Skunk2 BP intake manifold

#21

Way. The OEM BP manifolds are all shaped to be able to get a air ratchet in there. We had to use a very pricey set of Mac open/box wrenches to reach the fasteners. The buttress ribs underneath the runners means you get about 45° swing then flip the wrench over and swing another 45°. Fun!

The OEM lower flange bolts can almost all be reached using a wobble and long extension through the RF wheel well. Tough, but still easier than the Skunk2. No big deal, just a heads up.

The OEM lower flange bolts can almost all be reached using a wobble and long extension through the RF wheel well. Tough, but still easier than the Skunk2. No big deal, just a heads up.

__________________

#23

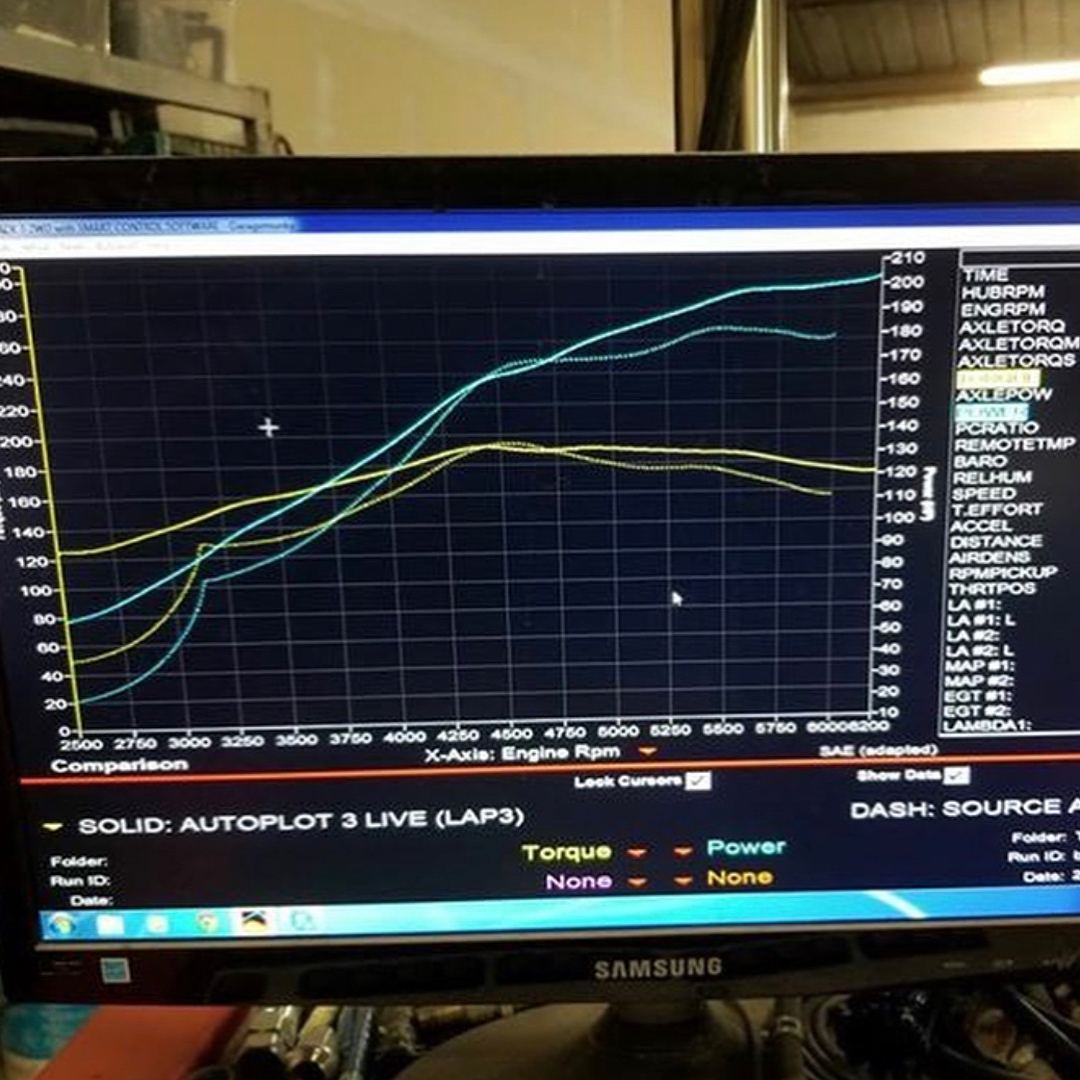

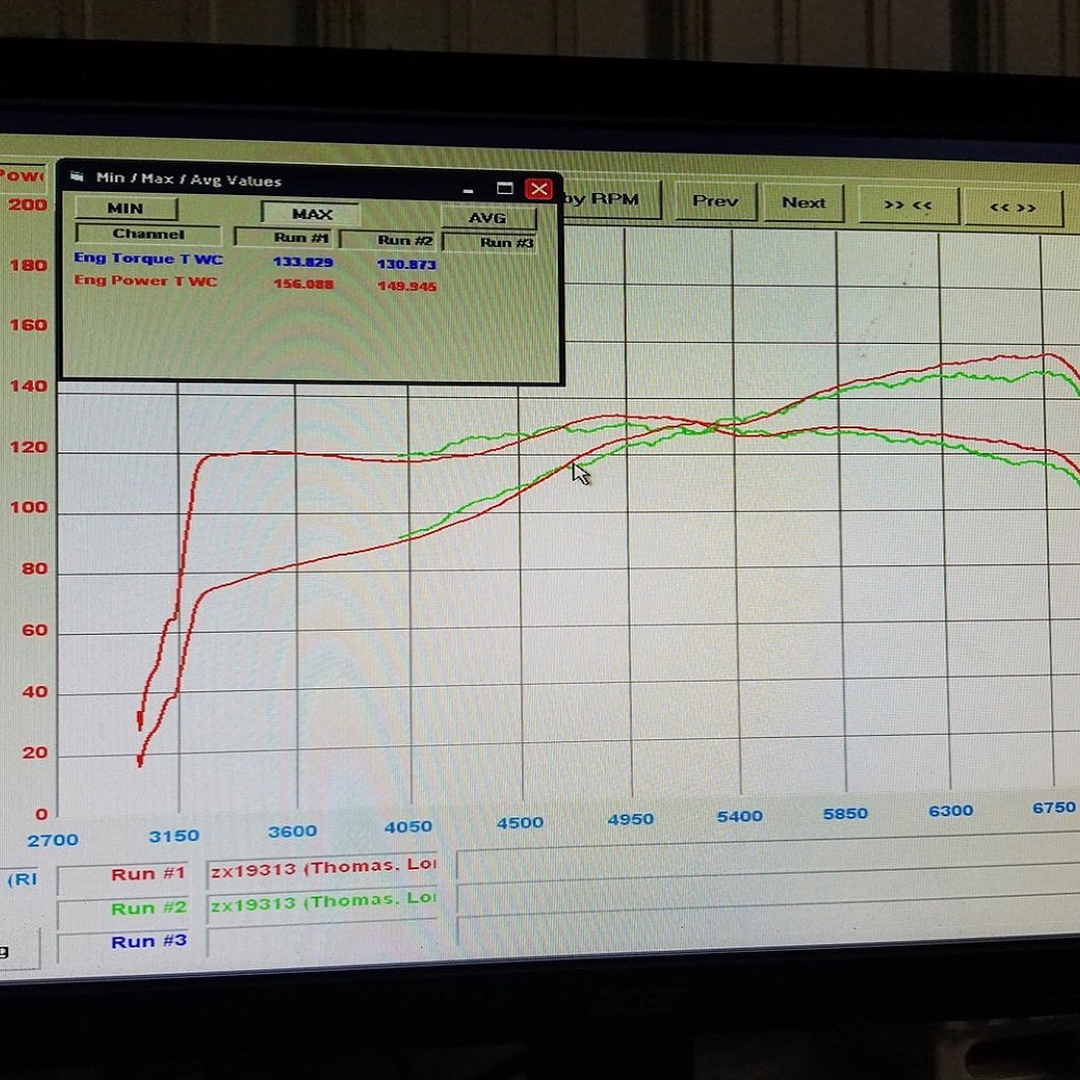

I'd actually rather not post random conjecture or confusing posts in this thread. W/o supporting data, that dynoi plot only serves to muddle. Good info for the other "junk2" thread. Those images have also been floating around for a few weeks.

If it doesn't serve to clarify things, leave it out please.

If it doesn't serve to clarify things, leave it out please.

__________________

#24

Thanks,

~Ryan

#25

Didn't bother. It will be immediately apparent when you attempt to line it up. Not complicated or hard to figure out where to cut it.

__________________

#27

Way. The OEM BP manifolds are all shaped to be able to get a air ratchet in there. We had to use a very pricey set of Mac open/box wrenches to reach the fasteners. The buttress ribs underneath the runners means you get about 45° swing then flip the wrench over and swing another 45°. Fun!

The OEM lower flange bolts can almost all be reached using a wobble and long extension through the RF wheel well. Tough, but still easier than the Skunk2. No big deal, just a heads up.

The OEM lower flange bolts can almost all be reached using a wobble and long extension through the RF wheel well. Tough, but still easier than the Skunk2. No big deal, just a heads up.

- it's a bitch of a job.

#28

Way. The OEM BP manifolds are all shaped to be able to get a air ratchet in there. We had to use a very pricey set of Mac open/box wrenches to reach the fasteners. The buttress ribs underneath the runners means you get about 45° swing then flip the wrench over and swing another 45°. Fun!

The OEM lower flange bolts can almost all be reached using a wobble and long extension through the RF wheel well. Tough, but still easier than the Skunk2. No big deal, just a heads up.

The OEM lower flange bolts can almost all be reached using a wobble and long extension through the RF wheel well. Tough, but still easier than the Skunk2. No big deal, just a heads up.

With the mounts out I changed the manifold while the engine was held up with the hoist. I might unbolt the mounts this time to get a little more room.

Thank you for all the heads up.

#29

After reading the install notes, I am really glad that whichever manifold I go with is going onto a newly built engine for me. Emilio, thanks for all the detailed write ups! Can't wait to see your results.

#30

Sorry if this was mentioned before. Gasket material between spacers? And is there some rule of thumb for ideal plenum volume and runner length? Or more directly, is there such thing as too much volume.

#31

Found this on the google machine.

the volume of an intake plenum generally matches the displacement of an engine. This means if an engine displaces 500 cubic inches, then the volume inside the plenum is typically going to also have a volume of around 500 cubic inches. Under this type of design, ideally no cylinder is starved for air because the volume inside the plenum is enough to fill all the cylinders simultaneously.

Tech Feature: Custom Racing Intake Manifolds - EngineLabs

Tech Feature: Custom Racing Intake Manifolds - EngineLabs

#32

Runner lengths/diameter, it seems most on here understand, has to do with target rpm for peak power and torque

I think that the added ability to change the plenum volume easily is a great feature. Two of the craziest designs I have seen(FSAE) was one that had an infinitely variable runner length and another similar but variable plenum volume.

#33

I'd also be very curious to see some large plenum testing. I think the impact of a large plenum on throttle response is overstated. We did a lot of testing on our FSAE team with plenum volume, and ended up with a plenum that was constrained by chassis packaging. All I'll say is it was way over 5 times the displacement (which it may need to be larger for peak power with a single cylinder). We didn't see any impact on TR, and even when having other teams drive our car they were expecting poor response but commented that it felt just right. We were making 140 whp/L on a Mustang dyno. I don't think I've seen plenums that large on a larger motor (over 1L), so I think it'd be cool to see the gains.

#34

We plan to test 1 then 2 spacers. If the trend is gains then we'll keep adding spacers until it stops working.

Brief test drive this morning to do a systems check and rough street tune before dynoing.

- Seems like the throttle response is better. Immediately noticeable as I pulled out on to the street and went up through the gears. The better flow path equals higher avg velocity which means better response. No data there, just SOTP.

- It's louder. Peak torque on an NB2 with header usually falls around 4600rpm. With the S2, it turns into a hard edged, Honda-like growl at 6000. Like a mini VTec step. Didn't feel like extra power at that step, just suddenly louder. fun.

Brief test drive this morning to do a systems check and rough street tune before dynoing.

- Seems like the throttle response is better. Immediately noticeable as I pulled out on to the street and went up through the gears. The better flow path equals higher avg velocity which means better response. No data there, just SOTP.

- It's louder. Peak torque on an NB2 with header usually falls around 4600rpm. With the S2, it turns into a hard edged, Honda-like growl at 6000. Like a mini VTec step. Didn't feel like extra power at that step, just suddenly louder. fun.

__________________

#37

#38

Same 10" runner as OEM so same 2nd order frequency. Not sure why it sounds so different other than that there is less disruption to the air mass and pressure waves moving through the throttle body in both directions.

Think of it this way. Person in room 10' away in direct line of site. Claps loudly. Same person also 10' away but now around corner in hallway with book case in between. One is muted, lower sound energy. The other is higher energy with more audible frequencies.

Think of it this way. Person in room 10' away in direct line of site. Claps loudly. Same person also 10' away but now around corner in hallway with book case in between. One is muted, lower sound energy. The other is higher energy with more audible frequencies.

__________________

Last edited by emilio700; 10-26-2017 at 06:23 PM.

#40

Yours truly, a Powertrain NVH engineer.