Temp gauge reading low after head gasket / reroute install

#1

Thread Starter

Junior Member

iTrader: (5)

Joined: Oct 2011

Posts: 400

Total Cats: 23

From: San Diego, CA

Just curious if anyone would have an idea why the temp gauge in my dash is reading low after I installed the BP26 head gasket with Skou's reroute.

TunerStudio seems to be reading temperatures fine. I did that gauge linearization mod a long time ago and it should be between 11-12 between 180-200F. But now it just barely moves from maybe 8-9 o'clock from cold to 200F.

It's my understanding that there's just 1 sensor for NB2s correct? I did have to lengthen the leads on the sensor by a few inches, but again, TunerStudio temps looks exactly like they should/used to before the reroute.

TunerStudio seems to be reading temperatures fine. I did that gauge linearization mod a long time ago and it should be between 11-12 between 180-200F. But now it just barely moves from maybe 8-9 o'clock from cold to 200F.

It's my understanding that there's just 1 sensor for NB2s correct? I did have to lengthen the leads on the sensor by a few inches, but again, TunerStudio temps looks exactly like they should/used to before the reroute.

#4

That is correct on the block, but you need to seperatly ground the reroute block, because the gauge cluster temp sensor is seperate in the sender and needs to be grounded through the body of the sender. The reroute block might not have a good ground because of the gaskets and maybe RTV you used, try to get a ground wire on your reroute block and see what happens...

#6

Thread Starter

Junior Member

iTrader: (5)

Joined: Oct 2011

Posts: 400

Total Cats: 23

From: San Diego, CA

I'm running a MegaSquirt standalone ECU so no OBD codes, gauge in cluster barely moves but ECU shows correct temp.

I haven't relocated the ground for the sensor yet as Zaphod instructed, but I'm pretty sure that's the problem. I will do so later this week and report back with my findings.

I haven't relocated the ground for the sensor yet as Zaphod instructed, but I'm pretty sure that's the problem. I will do so later this week and report back with my findings.

#8

Thread Starter

Junior Member

iTrader: (5)

Joined: Oct 2011

Posts: 400

Total Cats: 23

From: San Diego, CA

I don't think that's the idea we or at least I was thinking. There is a ground strap that is part of the loom that ties in close to the Coolant Temp sensor. This ground I believe needs to be grounded to the same piece of metal as the sensor.

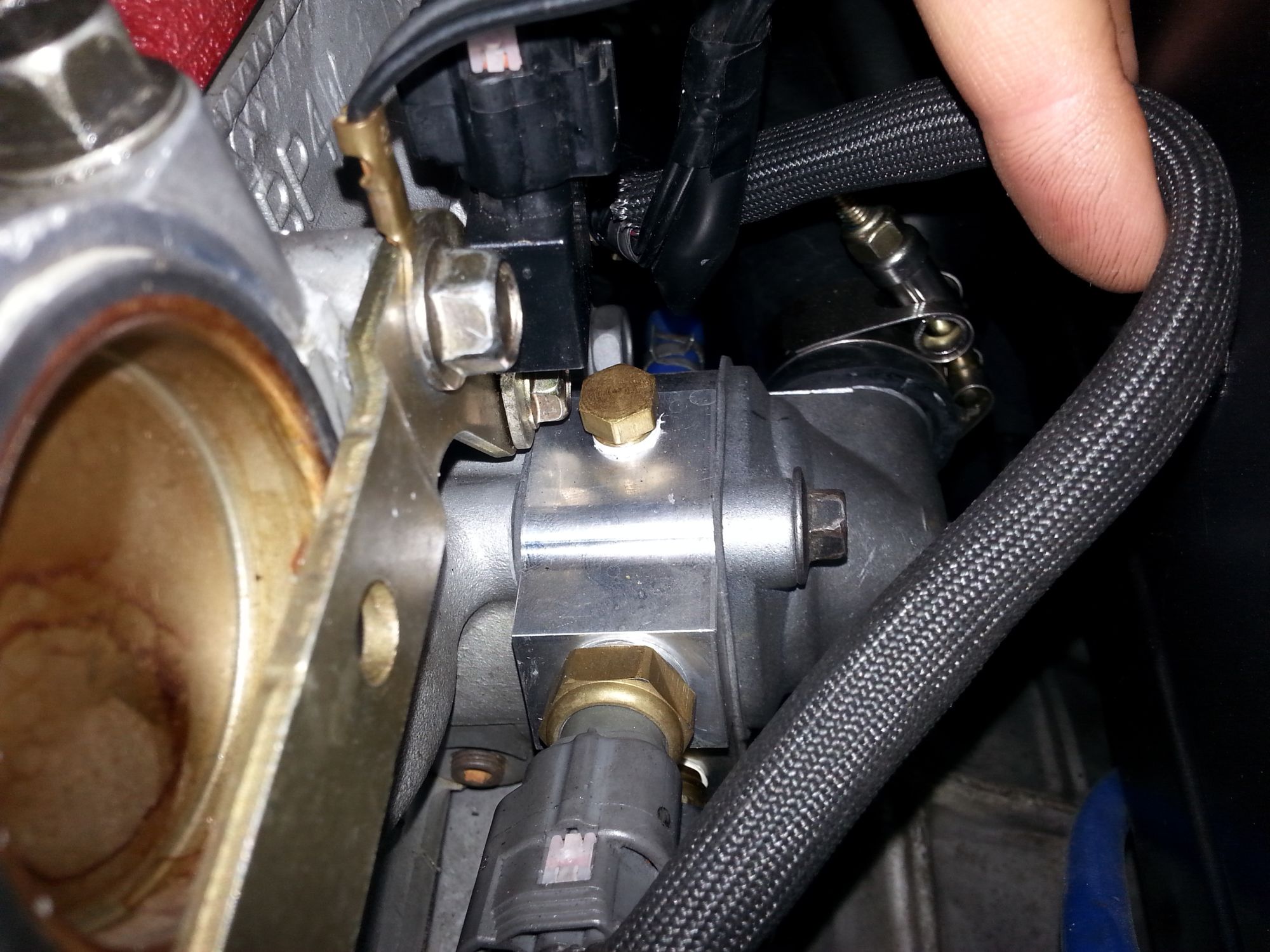

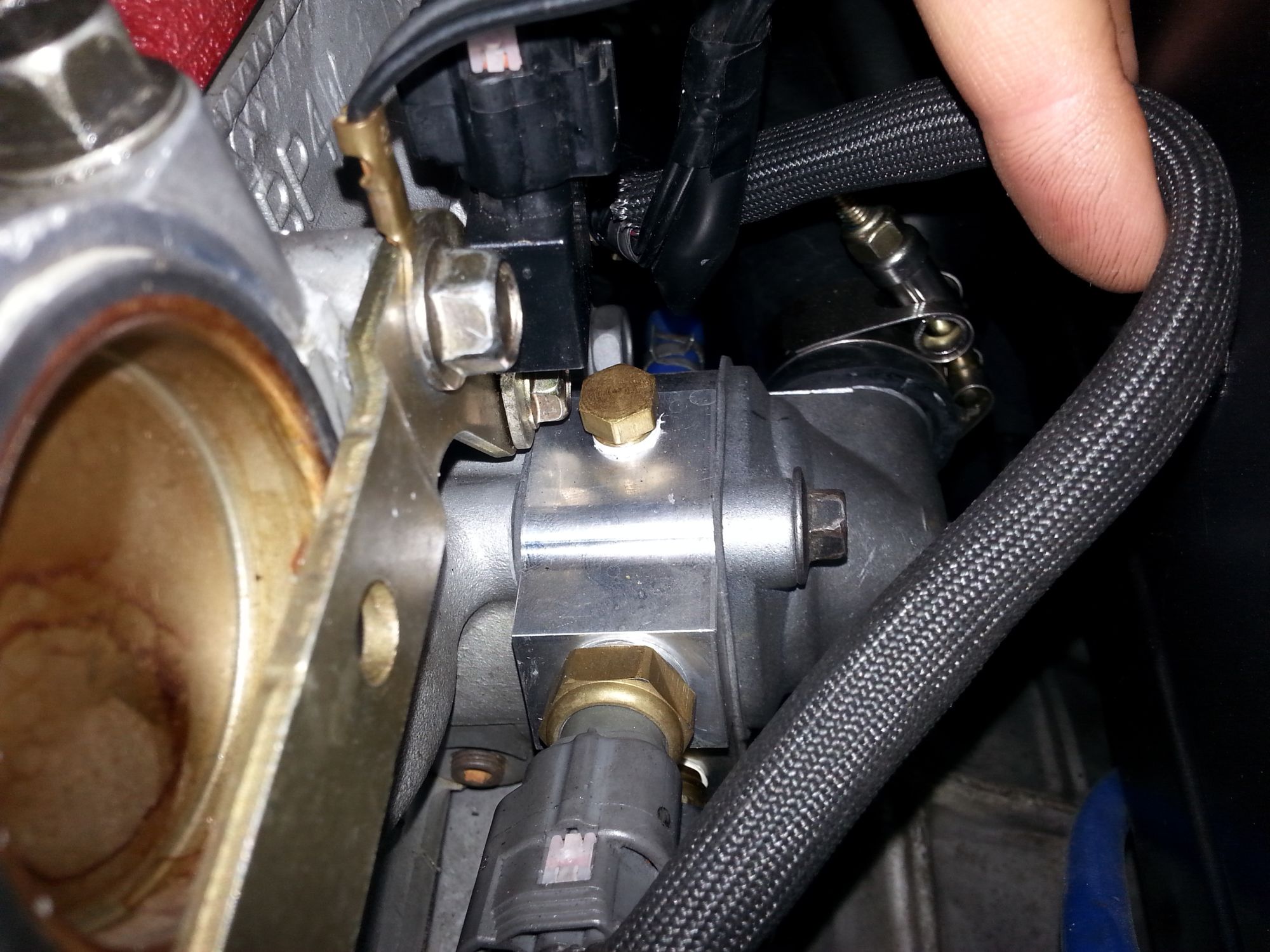

In this picture you can see the ground bolted to the back of the head. I think I need to take if off here and bolt it to one of the 2 bolts hold the reroute together.

And you should look into getting something like this to protect your heater hoses. It looks like yours are way closer to the exhaust than mine.

In this picture you can see the ground bolted to the back of the head. I think I need to take if off here and bolt it to one of the 2 bolts hold the reroute together.

And you should look into getting something like this to protect your heater hoses. It looks like yours are way closer to the exhaust than mine.

#9

Thread Starter

Junior Member

iTrader: (5)

Joined: Oct 2011

Posts: 400

Total Cats: 23

From: San Diego, CA

But now that I'm looking at it and thinking. I'm not sure if that's going to be much better because the bolts holding the reroute don't really touch the reroute spacer. The pieces are insulated by the gaskets. The bolts may touch the spacer where they slide through though.

EDIT: Maybe I could ground it at the top of the spacer on the extra 1/8NPT port that I've got the plug in.

EDIT2: OK. I just reread what Zaphod said and I see what you did and why. It kinda sounds like you did the right thing. I'll try to get mine done this week and still let you know what happens.

EDIT: Maybe I could ground it at the top of the spacer on the extra 1/8NPT port that I've got the plug in.

EDIT2: OK. I just reread what Zaphod said and I see what you did and why. It kinda sounds like you did the right thing. I'll try to get mine done this week and still let you know what happens.

#12

Call me crazy, but if your ground is on the head and you're concerned about the ground path to the sensor body, is there any reason to not just drag out the ol' multimeter and see if that might be a concern?

Gaskets being gaskets, there should still be a pair of bolts holding the housing in place, yes?

Gaskets being gaskets, there should still be a pair of bolts holding the housing in place, yes?

#13

Call me crazy, but if your ground is on the head and you're concerned about the ground path to the sensor body, is there any reason to not just drag out the ol' multimeter and see if that might be a concern?

Gaskets being gaskets, there should still be a pair of bolts holding the housing in place, yes?

Gaskets being gaskets, there should still be a pair of bolts holding the housing in place, yes?

#16

Thread Starter

Junior Member

iTrader: (5)

Joined: Oct 2011

Posts: 400

Total Cats: 23

From: San Diego, CA

[QUOTE=

P.S. Where did you get that heat shield for your heater hoses?[/QUOTE]

Amazon.com: cool-tube: All Departments

Just figure out what size you want. I think I cut it down the middle and wraped it around the hoses. Was a little tough to work with, but once you've got it set, it works pretty well.

P.S. Where did you get that heat shield for your heater hoses?[/QUOTE]

Amazon.com: cool-tube: All Departments

Just figure out what size you want. I think I cut it down the middle and wraped it around the hoses. Was a little tough to work with, but once you've got it set, it works pretty well.

#18

Grounding to the bolts that pass through everything won't do anything.

Here's the issue: The half of the sensor that feeds the gauge grounds through the sensor body itself. Sensor body threads into spacer.

You have head --> gasket --> spacer --> gasket --> water neck

The only way the spacer will ever work as a ground is if it happens to be touching one or both of the bolts. Holes for the bolts are bigger than they need to be, so that's not happening consistently, especially on our vibrating special motors.

I'm not a fan. I'm swapping to the M-Tuned solution over winter. Been fighting this issue for about 2 months now and i'm too stubborn to run a new ground, because really, i shouldn't have to.

Here's the issue: The half of the sensor that feeds the gauge grounds through the sensor body itself. Sensor body threads into spacer.

You have head --> gasket --> spacer --> gasket --> water neck

The only way the spacer will ever work as a ground is if it happens to be touching one or both of the bolts. Holes for the bolts are bigger than they need to be, so that's not happening consistently, especially on our vibrating special motors.

I'm not a fan. I'm swapping to the M-Tuned solution over winter. Been fighting this issue for about 2 months now and i'm too stubborn to run a new ground, because really, i shouldn't have to.

#19

Thread Starter

Junior Member

iTrader: (5)

Joined: Oct 2011

Posts: 400

Total Cats: 23

From: San Diego, CA

Grounding to the bolts that pass through everything won't do anything.

Here's the issue: The half of the sensor that feeds the gauge grounds through the sensor body itself. Sensor body threads into spacer.

You have head --> gasket --> spacer --> gasket --> water neck

Here's the issue: The half of the sensor that feeds the gauge grounds through the sensor body itself. Sensor body threads into spacer.

You have head --> gasket --> spacer --> gasket --> water neck

It would probably remain a good, mediocre or bad ground, as tested.

It would probably remain a good, mediocre or bad ground, as tested.