How to Final Wash an Engine Block

#1

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

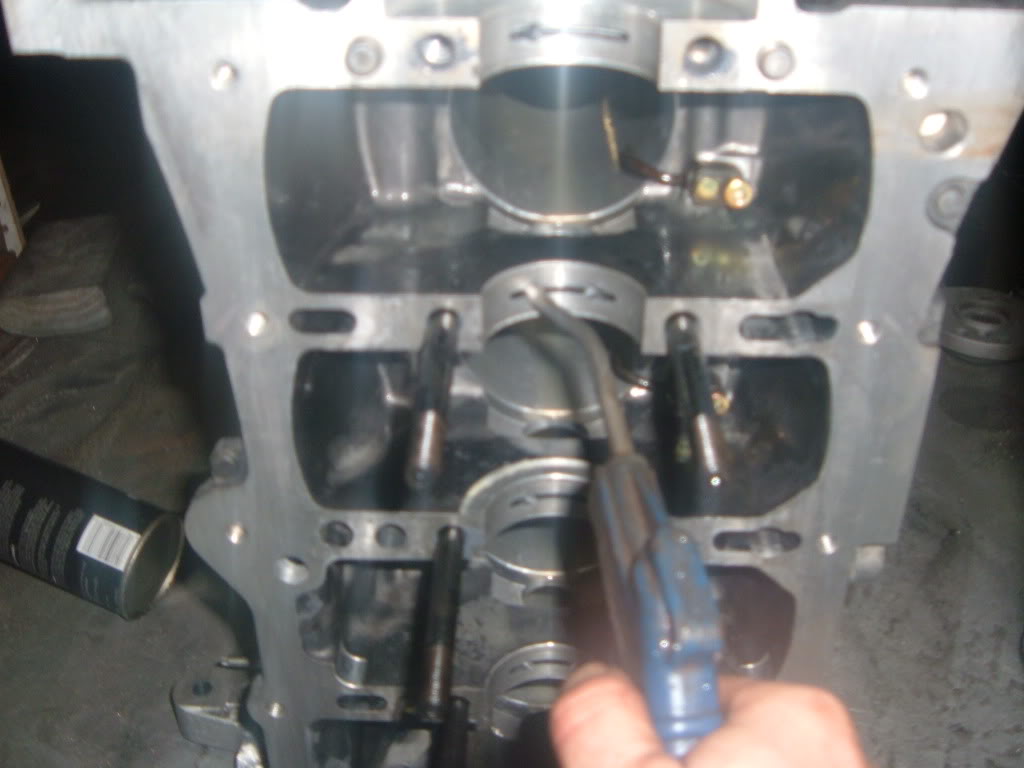

How to final wash an Engine Block

You just picked up your block from the machine shop, and your ready to build your engine.

The block may look clean, but it is not.

It still has grim and grit from machining in it.

It is up to you as the builder to final wash the block.

First gather together what you will need to clean the block.

Lint free paper towels, WD-40 , a good degreaser and a can of brake cleaner.

Now find a place to wash the block, a table or engine stand will be fine to use.

Now spray the degreaser all over the block, take good care to get the inside of the block and cylinder walls.

Let the degreaser work for 15 to 30 minutes, Do NOT let the block dry, reapply as needed.

Now spay the block down with clean water till the water runs clear.

Now quickly blow the cylinders and main bearing saddle surfaces dry with compressed air.

Now spray WD-40 in the cylinders and main bearing saddle surfaces to prevent rust.

Now spin the block around and spray brake cleaner into the oil galleys, I would recommend that any oil galley plugs be removed for this step if they were not at the machine shop. Just make sure to install them back.

At this point, take compressed air and blow through all the oil galleys,

main and head bolt holes.

Repeat till all signs of grit and old oil is removed.

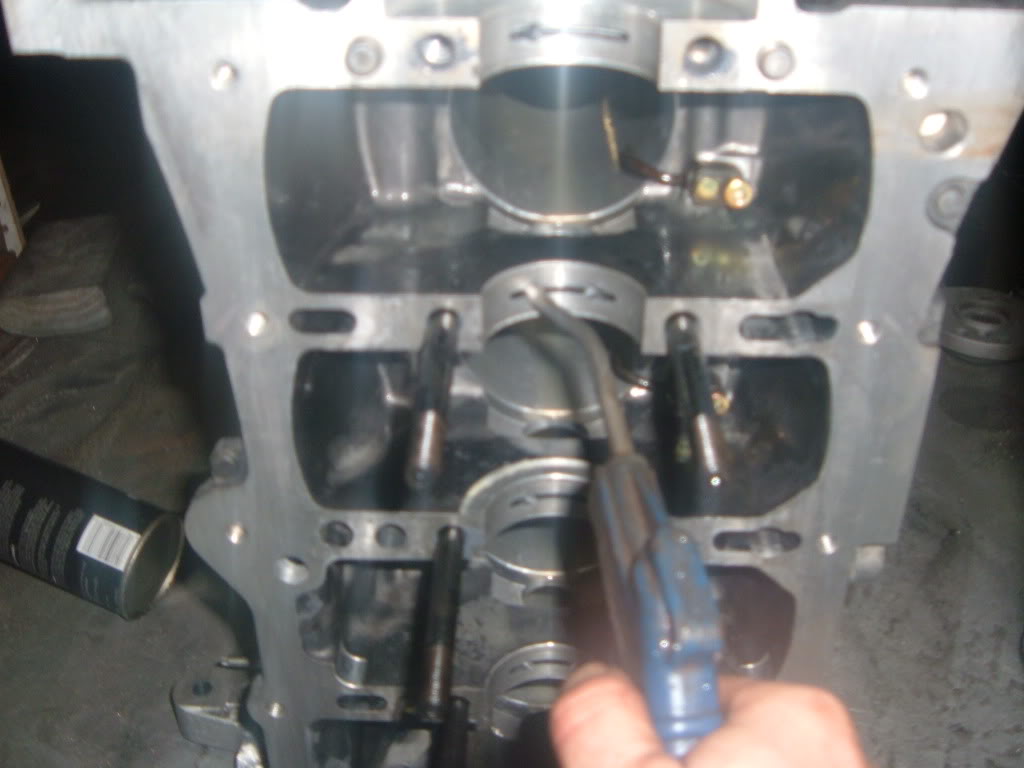

Now take a couple paper towels and fold into ¼ and spray WD-40 on them, soaking them well.

Now wipe the cylinders down

Look at the paper towel now. This is hone stone grit and rust. Leaving this in the cylinders can cause issues with the rings glazing and not sealing.

Keep flipping and folding the paper towel and soaking with WD-40 until the paper towel comes back out clean!!

Now look in the corners inside the block and in general give the block a good look over for anything missed.

Make sure any oil galley plugs that were removed are replaced.

You can not get your block too clean!!

You just picked up your block from the machine shop, and your ready to build your engine.

The block may look clean, but it is not.

It still has grim and grit from machining in it.

It is up to you as the builder to final wash the block.

First gather together what you will need to clean the block.

Lint free paper towels, WD-40 , a good degreaser and a can of brake cleaner.

Now find a place to wash the block, a table or engine stand will be fine to use.

Now spray the degreaser all over the block, take good care to get the inside of the block and cylinder walls.

Let the degreaser work for 15 to 30 minutes, Do NOT let the block dry, reapply as needed.

Now spay the block down with clean water till the water runs clear.

Now quickly blow the cylinders and main bearing saddle surfaces dry with compressed air.

Now spray WD-40 in the cylinders and main bearing saddle surfaces to prevent rust.

Now spin the block around and spray brake cleaner into the oil galleys, I would recommend that any oil galley plugs be removed for this step if they were not at the machine shop. Just make sure to install them back.

At this point, take compressed air and blow through all the oil galleys,

main and head bolt holes.

Repeat till all signs of grit and old oil is removed.

Now take a couple paper towels and fold into ¼ and spray WD-40 on them, soaking them well.

Now wipe the cylinders down

Look at the paper towel now. This is hone stone grit and rust. Leaving this in the cylinders can cause issues with the rings glazing and not sealing.

Keep flipping and folding the paper towel and soaking with WD-40 until the paper towel comes back out clean!!

Now look in the corners inside the block and in general give the block a good look over for anything missed.

Make sure any oil galley plugs that were removed are replaced.

You can not get your block too clean!!

#4

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

shuiend.... no it is not clean from the machine shop, yes it is cleaner than when you took it in, but IMHO it is not clean enough to be assembled.

When the block first goes in the shop it is pun in a hot tank or spray cabinet, this will remove the heavy greese and grime.

Then it will be buffed with a wire brush to remove the gaskets that are left behind.

The block will then be machined, bored, honed, decked. Whatever work you requested done.

When honed, the hone machine will pump hone oil in the cylinders and over the block. This oil will have particles of stone and metal in it.

Now once the hone work is done, the block will be put back in the same spray cabinet that it first went in (this is most shops, some, few will have a "clean" wash tank) that is loaded with the grit it first washed off.

So it may look clean, but it really is not.

Hustler... Glad you like it.

When the block first goes in the shop it is pun in a hot tank or spray cabinet, this will remove the heavy greese and grime.

Then it will be buffed with a wire brush to remove the gaskets that are left behind.

The block will then be machined, bored, honed, decked. Whatever work you requested done.

When honed, the hone machine will pump hone oil in the cylinders and over the block. This oil will have particles of stone and metal in it.

Now once the hone work is done, the block will be put back in the same spray cabinet that it first went in (this is most shops, some, few will have a "clean" wash tank) that is loaded with the grit it first washed off.

So it may look clean, but it really is not.

Hustler... Glad you like it.

#5

shuiend.... no it is not clean from the machine shop, yes it is cleaner than when you took it in, but IMHO it is not clean enough to be assembled.

When the block first goes in the shop it is pun in a hot tank or spray cabinet, this will remove the heavy greese and grime.

Then it will be buffed with a wire brush to remove the gaskets that are left behind.

The block will then be machined, bored, honed, decked. Whatever work you requested done.

When honed, the hone machine will pump hone oil in the cylinders and over the block. This oil will have particles of stone and metal in it.

Now once the hone work is done, the block will be put back in the same spray cabinet that it first went in (this is most shops, some, few will have a "clean" wash tank) that is loaded with the grit it first washed off.

So it may look clean, but it really is not.

Hustler... Glad you like it.

When the block first goes in the shop it is pun in a hot tank or spray cabinet, this will remove the heavy greese and grime.

Then it will be buffed with a wire brush to remove the gaskets that are left behind.

The block will then be machined, bored, honed, decked. Whatever work you requested done.

When honed, the hone machine will pump hone oil in the cylinders and over the block. This oil will have particles of stone and metal in it.

Now once the hone work is done, the block will be put back in the same spray cabinet that it first went in (this is most shops, some, few will have a "clean" wash tank) that is loaded with the grit it first washed off.

So it may look clean, but it really is not.

Hustler... Glad you like it.

You sir are going to get some props.

#7

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

2 years ago, I was and still am in Pensacola Fl, In my shop doing machine work!

I did not have a coustomer who wanted a turbo 1.8 tho, so , sadly I did not know of your fourm board.

I post this info so the new guys can learn, and do better engine builds.

#8

Thank you for the props!

2 years ago, I was and still am in Pensacola Fl, In my shop doing machine work!

I did not have a coustomer who wanted a turbo 1.8 tho, so , sadly I did not know of your fourm board.

I post this info so the new guys can learn, and do better engine builds.

2 years ago, I was and still am in Pensacola Fl, In my shop doing machine work!

I did not have a coustomer who wanted a turbo 1.8 tho, so , sadly I did not know of your fourm board.

I post this info so the new guys can learn, and do better engine builds.

me gusta

#9

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

It is only inappropriate if I do not like it!!

Devin... It is the people like you I do this for.

I grew up around engines and cars, I went to school for auto tech, Had a sleeve full of ASE certs.

Some of the things I post are "Backyard", That is so you can do the same thing, and it works.

Keep reading!!

Devin... It is the people like you I do this for.

I grew up around engines and cars, I went to school for auto tech, Had a sleeve full of ASE certs.

Some of the things I post are "Backyard", That is so you can do the same thing, and it works.

Keep reading!!

#10

I agree completely. I would also offer the advice to check everything with clean, bare hands/fingers. If you can feel any grit, it's not clean enough.

While you are not really telling me anything I don't already know, your pictures and writeups are certainly interesting reading. Obviously it's not as common knowledge as I has assumed, so it has a place here. Thank you for taking the time to do it.

While you are not really telling me anything I don't already know, your pictures and writeups are certainly interesting reading. Obviously it's not as common knowledge as I has assumed, so it has a place here. Thank you for taking the time to do it.

#12

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

rleete... Good you have this knowlage! Ill have to dig and see if I can come up with something you do not know.

Commie.... I am not sure I like the idea of ajax, the point of the final wash is to get rid of all the grit. Ajax is an abrasive. So that may counter act the hone marks and oil retention of them.

Now back in the day, I was "taught" that if the rings are stuck or not seating, to mix ajax in a jar with water and pour it down the carb slowly so the ajax and rings could hone the block and get the rings to seat.

But this was an old man from the back woods who also thought a torque wrench was for sissys

Commie.... I am not sure I like the idea of ajax, the point of the final wash is to get rid of all the grit. Ajax is an abrasive. So that may counter act the hone marks and oil retention of them.

Now back in the day, I was "taught" that if the rings are stuck or not seating, to mix ajax in a jar with water and pour it down the carb slowly so the ajax and rings could hone the block and get the rings to seat.

But this was an old man from the back woods who also thought a torque wrench was for sissys

#13

Interesting..

For stuck rings, I prepare a cocktail of three parts WD-40 to one part 5W30 oil, and just dump a few ounces into each cylinder through the spark plug hole. (Figure about 1/2 deep on the piston top.)

I then let it soak for a few hours, and crank the engine with loose rags over the plug holes to catch the shooting oil. Then comes compressed air to clean a little more.

Granted, the engine smokes to high heaven when you first fire it up, but it clears in a few minutes, and compression test results show a great deal of improvement.

I saved a BMW and a Saab that were just parked for extended periods, and would not start (read = 0 compression) at all.

Just my 2 cents.

Edit: You then install a fresh set of plugs once everything is sorted out.. Goes without saying.

For stuck rings, I prepare a cocktail of three parts WD-40 to one part 5W30 oil, and just dump a few ounces into each cylinder through the spark plug hole. (Figure about 1/2 deep on the piston top.)

I then let it soak for a few hours, and crank the engine with loose rags over the plug holes to catch the shooting oil. Then comes compressed air to clean a little more.

Granted, the engine smokes to high heaven when you first fire it up, but it clears in a few minutes, and compression test results show a great deal of improvement.

I saved a BMW and a Saab that were just parked for extended periods, and would not start (read = 0 compression) at all.

Just my 2 cents.

Edit: You then install a fresh set of plugs once everything is sorted out.. Goes without saying.

#15

I still like detergent and lots of water so hot it will burn you, with a stiff bristle brush to get the bores clean. The peaks and crevasses created during the honing process will trap the grit, and it has to be floated out. Scrubbing with a cloth will not get it as clean as the brush, soap, and really hot water. If I could use steam I would be there too.

You must get something on the bores as soon as it is dry (it doesnt take long when the block is hot from the water) I actually start spraying it down before it is dry if possible. Rust in those bores is as bad or worse than the grit!

I am not dissing you and your methods, just adding my .02

You must get something on the bores as soon as it is dry (it doesnt take long when the block is hot from the water) I actually start spraying it down before it is dry if possible. Rust in those bores is as bad or worse than the grit!

I am not dissing you and your methods, just adding my .02

#18

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

Alta.. There are 50 diffrent ways to make a peanut butter and jelly sammich..

I post the way I was taught, It works for me, you have a way that works for you.

It really does not matter how you get to the end result, as long as you get there and have a block that is clean. Only the engine builder will determin what he thinks is clean.

I post the way I was taught, It works for me, you have a way that works for you.

It really does not matter how you get to the end result, as long as you get there and have a block that is clean. Only the engine builder will determin what he thinks is clean.

#20

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

Reaper.. Sounds like you are having your head rebuilt, the most you should need to do is blow it off with compressed air.

The water jacket, and every open bolt hole.

Did the head get surfaced?

The water jacket, and every open bolt hole.

Did the head get surfaced?