3 issues with Rev Built MS3-Basic

#1

@thumpetto007 asked me to make separate thread, but the issues were discovered here: https://www.miataturbo.net/build-thr...a-build-86732/

Problem 1

what would be the simplest fix for this?

Problem #2

I'm going to re-install the .ini file today but if that doesn't work I'm clueless on what to try next.

thoughts?

Problem 1

since the car doesn't have dual-baro sensors, the only options for baro correction now is initial MAP reading and no correction. Initial MAP reading DOES NOT WORK properly. Something is wrong with the software, causing the car to peg rich no matter what. Disabling it makes everything peachy again.

COINCIDENTALLY - the other Rev Built MS3's I've set up all had this same problem. The latest being Gordons (EO2K) which did the same thing, pegged rich any time "initial map reading" was selected for BARO correction. Disabling BARO correction solved the issues. Not a big deal for EO2K since he's only a few hundred ft higher elevation than I.

The problem with OP is he's gonna be traveling from my area (100-200ft elevation) all the way up to the mountains (7,000-9,000ft elevation) relatively frequently. We're both a bit nervous about the tune getting all out of whack with such large elevation changes without BARO correction.

COINCIDENTALLY - the other Rev Built MS3's I've set up all had this same problem. The latest being Gordons (EO2K) which did the same thing, pegged rich any time "initial map reading" was selected for BARO correction. Disabling BARO correction solved the issues. Not a big deal for EO2K since he's only a few hundred ft higher elevation than I.

The problem with OP is he's gonna be traveling from my area (100-200ft elevation) all the way up to the mountains (7,000-9,000ft elevation) relatively frequently. We're both a bit nervous about the tune getting all out of whack with such large elevation changes without BARO correction.

Problem #2

We're running into a really weird wideband CAN connection/communication issue:

Every now and then, it loses all connection, freezes and just stops working. The TS gauge just freezes at whatever AFR it was showing before it does that, and the car then flips out, with EGO correction pulling fuel and all sorts of wacky stuff cause it thinks it's either rich or lean depending on what AFR it "froze" at.

Re-starting the car makes it work fine again.

@Reverant can you please help out with this?

Let me know what you need, a log, or whatever other troubleshooting. The AEM UEGO and CAN module came pre-wired, so I didn't touch any of the wires, and it works fine when it works. At first I thought maybe wiring issue, but re-starting car makes it work again, so I don't think that's it. Sometimes it actually un-freezes on it's own and works again without re-starting the car.

Every now and then, it loses all connection, freezes and just stops working. The TS gauge just freezes at whatever AFR it was showing before it does that, and the car then flips out, with EGO correction pulling fuel and all sorts of wacky stuff cause it thinks it's either rich or lean depending on what AFR it "froze" at.

Re-starting the car makes it work fine again.

@Reverant can you please help out with this?

Let me know what you need, a log, or whatever other troubleshooting. The AEM UEGO and CAN module came pre-wired, so I didn't touch any of the wires, and it works fine when it works. At first I thought maybe wiring issue, but re-starting car makes it work again, so I don't think that's it. Sometimes it actually un-freezes on it's own and works again without re-starting the car.

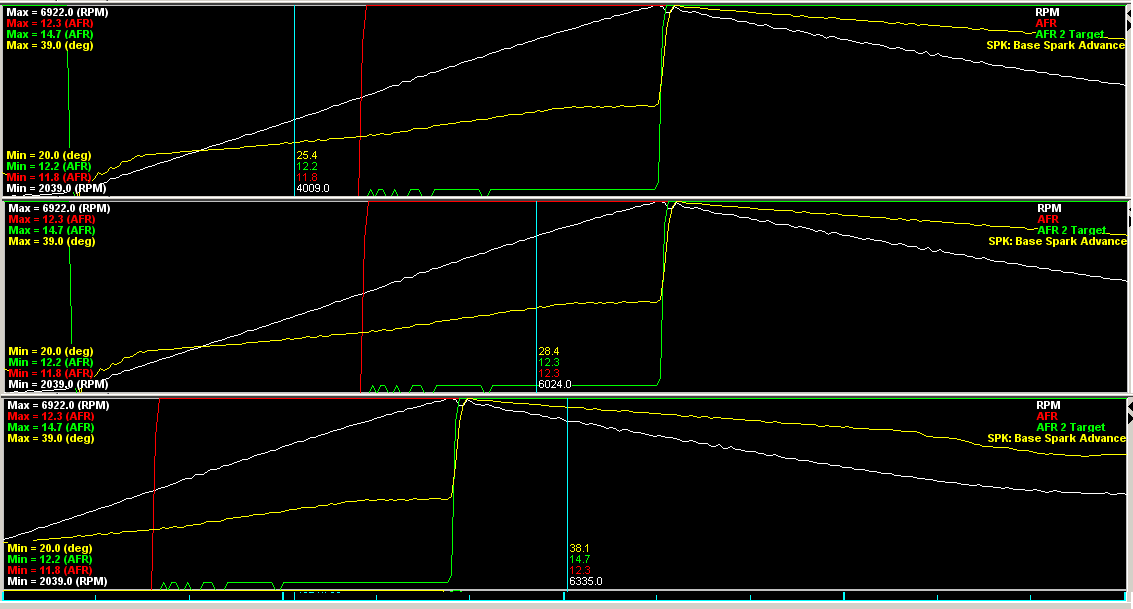

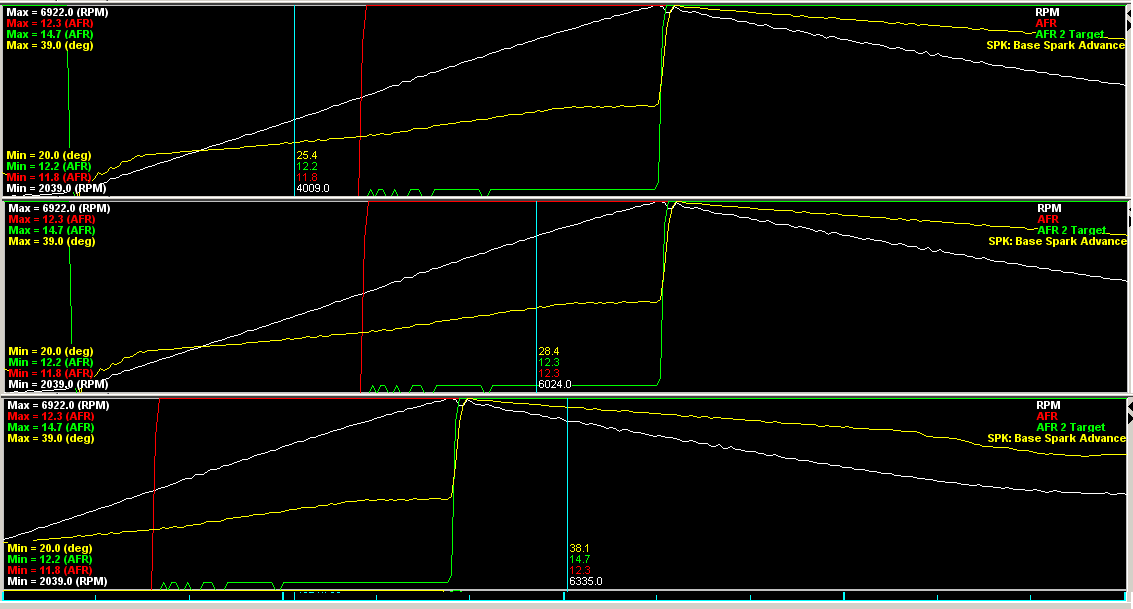

Here's a decent representation of what's happening in a log:

same run in all 3 rows, you can see when it's working and hitting 11.8 when triggering 12.3

then it freezes at 12.3 and stays there for the remainder of the pull

even when you let off and car is triggering 14.7, it's still stuck on 12.3 and won't move

during this time if EGO corr is on it will start pulling fuel and cause the car to run lean, obviously.

most of the time, turning the car off and starting back up fixes the problem and it works again.

@Reverant@thumpetto007

same run in all 3 rows, you can see when it's working and hitting 11.8 when triggering 12.3

then it freezes at 12.3 and stays there for the remainder of the pull

even when you let off and car is triggering 14.7, it's still stuck on 12.3 and won't move

during this time if EGO corr is on it will start pulling fuel and cause the car to run lean, obviously.

most of the time, turning the car off and starting back up fixes the problem and it works again.

@Reverant@thumpetto007

thoughts?

#2

Must add second baro sensor for the first problem. Any megasquirt using initial baro value can cause problems, especially partial stalls or restarts. I don't travel much and have mine locked at 98kpa. If I ever stall and bump start it on accident I don't have to worry about it targeting manifold vac as atmo.

For the wideband can module, is the lag factor set at the minimum, I think it's 10? when I originally set mine up I had it set at 50, would do all sorts of weird stuff over can. Probably not the problem, but worth a shot.

For the wideband can module, is the lag factor set at the minimum, I think it's 10? when I originally set mine up I had it set at 50, would do all sorts of weird stuff over can. Probably not the problem, but worth a shot.

#4

I agree that the simplest fix for the baro issue is to just install a baro pressure sensor.

My first guess on the wideband bus thing would be that whatever is transmitting the CAN bus AFR signal has stopped doing so. You could confirm that with an Arduino, a CAN shield, and a teeny bit of software. Is the AEM transmitting CAN natively, or does it have a RS232-to-CAN converter like I'm using for my LC-2?

What's the third issue?

--Ian

My first guess on the wideband bus thing would be that whatever is transmitting the CAN bus AFR signal has stopped doing so. You could confirm that with an Arduino, a CAN shield, and a teeny bit of software. Is the AEM transmitting CAN natively, or does it have a RS232-to-CAN converter like I'm using for my LC-2?

What's the third issue?

--Ian

#6

Can anyone explain EXACTLY how to install/hookup/add the second (oem) baro sensor?

Like can it be added to one of the sensor banks (iirc) of the megasquirt? or does it need to be soldered into the motherboard or something?

Please go so far as to say connect this to that, or solder this to that, specifically. Thank you very much.

Like can it be added to one of the sensor banks (iirc) of the megasquirt? or does it need to be soldered into the motherboard or something?

Please go so far as to say connect this to that, or solder this to that, specifically. Thank you very much.

#8

Can anyone explain EXACTLY how to install/hookup/add the second (oem) baro sensor?

Like can it be added to one of the sensor banks (iirc) of the megasquirt? or does it need to be soldered into the motherboard or something?

Please go so far as to say connect this to that, or solder this to that, specifically. Thank you very much.

Like can it be added to one of the sensor banks (iirc) of the megasquirt? or does it need to be soldered into the motherboard or something?

Please go so far as to say connect this to that, or solder this to that, specifically. Thank you very much.

I'm using a GM 3 bar map sensor as my main map sensor now (https://www.diyautotune.com/product/...ar-map-sensor/). This needs 3 wires -- power, ground and signal. Signal goes to "EXT_MAP input" on the db37 (pin 11 on mine, but note that I have an early-build, so I don't guarantee that the pinouts are the same on yours). Ground is "sensor ground" (pin 3), and power needs to be 5 volts. My Rev board didn't supply +5 on the db37, so I had to open it up and solder a wire from a +5 source inside the box to an unused pin on the db37. Once I hooked up the GM 3 bar sensor as the main map, I switched it to use the built-in map sensor as the baro source (make sure to remove the vacuum hose going to it before doing this). Software allows you to configure which sensor is used for which purpose.

I haven't used the OEM sensor so I'm not 100% sure this is accurate, but it looks fairly straightforward. Assuming we're talking about using the one in the engine bay labelled "BOOST" (used for EGR in the factory config, but only goes up to 1 bar), then it should already have power and ground, and the signal wire is in the main harness (pin 3S on my 99 ECU harness -- this varies by year). I dunno if Rev wires that to anything on the current-gen boxes (mine is not connected). If it's connected, you might just need to tweak the software config, if it's not connected then you'll need to wire it internally in the box to an input on the MS3. You could, for example, just solder a wire connecting the solder legs for the appropriate pin on the OEM ECU connector to the EXT_MAP pin on the db37.

Once hooked up, you'll need to configure the sensor in software, which means telling it what voltage values correspond to what pressures, and telling the MS3 what sensors to use for what purpose. For the transfer function, a generic sensor like the GM 3 bar one comes with a data sheet containing the specs on that. I dunno what the specs are for the OEM baro sensor -- worst case you could plumb it and the built-in MAP sensor together, hook up a mity-vac vacuum tester, and measure the voltage on the OEM sensor at various vacuum values. Cross-referencing that with the value that the OEM sensor gives you will allow you to derive the transfer function.

Make sure you don't forget to remove the vacuum line connecting whatever sensor you decide to use for baro measurement!

--Ian

#9

1) The "Initial MAP reading" method is used on all the MS3s I send out. At some point in time, still on the 1.3.4 firmware, I disabled it because there was firmware bug that actually applied barometric correction regardless of the settings, so if you had that enabled, it applies baro a second time. But it would do the same whether you had initial MAP reading or second sensor selected. It has been fixed on 1.4.0. I literally can't think of any reason why it would do what you described , unless you crank immediatelly upon turning the key (ie not waiting for the 2 second pump priming to end).

2) Waiting for you to install the .ini file.

3) What's issue #3?

2) Waiting for you to install the .ini file.

3) What's issue #3?

#10

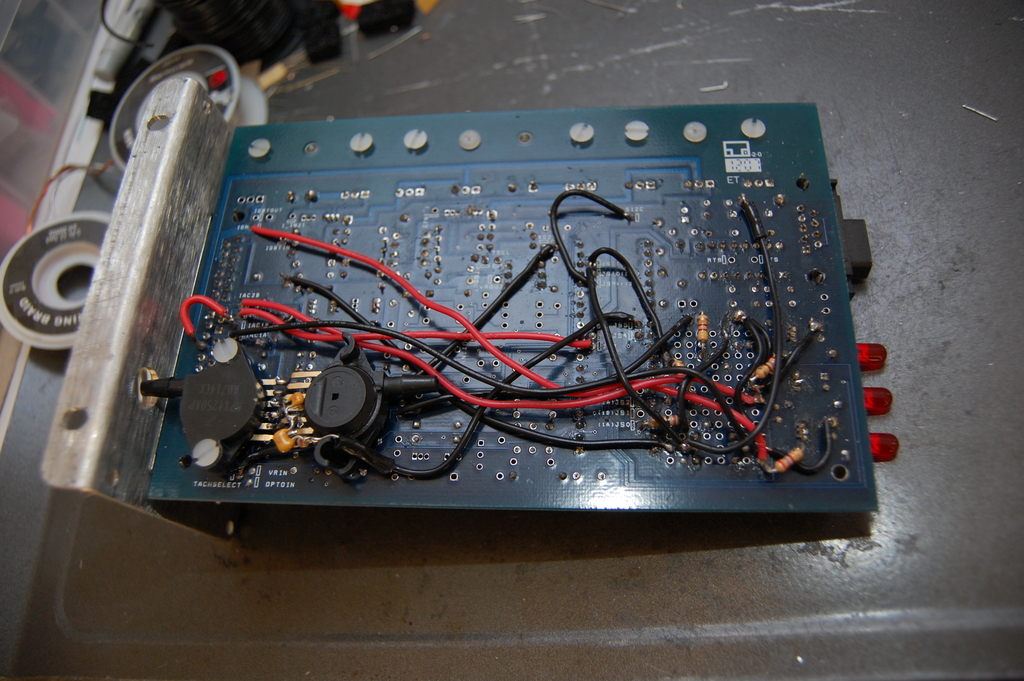

You can stack a second map sensor inside other megasquirts, I'm not sure on the rev board though...

https://www.diyautotune.com/product/...ar-map-sensor/

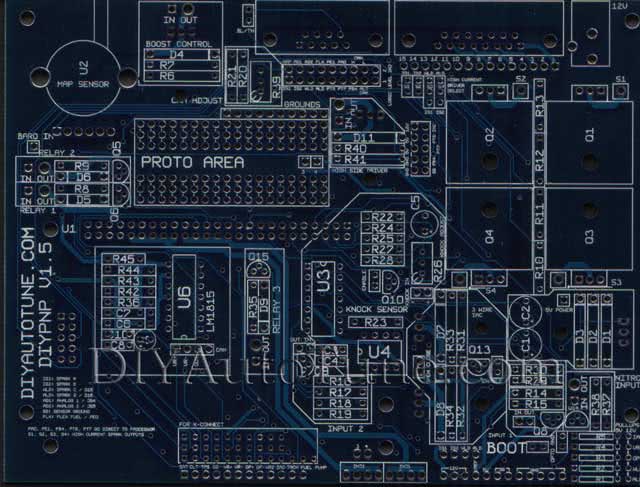

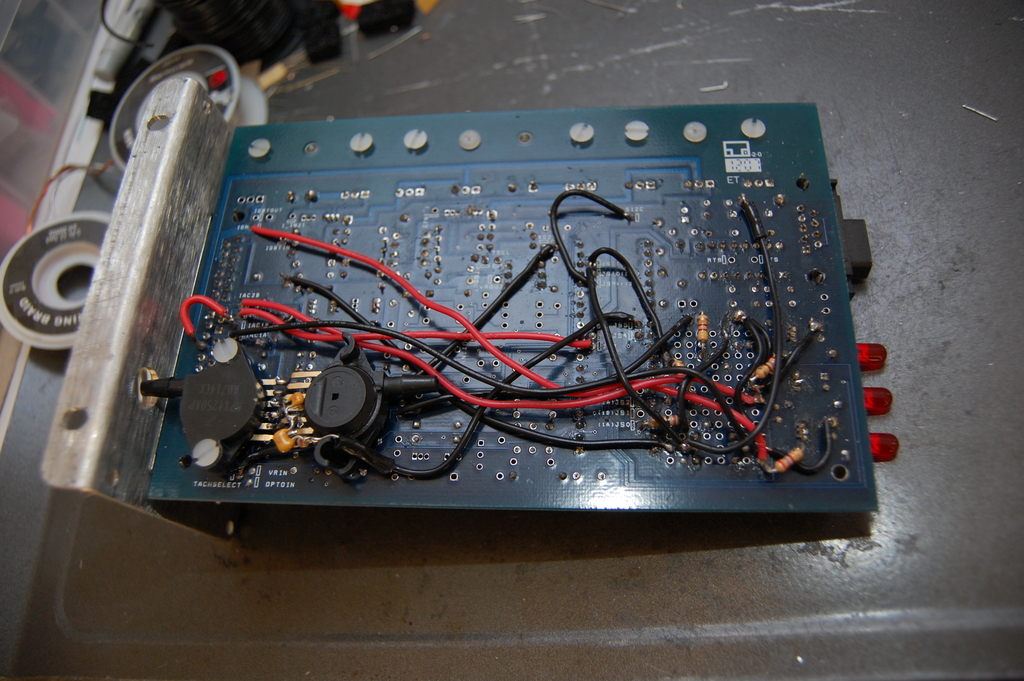

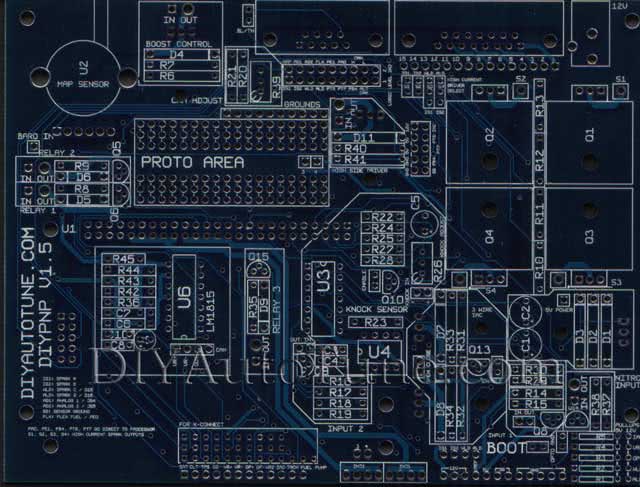

How to wire it up

See here, this is a DIYPNP. Check the upper left corner, see the little straggling pin, labeled "baro in" I'd open your ECU and look see if you could doo this real easy like.

Reverent makes a serial to CAN adapter for the AEM and Innovate serial protocol, I know that much. It's not a native CAN device, AFAIK.

https://www.diyautotune.com/product/...ar-map-sensor/

How to wire it up

See here, this is a DIYPNP. Check the upper left corner, see the little straggling pin, labeled "baro in" I'd open your ECU and look see if you could doo this real easy like.

Reverent makes a serial to CAN adapter for the AEM and Innovate serial protocol, I know that much. It's not a native CAN device, AFAIK.

#11

Thanks everyone for your detailed responses.

1) I am just a little peeved that the megasquirt didn't just come with dual baros. I specifically told you that I'd be frequently driving between sea level and 9000 feet. It was the answer to one of the questions in the questionnaire I filled out prior to purchase. Not really sure why this wouldn't have been done. I would have gladly paid extra, on top of my tip, for the ease of install, and peace of mind.

2) we installed the ini file, but all it gave us was another "dashboard" on the tuner studio. Time will tell if the communication issues are resolved with this addition.

1) I am just a little peeved that the megasquirt didn't just come with dual baros. I specifically told you that I'd be frequently driving between sea level and 9000 feet. It was the answer to one of the questions in the questionnaire I filled out prior to purchase. Not really sure why this wouldn't have been done. I would have gladly paid extra, on top of my tip, for the ease of install, and peace of mind.

2) we installed the ini file, but all it gave us was another "dashboard" on the tuner studio. Time will tell if the communication issues are resolved with this addition.

#12

Joined: Jan 2013

Posts: 5,012

Total Cats: 859

From: Seneca, SC

I see in TS where to turn on baro correction, but not where to set the curve/table. Where is that, and what values are typical?

Yeah, I found it. Mine was all zeroed out, however. Still don't know what typical values are.

Yeah, I found it. Mine was all zeroed out, however. Still don't know what typical values are.

Last edited by DNMakinson; 03-10-2016 at 12:41 PM.

#13

Nope. I have absolutely no idea what it even is let alone how to use/do it.

Circuitry is over my head, as I've said.

Sounds like modifications are required or at least something way more than just simply connecting 3 wires to the spare inputs/outputs on the ms3. Right?

Sorry if I sound stupid, but while I'm pretty handy with wrenching on and tuning these things, and can handle your typical power/ground/signal wire connecting (barely), I'm really quite scared of circuitry or any moderate amount of electronics/wiring stuff. I'll keep reading and trying to comprehend exactly all what's needed, and perhaps muster up the courage to do this.

1) I have no idea why it's not working either. Actually, it works like 20% of the time. If you cycle on/off enough times it will after a few tries actually work like intended.

I have definitely tried to give it at least 4-5 seconds before starting, as well as tried to fire immediately - just to test what you're saying. It didn't really change anything either way.

You think it needs more than about 5 seconds to get a sample? I can try it I suppose, but I can't imagine OP being happy about having to wait 10+ seconds to start the car each time lol

2) we did last night. we'll see. it's been happening a lot less often lately, so perhaps with the .ini re-install yesterday it will disappear altogether.

3) I was going to mention the long-sync issue on startup then remembered you mentioned in the original thread that you'd work on a fix for it?

Another thing to point out on that is it seems like VVT angle spikes like crazy during the 1st split second of startup. I'm not sure if perhaps the intake cam advancing during startup throws the car off and delays sync?

We have the cam completely zero'd out, even -1* in those cells just to make sure it's not the map commanding it to advance on startup like this. LMK if you want startup logs or composite log showing the long start-sync issue.

Circuitry is over my head, as I've said.

I haven't used the OEM baro sensor, but I have hooked up a bunch of external pressure sensors to my early-build Rev MS3 basic.

I'm using a GM 3 bar map sensor as my main map sensor now (https://www.diyautotune.com/product/...ar-map-sensor/). This needs 3 wires -- power, ground and signal. Signal goes to "EXT_MAP input" on the db37 (pin 11 on mine, but note that I have an early-build, so I don't guarantee that the pinouts are the same on yours). Ground is "sensor ground" (pin 3), and power needs to be 5 volts. My Rev board didn't supply +5 on the db37, so I had to open it up and solder a wire from a +5 source inside the box to an unused pin on the db37. Once I hooked up the GM 3 bar sensor as the main map, I switched it to use the built-in map sensor as the baro source (make sure to remove the vacuum hose going to it before doing this). Software allows you to configure which sensor is used for which purpose.

I haven't used the OEM sensor so I'm not 100% sure this is accurate, but it looks fairly straightforward. Assuming we're talking about using the one in the engine bay labelled "BOOST" (used for EGR in the factory config, but only goes up to 1 bar), then it should already have power and ground, and the signal wire is in the main harness (pin 3S on my 99 ECU harness -- this varies by year). I dunno if Rev wires that to anything on the current-gen boxes (mine is not connected). If it's connected, you might just need to tweak the software config, if it's not connected then you'll need to wire it internally in the box to an input on the MS3. You could, for example, just solder a wire connecting the solder legs for the appropriate pin on the OEM ECU connector to the EXT_MAP pin on the db37.

Once hooked up, you'll need to configure the sensor in software, which means telling it what voltage values correspond to what pressures, and telling the MS3 what sensors to use for what purpose. For the transfer function, a generic sensor like the GM 3 bar one comes with a data sheet containing the specs on that. I dunno what the specs are for the OEM baro sensor -- worst case you could plumb it and the built-in MAP sensor together, hook up a mity-vac vacuum tester, and measure the voltage on the OEM sensor at various vacuum values. Cross-referencing that with the value that the OEM sensor gives you will allow you to derive the transfer function.

Make sure you don't forget to remove the vacuum line connecting whatever sensor you decide to use for baro measurement!

--Ian

I'm using a GM 3 bar map sensor as my main map sensor now (https://www.diyautotune.com/product/...ar-map-sensor/). This needs 3 wires -- power, ground and signal. Signal goes to "EXT_MAP input" on the db37 (pin 11 on mine, but note that I have an early-build, so I don't guarantee that the pinouts are the same on yours). Ground is "sensor ground" (pin 3), and power needs to be 5 volts. My Rev board didn't supply +5 on the db37, so I had to open it up and solder a wire from a +5 source inside the box to an unused pin on the db37. Once I hooked up the GM 3 bar sensor as the main map, I switched it to use the built-in map sensor as the baro source (make sure to remove the vacuum hose going to it before doing this). Software allows you to configure which sensor is used for which purpose.

I haven't used the OEM sensor so I'm not 100% sure this is accurate, but it looks fairly straightforward. Assuming we're talking about using the one in the engine bay labelled "BOOST" (used for EGR in the factory config, but only goes up to 1 bar), then it should already have power and ground, and the signal wire is in the main harness (pin 3S on my 99 ECU harness -- this varies by year). I dunno if Rev wires that to anything on the current-gen boxes (mine is not connected). If it's connected, you might just need to tweak the software config, if it's not connected then you'll need to wire it internally in the box to an input on the MS3. You could, for example, just solder a wire connecting the solder legs for the appropriate pin on the OEM ECU connector to the EXT_MAP pin on the db37.

Once hooked up, you'll need to configure the sensor in software, which means telling it what voltage values correspond to what pressures, and telling the MS3 what sensors to use for what purpose. For the transfer function, a generic sensor like the GM 3 bar one comes with a data sheet containing the specs on that. I dunno what the specs are for the OEM baro sensor -- worst case you could plumb it and the built-in MAP sensor together, hook up a mity-vac vacuum tester, and measure the voltage on the OEM sensor at various vacuum values. Cross-referencing that with the value that the OEM sensor gives you will allow you to derive the transfer function.

Make sure you don't forget to remove the vacuum line connecting whatever sensor you decide to use for baro measurement!

--Ian

Sorry if I sound stupid, but while I'm pretty handy with wrenching on and tuning these things, and can handle your typical power/ground/signal wire connecting (barely), I'm really quite scared of circuitry or any moderate amount of electronics/wiring stuff. I'll keep reading and trying to comprehend exactly all what's needed, and perhaps muster up the courage to do this.

1) The "Initial MAP reading" method is used on all the MS3s I send out. At some point in time, still on the 1.3.4 firmware, I disabled it because there was firmware bug that actually applied barometric correction regardless of the settings, so if you had that enabled, it applies baro a second time. But it would do the same whether you had initial MAP reading or second sensor selected. It has been fixed on 1.4.0. I literally can't think of any reason why it would do what you described , unless you crank immediatelly upon turning the key (ie not waiting for the 2 second pump priming to end).

2) Waiting for you to install the .ini file.

3) What's issue #3?

2) Waiting for you to install the .ini file.

3) What's issue #3?

I have definitely tried to give it at least 4-5 seconds before starting, as well as tried to fire immediately - just to test what you're saying. It didn't really change anything either way.

You think it needs more than about 5 seconds to get a sample? I can try it I suppose, but I can't imagine OP being happy about having to wait 10+ seconds to start the car each time lol

2) we did last night. we'll see. it's been happening a lot less often lately, so perhaps with the .ini re-install yesterday it will disappear altogether.

3) I was going to mention the long-sync issue on startup then remembered you mentioned in the original thread that you'd work on a fix for it?

Another thing to point out on that is it seems like VVT angle spikes like crazy during the 1st split second of startup. I'm not sure if perhaps the intake cam advancing during startup throws the car off and delays sync?

We have the cam completely zero'd out, even -1* in those cells just to make sure it's not the map commanding it to advance on startup like this. LMK if you want startup logs or composite log showing the long start-sync issue.

#14

1) Please capture two logs, one with baro deactivated and one with it set to initial map reading. You should definitely not need more than 2 seconds.

2) I shouldn't change anything other than provide more debugging info

3) This is 100% a firmware issue. It goes all the way back to the MS2. This is stock firmware we are talking about, so I've asked the firmware developers to look into it. The VVT startup issue also a firmware issue, I recall it started happening on my car as well after I upgraded from 1.3.2 to 1.4 beta.

2) I shouldn't change anything other than provide more debugging info

3) This is 100% a firmware issue. It goes all the way back to the MS2. This is stock firmware we are talking about, so I've asked the firmware developers to look into it. The VVT startup issue also a firmware issue, I recall it started happening on my car as well after I upgraded from 1.3.2 to 1.4 beta.

#16

As for using the factory EGR boost sensor, it depends on how Rev has that board wired. It might just be software config tweaks, or it might require running one wire to an unused input on the MS3. The catch is that the one wire is already run to the factory ECU connector, and if that pin isn't wired internally to the MS3, then you'd have to cut the factory harness to get it to the db37. If that were the case, then soldering a wire inside the MS3 would be better approach.

--Ian

#18

It should be as simple as hooking up power and ground to an external MAP sensor, hooking the signal wire to the correct pin/wire on the DB37, moving one well-marked jumper inside the ECU, then activating the external MAP sensor in the settings. Zero soldering, zero internal mods (beyond moving the jumper). You are a competent individual when it comes to ECUs, so I have no doubt you can manage this.