Help me weed through the BS about NB fuel pumps

#1

So we now have a lovely BP5A engine in the eggplant Swagmobile. After 277k miles I think it is time to replace the fuel pump. I seem to have a slight hesitation off idle as well as it makes me feel warm and fluffy inside to know that the stupid amount of money I have spent on a full drivetrain swap will be fed well.

Assume that I will make about 140-150 rwhp at most naturally aspirated, but I do explore the funner side of my 7500 rpm rev limit on a daily basis. Much like concealer404, I have a few breathing mods to make power in the higher registers, but I feel like I am starving out a little at higher engine and vehicle speeds. Granted, I do not have a wideband on the car yet to confirm, but humor me a little.

Given the possibility of throwing very mild boost at this engine sometime in the future with a supercharger, what pump would be recommended by the masses for my 2000 returnless fuel system? I currently sport a set of flow matched stock NB1 injectors as well as a deleted frame mounted fuel pulsation damper and a BP5A ECU.

I see a lot of talk about overrunning the stock fuel pressure regulator, but just as much conversation saying that was only an NA miata problem and anything goes with the NB.

Assume that I will make about 140-150 rwhp at most naturally aspirated, but I do explore the funner side of my 7500 rpm rev limit on a daily basis. Much like concealer404, I have a few breathing mods to make power in the higher registers, but I feel like I am starving out a little at higher engine and vehicle speeds. Granted, I do not have a wideband on the car yet to confirm, but humor me a little.

Given the possibility of throwing very mild boost at this engine sometime in the future with a supercharger, what pump would be recommended by the masses for my 2000 returnless fuel system? I currently sport a set of flow matched stock NB1 injectors as well as a deleted frame mounted fuel pulsation damper and a BP5A ECU.

I see a lot of talk about overrunning the stock fuel pressure regulator, but just as much conversation saying that was only an NA miata problem and anything goes with the NB.

#2

Joined: Sep 2005

Posts: 33,556

Total Cats: 6,933

From: Chicago. (The less-murder part.)

I see a lot of talk about overrunning the stock fuel pressure regulator, but just as much conversation saying that was only an NA miata problem and anything goes with the NB.

NBs running extremely high HP (and, thus, extremely high fuel flow rates) can experience a drop in fuel pressure proportionate to load, as the rear-mounted regulator has no way of compensating for pressure drop across the fuel supply line, but this isn't related in any way to pump capacity, nor is it likely to trouble a stock or mildly-boosted engine.

#3

No first-hand experience here, but I can't see why there'd be any difference. Both the NA and NB use a bypass-style fuel pressure regulator. The only difference is that in the NA, the regulator is referenced to manifold pressure and located up front, while on the NB it runs at a fixed absolute pressure and located in the back.

NBs running extremely high HP (and, thus, extremely high fuel flow rates) can experience a drop in fuel pressure proportionate to load, as the rear-mounted regulator has no way of compensating for pressure drop across the fuel supply line, but this isn't related in any way to pump capacity, nor is it likely to trouble a stock or mildly-boosted engine.

NBs running extremely high HP (and, thus, extremely high fuel flow rates) can experience a drop in fuel pressure proportionate to load, as the rear-mounted regulator has no way of compensating for pressure drop across the fuel supply line, but this isn't related in any way to pump capacity, nor is it likely to trouble a stock or mildly-boosted engine.

Even though this is a simple job, I like to do things once if possible.

#4

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

The fuel regulator overpowering story seems to be related to the 90-93 regulators.

If you want to only do things once then convert to a returness fuel system with a vacuum referenced AFPR and be done with it.

Otherwise stick a walbro 255 in it and call it good.

Light boost you will be fine.

If you want to only do things once then convert to a returness fuel system with a vacuum referenced AFPR and be done with it.

Otherwise stick a walbro 255 in it and call it good.

Light boost you will be fine.

#5

Why did you delete the fuel pulse damper? IMHO, unless you're going over mid-200s rwhp, you're much better off sticking with a stock pump, stock regulator, stock damper, just swap the injectors and possibly the rail. As for why -- my experience is that yes, a big pump (Walbro 255 here) overwhelms the stock NB regulator at low injector duty cycles. It looks like this:

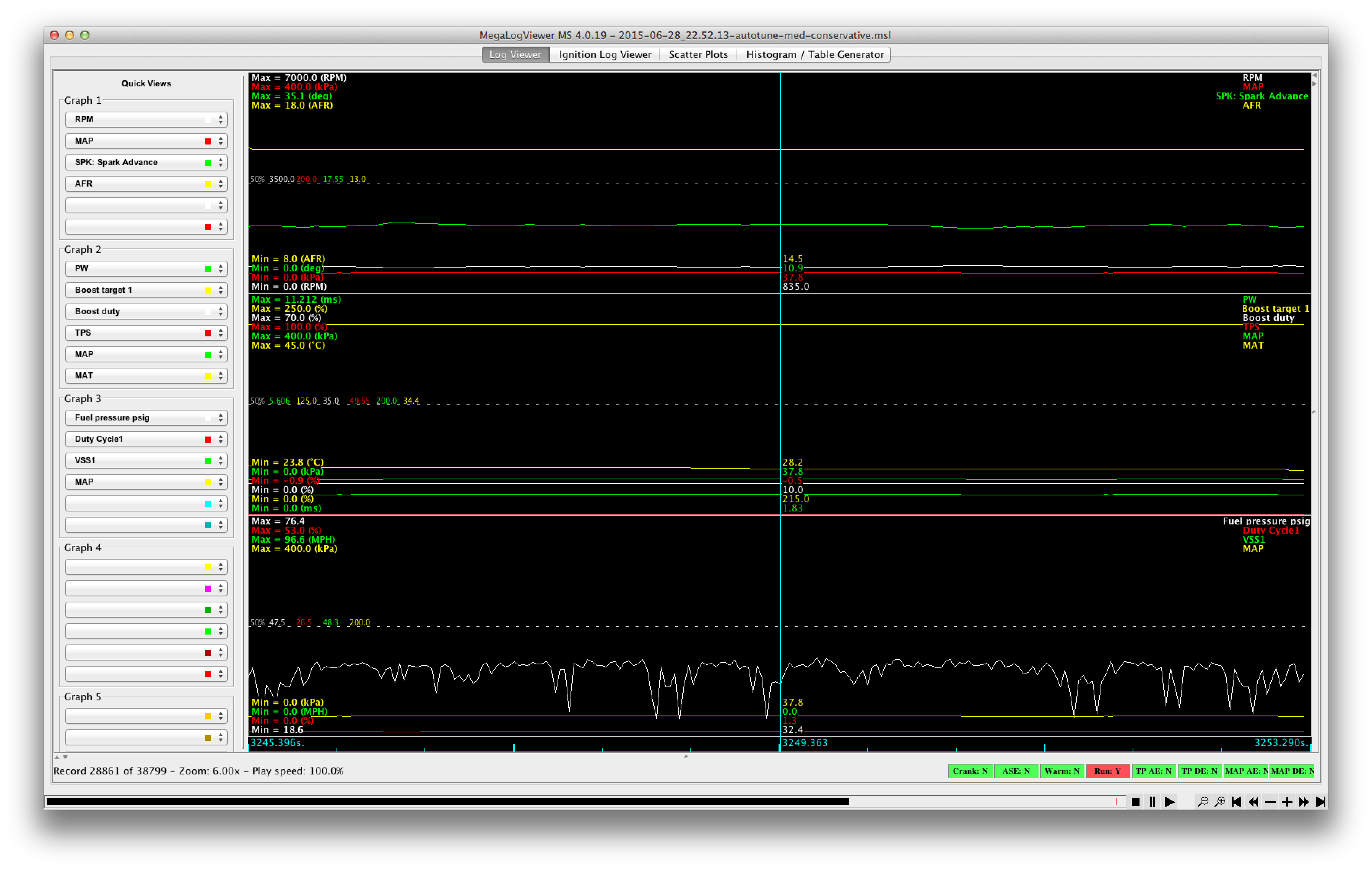

(bottom graph -- white is fuel pressure, red is injector duty cycle. Fuel pressure should be flat and it's obviously not).

I swapped in an FM "big fuel kit" with an AEM regulator mounted back by the tank, this fixed the unregulated idle pressure, but because it deleted the pulse damper I started getting noise in the fuel pressure. The bottom white graph is again fuel pressure.

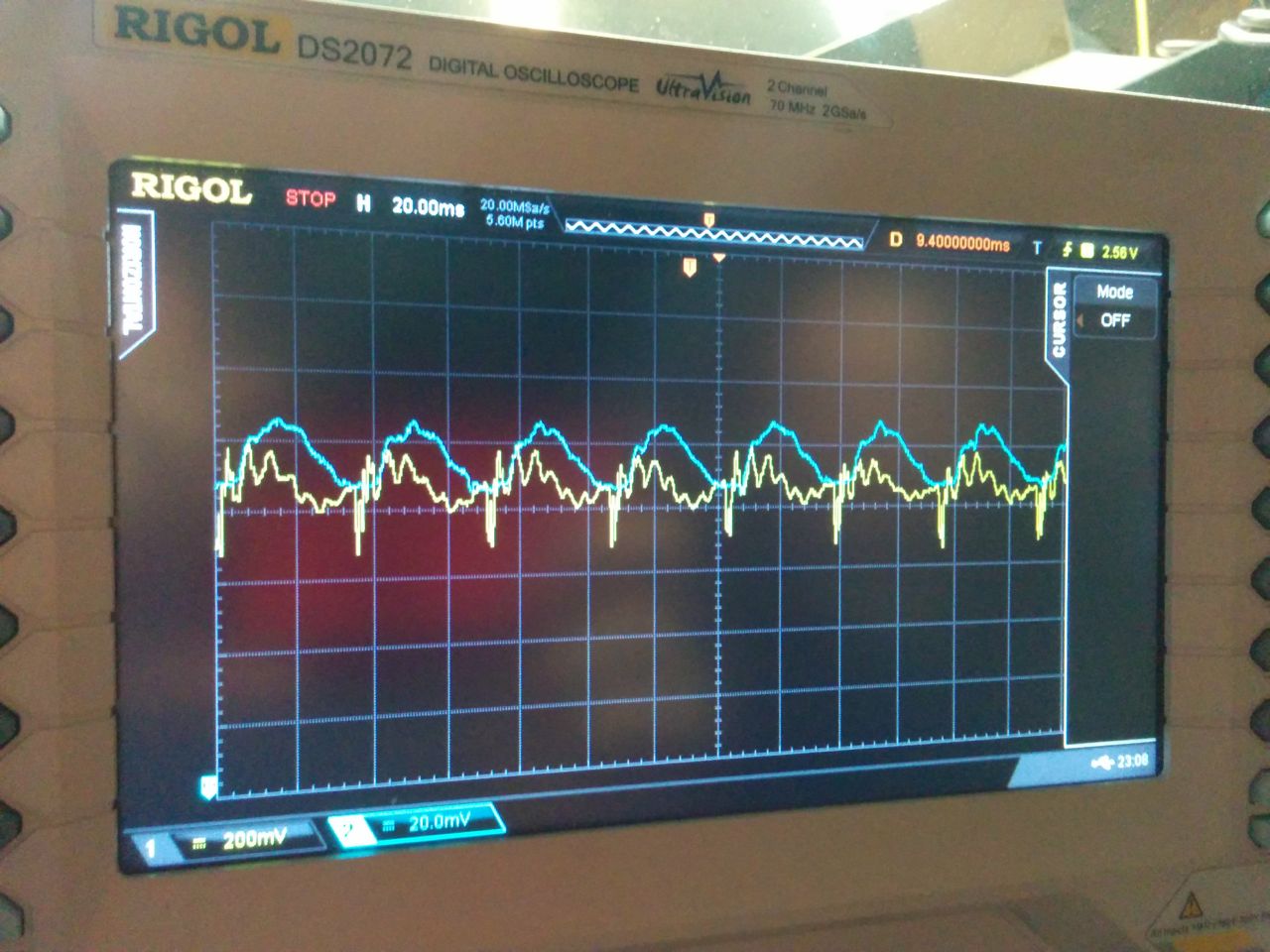

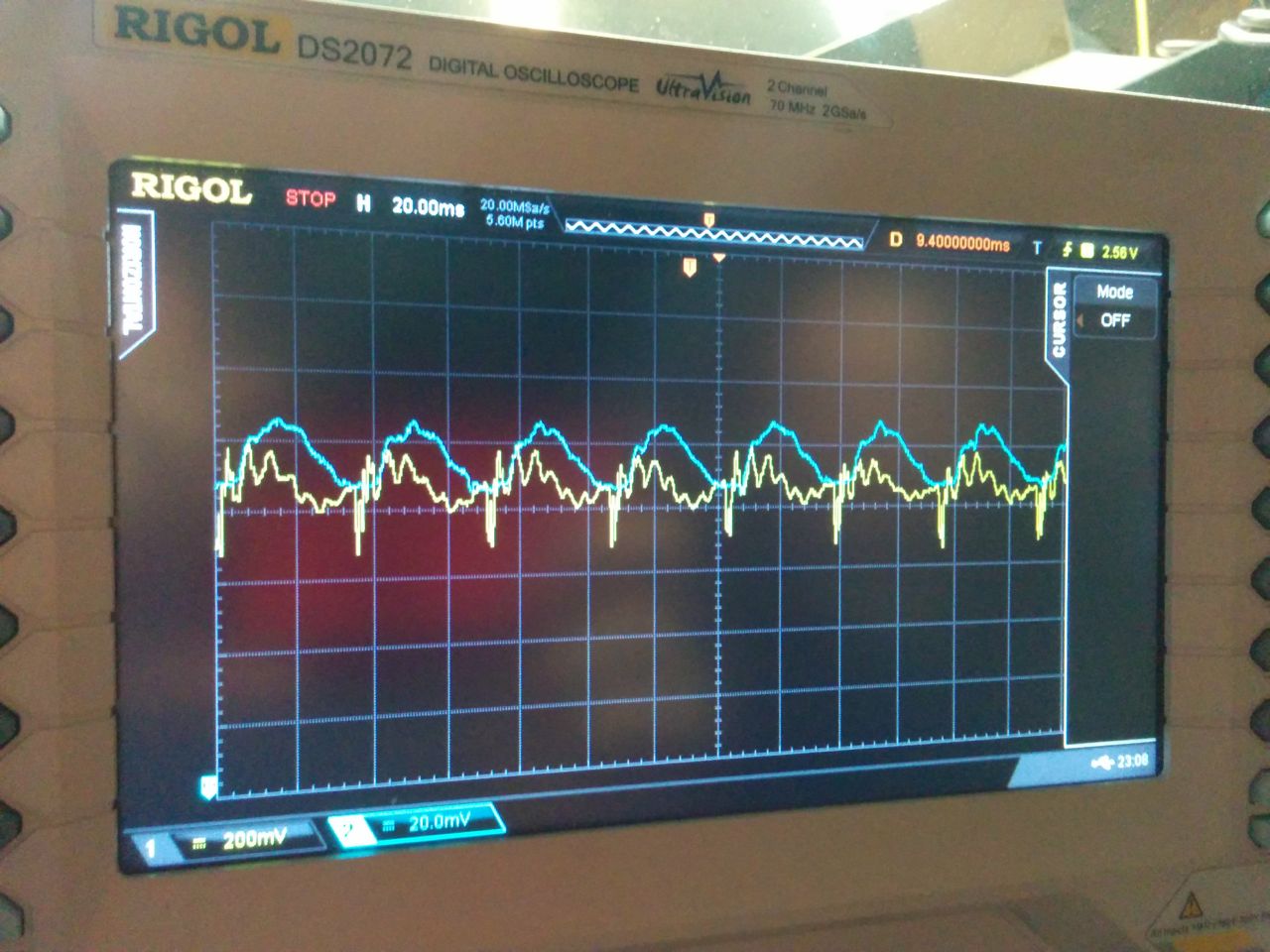

We pulled out the oscilloscope to look at the signal more closely and saw a pattern that the MS3 data logging wasn't fast enough to show:

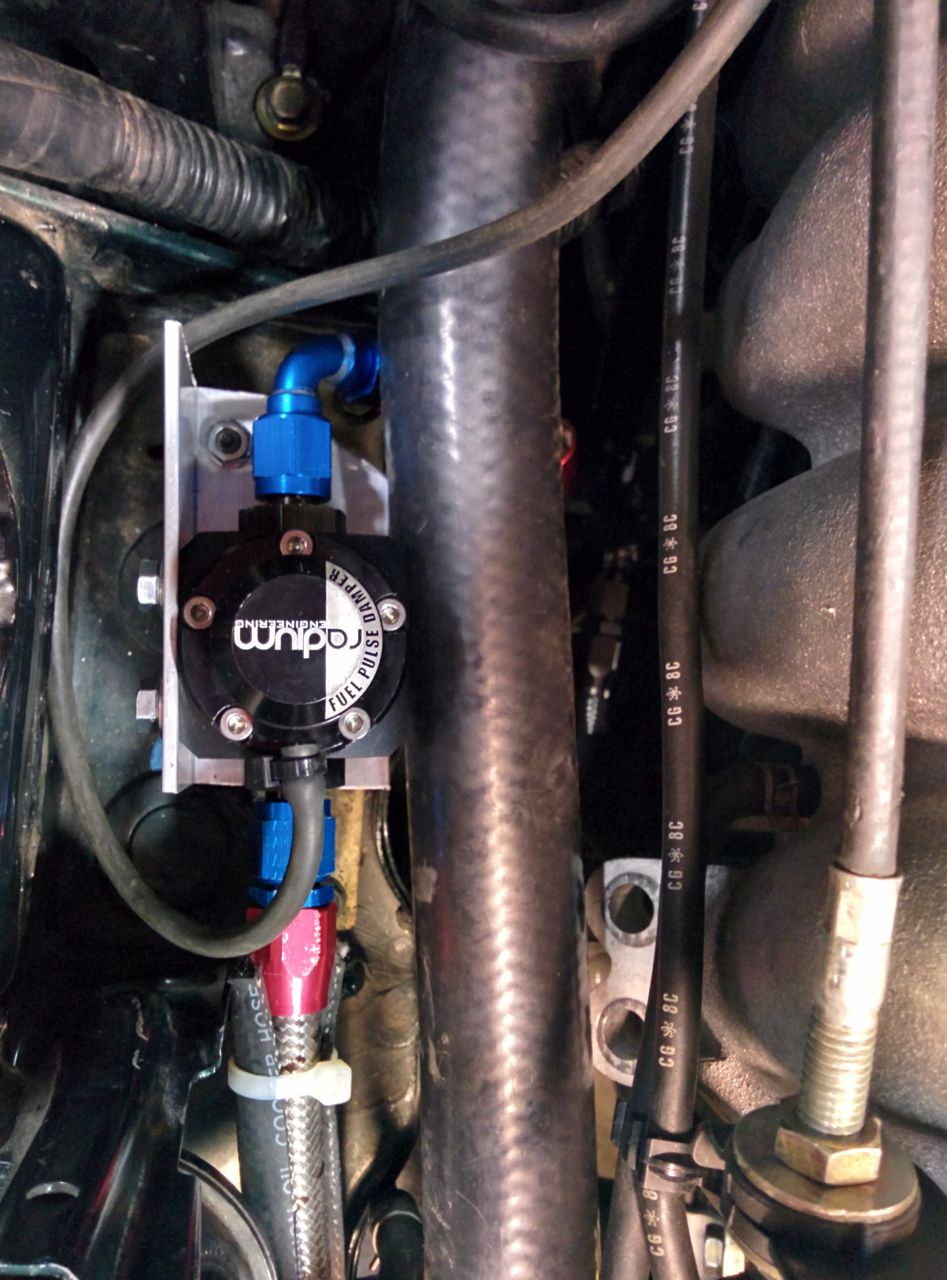

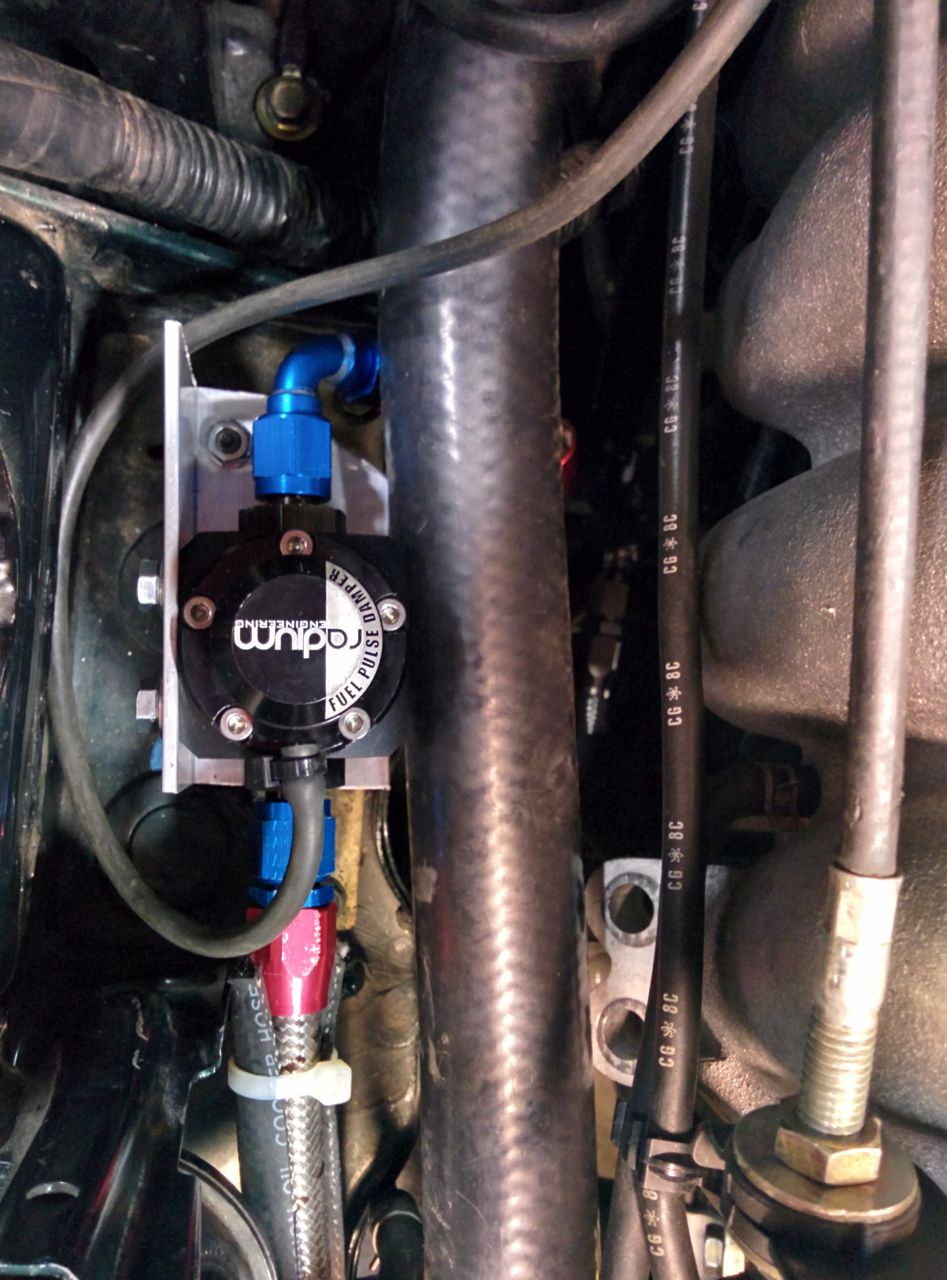

Yellow is fuel pressure, blue is manifold pressure. When the injectors fire the pressure drops rapidly, then overshoots on the way back up. Basically, the fact that the regulator is six feet away from the fuel rail means that it's sluggish to respond. It either needed a return fuel system or a pulse damper. Since I'd gone to a complete -6 AN fuel system, I didn't want to stick the 5/16 stock damper back in, so I bought an aftermarket one from Radium Engineering and installed it:

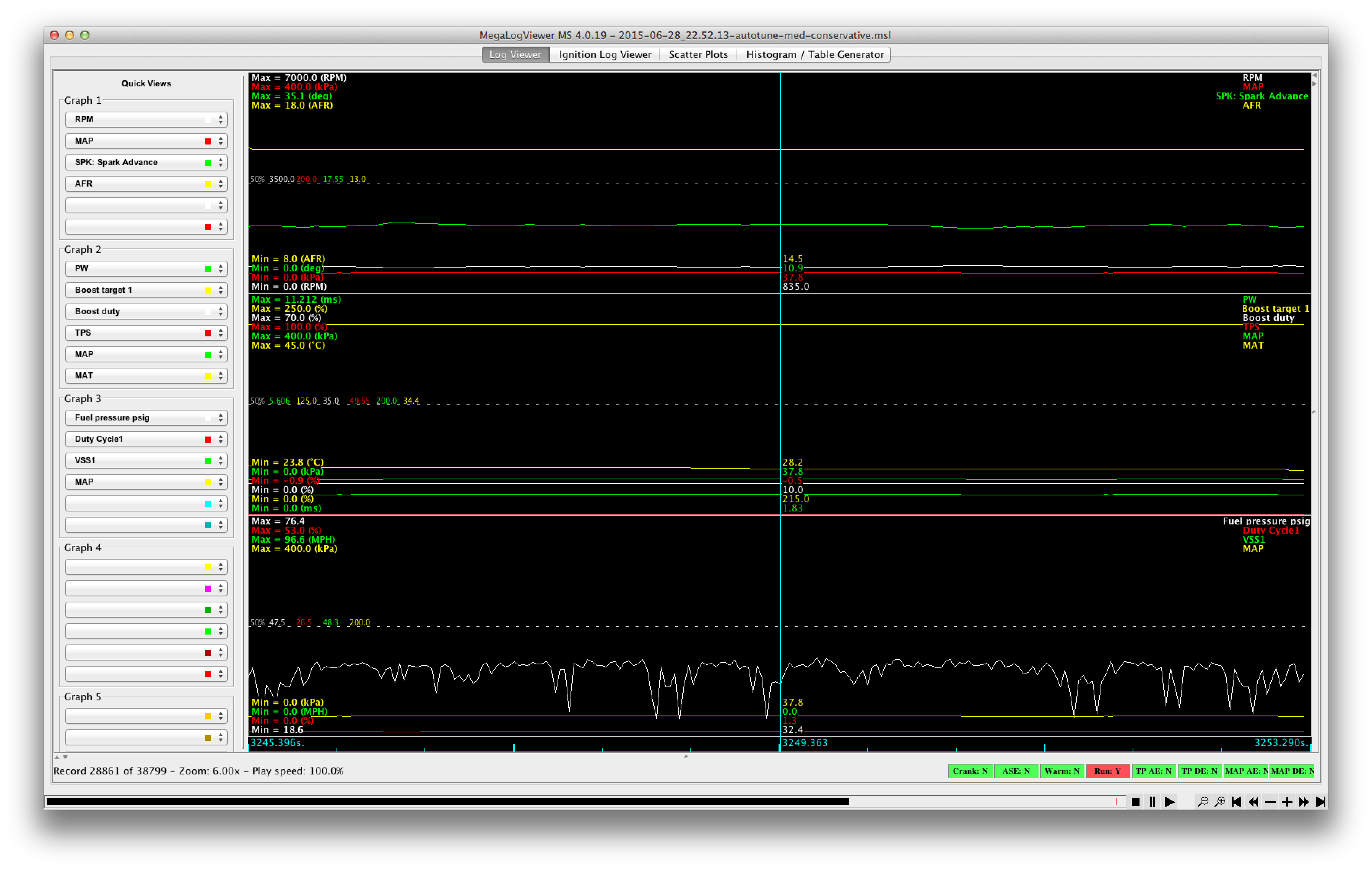

After that, the idle fuel pressure is much improved:

More details in my build thread, linked in my sig.

--Ian

(bottom graph -- white is fuel pressure, red is injector duty cycle. Fuel pressure should be flat and it's obviously not).

I swapped in an FM "big fuel kit" with an AEM regulator mounted back by the tank, this fixed the unregulated idle pressure, but because it deleted the pulse damper I started getting noise in the fuel pressure. The bottom white graph is again fuel pressure.

We pulled out the oscilloscope to look at the signal more closely and saw a pattern that the MS3 data logging wasn't fast enough to show:

Yellow is fuel pressure, blue is manifold pressure. When the injectors fire the pressure drops rapidly, then overshoots on the way back up. Basically, the fact that the regulator is six feet away from the fuel rail means that it's sluggish to respond. It either needed a return fuel system or a pulse damper. Since I'd gone to a complete -6 AN fuel system, I didn't want to stick the 5/16 stock damper back in, so I bought an aftermarket one from Radium Engineering and installed it:

After that, the idle fuel pressure is much improved:

More details in my build thread, linked in my sig.

--Ian

#6

Argh, I dunno why mt.net keeps double-posting stuff.

BTW, what happens when the big pump overwhelms the stock regulator is that the fuel pressure depends on how well the pump is performing. That means it varies with things like battery voltage, temperature, level of fuel in the tank, etc. I saw pressures as high as 75 psi at idle.

--Ian

BTW, what happens when the big pump overwhelms the stock regulator is that the fuel pressure depends on how well the pump is performing. That means it varies with things like battery voltage, temperature, level of fuel in the tank, etc. I saw pressures as high as 75 psi at idle.

--Ian

#8

Joined: Sep 2005

Posts: 33,556

Total Cats: 6,933

From: Chicago. (The less-murder part.)

We know from empirical evidence that the stock fuel system on an NB, in good working order, will easily support power levels in the low 200s, just like the stock fuel system on an NA.

A lot of the posts extolling the virtues of installing comically-oversized fuel pumps were written by people who were replacing a stock fuel pump which had 10+ years and 200,000+ miles on it, not to mention questionable electrical connections.

If your electrics are in good shape, your injectors are properly sized, and your stock (or stock-equivalent) fuel pump is up to spec, you're good to go for "very mild boost."

If this makes you nervous, then by all means go ahead and install a Deatschwerks 200 or a Walbro 190. They're not going to cause any harm, and they cost less than a ******* from a reputable upper east side hooker.

If you plan on shooting for 300 HP, then all of this is moot as you'll be ripping out the stock fuel system anyway.

A lot of the posts extolling the virtues of installing comically-oversized fuel pumps were written by people who were replacing a stock fuel pump which had 10+ years and 200,000+ miles on it, not to mention questionable electrical connections.

If your electrics are in good shape, your injectors are properly sized, and your stock (or stock-equivalent) fuel pump is up to spec, you're good to go for "very mild boost."

If this makes you nervous, then by all means go ahead and install a Deatschwerks 200 or a Walbro 190. They're not going to cause any harm, and they cost less than a ******* from a reputable upper east side hooker.

If you plan on shooting for 300 HP, then all of this is moot as you'll be ripping out the stock fuel system anyway.

#9

We know from empirical evidence that the stock fuel system on an NB, in good working order, will easily support power levels in the low 200s, just like the stock fuel system on an NA.

A lot of the posts extolling the virtues of installing comically-oversized fuel pumps were written by people who were replacing a stock fuel pump which had 10+ years and 200,000+ miles on it, not to mention questionable electrical connections.

If your electrics are in good shape, your injectors are properly sized, and your stock (or stock-equivalent) fuel pump is up to spec, you're good to go for "very mild boost."

If this makes you nervous, then by all means go ahead and install a Deatschwerks 200 or a Walbro 190. They're not going to cause any harm, and they cost less than a ******* from a reputable upper east side hooker.

If you plan on shooting for 300 HP, then all of this is moot as you'll be ripping out the stock fuel system anyway.

A lot of the posts extolling the virtues of installing comically-oversized fuel pumps were written by people who were replacing a stock fuel pump which had 10+ years and 200,000+ miles on it, not to mention questionable electrical connections.

If your electrics are in good shape, your injectors are properly sized, and your stock (or stock-equivalent) fuel pump is up to spec, you're good to go for "very mild boost."

If this makes you nervous, then by all means go ahead and install a Deatschwerks 200 or a Walbro 190. They're not going to cause any harm, and they cost less than a ******* from a reputable upper east side hooker.

If you plan on shooting for 300 HP, then all of this is moot as you'll be ripping out the stock fuel system anyway.

#10

One possible reason why some people might have noticed this is that when the slip rings in the alternator start to wear out, the current output drops at higher RPMs. By 50K miles, my original alternator would do 65 amps at 2000 RPM, but only 30 at 7000 RPM. 30 is barely enough to run the normal loads in the car, so at night with the headlights on the voltage would drop to around 10.5, and that's going to significantly impact the fuel pump performance. So an alternator on its way out could manifest as a failure to keep up fuel pressure at high RPMs.

--Ian

#12

I didn't try converting to a return system because doing it in -6 would have required something like $300 worth of parts, and the radium damper was about a third of that price.

--Ian

Thread

Thread Starter

Forum

Replies

Last Post