The custom fabrication thread! (Post pics of stuff you have made)

#863

why didn't you machine an AN fitting right onto it?

Or step the inlet a hair for a weld-on type AN fitting if you don't have a threading attachment for your lathe?

I have a similar adapter for power steering pump to AN. I had it threaded to use a pipe thread adapter, but it works much better and is a lot cleaner in function with the welded on AN adapter.

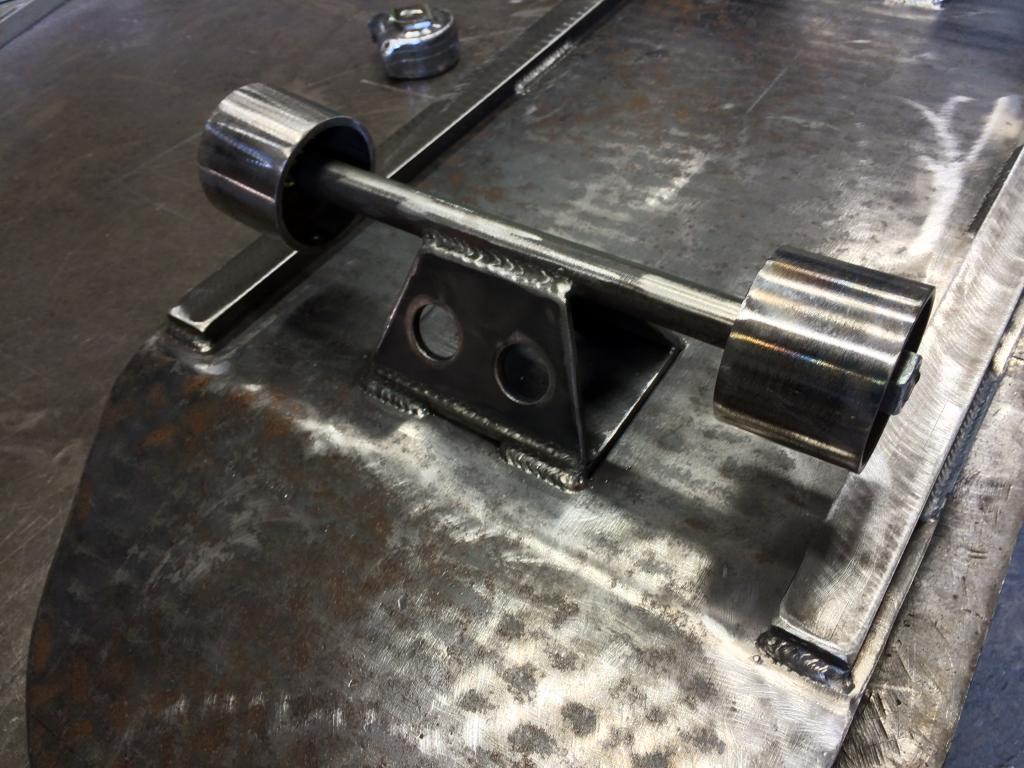

Ps adapter by HellaFab, on Flickr

Ps adapter by HellaFab, on Flickr

Or step the inlet a hair for a weld-on type AN fitting if you don't have a threading attachment for your lathe?

I have a similar adapter for power steering pump to AN. I had it threaded to use a pipe thread adapter, but it works much better and is a lot cleaner in function with the welded on AN adapter.

Ps adapter by HellaFab, on Flickr

Ps adapter by HellaFab, on Flickr

#864

Machine a male AN fitting? It would have significantly add more cost and complexity to the machining, and seeing it's only a one off part I was trying to make it cheap as possible.

I thought of just making a simple adapter (general shape of it) which would accept welded on AN fittings, but I don't have the capability to weld aluminum :(

I thought of just making a simple adapter (general shape of it) which would accept welded on AN fittings, but I don't have the capability to weld aluminum :(

#865

Having only female thread exposed on the block isnt the worst thing. On the one hand you have an additional threaded connection which could leak. On the other you're less likely to turn that expensive machined bit into a hunk of scrap by accidentally hitting it putting the engine in or out, or doing something with the coolant line off.

#867

Leafy, this was my train of thought, I wanted to reduce the risk of damaging the threads or any of the sealing surfaces. A -20AN (if I were to machine a male AN fitting to accept the lower radiator hose; assuming I weld a -20AN fitting on the radiator) has a thread of 1-5/8 -12 and the die is roughly ~$140 on mcmaster carr.

I'm also aware of the -AN caps, but that's just added cost

Also I didn't even think the female threads near a heat source would not be ideal. Thermal expansion which would cause leaks? Just taking a guess at it. If you could elaborate on that thought, that would be awesome.

I'm also aware of the -AN caps, but that's just added cost

Also I didn't even think the female threads near a heat source would not be ideal. Thermal expansion which would cause leaks? Just taking a guess at it. If you could elaborate on that thought, that would be awesome.

#868

Your design is exactly what tapered threads are for. Just use a proper tape or paste on the threads. It's funny to see people go through the effort to weld male AN fittings on things... The last thing I want is a machined surface sticking out that would require engine removal to fix...

Leaks from thermal effects? Look at every single oil sandwich plate with AN adapters if you want to feel better about it.

Leaks from thermal effects? Look at every single oil sandwich plate with AN adapters if you want to feel better about it.

#871

1. a tapered thread adapter with what is pictured above will be significantly longer length than a similar one with the final thread type for the fitting; and

2. You only have one point of failure with a one piece adapter

3.The lower water neck is bolted to the water pump directly and is easily accessible with 2 12mm head through bolts. it can come off in less than 15 seconds if your cooling system is dry, with the engine in the engine bay.

I don't know how many of those sandwich adapters you have used, but every one that I have seen on others cars have very distinct evidence of leakage with high temperature oil at normal operating temperatures that modified cars run at.

#875

NPTF has sharper/larger thread crest and root, physically deforms as you tighten it up. These parts are made to a much tighter tolerance, using them when you don't need a dry seal is silly.

The leakage point from a NPT thread without tape is between the crest and root of the threads, spiraling all the way down. Not a huge leak point, by any means. The flanks of the threads seal, the whole way down.

NPT is supposed to be lubed, no matter what anyone says. It doesn't always have to be taped to keep from leaking though.

I'd bet most cheap NPT fittings you buy at the hardware store are so out of tolerance they behave more like a NPTF than NPT...

The leakage point from a NPT thread without tape is between the crest and root of the threads, spiraling all the way down. Not a huge leak point, by any means. The flanks of the threads seal, the whole way down.

NPT is supposed to be lubed, no matter what anyone says. It doesn't always have to be taped to keep from leaking though.

I'd bet most cheap NPT fittings you buy at the hardware store are so out of tolerance they behave more like a NPTF than NPT...

#880

Just discovered this thread... LOVE it! I'll try to take some time to read it all the way through tonight.

Not Miata related, but I built bumpers from (mostly) scratch for my '92 Bronco (my other money pit project) this year...

Rear:

The driver's side swingout will get gas/water cans, but I need to buy some cans so I can finish the carrier.

Front:

Not Miata related, but I built bumpers from (mostly) scratch for my '92 Bronco (my other money pit project) this year...

Rear:

The driver's side swingout will get gas/water cans, but I need to buy some cans so I can finish the carrier.

Front: