How hard should a rebuilt motor be to turn?

#1

Hello, I have rebuilt a 1.8 motor with 9.0:1 supertech pistons and ACL bearings. As I have been building the motor I would turn it by the crank bolt and and a 1/2" ratchet. It always seemed to easy to turn, however, once I installed the motor and transmission into the car won't turn over easily.

I removed and tested the starter, it checked out fine. The motor turns easily until it I hit about 270 degrees, then it becomes hard to turn. I removed the spark plugs to see if it made it any easier, no difference.

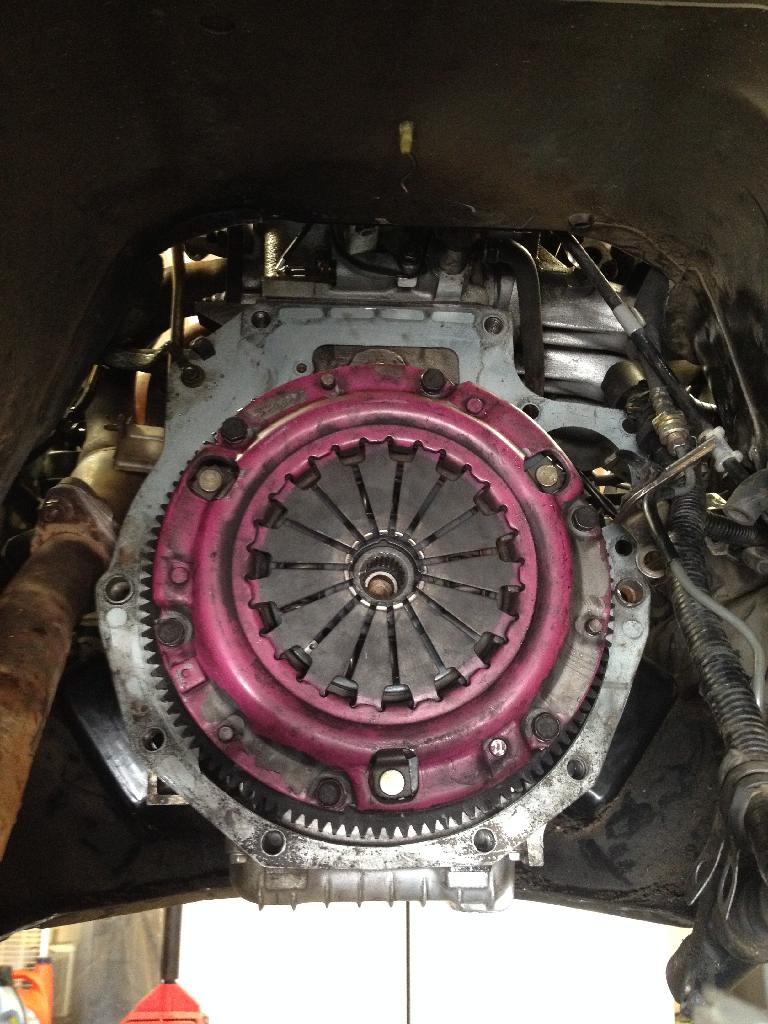

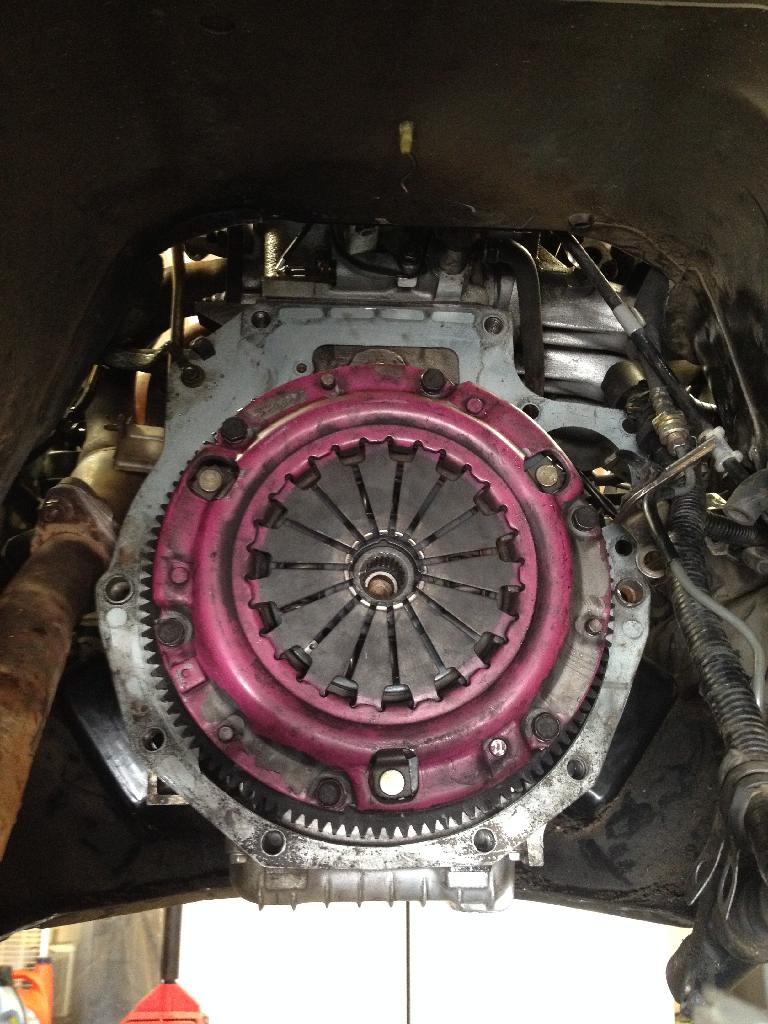

Today, I removed the transmission to looks for signs of metal on metal contact. I haven't seen any, but I am tired and its dark. I will do a closer inspection tomorrow in the daylight. But I was able to turn the motor by hand a little easier. I can turn the transmission input shaft by hand easily.

My question is how much resistance should there be in turning the motor by hand? Also, is there anything that can obstruct the flywheel from turning once the transmission is attatched?

Thank you in advance.

I removed and tested the starter, it checked out fine. The motor turns easily until it I hit about 270 degrees, then it becomes hard to turn. I removed the spark plugs to see if it made it any easier, no difference.

Today, I removed the transmission to looks for signs of metal on metal contact. I haven't seen any, but I am tired and its dark. I will do a closer inspection tomorrow in the daylight. But I was able to turn the motor by hand a little easier. I can turn the transmission input shaft by hand easily.

My question is how much resistance should there be in turning the motor by hand? Also, is there anything that can obstruct the flywheel from turning once the transmission is attatched?

Thank you in advance.

#8

Do you people even read the original post before you ask these questions? How can you expect to give any assistance at all whatsoever with his problem if you can't even read. Yeah, bet he want to take your advice or suggestions.

To the OP, why did you start with the starter? What happened when you tried to turn the motor over with the key? It just seemed so spin slow, or was their any noise?

Sounds like interference somewhere in the clutch, flywheel, starter area. Then again, it's kind of hard to know the way you talk about the motor turning over. At this point now that you have the sparkplugs pulled and the transmission down you said the motor turns easier, but almost sounds like you are still concerned with how it turns.

With no plugs, no tranny, and no belts, you should probably be able to turn it with a 3/8" ratchet, so a 1/2" ratchet should be with only a little resistance twice in the rotation as you reach TDC and push the compression out the sparkplug hole.

To the OP, why did you start with the starter? What happened when you tried to turn the motor over with the key? It just seemed so spin slow, or was their any noise?

Sounds like interference somewhere in the clutch, flywheel, starter area. Then again, it's kind of hard to know the way you talk about the motor turning over. At this point now that you have the sparkplugs pulled and the transmission down you said the motor turns easier, but almost sounds like you are still concerned with how it turns.

With no plugs, no tranny, and no belts, you should probably be able to turn it with a 3/8" ratchet, so a 1/2" ratchet should be with only a little resistance twice in the rotation as you reach TDC and push the compression out the sparkplug hole.

#10

When I tried to start the car, there was a metal scraping/grinding sound coming from the starter/bellhousing area. My original idea was that the starter wasn't aligned or the transmission could be misaligned.

"Are you in neutral?"

I attempted to start the car in neutral and with the clutched pressed in. I had the same result in both cases.

"Timing belt too tight? The 1/2" ratchet was fully assembled motor on the engine stand?

Stock valve train?

Hydraulic lifter weirdness?

So the motor went in, and then the starter was used to prime the oil pump and pressurize the system?

Sorry, just more questions."

Not sure how the timing belt could be on too tight, I thought the belt tensioner was spring actuated. The 1/2" ratchet was on the engine stand initially. I made sure the motor was easy to turn after added any major assembly piece during the build, ie: pistons, head, timing belt.

Yes, stock valve train.

Not sure what you mean by hydraulic lifter weirdness, I disassembled the HLA's, cleaned them and put them back together in the same spot they came out of.

I wasn't aware of needing to prime the oil pump, used Lucas engine assembly lube on everything during the build.

Its almost warm enough for me to go back under the car, thank you for your suggestions and I'll updated the thread as I find out more.

#13

I inspected the bellhousing area, no metal shavings or signs of metal on metal contact. I going to start taking off the accessory belts and check the timing belt.

This is the point at which the motor becomes difficult to turn. After the timing marks hit the 12 o'clock position, the motor turns with little to no resistance.

This is the point at which the motor becomes difficult to turn. After the timing marks hit the 12 o'clock position, the motor turns with little to no resistance.

#14

I inspected the bellhousing area, no metal shavings or signs of metal on metal contact. I going to start taking off the accessory belts and check the timing belt.

...

This is the point at which the motor becomes difficult to turn. After the timing marks hit the 12 o'clock position, the motor turns with little to no resistance.

...

...

This is the point at which the motor becomes difficult to turn. After the timing marks hit the 12 o'clock position, the motor turns with little to no resistance.

...

The engine is basically back to the way it was on the stand, only it's installed in the car, yet it has now become difficult to turn EVEN WITH THE STARTER AND TRANNY NOW OUT OF THE EQUATION?

If that is the case, then something is messed up in the motor or perhaps a socket/wrench/bolt/etc. fell down into the timing belt area and became entangled with the belt/pulleys when you tilted the motor reinstalling it?

WAG

WAG

#15

With the starter and transmission out the motor, it was still hard to turn, but only once. After that, I couldn't replicate the problem. I am stumped(not that I'm a very experience mechanic anyway.)

The timing belt is aligned properly. I loosened and re-tightened the tensioner pulley just in case. I will start to put the car back together this week little by little after work.

Thank you for all your input. I will still post here, hopefully it will start this time.

The timing belt is aligned properly. I loosened and re-tightened the tensioner pulley just in case. I will start to put the car back together this week little by little after work.

Thank you for all your input. I will still post here, hopefully it will start this time.

#16

I dropped a small socket down between the crank pulley and timing belt without noticing it one time. The motor turned over fine until it pinched the socket between the belt and pulley and completely stopped. That's probably not the issue, but it might be worth checking to see if something found it's way down there.

#19

It definitely sounds like you need to break the motor down and find the problem. With the starter and trans out of the equation you know the resistance you last felt was from the engine side of things. I would start with accessories and see if they turn freely. Water pumps go bad all the time so I would try ti find the problem with PS/AC/WP, then remove timing belt covers. If you do not identify the problem then I would break the engine down completely and start over. I like to take lots of pictures to both document what I did for potential resale and so I can look at my pictures and see that I did use assembly lube on every bearing surface, every connecting rod has TWO nuts, main caps, yada yada yada....

PLEASE find it, and make sure you tell us what the problem was so we can all learn from this.

PLEASE find it, and make sure you tell us what the problem was so we can all learn from this.