Boost PID=200,0,0 - still hits boost limit

#1

Thread Starter

Joined: Feb 2008

Posts: 2,331

Total Cats: 203

From: Loganville, GA

Here is my problem. I have been running in closed loop for the past several weeks but since my boost was not tailored to this car, I decided to tune my PID settings. The boost hadn't been steady to my satisfaction and I figured it was time to start fine tuning.

To start with, I switched over to open-loop and set the entire table to 100 and did a pull. I immediately hit boost limit. I then switched the polarity to inverse and tried again. Now I was essentially on wastegate.

I then set my P to 100, I to zero, and D to zero.

I did a pull. almost immediately I hit my boost limit of 175kpa. I upped my P to 150. Same thing. Finally to 200, and same result.

What could be causing me to immediately hit boost limit in closed loop so quickly?

However, when I originally had my PID set to 22,20,70 and normal polarity I was fine, if sub-par.

I am using a new style DIYautotune boost solenoid.

Any thoughts? I'd really like to start turning the boost up slowly and maybe doing some gear based boost stuff but until I get the closed loop stuff working perfectly I don't think it's the right time.

Thanks!

To start with, I switched over to open-loop and set the entire table to 100 and did a pull. I immediately hit boost limit. I then switched the polarity to inverse and tried again. Now I was essentially on wastegate.

I then set my P to 100, I to zero, and D to zero.

I did a pull. almost immediately I hit my boost limit of 175kpa. I upped my P to 150. Same thing. Finally to 200, and same result.

What could be causing me to immediately hit boost limit in closed loop so quickly?

However, when I originally had my PID set to 22,20,70 and normal polarity I was fine, if sub-par.

I am using a new style DIYautotune boost solenoid.

Any thoughts? I'd really like to start turning the boost up slowly and maybe doing some gear based boost stuff but until I get the closed loop stuff working perfectly I don't think it's the right time.

Thanks!

#2

Change the polarity back to normal.

Be careful using settings from ebc tuning threads esp for ms2. Older msextra firmwares were written such that less duty = more boost. The latest versions have been changed so that more duty = more boost. If the polarity and/or open and closed duties are backwards it will overboost regardless of the pid settings.

Be careful using settings from ebc tuning threads esp for ms2. Older msextra firmwares were written such that less duty = more boost. The latest versions have been changed so that more duty = more boost. If the polarity and/or open and closed duties are backwards it will overboost regardless of the pid settings.

#3

Thread Starter

Joined: Feb 2008

Posts: 2,331

Total Cats: 203

From: Loganville, GA

Will do, but why don't they say that on the ms3 documentation site? It still says 0% duty means closed wastegate and more boost.

Boost Control

Boost Control

Output Polarity - This is used to set the polarity of the output. Set properly, lower reported duty should correspond to a more closed wastegate and yield more boost.

Available options include:

Normal - 100% output pin duty means the wastegate is fully open.

Inverted - 0% output pin duty means the wastegate is fully open.

Available options include:

Normal - 100% output pin duty means the wastegate is fully open.

Inverted - 0% output pin duty means the wastegate is fully open.

#8

Thread Starter

Joined: Feb 2008

Posts: 2,331

Total Cats: 203

From: Loganville, GA

Yes, but I am not happy with how it is holding boost. I spent about an hour on it yesterday and I am not any happier with MY numbers than the numbers I started out with.

I am not hitting and staying at my targets. My target is 162kpa.

Attached are logs at different PID settings. The numbers are in the file name.

P19,I20,D71 is what I started with yesterday and what I returned to today.

P18,I36,D55 is what I ended with yesterday and I didn't see/feel enough of an improvement and I was unsure if I actually made an improvement.

I am not hitting and staying at my targets. My target is 162kpa.

Attached are logs at different PID settings. The numbers are in the file name.

P19,I20,D71 is what I started with yesterday and what I returned to today.

P18,I36,D55 is what I ended with yesterday and I didn't see/feel enough of an improvement and I was unsure if I actually made an improvement.

#12

Thread Starter

Joined: Feb 2008

Posts: 2,331

Total Cats: 203

From: Loganville, GA

The idea is to start by getting 10psi as soon as possible and ride it to redline. From there, add a pound or so at a time while working on my tune. My eventual goal is about 220lb/ft torque and whatever HP comes with it. You think I would be better served upping my boost target to 175kpa or so while tuning?

By "eventual" I mean the max I am comfortable with until I build an engine.

By "eventual" I mean the max I am comfortable with until I build an engine.

#13

Thread Starter

Joined: Feb 2008

Posts: 2,331

Total Cats: 203

From: Loganville, GA

Upped the 100% throttle line target from 162kpa to 170kpa. Raised the overboost to 180kpa.

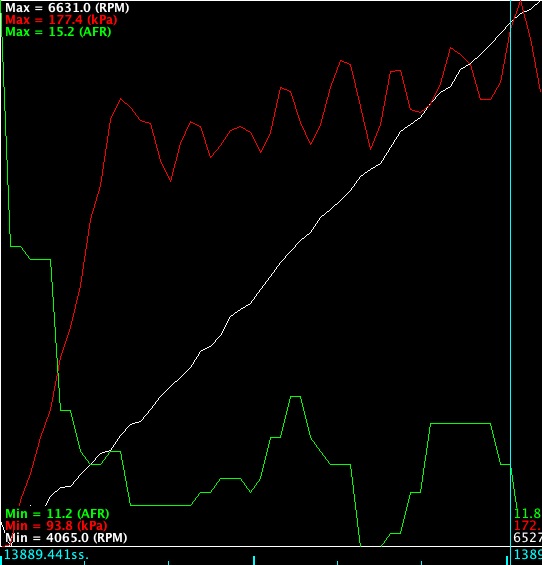

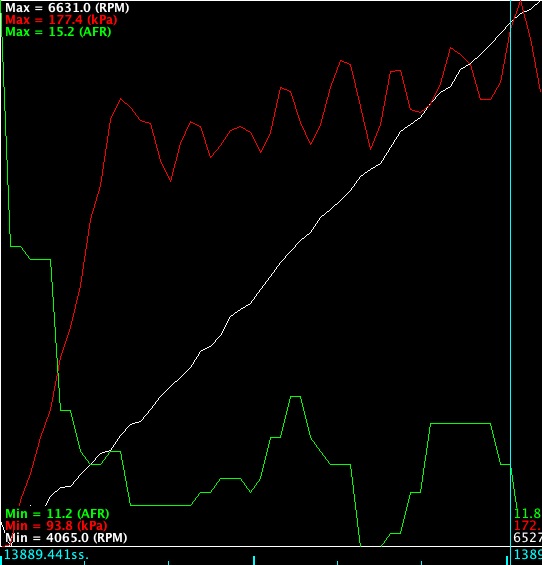

This is the result:

Is the "sawtooth" motion normal cycling of the valve? Would I need to raise I and lower P in order to reach my targets?

This is the result:

Is the "sawtooth" motion normal cycling of the valve? Would I need to raise I and lower P in order to reach my targets?

#14

i dont think you have enough p. i feel like most people end up around 25-30 or so for p.

you should be tuning by:

starting with like 100p only, the rest at zero.

reduce p until you breach your tuning during spool up.

start doing pulls to redline, increase i to hold target to redline.

increase p as you increase i to maintain the spool-up target.

increase d to reduce the sin-wave pattern.

increase p and i to keep hitting spool-up target and maintain target to redline.

increase d to reduce the sin-wave pattern.

increase p and i to keep hitting spool-up target and maintain target to redline.

eventually get close enough where when you spool you should end up with a 1psi spike over target and hold it to redline with very minimal oscillation.

you should be tuning by:

starting with like 100p only, the rest at zero.

reduce p until you breach your tuning during spool up.

start doing pulls to redline, increase i to hold target to redline.

increase p as you increase i to maintain the spool-up target.

increase d to reduce the sin-wave pattern.

increase p and i to keep hitting spool-up target and maintain target to redline.

increase d to reduce the sin-wave pattern.

increase p and i to keep hitting spool-up target and maintain target to redline.

eventually get close enough where when you spool you should end up with a 1psi spike over target and hold it to redline with very minimal oscillation.

#15

Thread Starter

Joined: Feb 2008

Posts: 2,331

Total Cats: 203

From: Loganville, GA

Actually that's exactly what I did.

I think that by having my target so close to wastegate I might have been making it difficult to really see what is going on. I am going to start over and set boost limit to 185kpa with a 170 target.

Part of the headache is doing this all myself with a sub-par location to do test runs.

What gear are you tuning your P in by the way? How about the other two?

I think that by having my target so close to wastegate I might have been making it difficult to really see what is going on. I am going to start over and set boost limit to 185kpa with a 170 target.

Part of the headache is doing this all myself with a sub-par location to do test runs.

What gear are you tuning your P in by the way? How about the other two?

#16

Thread Starter

Joined: Feb 2008

Posts: 2,331

Total Cats: 203

From: Loganville, GA

Should I be switching my closed and open duty percentages as well since I a running "Normal"?

Tried working on it during an hour long drive home on country roads. Unfortunately, I hit the + button instead of the = button. I wanted to set my target boost to 62kpa, instead I set it to a target of 330ish kpa with my over boost set to 173. No wonder it wasn't acting predictably. Back to the drawing boards tomorrow.

Tried working on it during an hour long drive home on country roads. Unfortunately, I hit the + button instead of the = button. I wanted to set my target boost to 62kpa, instead I set it to a target of 330ish kpa with my over boost set to 173. No wonder it wasn't acting predictably. Back to the drawing boards tomorrow.

#17

Thread Starter

Joined: Feb 2008

Posts: 2,331

Total Cats: 203

From: Loganville, GA

My tunerstudio file says I am running MS3.

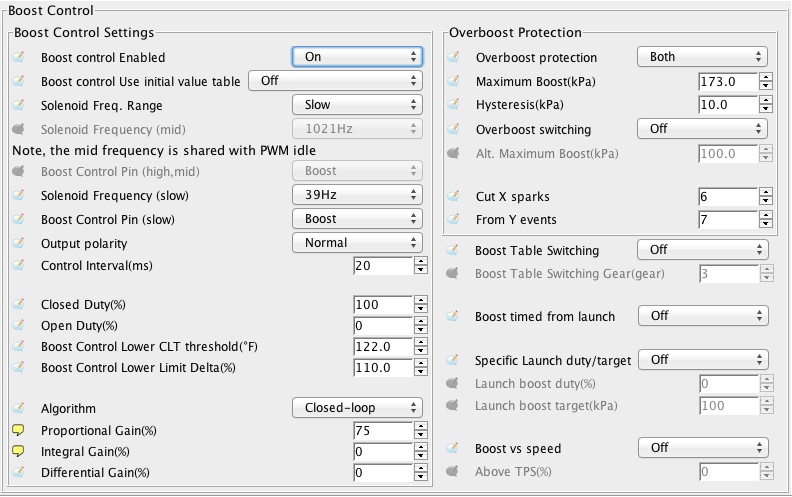

Here are my pages as they stand this morning:

What gear are you starting your "P" Pull. What RPM?

I feel like I am starting with something wrong in my setup which is really making it worse than it needs to be. Also, I don't have tooltips as far as I can tell.

#20

Thread Starter

Joined: Feb 2008

Posts: 2,331

Total Cats: 203

From: Loganville, GA

I was right about stuff being fubar. I checked my project properties and it indicated I was running MSZ3 .262 or something like that. I did a "check for ECU" or whatever that button was and it came back with a firmware of 1.2.1.

So I have been running a mismatch of sorts between what tunerstudio thought I was running and what I actually was. This might have something to do with many of my random minor problems.

Brain: If I was using alpha code where I would be running normal as opposed to inverted, would I still be keeping closed = 0% and open = 100%?

If I were to start over with Alpha code, my settings should be to start:

Output Polarity: Normal

Closed Duty: 0

Open Duty: 100

Start P at 100 etc...

Correct?

Am I better off just going to 1.2.3 and running inverted for now to minimize having to make other adjustments?

So I have been running a mismatch of sorts between what tunerstudio thought I was running and what I actually was. This might have something to do with many of my random minor problems.

Brain: If I was using alpha code where I would be running normal as opposed to inverted, would I still be keeping closed = 0% and open = 100%?

If I were to start over with Alpha code, my settings should be to start:

Output Polarity: Normal

Closed Duty: 0

Open Duty: 100

Start P at 100 etc...

Correct?

Am I better off just going to 1.2.3 and running inverted for now to minimize having to make other adjustments?