Huge lean spike, tuning issue or fuel delivery issue?

#1

Thread Starter

Senior Member

iTrader: (1)

Joined: Dec 2007

Posts: 695

Total Cats: 354

From: San Jose

Dropped an 01 motor into my 94, did the wiring the way Andrew suggested, and have been working out the initial bugs. It'll idle, and I've had some success in getting that idle stable. It's still a little dicey at the transition off the end of the PWM Idle Duty table.

But that's not my concern right now.

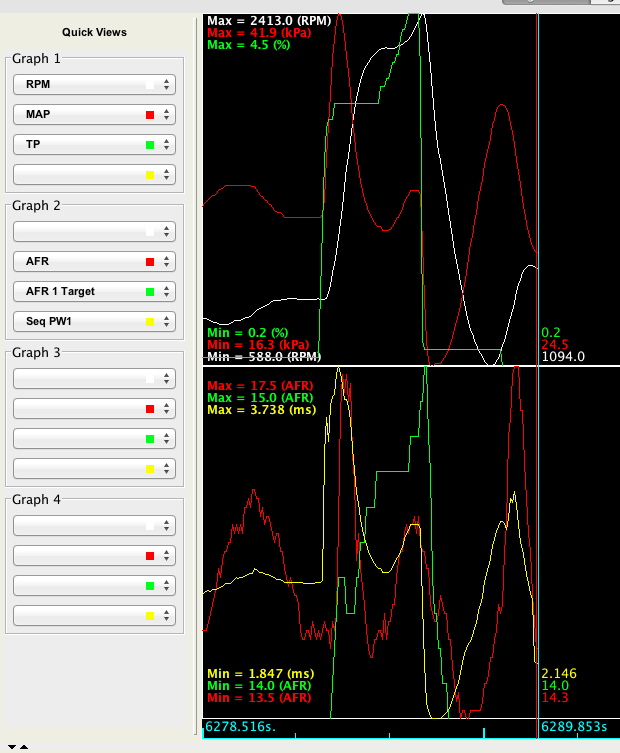

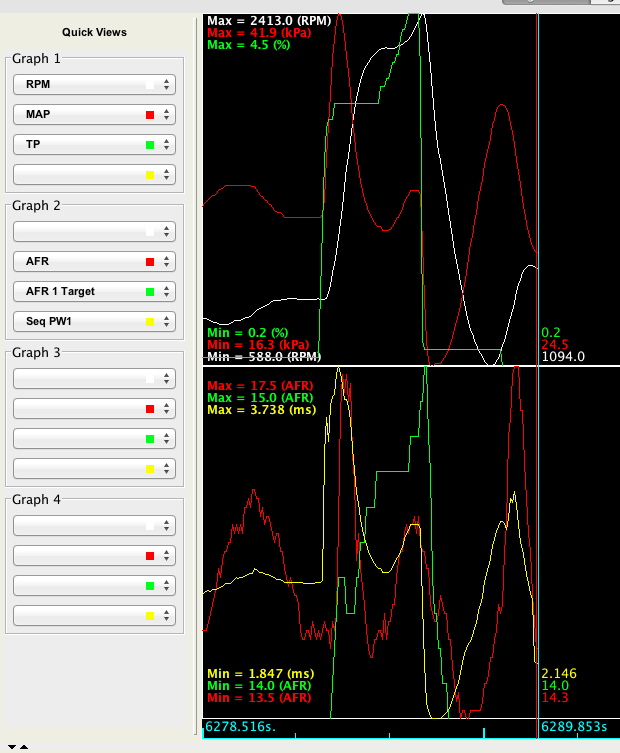

After warming up to operating temp and making sure the idle cells looked good, I turned on VEAL and started making sure the zero-load cells were sane, at which point I discovered that I can't rev past ~2500rpm. Huge lean spike and it sounds like knock. Tried not to do that too often

Rather than coming crying to you all, I captured a log and looked at it myself. The only problem is, I only sort of think I understand what I should be looking for and what should be happening.

Attached is my MSQ and a log.

I see the huge lean spike, but I also see that my pulse width actually spikes there. Which makes me think: MS sees things going lean, asks for more PW, but there's no fuel, so things just continue to go lean and I get knock.

I've had trouble finding a good NA VVT starting point, so perhaps this is just a matter of being completely untuned. But I also just put this motor in and it's completely possible that I fucked up the connections at the fuel rail.

Which of my idiocies is causing this issue?

Thanks in advance!

But that's not my concern right now.

After warming up to operating temp and making sure the idle cells looked good, I turned on VEAL and started making sure the zero-load cells were sane, at which point I discovered that I can't rev past ~2500rpm. Huge lean spike and it sounds like knock. Tried not to do that too often

Rather than coming crying to you all, I captured a log and looked at it myself. The only problem is, I only sort of think I understand what I should be looking for and what should be happening.

Attached is my MSQ and a log.

I see the huge lean spike, but I also see that my pulse width actually spikes there. Which makes me think: MS sees things going lean, asks for more PW, but there's no fuel, so things just continue to go lean and I get knock.

I've had trouble finding a good NA VVT starting point, so perhaps this is just a matter of being completely untuned. But I also just put this motor in and it's completely possible that I fucked up the connections at the fuel rail.

Which of my idiocies is causing this issue?

Thanks in advance!

#2

Thread Starter

Senior Member

iTrader: (1)

Joined: Dec 2007

Posts: 695

Total Cats: 354

From: San Jose

Also, WTF is up with my TP being a straight line for a while there? I don't think my foot is capable of maintaining a perfectly-flat line like that, mid tip-in. Noise on the sensor wires or ? My throttle cable does have a kink in it at the throttle end, but I don't think it's discernable from the cockpit...

#4

Thread Starter

Senior Member

iTrader: (1)

Joined: Dec 2007

Posts: 695

Total Cats: 354

From: San Jose

OK, what the ****.

New log attached. Sorry it's kind of long, but you can cut to 6535 seconds or so and see some weird *** ****.

2600rpm is like a wall. Can't go above it. And then the "cranking" flag comes on when I get there?

Sorry, this shouldn't be this complicated, I'm driving myself nuts. I disconnected the VVT, and have been VEAL'ing with good improvements, but this is just... ******* weird.

What patently obvious thing am I missing?

New log attached. Sorry it's kind of long, but you can cut to 6535 seconds or so and see some weird *** ****.

2600rpm is like a wall. Can't go above it. And then the "cranking" flag comes on when I get there?

Sorry, this shouldn't be this complicated, I'm driving myself nuts. I disconnected the VVT, and have been VEAL'ing with good improvements, but this is just... ******* weird.

What patently obvious thing am I missing?

#6

Thread Starter

Senior Member

iTrader: (1)

Joined: Dec 2007

Posts: 695

Total Cats: 354

From: San Jose

OK, still at it, eliminated a couple of potential issues, I think:

Tested the vacuum connection at the FPR, since I had to muck with that during the swap. FPR has vacuum source, and when I apply vacuum to FPR at idle, idle changes. Thus, FPR is not culprit.

Went in and manually modified the VE table, making it richer (I think).

Still no dice.

Questions:

I've seen lots of conflicting opinions: should I have PID EGO control "on" while using VEAL? And what are decent "almost completely untuned" PID settings for such?

I've tried different VVT motor VE tables, spark tables, and AFR target tables, this wall appears to be constant.

What am I missing?

This motor was a perfectly-running low-mile donor that was hit hard on the right front. An ear broke off the water pump, and the crank accessory pulley was chewed up, but otherwise the motor appeared fine. The 94 was running perfectly before this swap.

Timing is spot on in static timing mode, though a bit jittery.

Tested the vacuum connection at the FPR, since I had to muck with that during the swap. FPR has vacuum source, and when I apply vacuum to FPR at idle, idle changes. Thus, FPR is not culprit.

Went in and manually modified the VE table, making it richer (I think).

Still no dice.

Questions:

I've seen lots of conflicting opinions: should I have PID EGO control "on" while using VEAL? And what are decent "almost completely untuned" PID settings for such?

I've tried different VVT motor VE tables, spark tables, and AFR target tables, this wall appears to be constant.

What am I missing?

This motor was a perfectly-running low-mile donor that was hit hard on the right front. An ear broke off the water pump, and the crank accessory pulley was chewed up, but otherwise the motor appeared fine. The 94 was running perfectly before this swap.

Timing is spot on in static timing mode, though a bit jittery.

#7

Thread Starter

Senior Member

iTrader: (1)

Joined: Dec 2007

Posts: 695

Total Cats: 354

From: San Jose

Spamming my own thread.

Looked at a composite log, just for kicks, saw that I was having some sync loss when revving. I haven't fooled with the crank sensor, but checked the gap anyhow.

Gap started at 0.045" or so, within limits.

Attempted to set it at 0.030", just to be "closer". I mashed the sensor against the feeler and set it, now the largest feeler that will slide in is 0.026, towards the narrower end of the spec. Fine.

Still no dice. Composite log attached.

Looked at a composite log, just for kicks, saw that I was having some sync loss when revving. I haven't fooled with the crank sensor, but checked the gap anyhow.

Gap started at 0.045" or so, within limits.

Attempted to set it at 0.030", just to be "closer". I mashed the sensor against the feeler and set it, now the largest feeler that will slide in is 0.026, towards the narrower end of the spec. Fine.

Still no dice. Composite log attached.

#8

Thread Starter

Senior Member

iTrader: (1)

Joined: Dec 2007

Posts: 695

Total Cats: 354

From: San Jose

OK, chatting with myself here, but that's OK.

Can we change the title to "this idiot has sync loss" or something?

here's what I got going on. Log attached, showing sync errors and lost sync reasons (31 and 32 natch).

This is after gapping the crank sensor properly and moving the crank/cam wires in the engine bay as far away from the injectors/coils as possible.

Would my adjustment of the trimpots during the MegaSquirt build be influencing this? Ie, would adjusting them to other values be helpful here?

What's my next move here?

EDIT:

OK, adjusted the R11 trim pot, no more sync loss. Now I think it's just a tuning issue. I'm able to cross the 2500rpm line now! Woot!

Also, this post saved me hours of troubleshooting. Prop'd!

Can we change the title to "this idiot has sync loss" or something?

here's what I got going on. Log attached, showing sync errors and lost sync reasons (31 and 32 natch).

This is after gapping the crank sensor properly and moving the crank/cam wires in the engine bay as far away from the injectors/coils as possible.

Would my adjustment of the trimpots during the MegaSquirt build be influencing this? Ie, would adjusting them to other values be helpful here?

What's my next move here?

EDIT:

OK, adjusted the R11 trim pot, no more sync loss. Now I think it's just a tuning issue. I'm able to cross the 2500rpm line now! Woot!

Also, this post saved me hours of troubleshooting. Prop'd!

Last edited by thebeerbaron; 05-27-2013 at 12:17 AM. Reason: Didn't want to make another post

Thread

Thread Starter

Forum

Replies

Last Post