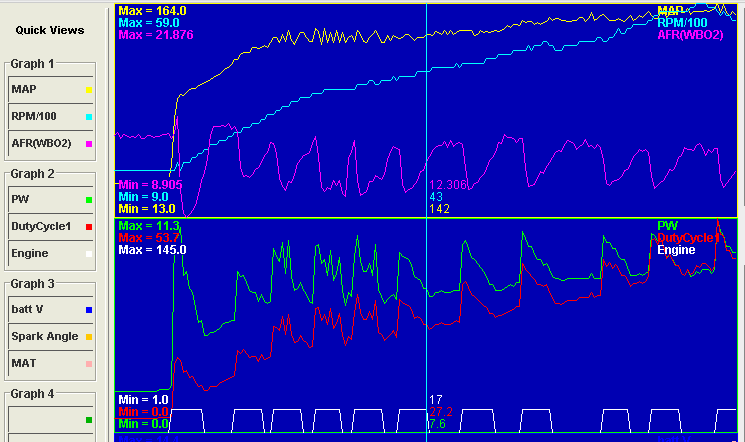

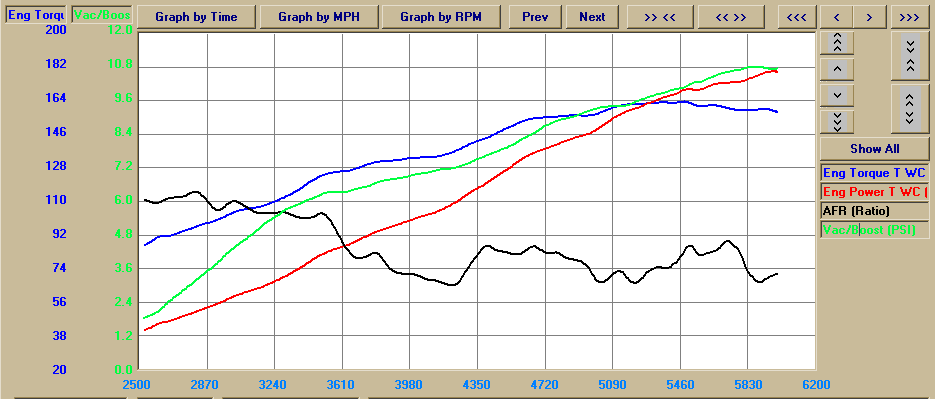

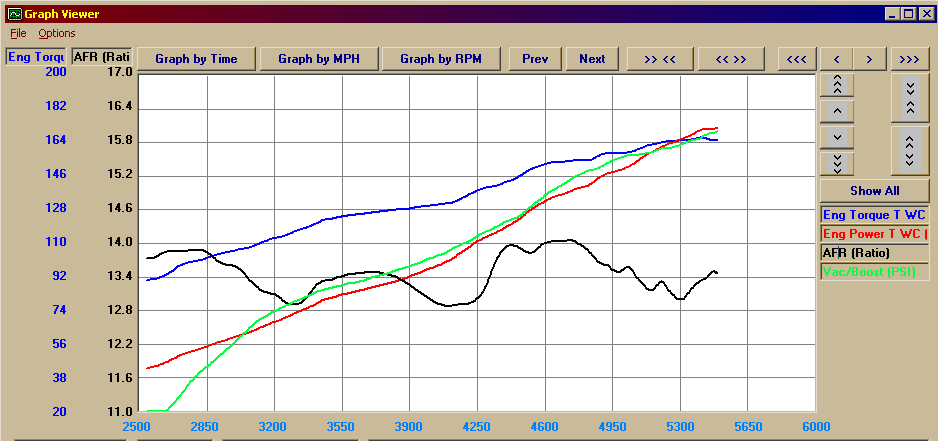

Some success. Here is our best run, so far: 180 HP / 164 ft-lb - over 20 HP gain after installing the MS unit.

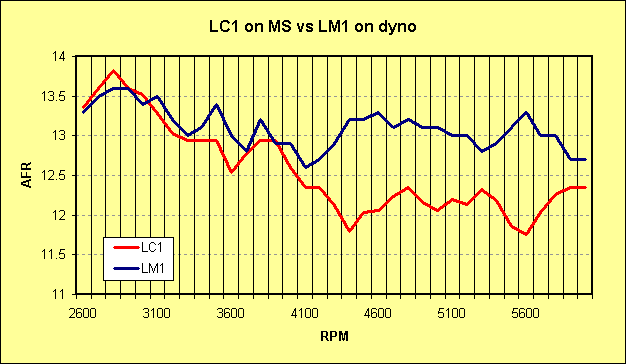

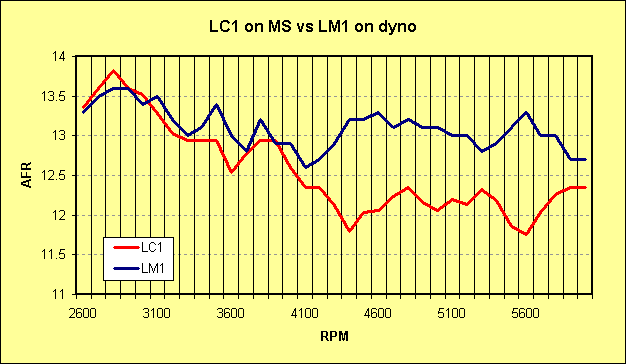

But we have a problem with the MS AFR readings. Here is a data log showing the LC1 - MS readings:

(BTW we change AE to RPM-based and the PW and Duty Cycle curves cleaned up well, as you can see)

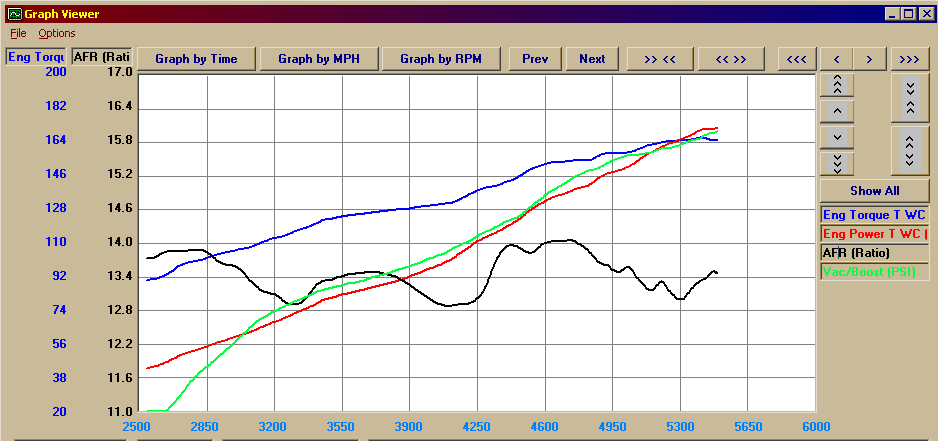

Here is the dyno's LM1 attached to the same O2 sensor, shown on the dyno graph. Note the "bump" near 4600RPM. I have verified the LM1 against several other customer wideband meters: (note this is an earlier run than the dyno run above - we continued tuning using the LM1)

Any ideas? We recalibrated the LC1 setup once.

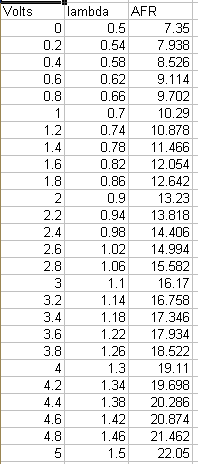

PS I was trying to load the data from both sources into Excel, but the MS data file stores the O2 voltage as opposed to the calculated wide band data. The relatioinship between the two doesn't seem to be linear? Is it supposed to be? eg at O2 = 4.922; WB = 21.820 or 4.433 AFR/volt but O2 = 1.706; WB = 12.365 or 7.248 AFR/volt. Do you know what formula the datalogger uses?

But we have a problem with the MS AFR readings. Here is a data log showing the LC1 - MS readings:

(BTW we change AE to RPM-based and the PW and Duty Cycle curves cleaned up well, as you can see)

Here is the dyno's LM1 attached to the same O2 sensor, shown on the dyno graph. Note the "bump" near 4600RPM. I have verified the LM1 against several other customer wideband meters: (note this is an earlier run than the dyno run above - we continued tuning using the LM1)

Any ideas? We recalibrated the LC1 setup once.

PS I was trying to load the data from both sources into Excel, but the MS data file stores the O2 voltage as opposed to the calculated wide band data. The relatioinship between the two doesn't seem to be linear? Is it supposed to be? eg at O2 = 4.922; WB = 21.820 or 4.433 AFR/volt but O2 = 1.706; WB = 12.365 or 7.248 AFR/volt. Do you know what formula the datalogger uses?

#6

Joined: Sep 2005

Posts: 33,556

Total Cats: 6,933

From: Chicago. (The less-murder part.)

If you're referring to the spike in AFR to 21.82 at the cursor, that's pretty normal on a quick throttle opening. If you have an analog TPS, you can add some TPSaccel.

Looking at the dyno plot, it's pretty obvious that they're doing some averaging. Data in real life don't produce those nice smooth lines- they produce jagged spikey stuff like you see in the MS log. I'd wager that the AFR spike is just getting smoothed out by the dyno's software.

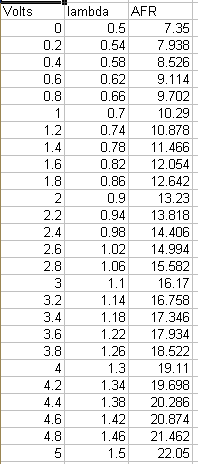

The relationship between O2 voltage and actual AFR is linear on the LC1's default wideband setting. 0v = 0.5λ, and 5v = 1.5λ. For gasoline, 0.5λ = 7.35:1 AFR and 1.5λ = 22.05:1 AFR. You can draw a straight line between these two points, and all values will be accurate.

Internally, the MS computes AFR based on the raw data coming out of an 8 bit analog to digital converter (referred to as egoADC), where 0v = 000 and 5v = 255 (assuming proper calibration.) It uses the following formulas:

lambda = egoADC/255.0 + 0.5

afr = lambda * 14.7

which can also be expressed as:

afr = 7.35 + egoADC * 0.057647

This is all in the lambdasensors.ini file, which is located in \Program Files\MegaSquirt\MegaTune2.25\mtCfg

Why MegaTune translates egoADC into volts for logging is beyond me. Most of the analog values it logs are raw ADC, which actually makes life a tad simpler.

Looking at the dyno plot, it's pretty obvious that they're doing some averaging. Data in real life don't produce those nice smooth lines- they produce jagged spikey stuff like you see in the MS log. I'd wager that the AFR spike is just getting smoothed out by the dyno's software.

The relationship between O2 voltage and actual AFR is linear on the LC1's default wideband setting. 0v = 0.5λ, and 5v = 1.5λ. For gasoline, 0.5λ = 7.35:1 AFR and 1.5λ = 22.05:1 AFR. You can draw a straight line between these two points, and all values will be accurate.

Internally, the MS computes AFR based on the raw data coming out of an 8 bit analog to digital converter (referred to as egoADC), where 0v = 000 and 5v = 255 (assuming proper calibration.) It uses the following formulas:

lambda = egoADC/255.0 + 0.5

afr = lambda * 14.7

which can also be expressed as:

afr = 7.35 + egoADC * 0.057647

This is all in the lambdasensors.ini file, which is located in \Program Files\MegaSquirt\MegaTune2.25\mtCfg

Why MegaTune translates egoADC into volts for logging is beyond me. Most of the analog values it logs are raw ADC, which actually makes life a tad simpler.

#7

I wasn't actually looking at that spike, since, as you suggested, I can play with the AE settings and the dyno actually is set to start recording from 2500 RPM, so it misses that part of the data log.

There is some smoothing on the dyno graph, but I checked the scatter graph and it is not significant.

I was more concerned that, in the main part of the run, the shape of the curves are different.

I did 2 runs today, one with the LM1 and one with the LC1 and I am trying to combine the data per your formula's. I don't have a value "egoADC" but I do have "O2" which looks like volts. However, the formula don't produce reasonable AFR values - they're all at about 7. This is since the O2 value divided by 255 is such a small number. I do get reasonable values when I used a lookup table constructed from the 0-5volt vs lamba values.

I will post that graph when I get it done.

There is some smoothing on the dyno graph, but I checked the scatter graph and it is not significant.

I was more concerned that, in the main part of the run, the shape of the curves are different.

I did 2 runs today, one with the LM1 and one with the LC1 and I am trying to combine the data per your formula's. I don't have a value "egoADC" but I do have "O2" which looks like volts. However, the formula don't produce reasonable AFR values - they're all at about 7. This is since the O2 value divided by 255 is such a small number. I do get reasonable values when I used a lookup table constructed from the 0-5volt vs lamba values.

I will post that graph when I get it done.

#8

Here is the graph comparing the 2 wideband data logs. There is some smoothing due to the way I wrote the VBA code in Excel. But there is still a significant variance in the value and slopes of the curves. The LC1 is reading rich vs the LM1 which could be dangerous (assuming the LM1 is correct)

This is the lookup table I built: (I actually used one with .1 volt increments)

This is the lookup table I built: (I actually used one with .1 volt increments)

#10

Thanks. I'll try that. I'll have to borrow a cable since the LM1 on the dyno didn't come with the data cable (it's $12, but $57 for shipping, from Innovative  )

)

Just realized that you meant to use Logworks on the LC1. I'll do that.

)

)Just realized that you meant to use Logworks on the LC1. I'll do that.

Last edited by dynodragon; 01-08-2009 at 12:05 PM. Reason: new info

Thread

Thread Starter

Forum

Replies

Last Post

Zaphod

MEGAsquirt

47

10-27-2018 12:00 AM

stoves

Suspension, Brakes, Drivetrain

5

04-21-2016 04:00 PM