Post how much you spent on your video card to play Candy Crush

#121

Well that explains the CPU Fan message on boot, and the random lock ups. CPU fan had completely locked up. A few more fans are starting to fail too. Those Kaze fans move some air, but at the trade off for life span. Lots of bearing noise on all but one of them. I guess I'll buy a crate of whatever my favorite Cooler Master fans used to be.

EDIT: Newegg has a $6 savings promo code on the Cooler Master Silent 120mm 4-pack. Picked up the 4 pack for $17.97 shipped with 3 day UPS. Only move 1/3 the cfm, but still good enough.

Promo code good for 4 more days.

http://www.newegg.com/Product/Produc...82E16835103052

EDIT: Newegg has a $6 savings promo code on the Cooler Master Silent 120mm 4-pack. Picked up the 4 pack for $17.97 shipped with 3 day UPS. Only move 1/3 the cfm, but still good enough.

Promo code good for 4 more days.

http://www.newegg.com/Product/Produc...82E16835103052

#124

For in-car (Megasquirt + Audio testing) I use a 2009 MacBook Pro I bought used a year ago for $320. It had 8GB RAM and I've replaced the battery, added a 125 GB Solid State drive (SSD) in place of the OEM 250 GB HD and a 1TB conventional drive (HD) in place of the factory DVD drive.

Running OSX 10.9 "Mavericks", with Parallels9 I have two main WindowsOS Virtual machines (VM); one WinXP SP3 and one Windows8 Professional. The WinXP VM is used for motor tuning, and to run Dynomation5. A Belkin Serial to USB adapter works flawlessly.

Running OSX 10.9 "Mavericks", with Parallels9 I have two main WindowsOS Virtual machines (VM); one WinXP SP3 and one Windows8 Professional. The WinXP VM is used for motor tuning, and to run Dynomation5. A Belkin Serial to USB adapter works flawlessly.

#128

Joined: Sep 2005

Posts: 33,556

Total Cats: 6,933

From: Chicago. (The less-murder part.)

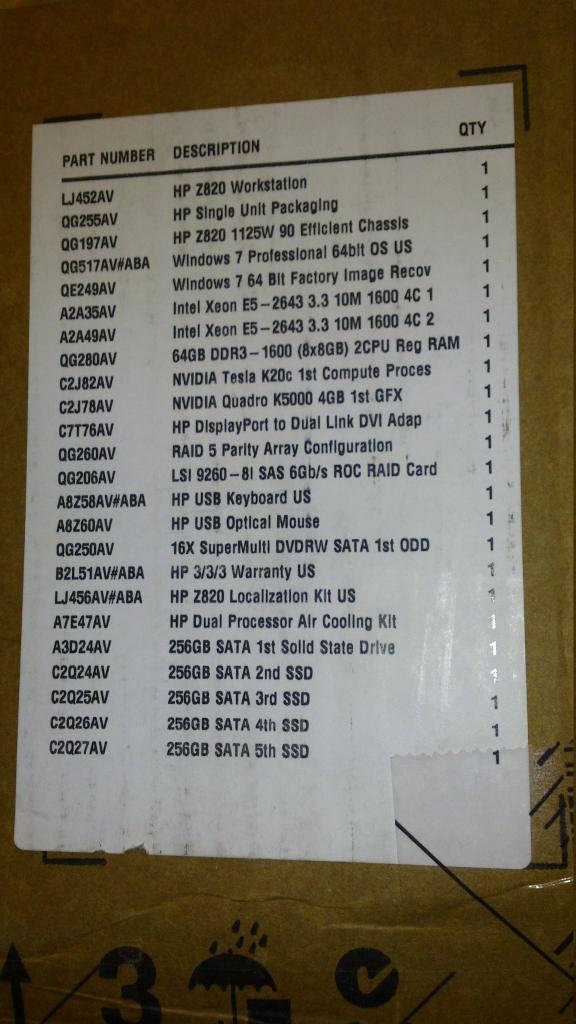

For those who don't know, the K20/K40 is practically a supercomputer on a PCI card. Totally useless for 99.9999% of "ordinary" computing applications, but just the thing when you need to compute the trajectory of every single subatomic particle in the first few milliseconds of a thermonuclear explosion, for example.

#130

Welp. Let the lapping commence. When taking off my H212 fan the other night I felt the compound that was dried up pop and then the entire heat sink starting floating. So I'm guessing the contact patch is all fuxxored now. Will go all out on this lap, down to copper, with a full polish with compounds on both processor and the H212. I need to come up with something to make the heat sink lock down tighter. I could never get it to pull down tight enough to not slide down under its own weight, putting it off center of the processor. I'm also going to do some case mods. I'm going to drill a grid of holes on the mobo side of the case, and through the mounting plate and install a fan to blow directly on the back of the processor and northbridge. The back side of the motherboard must get pretty hot since it has little to no ventilation. Might even get around to rigging up some of my spare 80mm case fans on the memory modules to draw air away from them and the motherboard.

I'm thinking I'm going to forego using any thermal paste. Once I get both surfaces lapped, I think I can take some fine compound and lap the two surfaces against one another to further flatten them together. They probably still won't be PERFECT, but it should be damn close. I guess it's worth a try anyway. Do it without, then try it with and see if it changes. If I do put any one, it's going to be super thin. Maybe use a razor blade to spread a tiny bead down the middle, just to cover the die.

I'm thinking I'm going to forego using any thermal paste. Once I get both surfaces lapped, I think I can take some fine compound and lap the two surfaces against one another to further flatten them together. They probably still won't be PERFECT, but it should be damn close. I guess it's worth a try anyway. Do it without, then try it with and see if it changes. If I do put any one, it's going to be super thin. Maybe use a razor blade to spread a tiny bead down the middle, just to cover the die.

Last edited by NA6C-Guy; 02-10-2014 at 09:06 AM.

#133

Why would that be a bad idea given both surfaces are flat and fully in contact? All thermal paste can possibly do is lessen heat transfer, again, given that both surfaces are perfectly flat. Even if it's not better, it's not going to burn up in the time it takes to load the OS and check the temps. I've run with no cooler for more than a few minutes without much issue. I've rear quite a few threads on various forums with people getting better results without it, since both metal surfaces are in direct contact, instead of a paper thin silicon/metallic paste layer between them. Probably will end up with some on there though. It's meant more as an experiment.

I would never do it with non lapped processor and heat sink, since you would end up with a pocket of air between the two surfaces, which will make for higher than normal temps. Especially with Intel.

I would never do it with non lapped processor and heat sink, since you would end up with a pocket of air between the two surfaces, which will make for higher than normal temps. Especially with Intel.

Last edited by NA6C-Guy; 02-10-2014 at 01:02 PM.

#134

Joined: Sep 2005

Posts: 33,556

Total Cats: 6,933

From: Chicago. (The less-murder part.)

If I was doing this work in a laboratory, using whatever honing machine they use at NASA JPL when they need something to be flat and smooth, even then I'd still use a tiny little schmear of thermal paste between the two surfaces.

I assume that you are using sandpaper, a kitchen table, and your hands.

#135

Because at a microscopic level, the surfaces are neither flat nor smooth.

If I was doing this work in a laboratory, using whatever honing machine they use at NASA JPL when they need something to be flat and smooth, even then I'd still use a tiny little schmear of thermal paste between the two surfaces.

I assume that you are using sandpaper, a kitchen table, and your hands.

If I was doing this work in a laboratory, using whatever honing machine they use at NASA JPL when they need something to be flat and smooth, even then I'd still use a tiny little schmear of thermal paste between the two surfaces.

I assume that you are using sandpaper, a kitchen table, and your hands.

#136

Joined: Sep 2005

Posts: 33,556

Total Cats: 6,933

From: Chicago. (The less-murder part.)

On the other hand, hey, what do I know? I'm sure that a couple of kids polishing their CPUs in their parents' basement know more about thermodynamics and heat transfer than the engineers who design spaceflight-certified embedded microcontrollers. I guess they (the engineers) are just pawns of the thermal-paste-manufacturing cabal.

Should be able to get a glass like finish, but I guess that's not enough, so say you.

#138

On the one hand, I'd be curious to see these accounts which claim that no thermal paste is needed after lapping of the CPU and cooler.

On the other hand, hey, what do I know? I'm sure that a couple of kids polishing their CPUs in their parents' basement know more about thermodynamics and heat transfer than the engineers who design spaceflight-certified embedded microcontrollers. I guess they (the engineers) are just pawns of the thermal-paste-manufacturing cabal.

If you get really bored some afternoon, have a look at a piece of glass under a scanning electronic microscope.

On the other hand, hey, what do I know? I'm sure that a couple of kids polishing their CPUs in their parents' basement know more about thermodynamics and heat transfer than the engineers who design spaceflight-certified embedded microcontrollers. I guess they (the engineers) are just pawns of the thermal-paste-manufacturing cabal.

If you get really bored some afternoon, have a look at a piece of glass under a scanning electronic microscope.

I know a piece of glass isn't anything near flat or free of pits, valleys, ridges, ect. I just wasn't aware that microscopic air pockets would be enough to cause cooling issues on something like a processor. I was thinking it would need to be on an almost visible to the eye level before it would cause major problems. Or something on a much higher temp range.

#140

Joined: Sep 2005

Posts: 33,556

Total Cats: 6,933

From: Chicago. (The less-murder part.)

I know a piece of glass isn't anything near flat or free of pits, valleys, ridges, ect. I just wasn't aware that microscopic air pockets would be enough to cause cooling issues on something like a processor. I was thinking it would need to be on an almost visible to the eye level before it would cause major problems.

Also, don't fear thermal paste as being somehow evil. Below the surface of that heat-spreader (the metallic outer shell of the CPU), there's thermal paste between it and the actual die itself.

Here's what a Haswell architecture i7-4770 looks like with the lid pried off:

And here's an Athlon x2 5600, similarly dismantled:

A lot of older CPUs used fluxless solder between the die and the heat-spreader, but these days they're using a paste much like what you put on the outside between the case and the fan/heatsink assembly.