Engine dies when I hit rev limit, comes back with a key cycle

#1

Can't seem to figre this one out... started happening recently. Hit the rev limit, engine dies out. If I'm in gear and coasting down, cycle the key and it comes back to life. When i work the throttle as the rpms are dropping, afr responds like it's still getting fuel. Seems like I'm losing spark. Lowered rev limit to 2k and it doesn't do it. Historically I lose sync when I hit rev limit, but never has caused any major issue. This happens with spark cut or fuel cut as well. No scary noises or anything mechanical going on. Runs like a raped ape till rev limit. A couple things have changed before this started happening, not sure if related or not.

-wired for seq ignition

-had a tuner messing with it on the dyno

Log and tune attached.

Halp :(

-wired for seq ignition

-had a tuner messing with it on the dyno

Log and tune attached.

Halp :(

#9

Lowered rev limit to 7k, with the hysteresis at 100, spark cut only, and got much much better response. No tach flopping, only had batt light flash maybe once (when it lost sync and voltage spiked), and didn't stall out. Tried 7100rpm and it was hit or miss. Would sometimes stall, sometimes not. Switched back to 7k and it was good again. First log attached shows the one time it lost sync, the second log shows 3 consecutive redline shifts without any problem.

#10

might be a long shot, but I found this while searching sync loss 31 and 32.

Megasquirt Support Forum (MSEXTRA) ? sync loss #31 ms3x (View topic)

Not exactly sure of the science behind it, but it kinda sounds like I could experiencing something similar? Will run fine up to 7k, dislikes 7100, and absolutely hates 7200?

Megasquirt Support Forum (MSEXTRA) ? sync loss #31 ms3x (View topic)

Not exactly sure of the science behind it, but it kinda sounds like I could experiencing something similar? Will run fine up to 7k, dislikes 7100, and absolutely hates 7200?

#12

I might have you pull the unit and open it up and have you readjust two pots on the inside to help clean up the crank/cam signals to see what effect that has on it. I may have them set for a 90-97 install, where the 99+ need different settings.

only thing I can think of right now.

I'll email you detailed instructions on what to do.

the developers released code that should prevent the voltage spikes on any sync-loss event. I can walk you through upgrading to this firmware as well if that doesn't solve the issue--you really shouldn't be seeing sync-loss at all.

only thing I can think of right now.

I'll email you detailed instructions on what to do.

the developers released code that should prevent the voltage spikes on any sync-loss event. I can walk you through upgrading to this firmware as well if that doesn't solve the issue--you really shouldn't be seeing sync-loss at all.

#14

Ok, mech5700@yahoo.com

Instructions on pot adjustments and how to do a firmware update, pleeeeeeeease

I'll copy over what scott sends me if he doesn't post it up, Dave.

Instructions on pot adjustments and how to do a firmware update, pleeeeeeeease

I'll copy over what scott sends me if he doesn't post it up, Dave.

#15

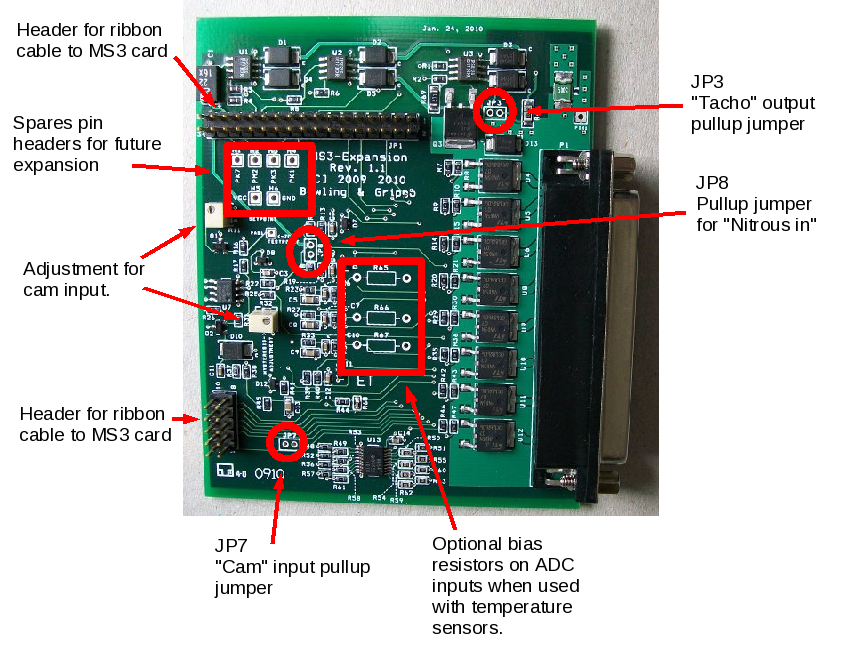

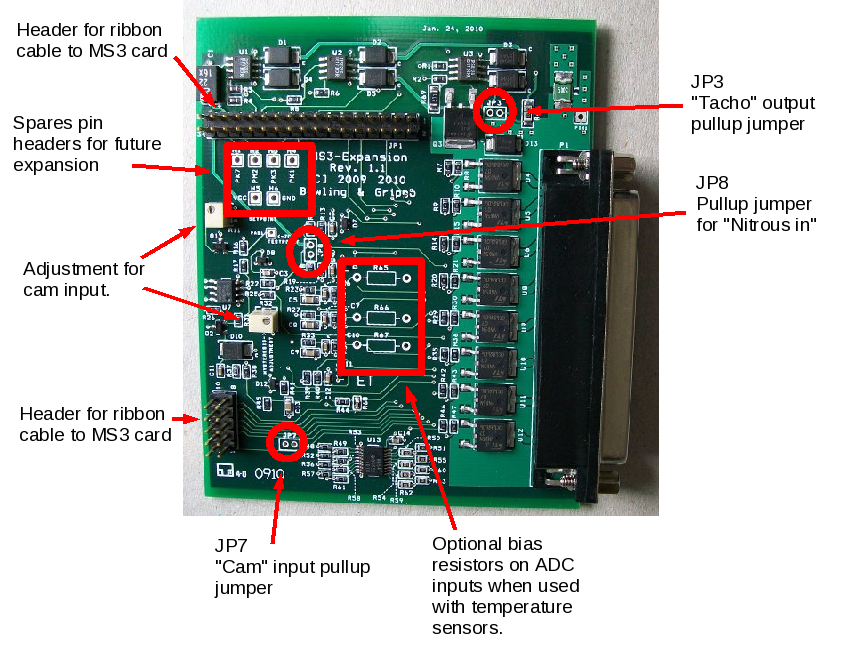

setting crank/cam pots.

Remove the MS.

Remove the two studs holding the Serial port to the case.

Remove the four screws on the dual DB37 side of the case.

Slide the PCB out of the case.

Lift the wide ribbon out of the way to expose the adjustment pot you need to turn.

It's R11, the top one closest to ribbon connector labeled "adjustment for cam input".

Using a small percision screwdriver, turn it 6 turns CCW.

Now turn it back 3.5 turns CW.

remove the two studs holding the green expander board to the case cover.

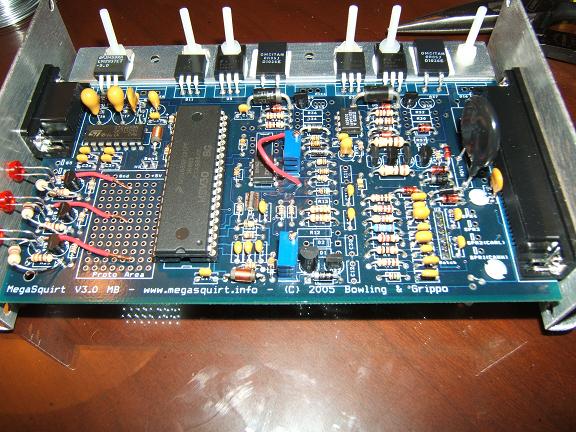

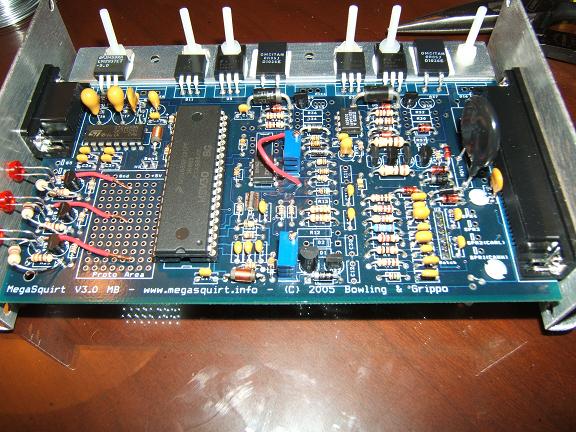

gently set it out of the way to expose the crank input adjustment pots.

shown above it's the two blue pots.

turn the top most pot (middle of board) 12 turns CCW. (same units do not have this pot, ignore this step if you have a resistor installed there instead)

turn the bottom most pot -R56 (edge of board) 12 full turns CCW.

now turn it CW 10.5 turns.

reinstall the expander back into the case cover.

carefully slide the pcb into the case (third slot up)

carefully position the expander board into the case (fourth from top)

replace the 4 screws.

replace the studs on the serial port.

reinstall the MS (dont forget the MAP sensor).

test it out.

Remove the MS.

Remove the two studs holding the Serial port to the case.

Remove the four screws on the dual DB37 side of the case.

Slide the PCB out of the case.

Lift the wide ribbon out of the way to expose the adjustment pot you need to turn.

It's R11, the top one closest to ribbon connector labeled "adjustment for cam input".

Using a small percision screwdriver, turn it 6 turns CCW.

Now turn it back 3.5 turns CW.

remove the two studs holding the green expander board to the case cover.

gently set it out of the way to expose the crank input adjustment pots.

shown above it's the two blue pots.

turn the top most pot (middle of board) 12 turns CCW. (same units do not have this pot, ignore this step if you have a resistor installed there instead)

turn the bottom most pot -R56 (edge of board) 12 full turns CCW.

now turn it CW 10.5 turns.

reinstall the expander back into the case cover.

carefully slide the pcb into the case (third slot up)

carefully position the expander board into the case (fourth from top)

replace the 4 screws.

replace the studs on the serial port.

reinstall the MS (dont forget the MAP sensor).

test it out.

Last edited by Braineack; 01-24-2015 at 02:01 PM.

#17

It's a simple process:

D/L the latest firmware. Pre 1.4 beta 10: MS3 pre-1.4 beta 10 firmware released - Megasquirt EFI

1. Save your current MSQ file.

2. DISCONNECT coils and/or Ignitor. The flashing process can damage coils if they are left connected during the process.

3. Turn car to key ON and connect laptop to MS.

4. run the ms3-loader.exe (or whatever it's called) from the firmware directory.

5. follow the prompts, you can go through just clicking enter for the options, it will find your MS com and everything.

6. let the loader run, takes about 2-3min.

7. Once it's complete open TS and create a new project. Detect your firmware and let TS find and d/l the new firmware. [I like to create a new project for any new firmware I run]

8. Once connected, load the msq you saved. Look at the error log page after loading, spot check the settings to make sure everything ported over correctly. Some firmwares make changes that add options or change how things work so you need to make sure nothing is going to be wrong. Typically new values have some crazy high value in there that are obvious.

9. double check your AFR, AIT, CLT calibrations. They shouldn't have changed, but doesn't hurt to make sure.

10. turn off MS. Reconnect coils.

11. Start car.

Every once in a blue moon the flash might fail, where you'll have to open the case, slide out the board and install a BOOT jumper on the ms3 daughterboard to attempt another reflash.

I'd try the adjustments first and if that solves the issue I'd wait until 1.4 is a final release before running the new firmware. Beta firmwares can have random bugs.

D/L the latest firmware. Pre 1.4 beta 10: MS3 pre-1.4 beta 10 firmware released - Megasquirt EFI

1. Save your current MSQ file.

2. DISCONNECT coils and/or Ignitor. The flashing process can damage coils if they are left connected during the process.

3. Turn car to key ON and connect laptop to MS.

4. run the ms3-loader.exe (or whatever it's called) from the firmware directory.

5. follow the prompts, you can go through just clicking enter for the options, it will find your MS com and everything.

6. let the loader run, takes about 2-3min.

7. Once it's complete open TS and create a new project. Detect your firmware and let TS find and d/l the new firmware. [I like to create a new project for any new firmware I run]

8. Once connected, load the msq you saved. Look at the error log page after loading, spot check the settings to make sure everything ported over correctly. Some firmwares make changes that add options or change how things work so you need to make sure nothing is going to be wrong. Typically new values have some crazy high value in there that are obvious.

9. double check your AFR, AIT, CLT calibrations. They shouldn't have changed, but doesn't hurt to make sure.

10. turn off MS. Reconnect coils.

11. Start car.

Every once in a blue moon the flash might fail, where you'll have to open the case, slide out the board and install a BOOT jumper on the ms3 daughterboard to attempt another reflash.

I'd try the adjustments first and if that solves the issue I'd wait until 1.4 is a final release before running the new firmware. Beta firmwares can have random bugs.