Tuning VVT - problem with Oil Temperature

#1

Thread Starter

Junior Member

iTrader: (10)

Joined: Jun 2011

Posts: 299

Total Cats: 3

From: Detroit Burbs

Hey guys,

My '90 1.8 VVT conversion is now on the road finally. I am using a custom standalone engine management system (long story), and have been playing with the VVT tuning.

By VVT tuning, I mean tuning the PID control values in order to acheive the target VVT position - not changing the target VVT position for optimum power/torque/fuel economy/whatever. I'll play with that later.

Based on the performance of the VVT response - I can provide proportional and derivative terms that work just fine (nice and stable, with good transient response) when the engine is fully warm.

However, once the engine is cold, the VVT goes crazy! It is totally unstable, and you can even see the instability in the stock oil pressure gauge.

In my software, I have included a factor to reduce the gain of the PID based on engine coolant temp. This works until the engine coolant temp gets to 90C (fully warm) but the oil temp isn't quite fully warm yet. Crazy unstable!

I guess my first thought is to add an oil temp sensor as an input, and use that to change the PID gain. But, I'm just curious how the VVTuner or MS3 takes care of this problem, as I don't think they use an oil temp input.

Any thoughts?

Also looking for recommendations for a good cheap OEM temp sensor with 1/8" NPT threads with a known transfer function (resistance versus temp) and easy to find junkyard connector so I can wire it in to my ECU.

My '90 1.8 VVT conversion is now on the road finally. I am using a custom standalone engine management system (long story), and have been playing with the VVT tuning.

By VVT tuning, I mean tuning the PID control values in order to acheive the target VVT position - not changing the target VVT position for optimum power/torque/fuel economy/whatever. I'll play with that later.

Based on the performance of the VVT response - I can provide proportional and derivative terms that work just fine (nice and stable, with good transient response) when the engine is fully warm.

However, once the engine is cold, the VVT goes crazy! It is totally unstable, and you can even see the instability in the stock oil pressure gauge.

In my software, I have included a factor to reduce the gain of the PID based on engine coolant temp. This works until the engine coolant temp gets to 90C (fully warm) but the oil temp isn't quite fully warm yet. Crazy unstable!

I guess my first thought is to add an oil temp sensor as an input, and use that to change the PID gain. But, I'm just curious how the VVTuner or MS3 takes care of this problem, as I don't think they use an oil temp input.

Any thoughts?

Also looking for recommendations for a good cheap OEM temp sensor with 1/8" NPT threads with a known transfer function (resistance versus temp) and easy to find junkyard connector so I can wire it in to my ECU.

#4

Thread Starter

Junior Member

iTrader: (10)

Joined: Jun 2011

Posts: 299

Total Cats: 3

From: Detroit Burbs

I'm greedy - I want good VVT response when cold AND hot. Seems like the oil temp sensor is the only way to achieve this.

But, then I wonder how does Mazda do this in the stock application? They didn't have an oil temp sensor, and obviously were able to overcome this issue. The only thing I can think of is that they had a software model of the oil temp (maybe based on coolant temperature, and integrated engine load over time), and used that as an input to the PID controller. I could do the same, but would need an oil temp sensor to generate the software model - which would then be unnecessary, as I could use the sensor input directly...

But, then I wonder how does Mazda do this in the stock application? They didn't have an oil temp sensor, and obviously were able to overcome this issue. The only thing I can think of is that they had a software model of the oil temp (maybe based on coolant temperature, and integrated engine load over time), and used that as an input to the PID controller. I could do the same, but would need an oil temp sensor to generate the software model - which would then be unnecessary, as I could use the sensor input directly...

#6

Thread Starter

Junior Member

iTrader: (10)

Joined: Jun 2011

Posts: 299

Total Cats: 3

From: Detroit Burbs

Well, I ended up putting in one of these:

and one of these:

Here's some warmup data from this morning. Normal relaxed pace drive in to work on city streets at 45 mph. Got a little randy at the end of the drive with a couple peaks up to redline.

Notice that Oil temp severely lags coolant temp. The drive was about 15 minutes, and Oil temp never stabilizes.

I ended putting a multiplier in to the PD factor based on Oil temp, and the control is MUCH better now. I'm still a little confused that I am the only one to run into this before...

and one of these:

Here's some warmup data from this morning. Normal relaxed pace drive in to work on city streets at 45 mph. Got a little randy at the end of the drive with a couple peaks up to redline.

Notice that Oil temp severely lags coolant temp. The drive was about 15 minutes, and Oil temp never stabilizes.

I ended putting a multiplier in to the PD factor based on Oil temp, and the control is MUCH better now. I'm still a little confused that I am the only one to run into this before...

#11

Thread Starter

Junior Member

iTrader: (10)

Joined: Jun 2011

Posts: 299

Total Cats: 3

From: Detroit Burbs

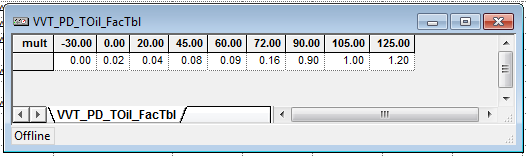

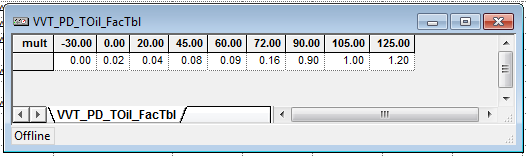

Here is the Multiplier to the P and D terms of the PID as a function of Oil temperature [in degrees C].

This is when using 5W40 Shell Rotella T6, and using the stock 1.8L oil cooler/warmer.

I'm still tweaking the table a little bit every day. I don't enable VVT until ECT > 60C.

The shape of the mutliplier curve is quite strange, and doesn't quite fit with the viscocity curve of the oil:

This is when using 5W40 Shell Rotella T6, and using the stock 1.8L oil cooler/warmer.

I'm still tweaking the table a little bit every day. I don't enable VVT until ECT > 60C.

The shape of the mutliplier curve is quite strange, and doesn't quite fit with the viscocity curve of the oil:

#14

Thread Starter

Junior Member

iTrader: (10)

Joined: Jun 2011

Posts: 299

Total Cats: 3

From: Detroit Burbs

See the first ECU on this page for some basic hardware info:

112-pin Module Family - MotoHawk

#15

I think I am experiencing exactly what you're describing here, with my ms3x.

I have been fighting a bucking/jerking/not smooth power delivery issue on my '01 for a bit. Tried all the timing map tweaks possible - nothing. Tried all the fueling tweaks possible - nothing. From about 1500-3000 it is jerky like crazy when the car/oil is cold. Reducing vvt target table on the low end definitely reduced the bucking alltogether when car is fully warmed up. But when cold it still goes nuts down there. Very jerky and unstable.

Today I'm going to zero out all vvt advance down low and see how it reacts tomorrow morning.

My guess is same as posted above though: OEM probably has a temp scale that retards/advances the vvt from cold start to operating temps.

I have been fighting a bucking/jerking/not smooth power delivery issue on my '01 for a bit. Tried all the timing map tweaks possible - nothing. Tried all the fueling tweaks possible - nothing. From about 1500-3000 it is jerky like crazy when the car/oil is cold. Reducing vvt target table on the low end definitely reduced the bucking alltogether when car is fully warmed up. But when cold it still goes nuts down there. Very jerky and unstable.

Today I'm going to zero out all vvt advance down low and see how it reacts tomorrow morning.

My guess is same as posted above though: OEM probably has a temp scale that retards/advances the vvt from cold start to operating temps.

#16

Thread Starter

Junior Member

iTrader: (10)

Joined: Jun 2011

Posts: 299

Total Cats: 3

From: Detroit Burbs

The issues I was seeing were less to do with the amount of advance when cold, and more to do with controlling to the target advance when cold. The oil pressure would be completely unstable, which would cause engine torque to be unstable as well (due to the cam position going crazy when the oil pressure was unstable).

The idea is - when cold, the oil pressure is high, as well as the fluid viscocity - which changes the amount of force exerted on the cam actuator for a given control valve position.

Do you have an oil pressure gauge you can look at to verify?

I have a map to reduce advance versus coolant temperature, but don't do anything with it. Also, I only turn on VVT control at 60C coolant temp. Below that, I figure the engine is cold - so you shouldn't be flogging it at WOT anyway.

Up to what temperature are you seeing your issue?

The idea is - when cold, the oil pressure is high, as well as the fluid viscocity - which changes the amount of force exerted on the cam actuator for a given control valve position.

Do you have an oil pressure gauge you can look at to verify?

I have a map to reduce advance versus coolant temperature, but don't do anything with it. Also, I only turn on VVT control at 60C coolant temp. Below that, I figure the engine is cold - so you shouldn't be flogging it at WOT anyway.

Up to what temperature are you seeing your issue?

#17

Ah I see, well our problems could be a bit different then.

Unfortunately I don't have a proper opg, just the NB stocker which is useless.

As for when it does that, I notice it start going away as soon as the oem water temp gauge is past the 1/4 marker. By the time its in the middle, its fine. I'll try to get a proper log sometime soon.

I discussed this briefly with y8s and he basically says that when cold and without using vtcs butterflies to limit air intake, vvt advance causes the car to run very unstable.

Sorry if this isn't related and off topic. At first glance I thought we were having similar issues. I guess not

Unfortunately I don't have a proper opg, just the NB stocker which is useless.

As for when it does that, I notice it start going away as soon as the oem water temp gauge is past the 1/4 marker. By the time its in the middle, its fine. I'll try to get a proper log sometime soon.

I discussed this briefly with y8s and he basically says that when cold and without using vtcs butterflies to limit air intake, vvt advance causes the car to run very unstable.

Sorry if this isn't related and off topic. At first glance I thought we were having similar issues. I guess not

#18

Thread Starter

Junior Member

iTrader: (10)

Joined: Jun 2011

Posts: 299

Total Cats: 3

From: Detroit Burbs

Well, about a month or two ago I was on a 3 hr road trip in my car, and somehow the VVT got stuck in the fully open position. The valve itself wasn't stuck - just the actuator itself got physically stuck. It totally sucked driving home at full advance. At anything below 3000 rpm the engine would surge/buck/misfire in various stages based on load. And, of course it would just stall when coming down to idle, so you had to keep your foot in it and rpm above 1500. I tried restarting it many times, both at speed and at idle, and nothing could "unstick" the actuator.

I was really kinda pissed off on that long drive home, and was loathing to take apart the cam actuator to see what caused it to stick. Then, when I was about 5 minutes from home, it unstuck itself and started working just fine. I haven't had the problem re-appear since.

Moral of the story - there is such a thing as too much advance at low engine speeds. I am still using the stock map that comes with the VVT Tuner for my target advance, but with a little less advance at the low speed/load range. Someday I may get on a dyno a tune for optimum torque.

I was really kinda pissed off on that long drive home, and was loathing to take apart the cam actuator to see what caused it to stick. Then, when I was about 5 minutes from home, it unstuck itself and started working just fine. I haven't had the problem re-appear since.

Moral of the story - there is such a thing as too much advance at low engine speeds. I am still using the stock map that comes with the VVT Tuner for my target advance, but with a little less advance at the low speed/load range. Someday I may get on a dyno a tune for optimum torque.

#19

Have any of you guys noticed your cam being off after it was calibrated? I'm sitting at idle aiming for 50 deg retard from the full advanced position (because thats the AEM logic) and its reading to me as 45 and of course there's not enough oil pressure for the computer to control it. Did my cam reluctor ring rotate?

#20

Moral of the story - there is such a thing as too much advance at low engine speeds. I am still using the stock map that comes with the VVT Tuner for my target advance, but with a little less advance at the low speed/load range. Someday I may get on a dyno a tune for optimum torque.

I actually learned this just yesterday/today. Took out a bunch of advance below 3k and voila - this morning it drives like a peach even when cold. Well, that plus I reduced my accel enrichment pump settings and set tps/map blend to 80%

I guess I was silly in thinking this ancient BP likes lowend vvt advance like the subaru's and evo's I tuned using this logic. Lots of lowend intake cam advance - feels like a big 'ol motor and is just pleasant around town. The BP simply responds with "Nope, I'm not doin that"

lol