Deviate gets a K20A2

#102

__________________

#104

So yeah, probably OK for a 7400 rpm K, but not ok for an 8800rpm K. This, according to a guy that has built maybe 100 K motors, consults for HRD here in the US and generally knows these engines inside out and backwards. I don't want it to be true because its a PITA and adds $$ to the build but he's the expert. David has run the **** out of his K24 without issues so it appears that is the sweet spot for this kit. Keep the revs down in a sane range, use junkyard engine parts mated to the kit and have something bombproof that makes 250whp N/A on E85.

edit: One caveat to this is that removing vtec cuts the volume requirement by quite a bit. Not sure what that does to oiling system requirements but I suspect one could run vtec kliller cams (goodbye idle) and have it live in the mid 9's.

__________________

#106

Old 2.0 Civic Si Grand Am cars ran with a baffled oil pan and an accusump...regularly saw 9000rpm.

Current HPD grand am spec motors have a Real Time Racing baffled pan like this (note current motors have an rpm max set by the rules, I believe it's under 8000rpm so doesn't really compare): Real Time Racing Honda K24 K20 Baffled Oil Pan | eBay

Does the longitudinal layout exacerbate the issue?

The STL civic Si (with K20z3) I raced in 2013 had a bone stock engine and oiling system...even down to the stupid balance shafts. That motor was used, abused, over-revved, etc etc. I think redline was set at 8500-8600. Regularly saw higher on down shifts (yay engine braking).

The guys at Hytech have way more experience with these engines than I do but it sounds like you're having to do way more with the oiling system than I would have anticipated.

Current HPD grand am spec motors have a Real Time Racing baffled pan like this (note current motors have an rpm max set by the rules, I believe it's under 8000rpm so doesn't really compare): Real Time Racing Honda K24 K20 Baffled Oil Pan | eBay

Does the longitudinal layout exacerbate the issue?

The STL civic Si (with K20z3) I raced in 2013 had a bone stock engine and oiling system...even down to the stupid balance shafts. That motor was used, abused, over-revved, etc etc. I think redline was set at 8500-8600. Regularly saw higher on down shifts (yay engine braking).

The guys at Hytech have way more experience with these engines than I do but it sounds like you're having to do way more with the oiling system than I would have anticipated.

Last edited by Efini~FC3S; 03-05-2015 at 10:07 AM. Reason: Added info

#107

Old 2.0 Civic Si Grand Am cars ran with a baffled oil pan and an accusump...regularly saw 9000rpm.

Current HPD grand am spec motors have a Real Time Racing baffled pan like this (note current motors have an rpm max set by the rules, I believe it's under 8000rpm so doesn't really compare): Real Time Racing Honda K24 K20 Baffled Oil Pan | eBay

Does the longitudinal layout exacerbate the issue?

The STL civic Si (with K20z3) I raced in 2013 had a bone stock engine and oiling system...even down to the stupid balance shafts. That motor was used, abused, over-revved, etc etc. I think redline was set at 8500-8600. Regularly saw higher on down shifts (yay engine braking).

The guys at Hytech have way more experience with these engines than I do but it sounds like you're having to do way more with the oiling system than I would have anticipated.

Current HPD grand am spec motors have a Real Time Racing baffled pan like this (note current motors have an rpm max set by the rules, I believe it's under 8000rpm so doesn't really compare): Real Time Racing Honda K24 K20 Baffled Oil Pan | eBay

Does the longitudinal layout exacerbate the issue?

The STL civic Si (with K20z3) I raced in 2013 had a bone stock engine and oiling system...even down to the stupid balance shafts. That motor was used, abused, over-revved, etc etc. I think redline was set at 8500-8600. Regularly saw higher on down shifts (yay engine braking).

The guys at Hytech have way more experience with these engines than I do but it sounds like you're having to do way more with the oiling system than I would have anticipated.

Right off the bat, John talked about the endemic weaknesses of the K series oiling system. If the motor has an achilles heel, it's the oiling system. Again, I will defer to the guys that have personally torn down many of these motors and datalogged everything over thousands of hours of racing. Maybe it's overkill. I lack the direct personal experience to second guess them. Contradictory testimonials from non-pro engine builders/drivers/backyard mechanics on the internets against one of the top pros hands-on. That's a no-brainer.

Keep in mind that David has successfully track tested a K24 at much lower revs. I'm guessing that envelope will cover 95% of the guys running these swaps. A few will need an Accusump. Maybe 2% will need to go deeper in the oiling system as I have.

__________________

#108

Iíll be the first to say that John at Hytech knows more about the K series than me, and Iím confident they are recommending the right solution for this car and rpm goals.

Here is what I do know about our kit, just as a heads up to current and future customers:

Iíve been running this k24a2 to 8200rpm since 2012, probably have 75 hours on it to be conservative. It went into the Miata at the beginning of 2014. Stock Type S oil pump, and our pan/pickup. No upgraded spring or porting, no accusump. I run about 6.5 quarts of oil. The rear section of our pan holds over 4 quarts, with 2 quarts up front and a half across the top of everything.

Oil pressure is always pegged at 80 psi on track, and I ran the car at Road America, Mid Ohio, Blackhawk Farms, Gingerman, and Autobahn for a total of 10 days before shipping product. Some of you may know that a couple of these tracks are notorious for causing oil pressure drops.

So I know our product works great within these parameters, but it hasnít been tested as far beyond the factory redline as Emilioís engine. As with any new idea, it takes industry leaders like Emilio and John to keep pushing the limits Ė something I certainly appreciate.

Here is what I do know about our kit, just as a heads up to current and future customers:

Iíve been running this k24a2 to 8200rpm since 2012, probably have 75 hours on it to be conservative. It went into the Miata at the beginning of 2014. Stock Type S oil pump, and our pan/pickup. No upgraded spring or porting, no accusump. I run about 6.5 quarts of oil. The rear section of our pan holds over 4 quarts, with 2 quarts up front and a half across the top of everything.

Oil pressure is always pegged at 80 psi on track, and I ran the car at Road America, Mid Ohio, Blackhawk Farms, Gingerman, and Autobahn for a total of 10 days before shipping product. Some of you may know that a couple of these tracks are notorious for causing oil pressure drops.

So I know our product works great within these parameters, but it hasnít been tested as far beyond the factory redline as Emilioís engine. As with any new idea, it takes industry leaders like Emilio and John to keep pushing the limits Ė something I certainly appreciate.

__________________

KPower Industries

Home of the original KMiata Swap

K24 NC swap is coming in 2024! Learn more

info@kpower.industries

Follow us on Facebook and Instagram

KPower Industries

Home of the original KMiata Swap

K24 NC swap is coming in 2024! Learn more

info@kpower.industries

Follow us on Facebook and Instagram

#109

Yes, I would agree the oiling system is the weakest aspect of the k motors.

The Grand Am cars definitely had/have problems if you don't run a baffled pan and/or an accusump.

Most of our engine failures when we were running the 2.0L Grand am cars were oil pressure related...some of which were assembly errors.

It sucks you have to dump so much money into the oiling system.

The Grand Am cars definitely had/have problems if you don't run a baffled pan and/or an accusump.

Most of our engine failures when we were running the 2.0L Grand am cars were oil pressure related...some of which were assembly errors.

It sucks you have to dump so much money into the oiling system.

#110

Oen other variable is the oil squirters. K24 doesn't have them, K20 does. They use up some volume and contribute to the system demands. I polled John about the system as it pertains to the K24A2. He thought 7500 or so would retain OEM like longevity. As K24's don't make much power above that without cams and porting, it makes sense to stay below 8k anyway. Sort of like 8k with a stock cam NB1 or NB2 engine. They can be made to rev there with stock cams and forged internals but quit making useful power by about 7200. Beyond that, ported pump and accusump would be a good idea. Keep in mind, this is counter to David's direct observed data so take that as an educated guess on Hytech's part.

__________________

#111

Oen other variable is the oil squirters. K24 doesn't have them, K20 does. They use up some volume and contribute to the system demands. I polled John about the system as it pertains to the K24A2. He thought 7500 or so would retain OEM like longevity. As K24's don't make much power above that without cams and porting, it makes sense to stay below 8k anyway. Sort of like 8k with a stock cam NB1 or NB2 engine. They can be made to rev there with stock cams and forged internals but quit making useful power by about 7200. Beyond that, ported pump and accusump would be a good idea. Keep in mind, this is counter to David's direct observed data so take that as an educated guess on Hytech's part.

As you mentioned, all I can share is my direct experience. But if you hop on k20a.org, you’ll find lots of road racing guys running stock k24a2 engines to 8000 rpm in a road racing environment (common in Honda Challenge).

There is a lot of good data on piston speeds as it relates to engine longevity using OEM Honda cast pistons. But as it stands, our motor is still healthy and we are on our way to 100+ hours on a $1000 junkyard engine putting out 230-240whp depending on chassis. Aaaand now it will probably blow up next event….

Edit: also worth noting, a k24a2 does make great power past 7500 rpm. 8000-8200 on stock ’06 TSX cams is typical. But yes, beyond that, cams and higher compression are key.

__________________

KPower Industries

Home of the original KMiata Swap

K24 NC swap is coming in 2024! Learn more

info@kpower.industries

Follow us on Facebook and Instagram

KPower Industries

Home of the original KMiata Swap

K24 NC swap is coming in 2024! Learn more

info@kpower.industries

Follow us on Facebook and Instagram

Last edited by KMiata; 03-05-2015 at 05:51 PM.

#112

The whole reason I chose a 99-00 NB with a K24 was to follow known working solutions. Did not want to be a pioneer, given my timeframes. Glad that Emilio has the time/resource to push the envelope for the benefit of others. Thanks!

Interesting discussion on oiling. Definitely the one Achilles Heel of the K-series. First K20 I owned blew up due to oiling problems...the classic issue of unbaffled sump allowing all the oil to run up the chain case in left-hand turns. Since running baffled pans, I've not had a direct oiling related failure (several money shifts, though).

A lot of things come together nicely for the K24, as far as rev limit. Oiling, piston/rod strength, and valvetrain debounce. If you use the K20 oil pump, you get enough oiling rev range to support the expanded revs of a built K24. OE cast pistons get squirters in the hi-po K-series models to keep them cool. Not needed when you go to forgings, plus the oil volume is more useful elsewhere in the motor. I always limit my stock internal K24A2's to 8000rpm, shifting at 7600. Built motors I shift at 8000-8200 and rev limit at 8500 for the track. With cams/compression/porting, power does not start to fall off until 8000 (torque starts to drop gradually at 7000).

Interesting discussion on oiling. Definitely the one Achilles Heel of the K-series. First K20 I owned blew up due to oiling problems...the classic issue of unbaffled sump allowing all the oil to run up the chain case in left-hand turns. Since running baffled pans, I've not had a direct oiling related failure (several money shifts, though).

A lot of things come together nicely for the K24, as far as rev limit. Oiling, piston/rod strength, and valvetrain debounce. If you use the K20 oil pump, you get enough oiling rev range to support the expanded revs of a built K24. OE cast pistons get squirters in the hi-po K-series models to keep them cool. Not needed when you go to forgings, plus the oil volume is more useful elsewhere in the motor. I always limit my stock internal K24A2's to 8000rpm, shifting at 7600. Built motors I shift at 8000-8200 and rev limit at 8500 for the track. With cams/compression/porting, power does not start to fall off until 8000 (torque starts to drop gradually at 7000).

#116

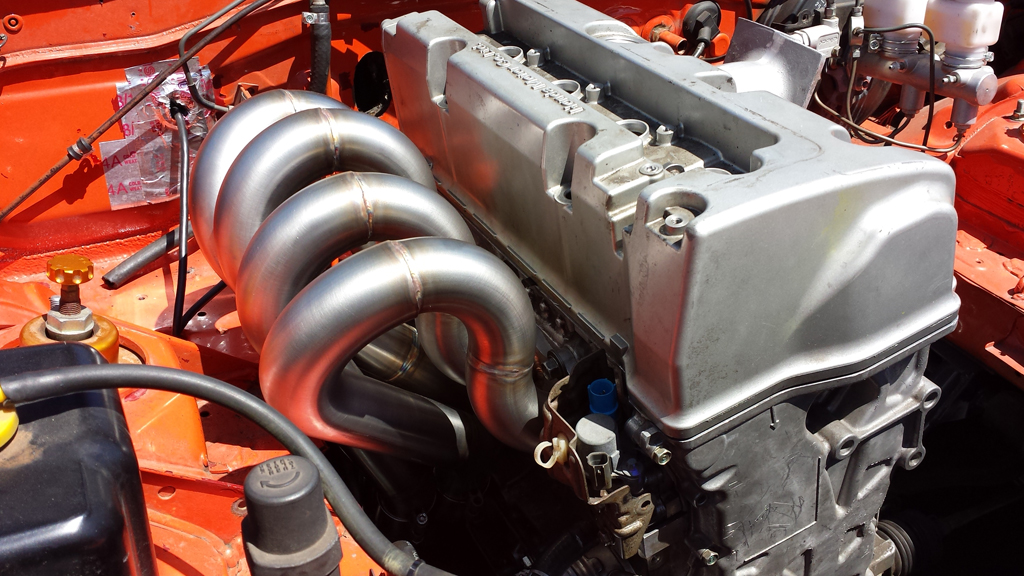

looks great!

__________________

KPower Industries

Home of the original KMiata Swap

K24 NC swap is coming in 2024! Learn more

info@kpower.industries

Follow us on Facebook and Instagram

KPower Industries

Home of the original KMiata Swap

K24 NC swap is coming in 2024! Learn more

info@kpower.industries

Follow us on Facebook and Instagram

#120

Looks great, well done. I can see the top of the collector alongside the engine, are you going 4-1 or 4-2-1? Also would love to see a shot underneath the car whenever you have it in the air.

__________________

KPower Industries

Home of the original KMiata Swap

K24 NC swap is coming in 2024! Learn more

info@kpower.industries

Follow us on Facebook and Instagram

KPower Industries

Home of the original KMiata Swap

K24 NC swap is coming in 2024! Learn more

info@kpower.industries

Follow us on Facebook and Instagram