The custom fabrication thread! (Post pics of stuff you have made)

#809

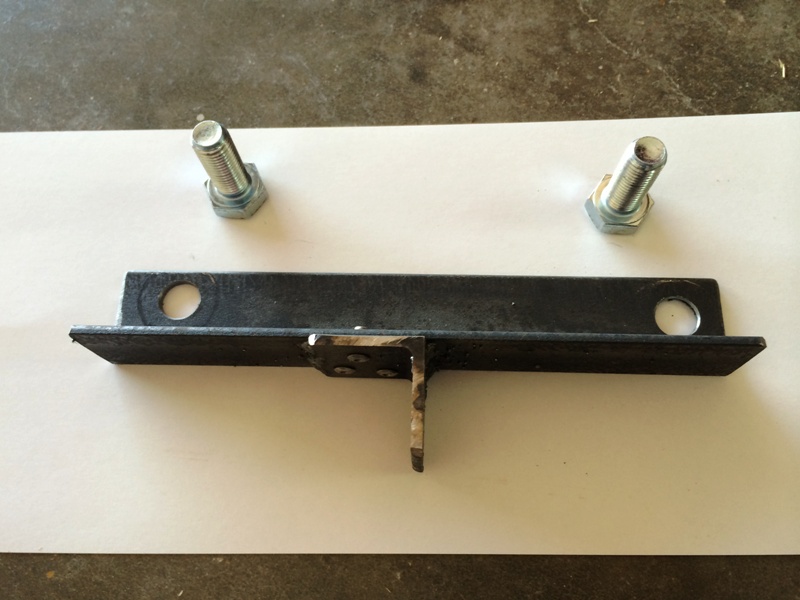

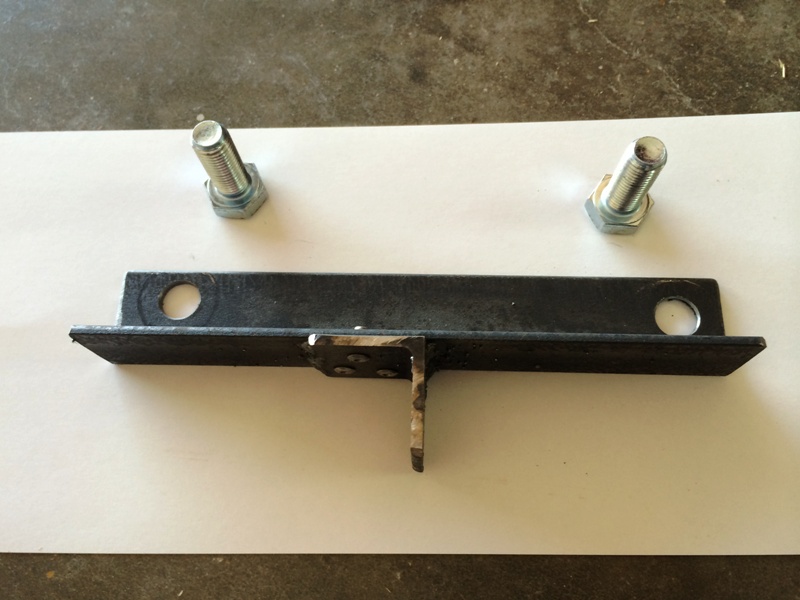

Having 2 Miatas and being a track addict, I seem to be assembling more engines than I used to. One part of assembly that was always a bit of a pain was torqueing the flywheel and crankshalf pulley bolts. Mazda has a SST (Special Service Tool) that locks the flywheel for this purpose. So, made my own out of some 1.25" angle iron. Pictures speak for themselves. I did the rivets and then went ahead and hit it with a welder. I don't know if rivets alone would have been sturdy enough.

Works great!

Works great!

#814

That is what I would figure also. Here is the story of the top hats. My friend wanted them welded up. He said he would be over one night with the stuff to be welded. I expected him to show up and have the top hats in hand with the pipes ready to roll. He shows up with the top hats still on the car. So had to remove them from there. He did bring a hole saw, but it was a shitty one and I only have a HF $9.99 drill. So drilling through them did not work well. They then took them to a friends house with a drill press. Unfortunately the hole saw was to messed up to make the cut. He took the top hats to his school and tried with a big *** drill press. Not sure why that failed. He then used some other tool and got the to hats into two pieces. The cuts were horrible and not very evenly around. So I did the best I could with what I was given on the welding.

#818

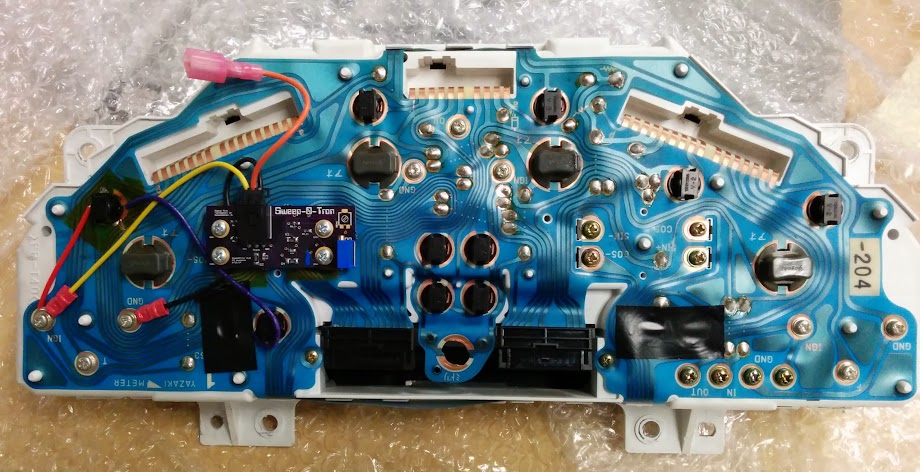

A different kind of fab, but I thought you all might enjoy it.

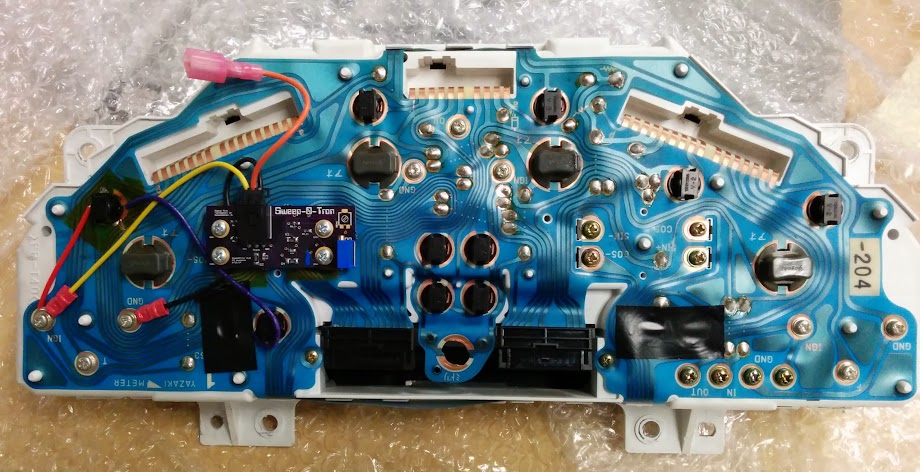

I bought a JDM 6-speed cluster for my NB.

I found that when using a US odometer unit, the speedometer wouldn't read right because the JDM speedometer tops out at around 190kph while the US speedometer is 260kph. The odometer drives the needle by angle, so it ended up being about 22% off from a true reading.

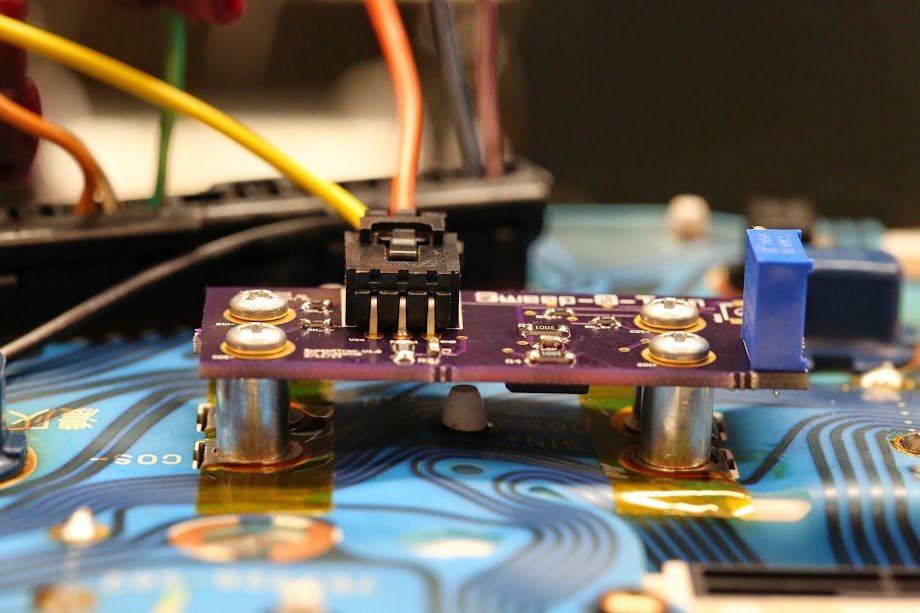

I taught myself some electronics and designed and built a custom circuit board that allows arbitrary scaling of the speedometer or tachometer. It reads the raw tach/vss signal from the cluster via a T-tap but doesn't require any permanent modification to the cluster. It's actually more accurate and has a faster response time than the stock gauges. On my cluster, I set it up to read mph rather than kph, so it's now a 180mph speedometer

The circuit is relatively simple: it implements a standalone air core motor driver and has a trimpot to fine-tune the scale while under way. It took about three board layout revisions to get the design perfect, but it works great now. On my cluster, I was able to get it within +/-1mph from GPS speed reading.

I bought a JDM 6-speed cluster for my NB.

I found that when using a US odometer unit, the speedometer wouldn't read right because the JDM speedometer tops out at around 190kph while the US speedometer is 260kph. The odometer drives the needle by angle, so it ended up being about 22% off from a true reading.

I taught myself some electronics and designed and built a custom circuit board that allows arbitrary scaling of the speedometer or tachometer. It reads the raw tach/vss signal from the cluster via a T-tap but doesn't require any permanent modification to the cluster. It's actually more accurate and has a faster response time than the stock gauges. On my cluster, I set it up to read mph rather than kph, so it's now a 180mph speedometer

The circuit is relatively simple: it implements a standalone air core motor driver and has a trimpot to fine-tune the scale while under way. It took about three board layout revisions to get the design perfect, but it works great now. On my cluster, I was able to get it within +/-1mph from GPS speed reading.

#819

I'll post a picture here that I posted in my personal fab thread. Check out the rest of the work in my thread if you havent already.

HellaFab Miata Vband bottom mount manifold by HellaFab, on Flickr

HellaFab Miata Vband bottom mount manifold by HellaFab, on Flickr

I have an EFR manifold coming up next.

HellaFab Miata Vband bottom mount manifold by HellaFab, on Flickr

HellaFab Miata Vband bottom mount manifold by HellaFab, on FlickrI have an EFR manifold coming up next.