Annoying engine vibration / buzz

#1

Thread Starter

Joined: Jun 2009

Posts: 3,224

Total Cats: 1,706

From: Istanbul, Turkey

The car is a 1998 NB, 1.8 engine.

Hotside MP62, custom header (thanks Gibbp), custom exhaust all the way to the rear bumper. No cat.

COP ignition

Custom 130 Amp alternator.

Skunk2 big throttle body

No A/C

No P/S pump (p/s converted to electric)

FM Stage 1 clutch

Mazda "competition" engine mounts

No intake manifold brace

Blocked off EGR, no EGR tube.

Coolant reroute

"Built" engine with 9.00:1 JE pistons, M-Tuned rods, Supertech valvetrain

I will gladly provide more specs if I missed anything of importance.

The problem is a very pronounced engine vibration or buzz between 2550 and 2950(ish) rpm range.

This happens regardless of:

* whether the engine is in gear or just revved in neutral while parked.

* whether the engine is accelerating or decelerating

* whether or not the supercharger belt is installed

* whatever gear the car may be in.

* whatever temp the engine may be at

* load

This thing had been and is happening before and after all the modifications listed above. (Meaning, all of those items can be ruled out as the culprit)

It's not the gearbox or the diff, because it happens in gear, in neutral and with the clutch depressed in neutral or while in gear.

I can put my hand on the engine and really feel the high frequency vibration as I increase/decrease the rpm past that dreaded range.

Definitely not the heat shield. I have none at this time. (plus, the heat shield rattle is a symptom, not the cause when that's the case - something just rattles that sucker)

I have been searching the forums, but all I can find is bits and pieces of my symptoms. Never the whole thing in one case.

Any ideas?

Hotside MP62, custom header (thanks Gibbp), custom exhaust all the way to the rear bumper. No cat.

COP ignition

Custom 130 Amp alternator.

Skunk2 big throttle body

No A/C

No P/S pump (p/s converted to electric)

FM Stage 1 clutch

Mazda "competition" engine mounts

No intake manifold brace

Blocked off EGR, no EGR tube.

Coolant reroute

"Built" engine with 9.00:1 JE pistons, M-Tuned rods, Supertech valvetrain

I will gladly provide more specs if I missed anything of importance.

The problem is a very pronounced engine vibration or buzz between 2550 and 2950(ish) rpm range.

This happens regardless of:

* whether the engine is in gear or just revved in neutral while parked.

* whether the engine is accelerating or decelerating

* whether or not the supercharger belt is installed

* whatever gear the car may be in.

* whatever temp the engine may be at

* load

This thing had been and is happening before and after all the modifications listed above. (Meaning, all of those items can be ruled out as the culprit)

It's not the gearbox or the diff, because it happens in gear, in neutral and with the clutch depressed in neutral or while in gear.

I can put my hand on the engine and really feel the high frequency vibration as I increase/decrease the rpm past that dreaded range.

Definitely not the heat shield. I have none at this time. (plus, the heat shield rattle is a symptom, not the cause when that's the case - something just rattles that sucker)

I have been searching the forums, but all I can find is bits and pieces of my symptoms. Never the whole thing in one case.

Any ideas?

#3

Thread Starter

Joined: Jun 2009

Posts: 3,224

Total Cats: 1,706

From: Istanbul, Turkey

And, there are no covers to rattle anymore. None. No heat shields, no exhaust manifold cover.

I have a one piece header/downpipe combo, and that's wrapped all the way to where the cat would be.

#6

Thread Starter

Joined: Jun 2009

Posts: 3,224

Total Cats: 1,706

From: Istanbul, Turkey

Apparently.

How would I deal with harmonics, then?

I'm guessing I would have to remove the crank+rods+pistons and balance them in a specific way...

My pistons and rods were all within 1 gram of each other, so I did not bother with a finer balance at the time I built the engine.

How would I deal with harmonics, then?

I'm guessing I would have to remove the crank+rods+pistons and balance them in a specific way...

My pistons and rods were all within 1 gram of each other, so I did not bother with a finer balance at the time I built the engine.

#11

I suffer from something similar, as does a mate.

The one thing that's similar, we all run/ran superchargers. I'm convinced it's a harmonic from the vibration dampner causing the issue. My vibration started when I installed the blower, and even after retuning to stock, the vibration stayed

I think the balancer became damaged in some way, possibly from the additional weight/stress of the additional 6 rib pulley? However my mate had a setup which used the OEM 4 rib belt. I guess the additional loads could also cause an issue?

The one thing that's similar, we all run/ran superchargers. I'm convinced it's a harmonic from the vibration dampner causing the issue. My vibration started when I installed the blower, and even after retuning to stock, the vibration stayed

I think the balancer became damaged in some way, possibly from the additional weight/stress of the additional 6 rib pulley? However my mate had a setup which used the OEM 4 rib belt. I guess the additional loads could also cause an issue?

#16

Thread Starter

Joined: Jun 2009

Posts: 3,224

Total Cats: 1,706

From: Istanbul, Turkey

Here's what I did:

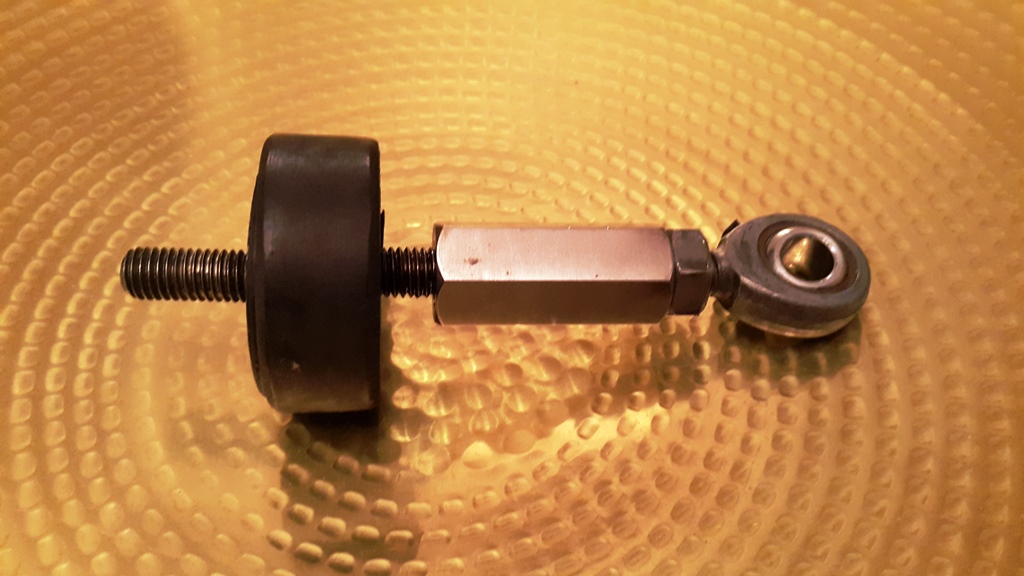

This is half of the underbrace for the blower:

(I did not think to take a picture of the whole thing, and it's too late now - but you guys get the idea.)

This brace obviously has a vibration damper..

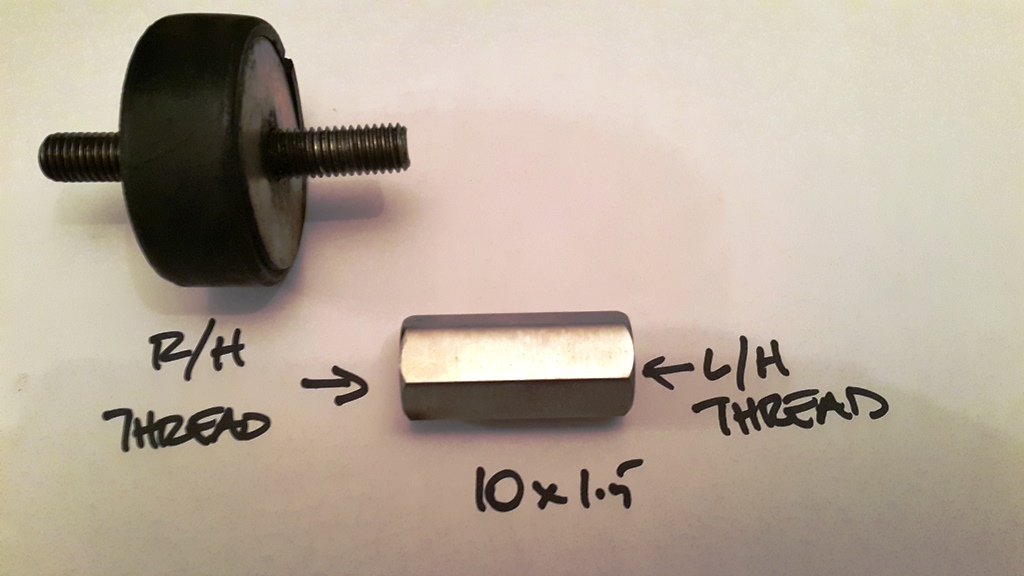

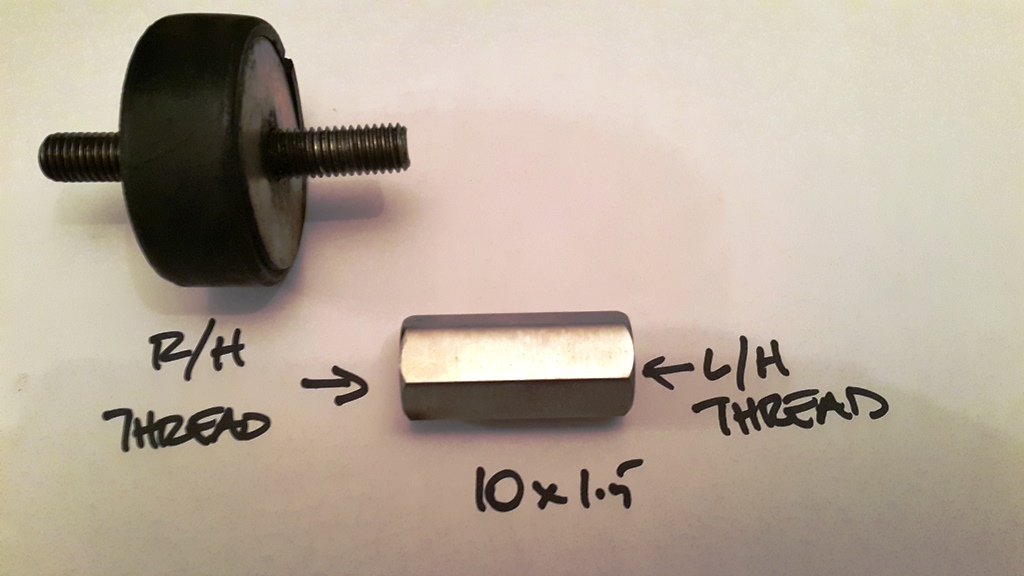

But a close inspection revealed this:

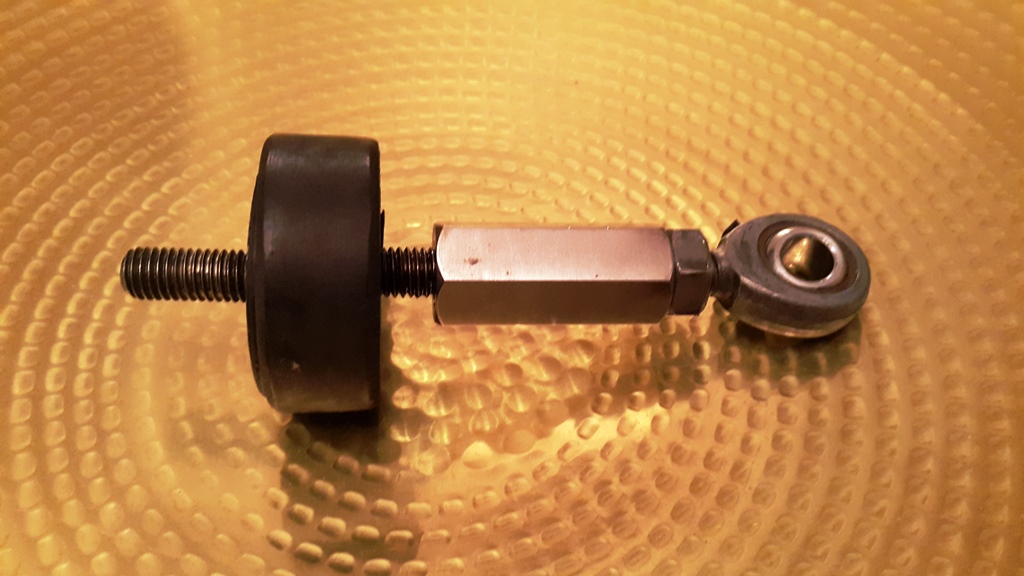

So, I not only replaced the bad damper, but modified the whole thing a little.

There is a long hex nut that connects the damper and the heim joint.

I went to a machine shop and had them make me one with r/h threads on one side, and l/h threads on the other.

I also bought a L/H thread heim joint for a couple bucks, and connected everything using lock nuts.

Installed it in place with the lock nuts loose, and started playing with the tension/neutral/compression setting of the brace.

The magic happened under slight compression.

90% of the vibration is gone.

The damper was the first one I saw at the industrial hardware store (under 2 bucks). (They were closing, so I had to hurry).

I may experiment with different diameters/densities/metal faced designs later when I have time, but this did it.

Just wanted to post details.. Could be of help for someone.

This is half of the underbrace for the blower:

(I did not think to take a picture of the whole thing, and it's too late now - but you guys get the idea.)

This brace obviously has a vibration damper..

But a close inspection revealed this:

So, I not only replaced the bad damper, but modified the whole thing a little.

There is a long hex nut that connects the damper and the heim joint.

I went to a machine shop and had them make me one with r/h threads on one side, and l/h threads on the other.

I also bought a L/H thread heim joint for a couple bucks, and connected everything using lock nuts.

Installed it in place with the lock nuts loose, and started playing with the tension/neutral/compression setting of the brace.

The magic happened under slight compression.

90% of the vibration is gone.

The damper was the first one I saw at the industrial hardware store (under 2 bucks). (They were closing, so I had to hurry).

I may experiment with different diameters/densities/metal faced designs later when I have time, but this did it.

Just wanted to post details.. Could be of help for someone.