How to Clean a Head Gasket Surface

#1

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

How to Clean a Head Gasket Surface

There are many ways to clean a head gasket surface.

This is just one way, and it is the method I prefer.

I do not like the use of “rol-locs” for cleaning a head gasket surface, for block or head.

Cast iron or aluminum.

This is for COMPOSITE Head gaskets, Not MLS

MLS Head gasket surfaces need more prep.

A rol-loc can an will “wave” a gasket surface when used improperly. In most cases it is.

So do not use this!!

What I prefer to use is a hard back body board with 80-100 grit sand paper.

The reason to do it this way is….

1) more coverage area

2) will not “wave” the gasket surface

3) will show low spots in the gasket surface

Use moderate pressure when going over the gasket surface.

and go at different angles, using long steady strokes

and

You want to go over it enough to just “shine” the surface and remove all the old traces of the head gasket but not remove the metal of the block or head.

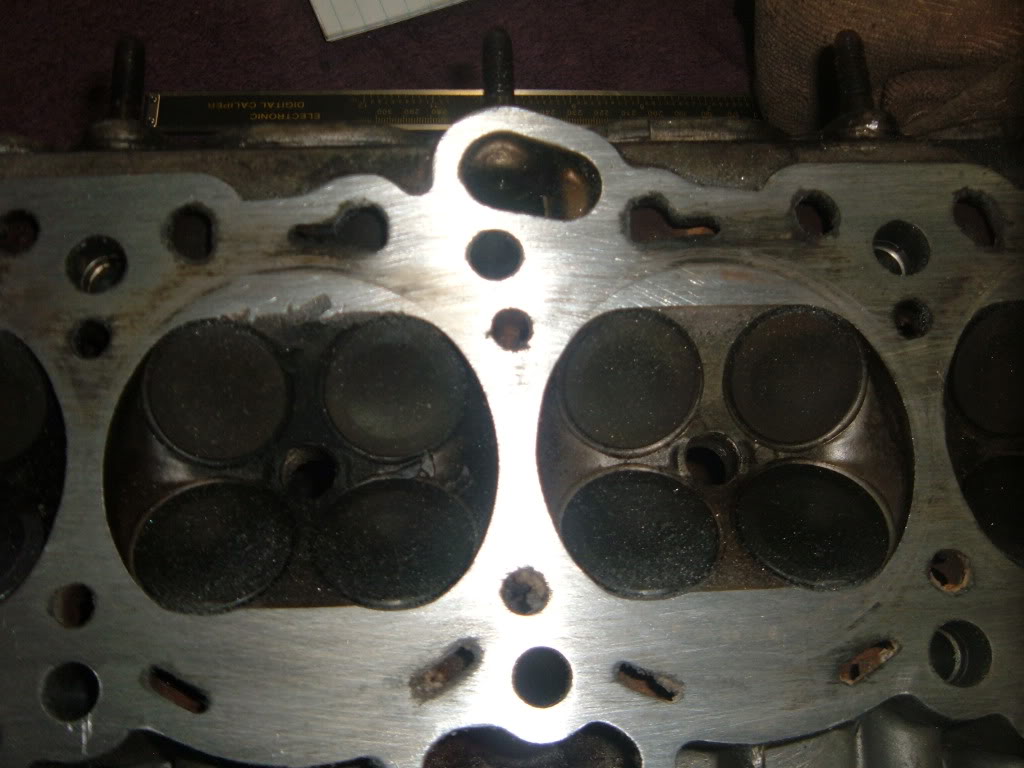

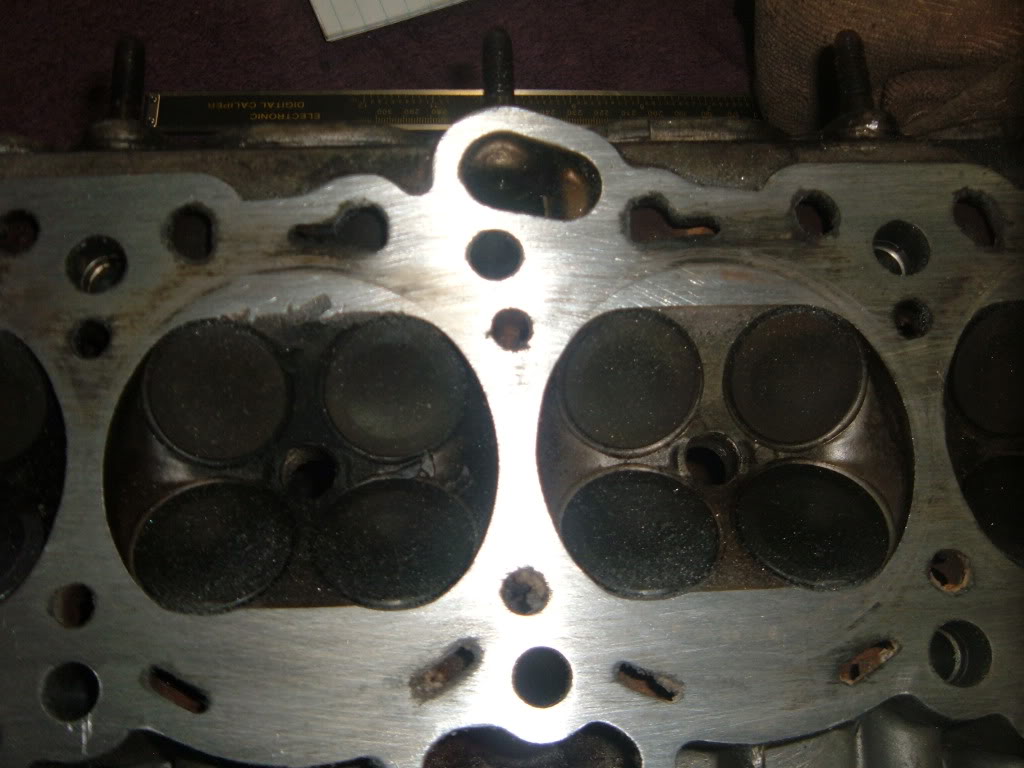

You should end up with something like this.

Now the surface is prepped so the head can be checked for warp and other imperfections.

Notice the dark marks above the exhaust valves and around the water ports, this shows the low areas and fire rings.

This head needs to be surfaced so to hold a head gasket properly.

There are many ways to clean a head gasket surface.

This is just one way, and it is the method I prefer.

I do not like the use of “rol-locs” for cleaning a head gasket surface, for block or head.

Cast iron or aluminum.

This is for COMPOSITE Head gaskets, Not MLS

MLS Head gasket surfaces need more prep.

A rol-loc can an will “wave” a gasket surface when used improperly. In most cases it is.

So do not use this!!

What I prefer to use is a hard back body board with 80-100 grit sand paper.

The reason to do it this way is….

1) more coverage area

2) will not “wave” the gasket surface

3) will show low spots in the gasket surface

Use moderate pressure when going over the gasket surface.

and go at different angles, using long steady strokes

and

You want to go over it enough to just “shine” the surface and remove all the old traces of the head gasket but not remove the metal of the block or head.

You should end up with something like this.

Now the surface is prepped so the head can be checked for warp and other imperfections.

Notice the dark marks above the exhaust valves and around the water ports, this shows the low areas and fire rings.

This head needs to be surfaced so to hold a head gasket properly.

#3

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

For a MLS, the head needs to shine.

This method will work with a MLS, depending on the finish that was there before.

Works just fine with a composite gasket.

This is mainly for geting the surface clean for inspection

This method will work with a MLS, depending on the finish that was there before.

Works just fine with a composite gasket.

This is mainly for geting the surface clean for inspection

Thread

Thread Starter

Forum

Replies

Last Post

StratoBlue1109

Miata parts for sale/trade

21

09-30-2018 02:09 PM