Wheel of Timing. Success at last!

#61

I think the reason why OEMs will sometimes use a missing tooth CKP with CMP is for falldown. The car can still run with a missing tooth CKP ring if there is a CMP failure. However if the CKP ring did not have a missing tooth, then the car could not run at all without a CMP signal.

#62

Some do.

I think the reason why OEMs will sometimes use a missing tooth CKP with CMP is for falldown. The car can still run with a missing tooth CKP ring if there is a CMP failure. However if the CKP ring did not have a missing tooth, then the car could not run at all without a CMP signal.

I think the reason why OEMs will sometimes use a missing tooth CKP with CMP is for falldown. The car can still run with a missing tooth CKP ring if there is a CMP failure. However if the CKP ring did not have a missing tooth, then the car could not run at all without a CMP signal.

#65

A missing tooth (or extra tooth) crank trigger wheel also allows VVT even if the CMP trigger wheel is on the cam with VVT. This allows the use of the CMP signal as the feedback input for the VVT algorithm as well.

Without a missing tooth, if you have 8 teeth on the crank trigger wheel (45* apart), you can't have VVT with a range close to 45*. As the VVT moves around, the CMP pulse needs to be always between the same 2 crank teeth. If the CMP pulse "crosses over" a crank pulse, the decoder can't tell which crank tooth is which.

With a missing or extra tooth, the decoder always knows which crank tooth is which, regardless of cam VVT phase. The significant cam pulse only needs to be always in between the missing or extra crank tooth.

BTW between 1 missing tooth and an extra tooth, the latter works better for wheels with fewer teeth. e.g. 36-1 and 24-1 may work well, but 12-1 or 8-1 doesn't. 12+1 or 8+1 would work well.

The reason for this is that during cranking, identifying the missing tooth from the tooth cadence becomes problematic because RPM can vary significantly between teeth.

With an extra tooth, said tooth needs to be closer to the previous tooth than to the next tooth. I determined mathematically that it should come 25% of the normal tooth gap, after the last normal tooth. Less than 25% is very diminishing returns.

Less than 25% is very diminishing returns.

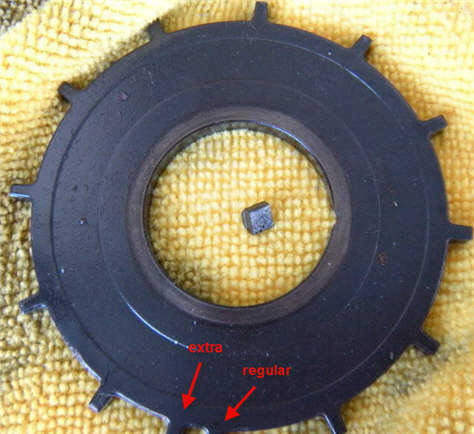

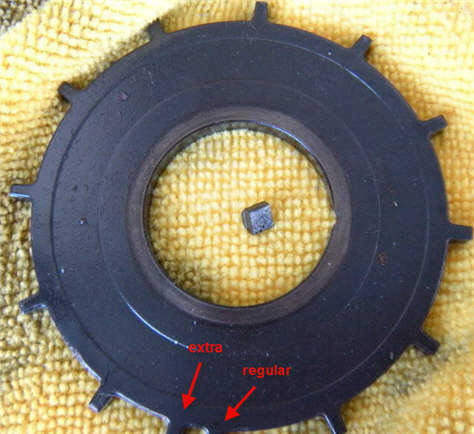

Indeed, that is what the K20 has:

Indeed, that is what the K20 uses:

Without a missing tooth, if you have 8 teeth on the crank trigger wheel (45* apart), you can't have VVT with a range close to 45*. As the VVT moves around, the CMP pulse needs to be always between the same 2 crank teeth. If the CMP pulse "crosses over" a crank pulse, the decoder can't tell which crank tooth is which.

With a missing or extra tooth, the decoder always knows which crank tooth is which, regardless of cam VVT phase. The significant cam pulse only needs to be always in between the missing or extra crank tooth.

BTW between 1 missing tooth and an extra tooth, the latter works better for wheels with fewer teeth. e.g. 36-1 and 24-1 may work well, but 12-1 or 8-1 doesn't. 12+1 or 8+1 would work well.

The reason for this is that during cranking, identifying the missing tooth from the tooth cadence becomes problematic because RPM can vary significantly between teeth.

With an extra tooth, said tooth needs to be closer to the previous tooth than to the next tooth. I determined mathematically that it should come 25% of the normal tooth gap, after the last normal tooth.

Less than 25% is very diminishing returns.

Less than 25% is very diminishing returns.Indeed, that is what the K20 has:

Indeed, that is what the K20 uses:

#66

Joined: Jun 2005

Posts: 19,338

Total Cats: 574

From: Fake Virginia

The VVT may not work with too many teeth on the crank because in order for the car to sync properly, the cam pulse must fall between two specific teeth on the crank. If you look at the cam and crank pulses for the whole range of VVT angles, the cam sync is always between the same teeth--it never crosses over into another gap.

I made a picture of two composite logs overlayed to help illustrate.

notice how the orange and green lines dont ever cross blue lines.

I'm not sure this would still work with too many crank pulses.

I made a picture of two composite logs overlayed to help illustrate.

notice how the orange and green lines dont ever cross blue lines.

I'm not sure this would still work with too many crank pulses.

#67

The VVT may not work with too many teeth on the crank because in order for the car to sync properly, the cam pulse must fall between two specific teeth on the crank. If you look at the cam and crank pulses for the whole range of VVT angles, the cam sync is always between the same teeth--it never crosses over into another gap.

This is how both of our AEM 30-1710 cars are set up - stock 01+ sensors with a 12+1 wheel.

#68

Joined: Jun 2006

Posts: 29,085

Total Cats: 375

From: Republic of Dallas

Help me understand simple concepts:

So on a sequential fuel or spark car, how does fuel and spark know where to fire if the CMP phased tooth is active after the 4th cylinder or on an adjustable cam? Is the ECM still relying on "counting CKP teeth" to trigger the fuel and spark? If the sequentially fired fuel injector is triggered to fire Xms prior to an ignition event (back-timed), isn't the placement of that phased CMP crucial?

So on a sequential fuel or spark car, how does fuel and spark know where to fire if the CMP phased tooth is active after the 4th cylinder or on an adjustable cam? Is the ECM still relying on "counting CKP teeth" to trigger the fuel and spark? If the sequentially fired fuel injector is triggered to fire Xms prior to an ignition event (back-timed), isn't the placement of that phased CMP crucial?

#69

Joined: Jun 2005

Posts: 19,338

Total Cats: 574

From: Fake Virginia

Only if you are relying on the cam sensor for sync. If you use a missing or added tooth for sync, and you only use the cam sensor for phasing, the cam signal can jump across crank teeth with no issue.

This is how both of our AEM 30-1710 cars are set up - stock 01+ sensors with a 12+1 wheel.

This is how both of our AEM 30-1710 cars are set up - stock 01+ sensors with a 12+1 wheel.

I'm sure a custom option could be made for the miata three pulse cam sensor.

#70

Joined: Jun 2006

Posts: 29,085

Total Cats: 375

From: Republic of Dallas

Is a 12-1 wheel too little resolution? Should I look at getting something with more teeth made? Now that I'm down to the computer only reading 11-teeth, I'm worried about scatter...but considering I'm going from a 2-tooth to a 12-tooth wheel, I can't really complain.

Last edited by hustler; 10-18-2011 at 04:22 PM.

#71

The cam edges just MUST NOT cross over the teeth that surround the extra or missing tooth. This only puts a constraint on where to put the missing or extra tooth, and actually on the number of cam teeth and their locations.

So you can have lots of crank teeth and have nearly 180* of VVT range lol, if you only have 2 cam teeth, or 2 "clusters" of cam teeth (like the miata).

So you can have lots of crank teeth and have nearly 180* of VVT range lol, if you only have 2 cam teeth, or 2 "clusters" of cam teeth (like the miata).

#73

Factory cam timing setup (or even if you retard a tooth like I'm thinking), and 12-1 wheel:

10* BTDC to 80* ATDC tooth #1/4 are bad.

Best tooth to remove is 20* ATDC #2/3. This is far away from the cam edges thru the VVT range, and this missing tooth will affect timing accuracy least.

Best tooth location for extra tooth for 12+1, is 7*-10* after the 20*ATDC #2/3 tooth.

10* BTDC to 80* ATDC tooth #1/4 are bad.

Best tooth to remove is 20* ATDC #2/3. This is far away from the cam edges thru the VVT range, and this missing tooth will affect timing accuracy least.

Best tooth location for extra tooth for 12+1, is 7*-10* after the 20*ATDC #2/3 tooth.

#76

Joined: Jun 2006

Posts: 29,085

Total Cats: 375

From: Republic of Dallas

Thanks.

How is Brain running a stock CAS and getting CMP phasing to work with a crank wheel?

If I have to cut off one CMP (NA) tooth, how do I select the tooth and align it with the adjustable CAS? Is there a tooth logger tool or something I can use with MS2? I assume one of those CMP teeth line-up with CKP#1, right?

I'm sorry to be so annoying with this stuff, thanks for the help.

How is Brain running a stock CAS and getting CMP phasing to work with a crank wheel?

If I have to cut off one CMP (NA) tooth, how do I select the tooth and align it with the adjustable CAS? Is there a tooth logger tool or something I can use with MS2? I assume one of those CMP teeth line-up with CKP#1, right?

I'm sorry to be so annoying with this stuff, thanks for the help.

#77

Joined: Jun 2005

Posts: 19,338

Total Cats: 574

From: Fake Virginia

if you have a 99 cam gear, it's got the bumps on it that show where the cam pulses are.

Just paypal me another $20 and I'll send you the CAS ready to rock. I think I have a spare pigtail with connector too.

Here's what a modified CAS looks like. outer wheel (big four tab one) is CKP. inner wheel is CMP.

All but one tab on the inner wheel has been clipped off and a new alignment hole has been drilled to move the sync pulse. I forget where it is, but it's whatever the Tec3 required. With the MS, you can log the cam pulse and crank pulses to determine where it falls and move it as needed.

If you need to change it, just get a tiny drill and make your new hole. Easy. If you look close you can see two dot-size holes on the upper right of the top wheel. the right-most one is the stock one. Outer wheel has a "D" hole. Inner wheel is a round hole (it may have also been D and drilled out--I forget).

(note speyside single malt in background)

Here's that locating pin that determines where the sync pulse is:

Just paypal me another $20 and I'll send you the CAS ready to rock. I think I have a spare pigtail with connector too.

Here's what a modified CAS looks like. outer wheel (big four tab one) is CKP. inner wheel is CMP.

All but one tab on the inner wheel has been clipped off and a new alignment hole has been drilled to move the sync pulse. I forget where it is, but it's whatever the Tec3 required. With the MS, you can log the cam pulse and crank pulses to determine where it falls and move it as needed.

If you need to change it, just get a tiny drill and make your new hole. Easy. If you look close you can see two dot-size holes on the upper right of the top wheel. the right-most one is the stock one. Outer wheel has a "D" hole. Inner wheel is a round hole (it may have also been D and drilled out--I forget).

(note speyside single malt in background)

Here's that locating pin that determines where the sync pulse is: