E-Supercharger

#2

There's a few universal kits out there that show promise, openflash is one...

ESC Development - OpenFlash PerformanceOpenFlash Performance

Few other threads around on 86s and NC miata using the things. Doesn't look like anything more than a turbo compressor with brushless motor in place of the chra. I kinda want to make one...

ESC Development - OpenFlash PerformanceOpenFlash Performance

Few other threads around on 86s and NC miata using the things. Doesn't look like anything more than a turbo compressor with brushless motor in place of the chra. I kinda want to make one...

#3

It seems BMW (and others BW, Garrett) are on the patent train for electronically assisted turbochargers to minimize turbo lag in "large for engine application" turbos.

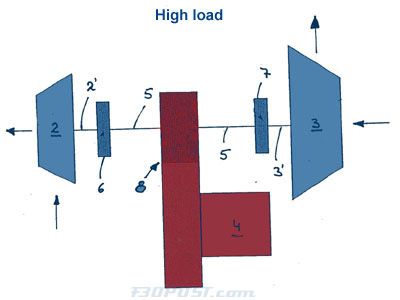

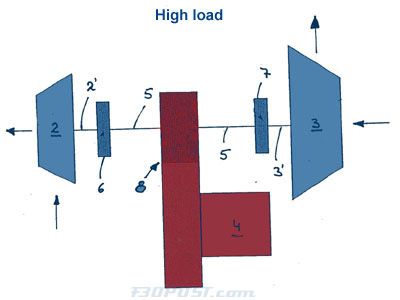

[from the BMW patent application]

[See image below: 1) turbo layout; 2) turbine; 2') turbine axle; 3) compressor; 3')compressor axle; 4) electric motor (and alternator); 5) turbine axle; 6) (turbine axle) clutch; 7) (compressor axle) clutch; 8) gearing]

I'm wondering how worth it it is for the e-assist turbo with its own 48V system (charging, storing, discharging). The alternative would be to use a secondary voltage system to power a hybrid electric drive motor to directly assist assist with wheel torque during turbo-lag inducing conditions.

Thinking about it, it would be a lighter, smaller, system; with less voltage and storage capacity needed to drive the smaller and less powerful motor, that is more modular, and easier to implement in a greater array of vehicles. Also probably, and most importantly, cheaper to implement. Sooooooo, technically more difficult to pull off than a hybrid drive but hopefully more effective with proper R&D (also known as money) applied. So, I'll be interested to see if/when this makes it to a production vehicle.

[from the BMW patent application]

[See image below: 1) turbo layout; 2) turbine; 2') turbine axle; 3) compressor; 3')compressor axle; 4) electric motor (and alternator); 5) turbine axle; 6) (turbine axle) clutch; 7) (compressor axle) clutch; 8) gearing]

I'm wondering how worth it it is for the e-assist turbo with its own 48V system (charging, storing, discharging). The alternative would be to use a secondary voltage system to power a hybrid electric drive motor to directly assist assist with wheel torque during turbo-lag inducing conditions.

Thinking about it, it would be a lighter, smaller, system; with less voltage and storage capacity needed to drive the smaller and less powerful motor, that is more modular, and easier to implement in a greater array of vehicles. Also probably, and most importantly, cheaper to implement. Sooooooo, technically more difficult to pull off than a hybrid drive but hopefully more effective with proper R&D (also known as money) applied. So, I'll be interested to see if/when this makes it to a production vehicle.

#4

Isn't the real issue how long does the battery charge last that powers the e-supercharger. From my brief reading about them in the NC/ND section on miata.net they are decent on the street doing a few pulls then letting the battery charge back up. Not something you could use out on a track, as the battery for the e-supercharger would be out of energy by the end of the first lap.

#5

Joined: Sep 2005

Posts: 33,556

Total Cats: 6,933

From: Chicago. (The less-murder part.)

There's been a lot of development of a tangentially-related system in F1 recently. In short, you put an electric motor in the CHRA of an otherwise conventional turbo, and also an electric motor in series with the crankshaft. When coming out of a braking zone, electricity is sent to the turbo motor to spool it up instantly, then once the engine is making power under boost, the flow of electricity is reversed with the turbo motor acting as a generator when sends power to the crankshaft motor.

A good writeup:

How Formula One's Amazing New Hybrid Turbo Engine Works

Seems like this sort of thing would be ideal in an OEM configuration in lieu of a more conventional (read: heavier and more expensive) hybrid system, where a tiny engine and a large alternator are paired with the e-supercharger. The unit is used to multiply engine power briefly when taking off from a stop and while overtaking.

A good writeup:

How Formula One's Amazing New Hybrid Turbo Engine Works

Seems like this sort of thing would be ideal in an OEM configuration in lieu of a more conventional (read: heavier and more expensive) hybrid system, where a tiny engine and a large alternator are paired with the e-supercharger. The unit is used to multiply engine power briefly when taking off from a stop and while overtaking.

#6

Electric superchargers will be perfect for street cars. Once I am done with my Miata I am eyeing one of these guys for my daily. Like NO2, there when I want it, but no drag on the engine and without the compelxity of makig a header/downpipe and such for a turbo.

http://www.phantomsuperchargers.com/

http://www.phantomsuperchargers.com/

#7

The biggest turn-off for me with the aftermarket kits is the rudimentary controller setup. If I recall correctly, they are utilizing a simple on-off switch on the throttle. Open the throttle past a certain point, the "boost" turns on. Drop the throttle back below that point, it turns off again.

I love the idea for a street car, but I want a smarter controller -- something that gradually feeds in more power as the throttle opens.

I love the idea for a street car, but I want a smarter controller -- something that gradually feeds in more power as the throttle opens.

#11

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

I wrote a college entrance essay about using an electric motor to supplement exhaust pressure to combat turbo lag. 6 years ago. The internet didn't have anything like it at the time.

I didn't get in. ******* ******** probably took my idea and patented it.

I didn't get in. ******* ******** probably took my idea and patented it.

#13

The biggest turn-off for me with the aftermarket kits is the rudimentary controller setup. If I recall correctly, they are utilizing a simple on-off switch on the throttle. Open the throttle past a certain point, the "boost" turns on. Drop the throttle back below that point, it turns off again.

I love the idea for a street car, but I want a smarter controller -- something that gradually feeds in more power as the throttle opens.

I love the idea for a street car, but I want a smarter controller -- something that gradually feeds in more power as the throttle opens.

Originally Posted by m.net

I have left the ECU's DBW mapping mostly stock with the exception of removing the 2nd gear torque limiter. I then mapped the Procede to start adding in boost starting as early as 40% throttle while giving full boost by 100% throttle. Since, in a stock car, 80% of torque is available at 40% throttle, this makes the applied throttle-to-actual torque relationship VERY linear. 50% torque at 50% pedal, 100% torque at 100% pedal, etc,. If the DBW maps have been remapped to be more sensitive, I think some may find the torque response to be non-linear and too eager.

More interesting tidbits:

The addition of the MAF straightener allowed us to put stock-like airflow values in the MAF calibration table. This means that you can install the ESC and run the STOCK tune as long as the ESC is turned off. Similarly, you can run the ESC tune with ESC removed and replaced with the stock airbox/intake and the only noticeable differences being the engine speeds at which the intake runner length control activates/deactivates and (in some case) max rev limit. Getting consistent MAF readings while using stock-like MAF calibration data has resulted in stock-like fuel trim behavior during closed loop conditions. In Bradford's car, I was seeing STFT and LTFT within +/- 2% during steady state cruise once the engine was warm. Good stuff.

The Procede's ESC control mapping offers a diagnosis mode that allows you to engage the ESC while the engine isn't running. The old WOT switch set-up would do the same thing. The difference is that the Procede will only kick it on to spin just enough to be audible (10%) whereas the the WOT switch setup would kick it on hard enough (100%) to be audible to a person 100 yards away The Procede is also mapped to stop the ESC 50rpm short of redline. This means that as the throttle blade closes, the ESC compressor brakes so there is never a condition where the ESC is pushing air against a close throttle. Similarly, the Procede will to apply the ESC brakes during traction control intervention. All in all, it's just far better integrated to the rest of the system than it was in the Gen1 version.

The Procede is also mapped to stop the ESC 50rpm short of redline. This means that as the throttle blade closes, the ESC compressor brakes so there is never a condition where the ESC is pushing air against a close throttle. Similarly, the Procede will to apply the ESC brakes during traction control intervention. All in all, it's just far better integrated to the rest of the system than it was in the Gen1 version.

With the Procede, we are also limiting ESC speed at very low engine speeds. It is completely disabled until 1400rpm at which time it starts to spin at min RPM. It smoothly transitions to max RPM by 2300rpm. Implementing this low rpm airflow limit fixes a MAF surge that occurs when you active the ESC at full speed, all of a sudden, at low RPM.

With Gen2, I think we are at the point where the ESC simply does not bring attention to itself while offering better performance, more power and ideal drivability. The new control strategies have been in the works for nearly a year so it's nice to finally see it come to fruition.

More interesting tidbits:

The addition of the MAF straightener allowed us to put stock-like airflow values in the MAF calibration table. This means that you can install the ESC and run the STOCK tune as long as the ESC is turned off. Similarly, you can run the ESC tune with ESC removed and replaced with the stock airbox/intake and the only noticeable differences being the engine speeds at which the intake runner length control activates/deactivates and (in some case) max rev limit. Getting consistent MAF readings while using stock-like MAF calibration data has resulted in stock-like fuel trim behavior during closed loop conditions. In Bradford's car, I was seeing STFT and LTFT within +/- 2% during steady state cruise once the engine was warm. Good stuff.

The Procede's ESC control mapping offers a diagnosis mode that allows you to engage the ESC while the engine isn't running. The old WOT switch set-up would do the same thing. The difference is that the Procede will only kick it on to spin just enough to be audible (10%) whereas the the WOT switch setup would kick it on hard enough (100%) to be audible to a person 100 yards away

The Procede is also mapped to stop the ESC 50rpm short of redline. This means that as the throttle blade closes, the ESC compressor brakes so there is never a condition where the ESC is pushing air against a close throttle. Similarly, the Procede will to apply the ESC brakes during traction control intervention. All in all, it's just far better integrated to the rest of the system than it was in the Gen1 version.

The Procede is also mapped to stop the ESC 50rpm short of redline. This means that as the throttle blade closes, the ESC compressor brakes so there is never a condition where the ESC is pushing air against a close throttle. Similarly, the Procede will to apply the ESC brakes during traction control intervention. All in all, it's just far better integrated to the rest of the system than it was in the Gen1 version.With the Procede, we are also limiting ESC speed at very low engine speeds. It is completely disabled until 1400rpm at which time it starts to spin at min RPM. It smoothly transitions to max RPM by 2300rpm. Implementing this low rpm airflow limit fixes a MAF surge that occurs when you active the ESC at full speed, all of a sudden, at low RPM.

With Gen2, I think we are at the point where the ESC simply does not bring attention to itself while offering better performance, more power and ideal drivability. The new control strategies have been in the works for nearly a year so it's nice to finally see it come to fruition.

#16

With the hard and software the public can get their hands on now, I think a C30-94 Rotrex, pile of Li-Ion batteries and some brushless DC motors could make something that works really well for a street car. For a track car, you would need more advanced ERS to sustain things for a 20-35 minute lapping session/race. The Torotrak variable ratio drive system project for the Rotrex project started in 2010 ended in 2014. Rotrex then started work on their own e-charger which is in use in industrial applications, albeit only on the tiny C8, C15 chargers.

Rotrex A/S

http://www.rotrex.com/media/bb84da96...20brochure_pdf

This behemoth is about 80 lbs. Not quite ready for racecar. In stationary industrial use where loads vary though, it makes a lot of sense.

Rotrex A/S

http://www.rotrex.com/media/bb84da96...20brochure_pdf

This behemoth is about 80 lbs. Not quite ready for racecar. In stationary industrial use where loads vary though, it makes a lot of sense.

__________________

#17

Joined: Sep 2005

Posts: 33,556

Total Cats: 6,933

From: Chicago. (The less-murder part.)

This, incidentally, is one area where NiMh batteries outshine lithiums. They have a lower energy density, which is why you don't see them in modern plug-in cars, but in return they are quite rugged and can absorb extremely high charge rates, which is why you see them in gas-only hybrids.

This behemoth is about 80 lbs. Not quite ready for racecar. In stationary industrial use where loads vary though, it makes a lot of sense.

I'm not asking out of turbo bigotry, but of the fact that turbochargers are the norm in everything from occasional-use standby generators to constant-duty maritime engines. Since most stationary piston engines are diesels, and diesels like to operate in boost pretty much all of the time, the use of any supercharger, much less an electrically-driven one, doesn't make any sense at all in this context.

#20

Seems like this sort of thing would be ideal in an OEM configuration in lieu of a more conventional (read: heavier and more expensive) hybrid system, where a tiny engine and a large alternator are paired with the e-supercharger. The unit is used to multiply engine power briefly when taking off from a stop and while overtaking.

The idea of an electric supercharger/turbo paired with an exhaust gas driven turbine/turbo makes a bit more sense. You could run a larger, laggy turbo on a small engine with this (like how audi is doing in emilio700's post). Make up for the low RPM by spooling the compressor to a lower PSI right away, for throttle response, and let the exhaust pressure take over at higher RPMS.

Then again, consider how the three hybrid hypercars went about it. Wouldn't it be better to use electric motors driving the wheels directly to overcome boost lag/low rpm issues on the high power engines? Kind of cuts out any inefficiencies of using electric power to first supplement a compressor which then supplements an engine.

If you're trying to modify a current platform car, e-superchargers or e-turbochargers would be good, but if you have the chance to design from the ground up, a hybrid system would probably work better.