Why NOT to let your head be belt surfaced

#1

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

Why not to let your head be belt surfaced/sanded

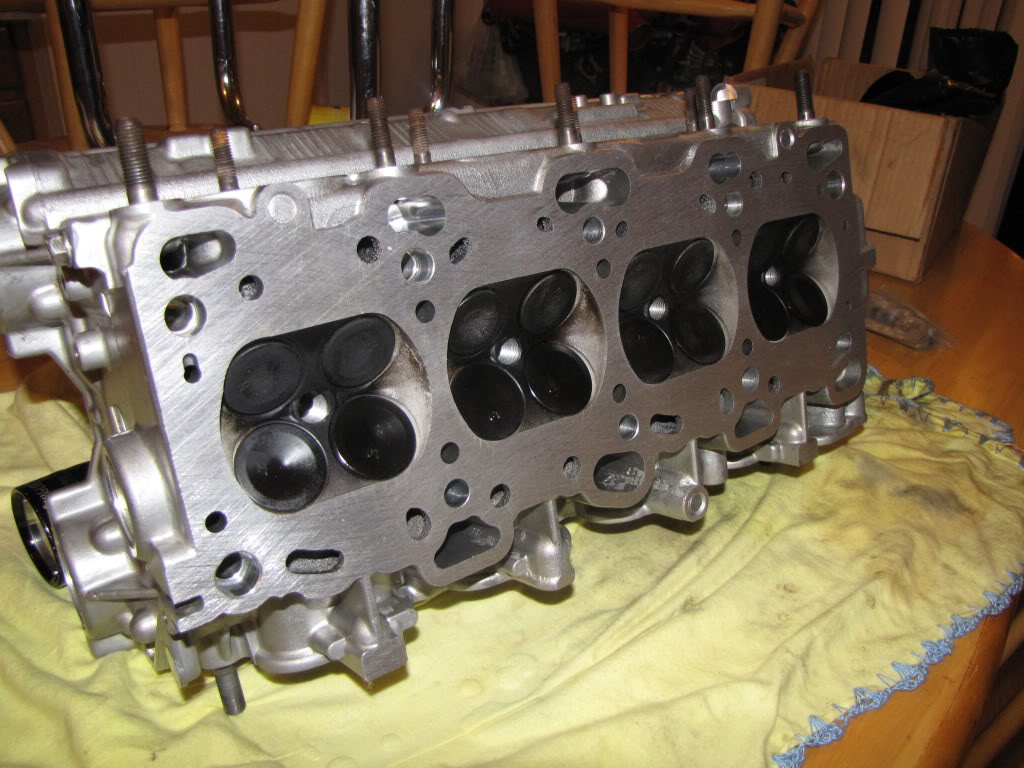

The subject head is a Mitsu 4G63T from an Evo VIII

This head was in very good shape to start.

The head was pulled due to a bottom end problem.

It was not overheated.

It was taken to another shop, NOT mine.

The customer was told it was surfaced .003-.004

It was then run and the bottom end failed, Then came to my shop.

The first thing I did was to check the thickness of the head.

I know a belt surfaced head will not be parallel nor square along with not having the proper surface finish for a MLS head gasket.

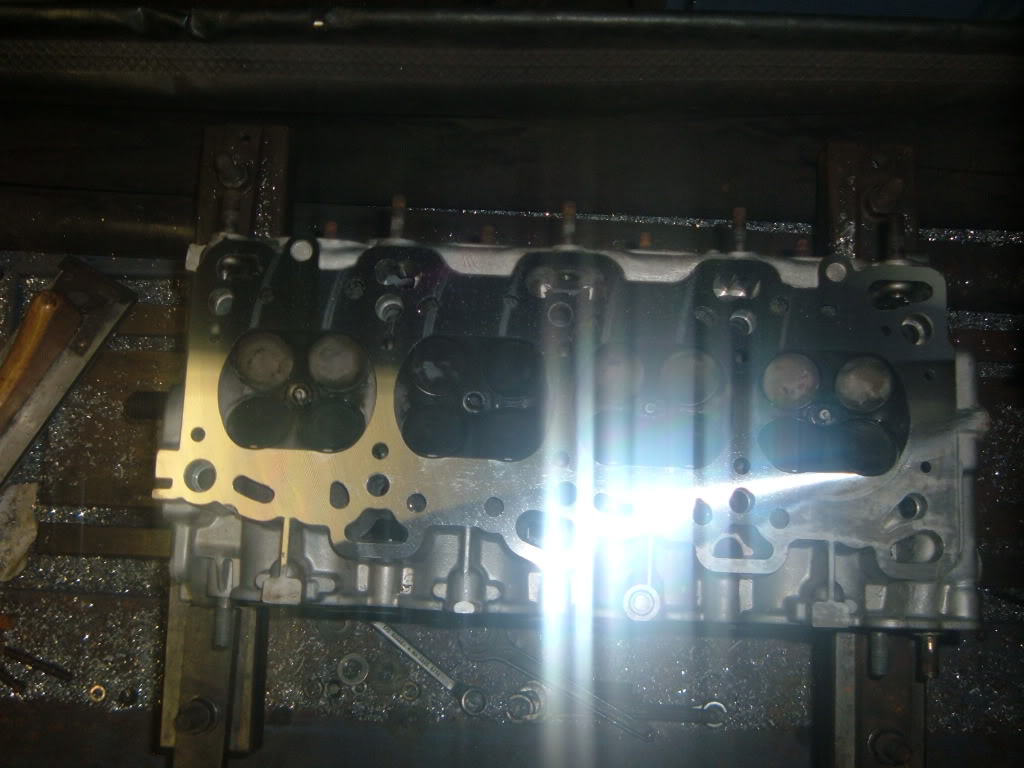

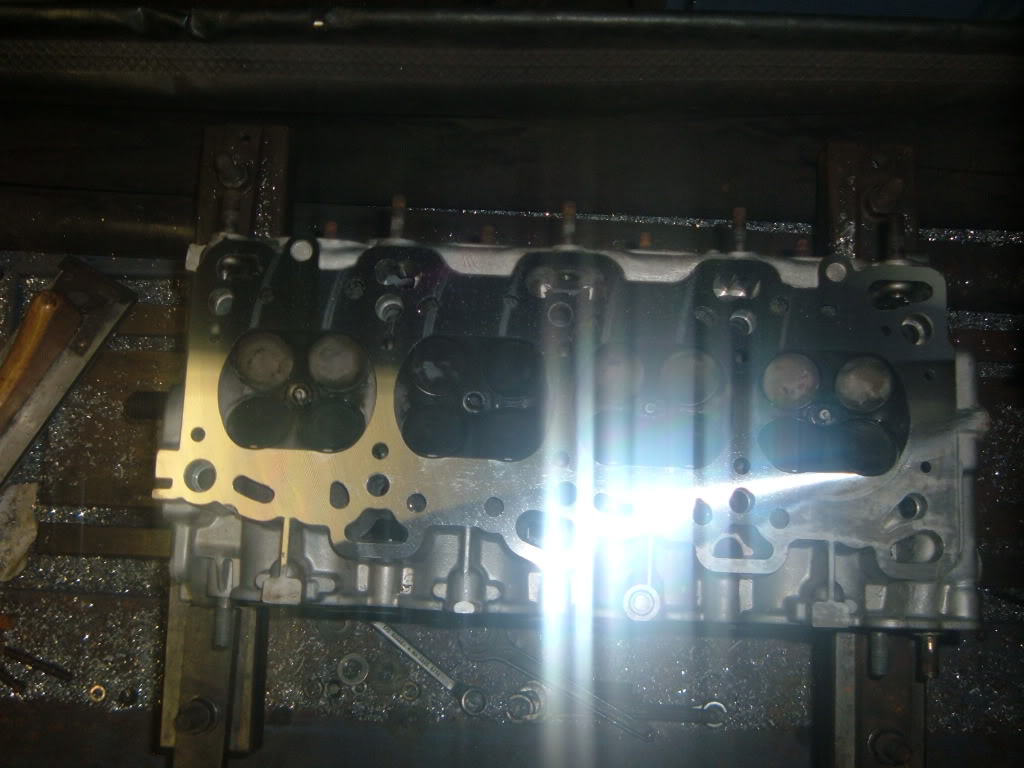

This is the surface finish left by a belt sander

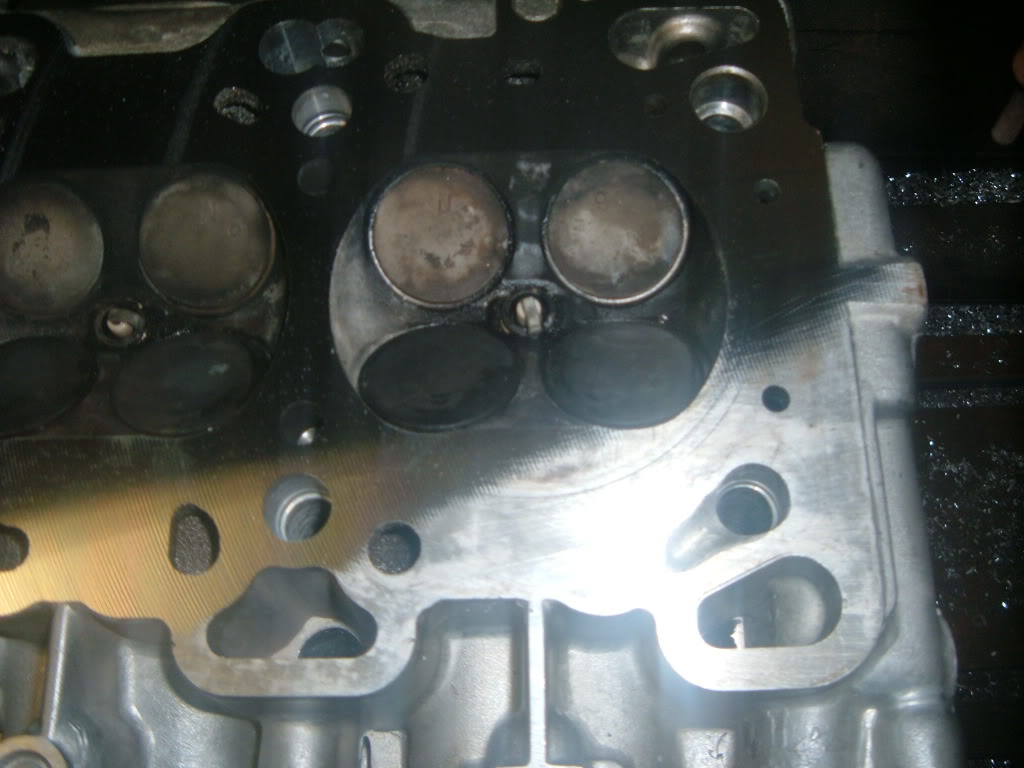

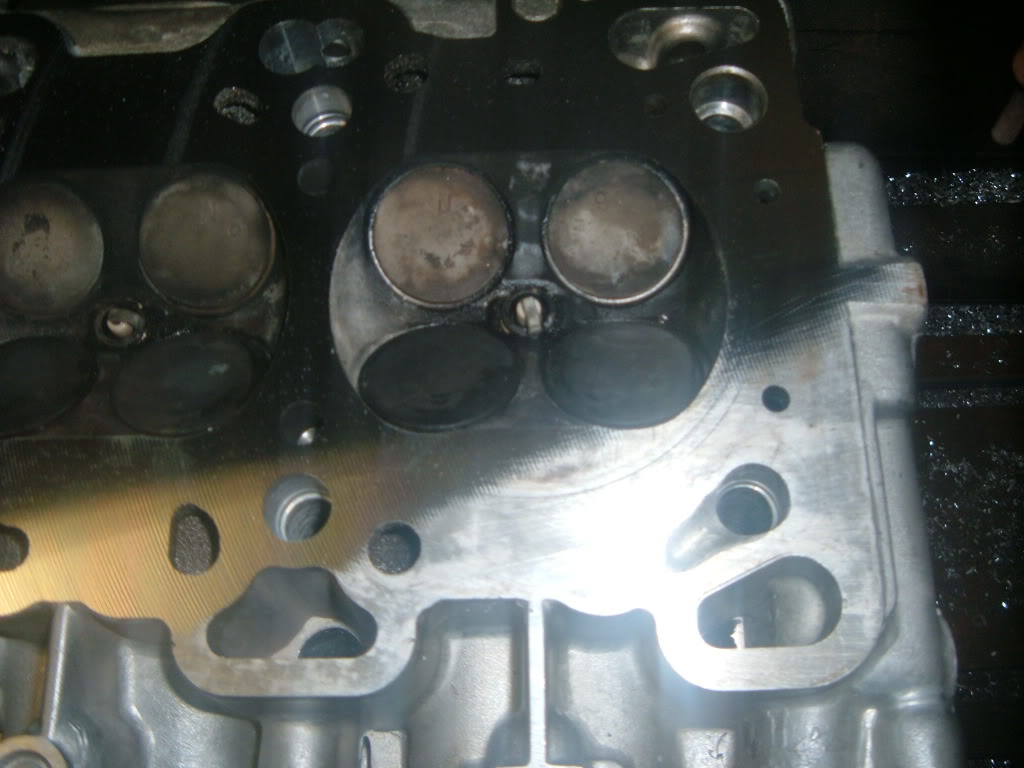

This is how the surface looked after I milled appox .002

It did cut most of the surface, but it was still low at one corner, and it would happen to be right around the oil feed port to the head.

I made another pass of about .002

This is how it looked.

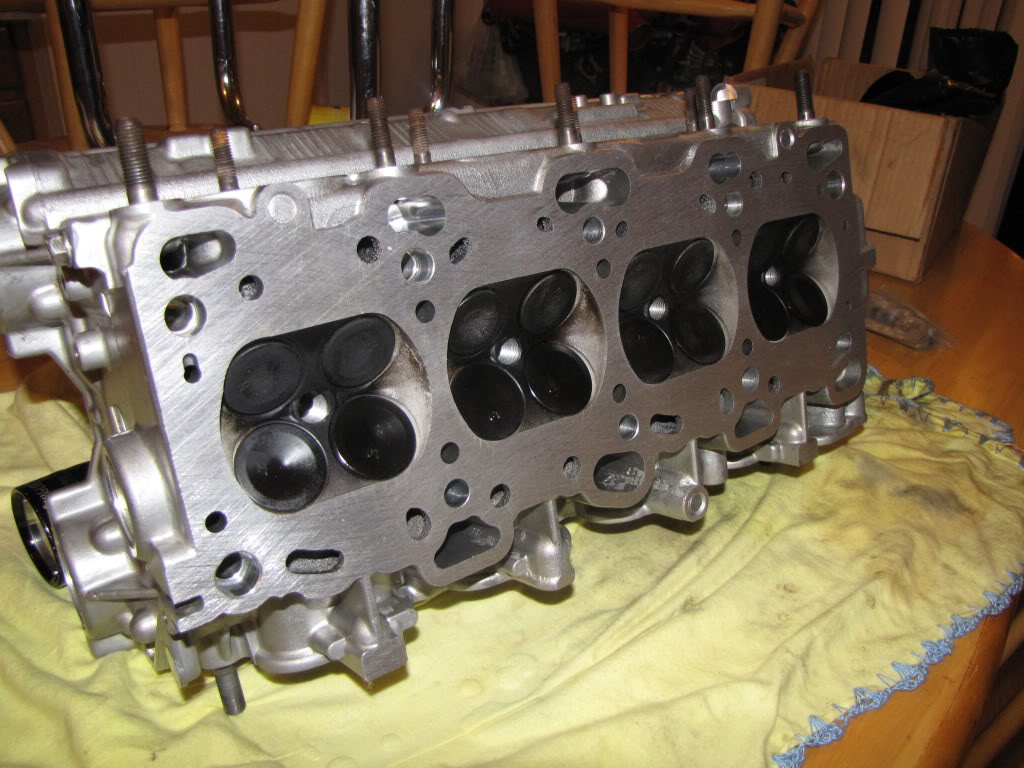

I made another .002 cut

And was to this

So one more pass to clean the gasket surface, and proper clamping force will be kept on the head gasket.

I measured the head again, and it was 5.183 at all 4 corners

When I cc’ed a combustion chamber it was 44cc

I also did “oil port mod #1” before I surfaced the head.

This head is now .002 below AREA min spec, but is still a useable head.

The subject head is a Mitsu 4G63T from an Evo VIII

This head was in very good shape to start.

The head was pulled due to a bottom end problem.

It was not overheated.

It was taken to another shop, NOT mine.

The customer was told it was surfaced .003-.004

It was then run and the bottom end failed, Then came to my shop.

The first thing I did was to check the thickness of the head.

I know a belt surfaced head will not be parallel nor square along with not having the proper surface finish for a MLS head gasket.

This is the surface finish left by a belt sander

This is how the surface looked after I milled appox .002

It did cut most of the surface, but it was still low at one corner, and it would happen to be right around the oil feed port to the head.

I made another pass of about .002

This is how it looked.

I made another .002 cut

And was to this

So one more pass to clean the gasket surface, and proper clamping force will be kept on the head gasket.

I measured the head again, and it was 5.183 at all 4 corners

When I cc’ed a combustion chamber it was 44cc

I also did “oil port mod #1” before I surfaced the head.

This head is now .002 below AREA min spec, but is still a useable head.

#7

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

I have an old Fujifilm Finepix 4 mega pixel camera I use around the shop.

From what I can remember I did not use a flash, I just have alot of lights up and on in the shop.

phillyb.. It is a belt surfacer, but it is nothing more than an overgrown belt sander, alot of machineshops have them and use them, they can do OK for a cast iron head with a composite gasket.

They are cheap to buy $10k and under new, and take very littler training to use, and they are quick to use.

But they mangle alum heads 99% of the time.

From what I can remember I did not use a flash, I just have alot of lights up and on in the shop.

phillyb.. It is a belt surfacer, but it is nothing more than an overgrown belt sander, alot of machineshops have them and use them, they can do OK for a cast iron head with a composite gasket.

They are cheap to buy $10k and under new, and take very littler training to use, and they are quick to use.

But they mangle alum heads 99% of the time.

Last edited by BogusSVO; 03-21-2012 at 11:45 AM.

#12

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

Luke..... I just came here to learn about the 1.8l, and share some of what I know and do. I am a small one man shop.

Maiter.... Honestly, I can not say what I did to fix the 2 valves that I tinged, it has been a few years since I orginaly wrote this.

But knowing what I do of hot spots and trubos, I proberly pitched the valves and grabbed a coupple stock used replacements and seated them in.

Maiter.... Honestly, I can not say what I did to fix the 2 valves that I tinged, it has been a few years since I orginaly wrote this.

But knowing what I do of hot spots and trubos, I proberly pitched the valves and grabbed a coupple stock used replacements and seated them in.

Thread

Thread Starter

Forum

Replies

Last Post

chris101

Miata parts for sale/trade

2

10-09-2015 10:08 AM