AFRs read rich and car bogs on acceleration

#1

Thread Starter

Joined: Feb 2008

Posts: 2,331

Total Cats: 203

From: Loganville, GA

I have been dealing with this issue for the past couple weeks and I figured it was time to let you guys take a crack at it.

These are all high boost issues. I never see a bog on high rpm/low load.

The symptoms are such:

I will post logs below. If a few images of the problem would be helpful I will be happy to post those but let me know what fields you want to see.

The file name will include bad or good to let you know what type of pull you are looking at.

These are all high boost issues. I never see a bog on high rpm/low load.

The symptoms are such:

- Upon acceleration, usually on an extended 1-2-3 pull I start to get maximum rich AFRs and a "bog" on the final pull.

- Logs indicate 10.3 afr but pulse widths don't seem any different from similar pulls at similar rpms and loads.

- I notice that I am having a knock event on cylinders 1 & 4 and I am getting up to 1.5 degrees of knock retard in some instances. I also noticed that plugs 1 & 4 had some discoloration and I have since replaced the plugs and coil. However, I am also having this knock event and retard in "good" pulls and it isn't making a difference.

- VVT angle vs target seems to be uniformly incorrect in these instances. For example, on good pulls the angle v. target is about perfect, but on the "bad" pulls the angle locks into 12.2 degrees on the 1nd/2rd gear portion and on the 3th gear portion of the pull it goes to .2 degrees no matter the VVT duty commanded. It is however interesting though that towards the high end of the RPM range the VVT angle v. target is not that far off and the AFRs never recover.

I will post logs below. If a few images of the problem would be helpful I will be happy to post those but let me know what fields you want to see.

The file name will include bad or good to let you know what type of pull you are looking at.

#2

Thread Starter

Joined: Feb 2008

Posts: 2,331

Total Cats: 203

From: Loganville, GA

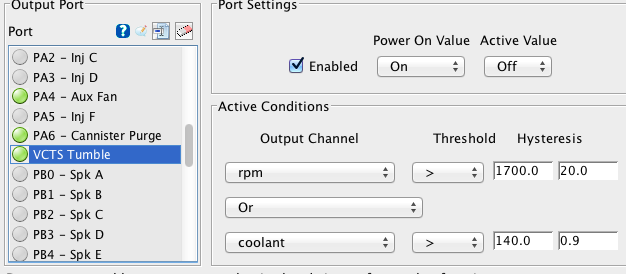

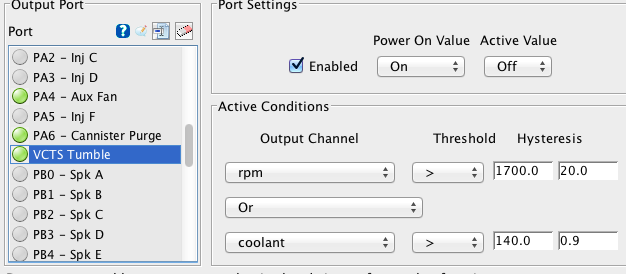

Just a thought before bed. Could this have something to do with VCTS?

It is my understanding that when the VCTS solenoid is open engine vacuum pulls shut the VCTS butterflies. If my VCTS solenoid is shot or not programmed properly in MS is it possible that between shifts when engine vacuum is high the butterflies are closed and when the throttle opens and begins pushing boost in there isn't time for the butterflies to snap back open? OR, is it possible that my engine vacuum between shifts is pulling enough vacuum to suck air through a closed solenoid thus closing the butterflies?

I realize my VVT is acting funny but to me that doesn't explain the full rich conditions. Closed butterflies seem to explain my problem. Closed butterflies would prevent engine from revving easily and the indicated engine MAP would be high meaning fuel injected would be cooresponding with that pressure meanwhile there is a severe restriction to the air entering the engine.

Thoughts?

Here are my VCTS settings:

It is my understanding that when the VCTS solenoid is open engine vacuum pulls shut the VCTS butterflies. If my VCTS solenoid is shot or not programmed properly in MS is it possible that between shifts when engine vacuum is high the butterflies are closed and when the throttle opens and begins pushing boost in there isn't time for the butterflies to snap back open? OR, is it possible that my engine vacuum between shifts is pulling enough vacuum to suck air through a closed solenoid thus closing the butterflies?

I realize my VVT is acting funny but to me that doesn't explain the full rich conditions. Closed butterflies seem to explain my problem. Closed butterflies would prevent engine from revving easily and the indicated engine MAP would be high meaning fuel injected would be cooresponding with that pressure meanwhile there is a severe restriction to the air entering the engine.

Thoughts?

Here are my VCTS settings:

Last edited by Chiburbian; 10-27-2015 at 12:19 AM.

#7

Thread Starter

Joined: Feb 2008

Posts: 2,331

Total Cats: 203

From: Loganville, GA

Ok, I will try and describe what is happening in the logs until you can look at them yourself.

(This is on the same pull)

First gear, VVT tracks with target angle for the most part. PID loop seems to be doing it's job.

Second gear, AFRs are fine but about 5,000 rpm the VVT angle locks into about 12 degrees to redline when it's supposed to taper down to near 5 degrees or so. Doing this from memory.

Third gear VVT angle is correct until 5k rpm again at which point AFR drops to 10.3 and VVT angle drops to .2 degrees to redline. VVT duty keeps rising trying to make it match to no avail.

I am due for an oil change so I will do that as soon as I can and see what it looks like and if there are any metal sparkles. I am sure I ran low on oil when I had that BEGI supply line fail and I wouldn't be surprised if I wore my bearings pretty well in that time which would certainly cause a low oil pressure situation. I was just hoping that I could get away with a rods only build and it looks like I may be better off building my second spare motor at this point. (if I am replacing oil pump with boundary engineering VVT pump I am pretty much blowing my low budget out of the water right there)

(This is on the same pull)

First gear, VVT tracks with target angle for the most part. PID loop seems to be doing it's job.

Second gear, AFRs are fine but about 5,000 rpm the VVT angle locks into about 12 degrees to redline when it's supposed to taper down to near 5 degrees or so. Doing this from memory.

Third gear VVT angle is correct until 5k rpm again at which point AFR drops to 10.3 and VVT angle drops to .2 degrees to redline. VVT duty keeps rising trying to make it match to no avail.

I am due for an oil change so I will do that as soon as I can and see what it looks like and if there are any metal sparkles. I am sure I ran low on oil when I had that BEGI supply line fail and I wouldn't be surprised if I wore my bearings pretty well in that time which would certainly cause a low oil pressure situation. I was just hoping that I could get away with a rods only build and it looks like I may be better off building my second spare motor at this point. (if I am replacing oil pump with boundary engineering VVT pump I am pretty much blowing my low budget out of the water right there)