ITT we discuss EAE on MS3

#1

Thread Starter

Joined: Jan 2013

Posts: 5,012

Total Cats: 859

From: Seneca, SC

I want to do an in-depth look at EAE to show that, though it seems quite complicated, the concept and the code is actually quite simple. However, though I believe that to be true, my initial attempt to present the simplified version has proven a bit difficult.

So, I'm going to open with a presentation of what I have, and how I got there, and what I think it all means.

AtW means extra % of fuel that at adheres to the manifold wall

WF means the Fuel that is in a puddle on the Wall

SfW means the % of that puddle that is evaporating back into the airstream

If used, EAE is active all the time in its normal manner EXCEPT during cranking and fuel cut. During cranking, I don't really understand what it does. During fuel cut, only SfW is active, reducing the WF.

Otherwise, each pulse is reduced by the SfW * WF, while additionally it is increased by the AtW. Then the extra fuel (above the normal steady-state requirement) is added to the WF.

That's the general idea.

So, I'm going to open with a presentation of what I have, and how I got there, and what I think it all means.

AtW means extra % of fuel that at adheres to the manifold wall

WF means the Fuel that is in a puddle on the Wall

SfW means the % of that puddle that is evaporating back into the airstream

If used, EAE is active all the time in its normal manner EXCEPT during cranking and fuel cut. During cranking, I don't really understand what it does. During fuel cut, only SfW is active, reducing the WF.

Otherwise, each pulse is reduced by the SfW * WF, while additionally it is increased by the AtW. Then the extra fuel (above the normal steady-state requirement) is added to the WF.

That's the general idea.

#2

Thread Starter

Joined: Jan 2013

Posts: 5,012

Total Cats: 859

From: Seneca, SC

Next, what to do with that:

Keys to tuning EAE:

1) The visual concept is that with each pulse, some fuel is Added to the puddle (AtW), but at the same time, some of the puddle is evaporated back (SfW). Though the math may go beyond the reality, in fact the picture can help.

2) When in transition, the normal thing to happen is that the engine goes lean on rising MAP, and goes rich on falling MAP. To watch this occur:

3) Have a gauge or log that shows AFR Error. This is more important than AFR, because, as MAP changes the target AFR changes too. What EAE is trying to do is keep the actual AFR the same in transient conditions that you have determined you want at steady state. I also like to have a log that shows WF, and it gives a picture of what's going on.

One trick is to set all AFR's (assuming you are using AFR in the fueling equation) to the same value. For instance, I temporarily set AFR from idle to 6K RPM and from the bottom to 85kPa to 14.7. Now, any deviation from 14.7 is an imperfect EAE, and AFR is as easy to use as AFR Error for evaluation. Not recommended into higher kPa.

4) Have your kPa, Temp, and RPM X-Axis set for the full range your engine will ever see, because, remember, EAE is on all the time.

5) Start with AtW (Temp) and AtW (RPM) set to 100%. Also SfW (Temp) and SfW (RPM) at 100% across the board. The AtW should be at some value like 11 across the board, and the SfW at about 6.4. To be honest, I don't know that these are the BEST values, but have not seen anything that suggests better ones, and will admit that is above my understanding.

6) Now drive in Steady State at low MAP, and a nominal RPM, and then make a step change in throttle. As MAP increases, the tendency is to go lean. Watch this occur or log it.

7) This is where I think most tutorials are confusing and lead people astray. They say:

A) If it goes rich on accel, decrease added-to-walls.

B) If it goes lean on accel, increase added-to-walls.

C) If it goes rich on decel, increase sucked-from-walls.

D) If it goes lean on decel, decrease sucked-from-walls.

This is basically correct. When you made the step throttle increase, resulting in a temporary lean situation (B), you want to increase the ATW, but NOT at the Starting MAP value, but rather at the Finishing MAP value.

In other words, start at 25 kPa, and fairly quickly run to 35 kPa. If you go lean (or PLUS AFR error) then add increase the AtW at 35 kPa, (and all kPa above that). For example, if you started with all at 11, then leave the 25 at 11, and move 35 and above to, say 12.

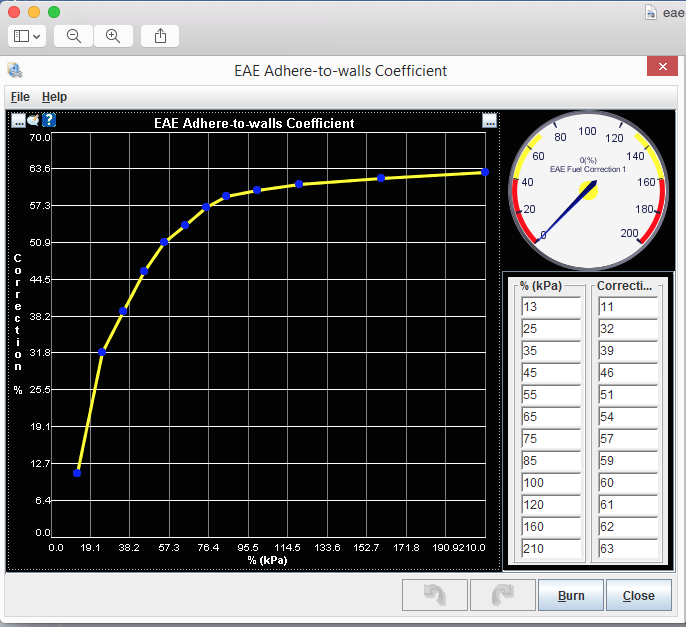

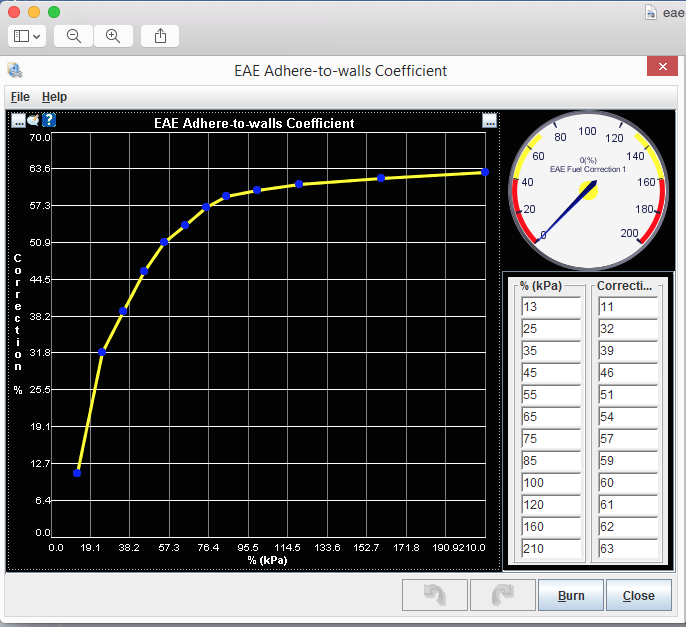

Keep ratcheting up until the curve tends to look like my finished one shown below:

You may wish to start with a curve similar to that, but with lower values, so you are closer to begin with.

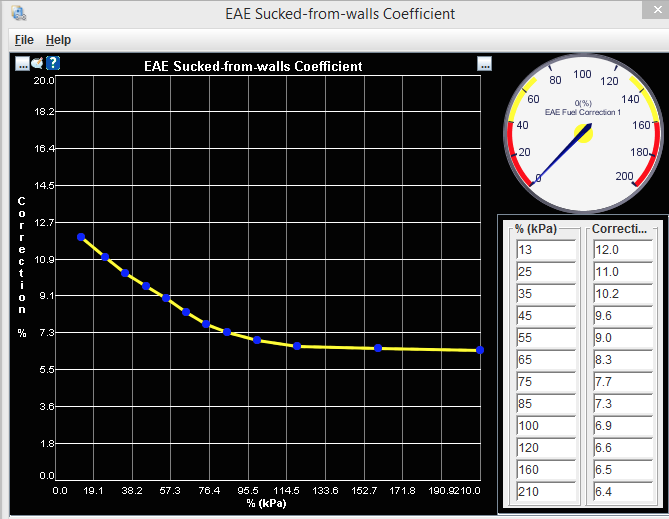

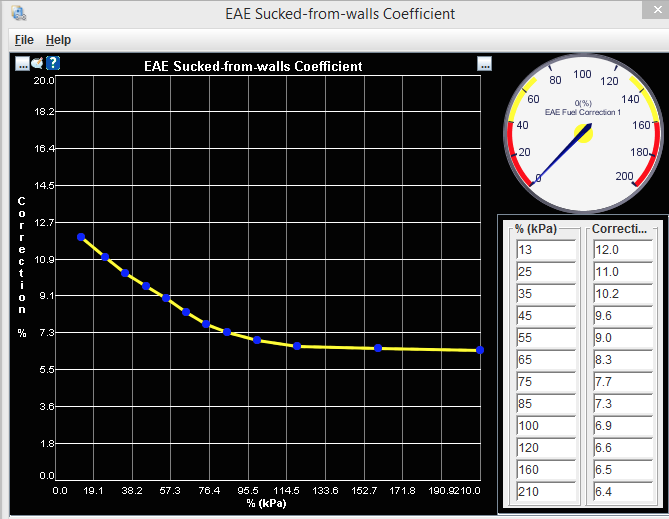

8) Now step down kPa from the maximum, to lower values and watch things go rich as in (C) above. Now same as in step 7, increase the SfW and the Finishing MAP value. The final curve should look something like this:

9) I have not seen any need to adjust the RPM curve from 100% across the board.

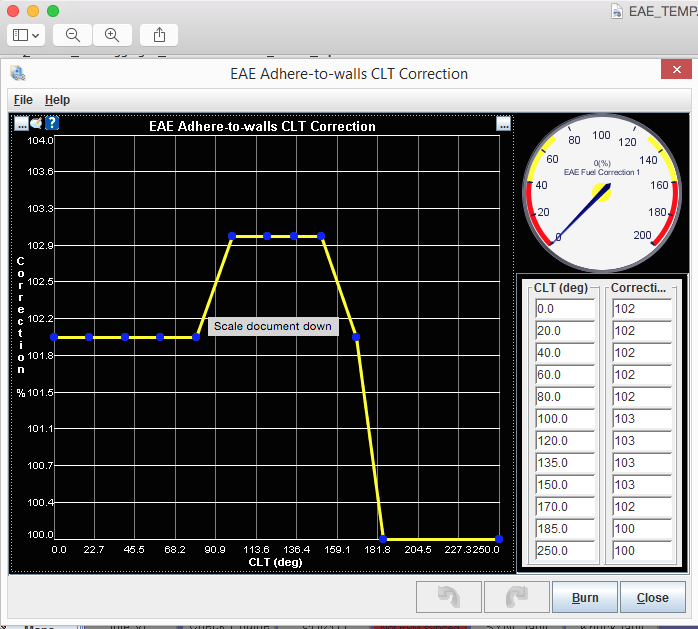

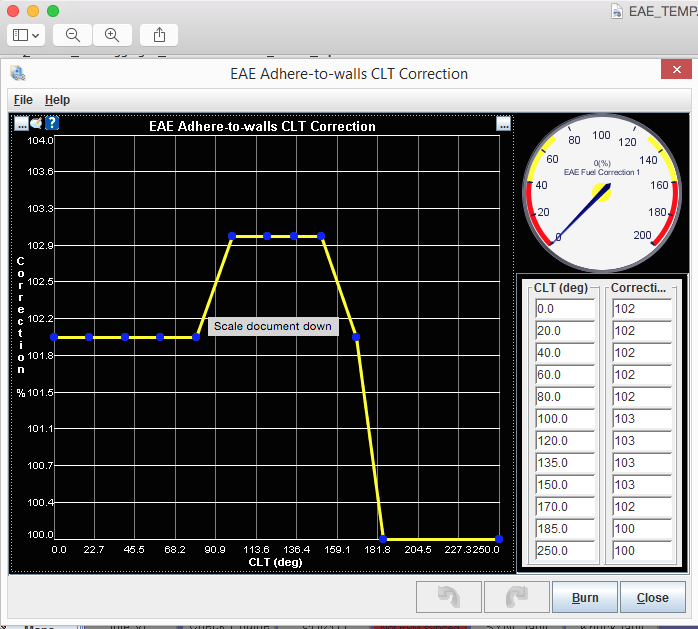

10) I have adjusted the AtW curve a little for temperature, but I'm not convinced yet it means a lot:

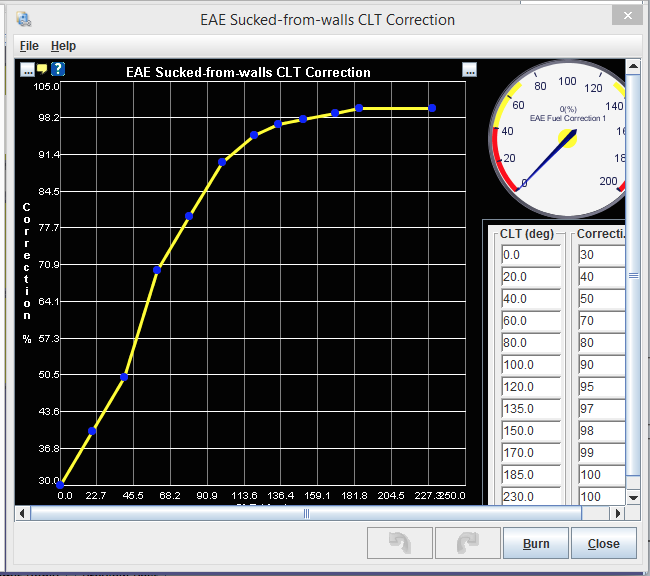

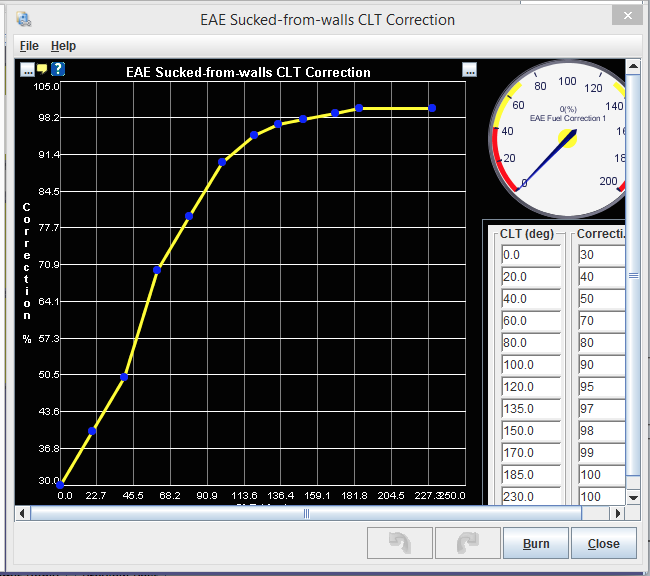

11) I have more purpose in adjusting the SfW for temperature. On cold starts, the WF builds up during cranking. Then when cranking is over, the SfW * WF would drive the pulse right to zero. Here is my curve (it may be a little extreme, as I am still trying to perfect after-start when cold):

That's it for now. I'll see how this looks on the site, and see what kind of comments I get from others that have something to add.

This is one thing that has worked well for me. Again, the key is change the AtW and SfW at the Ending MAP, not the Starting, when making the step changes.

Keys to tuning EAE:

1) The visual concept is that with each pulse, some fuel is Added to the puddle (AtW), but at the same time, some of the puddle is evaporated back (SfW). Though the math may go beyond the reality, in fact the picture can help.

2) When in transition, the normal thing to happen is that the engine goes lean on rising MAP, and goes rich on falling MAP. To watch this occur:

3) Have a gauge or log that shows AFR Error. This is more important than AFR, because, as MAP changes the target AFR changes too. What EAE is trying to do is keep the actual AFR the same in transient conditions that you have determined you want at steady state. I also like to have a log that shows WF, and it gives a picture of what's going on.

One trick is to set all AFR's (assuming you are using AFR in the fueling equation) to the same value. For instance, I temporarily set AFR from idle to 6K RPM and from the bottom to 85kPa to 14.7. Now, any deviation from 14.7 is an imperfect EAE, and AFR is as easy to use as AFR Error for evaluation. Not recommended into higher kPa.

4) Have your kPa, Temp, and RPM X-Axis set for the full range your engine will ever see, because, remember, EAE is on all the time.

5) Start with AtW (Temp) and AtW (RPM) set to 100%. Also SfW (Temp) and SfW (RPM) at 100% across the board. The AtW should be at some value like 11 across the board, and the SfW at about 6.4. To be honest, I don't know that these are the BEST values, but have not seen anything that suggests better ones, and will admit that is above my understanding.

6) Now drive in Steady State at low MAP, and a nominal RPM, and then make a step change in throttle. As MAP increases, the tendency is to go lean. Watch this occur or log it.

7) This is where I think most tutorials are confusing and lead people astray. They say:

A) If it goes rich on accel, decrease added-to-walls.

B) If it goes lean on accel, increase added-to-walls.

C) If it goes rich on decel, increase sucked-from-walls.

D) If it goes lean on decel, decrease sucked-from-walls.

This is basically correct. When you made the step throttle increase, resulting in a temporary lean situation (B), you want to increase the ATW, but NOT at the Starting MAP value, but rather at the Finishing MAP value.

In other words, start at 25 kPa, and fairly quickly run to 35 kPa. If you go lean (or PLUS AFR error) then add increase the AtW at 35 kPa, (and all kPa above that). For example, if you started with all at 11, then leave the 25 at 11, and move 35 and above to, say 12.

Keep ratcheting up until the curve tends to look like my finished one shown below:

You may wish to start with a curve similar to that, but with lower values, so you are closer to begin with.

8) Now step down kPa from the maximum, to lower values and watch things go rich as in (C) above. Now same as in step 7, increase the SfW and the Finishing MAP value. The final curve should look something like this:

9) I have not seen any need to adjust the RPM curve from 100% across the board.

10) I have adjusted the AtW curve a little for temperature, but I'm not convinced yet it means a lot:

11) I have more purpose in adjusting the SfW for temperature. On cold starts, the WF builds up during cranking. Then when cranking is over, the SfW * WF would drive the pulse right to zero. Here is my curve (it may be a little extreme, as I am still trying to perfect after-start when cold):

That's it for now. I'll see how this looks on the site, and see what kind of comments I get from others that have something to add.

This is one thing that has worked well for me. Again, the key is change the AtW and SfW at the Ending MAP, not the Starting, when making the step changes.

#3

Thread Starter

Joined: Jan 2013

Posts: 5,012

Total Cats: 859

From: Seneca, SC

No comments so far.

Too long?

Not clear?

Not accurate?

Not helpful?

No one else cares?

I was hoping to get some conversation on this subject, as well as pass on the best helpful hint in tuning, which is #7 in the above post: Adjust AtW or SfW at the ending MAP, after a step change in throttle, rather than at the starting MAP.

Too long?

Not clear?

Not accurate?

Not helpful?

No one else cares?

I was hoping to get some conversation on this subject, as well as pass on the best helpful hint in tuning, which is #7 in the above post: Adjust AtW or SfW at the ending MAP, after a step change in throttle, rather than at the starting MAP.

Last edited by DNMakinson; 04-02-2015 at 09:40 AM.

#4

Ok, I'll jump in:

1) MSextra had a GREAT write up on complete and thorough tuning of EAE. I even printed it out and used it when tuning my 01, and ended up with flawless values. Now that they changed format, I've looked for like a dozen times and can't find it. That really sucks. I'll see if I can find my hard copy

2) your writeup looks about right. your strategy looks about right. I think the topic is just not that popular cause many/most don't bother tuning this because car drives more or less fine without it, but I do agree that this is important.

3) My biggest breakthrough when tuning this last time was to rely FIRST on feel, and THEN on what the data outputs. What I mean by this is: you want the car to feel smooth and transition smooth, rather than feel rough but "look" good on a log. The two are NOT the same and don't necessarily have to match/jive. I know that sounds crazy but it really helped me. (same with AE, actually)

4) Keep in mind this is WAY more for steady state and almost completely useless for sharp throttle transitions, where AE is what the car relies on....Also keep in mind that if your VE table and AE isn't ALREADY TUNED to perfection, you're gonna have a really bad time with this.

Hope that helps, at least somewhat. I'll grab screen shots of my 01's values that I ended up with, but the car was very smooth and slow throttle tip in at cruise resulted in almost rock solid AFR's when I was done with it. (ps: they looked a lot like yours above, actually. In fact, I'd say that for most cars the overall curves will look exactly like that and only vary by a little bit in either direction)

1) MSextra had a GREAT write up on complete and thorough tuning of EAE. I even printed it out and used it when tuning my 01, and ended up with flawless values. Now that they changed format, I've looked for like a dozen times and can't find it. That really sucks. I'll see if I can find my hard copy

2) your writeup looks about right. your strategy looks about right. I think the topic is just not that popular cause many/most don't bother tuning this because car drives more or less fine without it, but I do agree that this is important.

3) My biggest breakthrough when tuning this last time was to rely FIRST on feel, and THEN on what the data outputs. What I mean by this is: you want the car to feel smooth and transition smooth, rather than feel rough but "look" good on a log. The two are NOT the same and don't necessarily have to match/jive. I know that sounds crazy but it really helped me. (same with AE, actually)

4) Keep in mind this is WAY more for steady state and almost completely useless for sharp throttle transitions, where AE is what the car relies on....Also keep in mind that if your VE table and AE isn't ALREADY TUNED to perfection, you're gonna have a really bad time with this.

Hope that helps, at least somewhat. I'll grab screen shots of my 01's values that I ended up with, but the car was very smooth and slow throttle tip in at cruise resulted in almost rock solid AFR's when I was done with it. (ps: they looked a lot like yours above, actually. In fact, I'd say that for most cars the overall curves will look exactly like that and only vary by a little bit in either direction)

#6

Thread Starter

Joined: Jan 2013

Posts: 5,012

Total Cats: 859

From: Seneca, SC

Thanks for the responses.

Since this write-up, I have added a bit more AtW with lower temps, up to about 5%.

I actually have no ACCEL pump on now. (tell it to be full at less than 10 RPM, and zero above 20 RPM, something like that).

I can't see where it would add anything to the response of the engine. I think I mentioned that the AFR lag that remains in the logs is simply because the O2 sensor sees the actual result of the lower kPa burning that took place a few milliseconds before a very fast throttle transition, whereas the MS sees the new table value of AFR target and AtW target (and responds) immediately.

Even when first cranked cold, the car will pull off with no hesitation.

I may be slightly agressive on the SfW coefficients as a quick release of throttle goes a bit lean, but I figure it doesn't matter as the engine is in decelleration in that transition.

Since this write-up, I have added a bit more AtW with lower temps, up to about 5%.

I actually have no ACCEL pump on now. (tell it to be full at less than 10 RPM, and zero above 20 RPM, something like that).

I can't see where it would add anything to the response of the engine. I think I mentioned that the AFR lag that remains in the logs is simply because the O2 sensor sees the actual result of the lower kPa burning that took place a few milliseconds before a very fast throttle transition, whereas the MS sees the new table value of AFR target and AtW target (and responds) immediately.

Even when first cranked cold, the car will pull off with no hesitation.

I may be slightly agressive on the SfW coefficients as a quick release of throttle goes a bit lean, but I figure it doesn't matter as the engine is in decelleration in that transition.

#8

Just wanted to follow up with this thread, as I finally started dialing in my EAE today.

1) This thread is really helpful, even for me who has tuned it before, as a refresher. Thank you David for making it. Props given.

2) the new firmware has a cool little SFW/ATW screen that is VERY similar if not the same as the one for AE, which has a live data stream/graph on the bottom where you can monitor how the AFR's follow KPA and Throttle inputs. This is very helpful.

3) My ATW values were very close, and graph was close too. My SFW values ended up being quite a bit higher, since running them as low as you or lower ended up with WAY too much sensitivity. I find it hilarious that some people DESIRE throttle response like this. It sucks. Car is so much easier, smoother, and more enjoyable to drive when its slightly dulled. When shifting slowly it doesn't buck or jerk thsi way.

4) I ended up tapering the CLT values for ATW from about 10% higher at low temps to level off after about 80* because I've noticed on cold starts when I immediately drive the car I get quite a bit of leanness for the 1st minute or two.

5) No idea what's happening with your SFW CLT correction but it doesn't make sense to me and I'm just keeping mine at 100 for now cause I have no problems with it.

6) RPM correction I left all at 100 too cause I really don't see much of a swing between required or desired EAE at different speeds. I'll test this more late when I've time.

1) This thread is really helpful, even for me who has tuned it before, as a refresher. Thank you David for making it. Props given.

2) the new firmware has a cool little SFW/ATW screen that is VERY similar if not the same as the one for AE, which has a live data stream/graph on the bottom where you can monitor how the AFR's follow KPA and Throttle inputs. This is very helpful.

3) My ATW values were very close, and graph was close too. My SFW values ended up being quite a bit higher, since running them as low as you or lower ended up with WAY too much sensitivity. I find it hilarious that some people DESIRE throttle response like this. It sucks. Car is so much easier, smoother, and more enjoyable to drive when its slightly dulled. When shifting slowly it doesn't buck or jerk thsi way.

4) I ended up tapering the CLT values for ATW from about 10% higher at low temps to level off after about 80* because I've noticed on cold starts when I immediately drive the car I get quite a bit of leanness for the 1st minute or two.

5) No idea what's happening with your SFW CLT correction but it doesn't make sense to me and I'm just keeping mine at 100 for now cause I have no problems with it.

6) RPM correction I left all at 100 too cause I really don't see much of a swing between required or desired EAE at different speeds. I'll test this more late when I've time.

#9

Thread Starter

Joined: Jan 2013

Posts: 5,012

Total Cats: 859

From: Seneca, SC

Here is my present ATW Temp Comp:

Response to 18:

1) Thanks, and glad to contribute.

2) I'll have to try that. I use that functionality on my logs, but real time could be helpful.

3) By "higher" do you mean the whole curve is shifted up? The advantage to low values is that the EAE lasts a little longer as the SFW takes more time to equalize the wall fuel (puddle).

4) See my latest curve, above.

5) If the theory matches reality, then mine makes sense. When cold, one should expect the fuel to not want to evaporate from the puddle. However, that is not why I have this CLT curve. It is because, on cold starts, the SFW, even when MAP was still in the 80-85 kPa range, would pull so much fuel as to actually go to zero pulse width. This was way too much and would kill engine or cause ugly stumble. With this curve, I don't get that.

6) Yep

I'm still running no throttle based AE. Don't need it. When I punch the throttle, the AFR never goes lean, only about a 100mS pause, and gauge follows the AFR targets. I'm still thinking this is lag between engine and O2 sensor.

DNM

Response to 18:

1) Thanks, and glad to contribute.

2) I'll have to try that. I use that functionality on my logs, but real time could be helpful.

3) By "higher" do you mean the whole curve is shifted up? The advantage to low values is that the EAE lasts a little longer as the SFW takes more time to equalize the wall fuel (puddle).

4) See my latest curve, above.

5) If the theory matches reality, then mine makes sense. When cold, one should expect the fuel to not want to evaporate from the puddle. However, that is not why I have this CLT curve. It is because, on cold starts, the SFW, even when MAP was still in the 80-85 kPa range, would pull so much fuel as to actually go to zero pulse width. This was way too much and would kill engine or cause ugly stumble. With this curve, I don't get that.

6) Yep

I'm still running no throttle based AE. Don't need it. When I punch the throttle, the AFR never goes lean, only about a 100mS pause, and gauge follows the AFR targets. I'm still thinking this is lag between engine and O2 sensor.

DNM

#10

I just tested out ATW and SFW CLT correction

increasing ATW with cooler CLT seemed to do nothing at all

decreasing SFW by a huge amount seemed to make the car finally richen up. in fact I zero'd it out and the car pegged so rich it died.

so I tapered SFW cLT correction down a lot with cooler temps, we shall see tomorrow morning if this works good.

once up to temp of course the car runs great

all this to say, I'm pretty sure your curve for SFW CLT is right on the money

this thread should probably be stickied cause it's probably the best and only recent EAE discussion that is helpful.

Propped all your posts David

increasing ATW with cooler CLT seemed to do nothing at all

decreasing SFW by a huge amount seemed to make the car finally richen up. in fact I zero'd it out and the car pegged so rich it died.

so I tapered SFW cLT correction down a lot with cooler temps, we shall see tomorrow morning if this works good.

once up to temp of course the car runs great

all this to say, I'm pretty sure your curve for SFW CLT is right on the money

this thread should probably be stickied cause it's probably the best and only recent EAE discussion that is helpful.

Propped all your posts David

Last edited by 18psi; 05-13-2015 at 02:09 AM.

#11

Thread Starter

Joined: Jan 2013

Posts: 5,012

Total Cats: 859

From: Seneca, SC

Vlad. Thanks again. It's in my nature to try to be a contributor.

Agree that ATW with CLT is a minor tweak.

Did you mean "lean" in that last sentence? That is what would make more sense to me, both by experience, and in context with your previous statement.

Agree that ATW with CLT is a minor tweak.

Did you mean "lean" in that last sentence? That is what would make more sense to me, both by experience, and in context with your previous statement.

#13

Thread Starter

Joined: Jan 2013

Posts: 5,012

Total Cats: 859

From: Seneca, SC

Right. When I read, "zeroed it out" I pictured a flat line at 100% at all temperatures. You mean that you drove it to zero at some given temperature (yep, that's what you said), so you get no driving of the wall fuel to equilibrium, hence rich.

#14

Thanks for this write up! I just tried it today and finally my car is driveable enough with eae on to actually make some adjustments. When I have tried in the past, I always ended up disabling it almost immediately, I am using both eae and time based. I hit my afr targets on accel almost instantly. Thanks also for the smooth feel advice over logs and numbers.

#16

I always disabled it before when I tried, but with no luck. I thought that you and Brain suggested keeping accel pump on for large transitions, by that I figured you meant time based. It is a bit rich on accel, but no lean step in. I will disable time based, try again and report back.

But still very happy with the results so far.

But still very happy with the results so far.

#19

Mine is also ms2, it would really be nice to get this working right. Looks like you guys are disabling time based. I set full accel above 30 rpm and zero above 55 rpm to disable. I was at least able to make a little progress with off idle accel using this write up, but I ran out of time and had to revert back to time based.