Custom VVT cam on a new build, startup problems

#1

I have finally reached the state when it's time to get the engine running, but the transfer of the Cam wings from the stock cam to the ground cam might have failed a number of degrees.

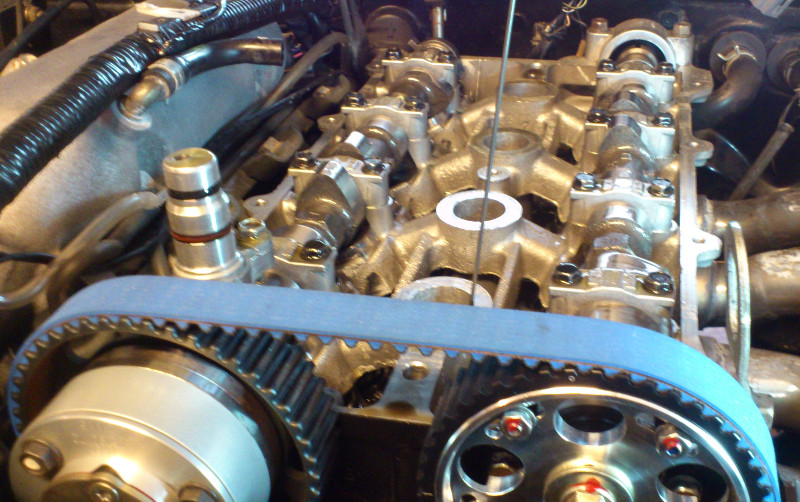

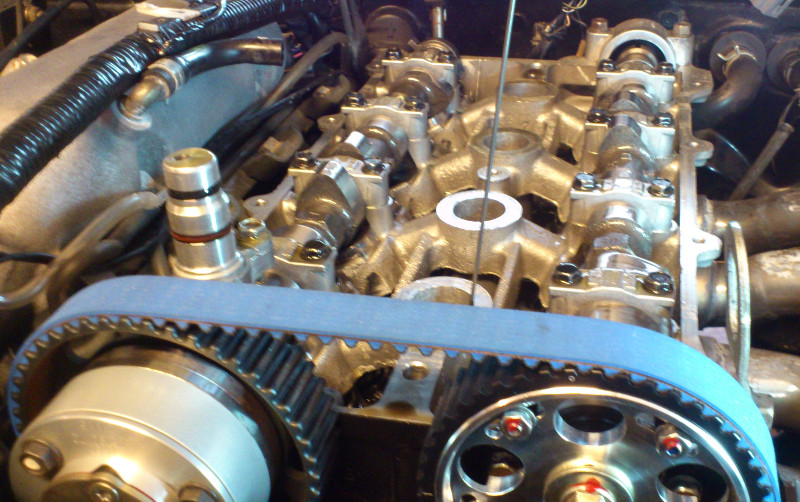

Pictures with the crank/cam zeroed

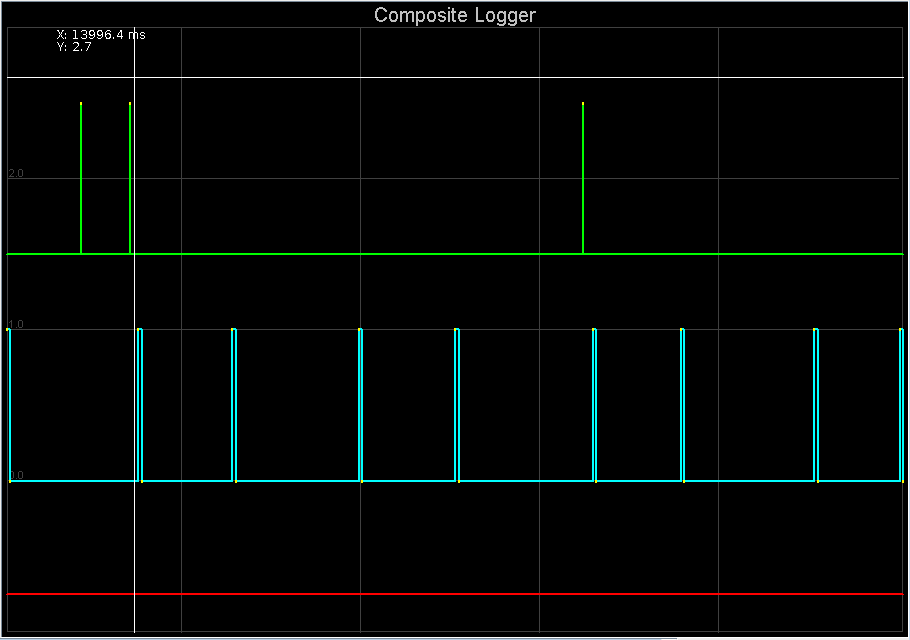

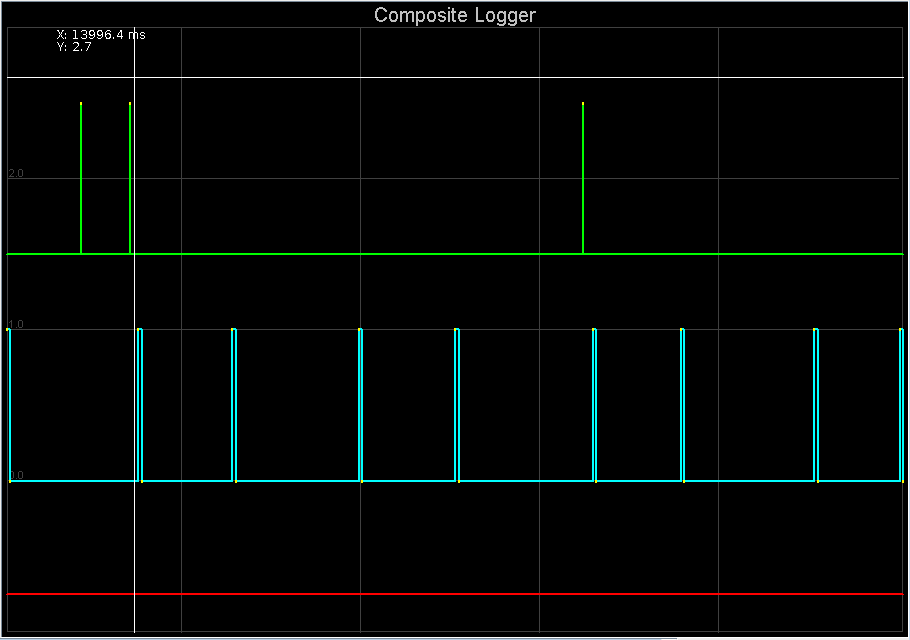

Composit log in TS, signals going through the VVTuner

VVTuner reports the Cam advanced to be 40-55 degree advanced during cranking.The VVT OCV is disconnected.

Does anyone have a picture of the VVT cam vings for a zeroed cam?

Even better if someone could guide me to how many degrees to move the wings based on the composit log (how to measure and basic math).

Don't even assume that I got the wings on the right way (unsure if it can be put backwards).

Pictures with the crank/cam zeroed

Composit log in TS, signals going through the VVTuner

VVTuner reports the Cam advanced to be 40-55 degree advanced during cranking.The VVT OCV is disconnected.

Does anyone have a picture of the VVT cam vings for a zeroed cam?

Even better if someone could guide me to how many degrees to move the wings based on the composit log (how to measure and basic math).

Don't even assume that I got the wings on the right way (unsure if it can be put backwards).

Last edited by NiklasFalk; 05-13-2013 at 05:23 AM. Reason: Changed the title

#2

Using Google Images it actually looks to be installed correctly, but maybe a bit too "retarded" (since it's half a tooth off due to decking).

I could have checked that first... (most pictures came for MT.net...)

Well, I have to start checking the coils thoroughly (1-4 works somewhat).

It spits randomly (and backfires as often).

I could have checked that first... (most pictures came for MT.net...)

Well, I have to start checking the coils thoroughly (1-4 works somewhat).

It spits randomly (and backfires as often).

#3

Mantra: Do your homework, do your homework...

Everything mechanical looks to be ok, the trigger plate is not installed backwards (compared to numerous images and a working engine).

But I changed the CMP and CKP sensors to ones from my other engine and now the sputtering started to sound very different and looking in TS it actually synced.

Increasing the CKP gap to a credit card thickness made the behavior as before, so new sensors are ordered.

When I got home I realized i have forgot to gap the plugs...

Tomorrow the battery will be recharged and with 0.8mm gaps and close to zero CKP gap It will have a better chance to start running (chance, I assume nothing).

Everything mechanical looks to be ok, the trigger plate is not installed backwards (compared to numerous images and a working engine).

But I changed the CMP and CKP sensors to ones from my other engine and now the sputtering started to sound very different and looking in TS it actually synced.

Increasing the CKP gap to a credit card thickness made the behavior as before, so new sensors are ordered.

When I got home I realized i have forgot to gap the plugs...

Tomorrow the battery will be recharged and with 0.8mm gaps and close to zero CKP gap It will have a better chance to start running (chance, I assume nothing).

#4

Trying to do my homework to the best of my ability but it does not help. :(

In an attempt to reduce sources of problems i bypassed the VVTuner and tried to get the thing started with only the DIYPNP, using the firmware and tune when the thing was running last (august 2011).

Adding another battery made the cranking a bit faster but it still just sputters and backfires when using WOT (to dry out the cylinders), and spits randomly when using no throttle or 10-40% throttle.

The only thing I can think of is that the cam overlap is too large to get it started with a poor tune (tune is not touched sine I used the OEM cams) or the ignition timing is very off.

At the same time the intake cam is more advanced than stock at the locked position since the decking made us jump one tooth.

Just to clarify, i cannot use the full VVT range without valve-piston contact, that is the reason for trying to get it started and run-in before even attempting to control the VVT.

One thing I'm contemplating to test is to attach the OCV to the VVTuner and set the table to 5 degrees retard all over and hope that this might help startup. A more complex way to test the same thing would be to retard the VVT can one tooth.

Am I even close to considering a reasonable solution (this would assume that the VVTuner can figure out what to do even though the cam is very close to the crank signal)?

If the closeness of the signals is the problem (and not cam overlap or just poor startup parameters), there is also the "solution" to move the wings of the cam a couple of degrees (they are not fixed on the back of the VVT cam).

Is there anyone who have been even close to these problems with VVT control?

Would a MS3x have different success?

In an attempt to reduce sources of problems i bypassed the VVTuner and tried to get the thing started with only the DIYPNP, using the firmware and tune when the thing was running last (august 2011).

Adding another battery made the cranking a bit faster but it still just sputters and backfires when using WOT (to dry out the cylinders), and spits randomly when using no throttle or 10-40% throttle.

The only thing I can think of is that the cam overlap is too large to get it started with a poor tune (tune is not touched sine I used the OEM cams) or the ignition timing is very off.

At the same time the intake cam is more advanced than stock at the locked position since the decking made us jump one tooth.

Just to clarify, i cannot use the full VVT range without valve-piston contact, that is the reason for trying to get it started and run-in before even attempting to control the VVT.

One thing I'm contemplating to test is to attach the OCV to the VVTuner and set the table to 5 degrees retard all over and hope that this might help startup. A more complex way to test the same thing would be to retard the VVT can one tooth.

Am I even close to considering a reasonable solution (this would assume that the VVTuner can figure out what to do even though the cam is very close to the crank signal)?

If the closeness of the signals is the problem (and not cam overlap or just poor startup parameters), there is also the "solution" to move the wings of the cam a couple of degrees (they are not fixed on the back of the VVT cam).

Is there anyone who have been even close to these problems with VVT control?

Would a MS3x have different success?

#6

Re-checking lash showed one intake valve at zero lash...

Pulling the cam revealed that one lashcap had escaped and was somehow making the lifter 2-3mm higher than the rest. Open valve give no bang...

Putting the lashcap back in place made it start and run on all four. Poorley of course since I've started from scratch with Alpha-N.

So no problems at all, unless that valve have been kinked by the piston (due to the extra lift). I was able to hold it running at 1100rpm tonight.

#9

Blank bought from Mazda Motorsport and ground locally.

There is to my knowledge only one blank left in the world (search and you will find).

Welding and grinding the stock cam is always an option. The Mazda blank did not have much meat anyway, down to 33mm base circle in my case.

There is to my knowledge only one blank left in the world (search and you will find).

Welding and grinding the stock cam is always an option. The Mazda blank did not have much meat anyway, down to 33mm base circle in my case.

Any good regrind service or shop that you guys can recommend?

Thread

Thread Starter

Forum

Replies

Last Post

Zaphod

MEGAsquirt

47

10-27-2018 12:00 AM

StratoBlue1109

Miata parts for sale/trade

21

09-30-2018 02:09 PM