The 4G63T PCV System

#1

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

I Know there are some differances between the Mazda BP engine and the Mitsubishi 4G63.

There is a fair amount in common between the two engines also, I felt this article whould have some valid use here, mainly how a PCV system works, and setting a catch can up for use on a turbo engine.

This was written and posted on DSMTuners.com By Calan

DSM Forums - View Profile: Calan

The 4G63T PCV System - DSM Forums

The 4G63T PCV System

________________________________________

Introduction

With very few exceptions, no topic generates more debate than the PCV system used on our turbo DSMs. I think it is mostly because of the huge amount of confusing and sometimes misleading information that has been posted in the forums over the years. It is for this reason that I decided to write this article, with the goal of clarifying a few things and providing answers to the most commonly asked questions.

Note: PCV stands for Positive Crankcase Ventilation. Don’t confuse this with PVC, which stands for Poly Vinyl Chloride and is a type of plastic commonly found in home plumbing. Also, the term “positive” doesn’t refer to any particular direction of flow or pressure value (like positive/negative); it is simply meant to imply a definite flow, rather than a passive system that may or may not be ventilating anything.

Also, the term “positive” doesn’t refer to any particular direction of flow or pressure value (like positive/negative); it is simply meant to imply a definite flow, rather than a passive system that may or may not be ventilating anything.

PCV systems were first used on automobiles starting in the 1960s, when crankcase emissions were discovered to be a source of pollution. Before that, most vehicles used a simple draft tube hanging off the engine, in which crankcase vapors were vented off under the car. The idea was that air flowing over the tube would create a low-pressure area and help pull the vapors from the crankcase, while fresh air was drawn in through a breather vent. But this wasn’t always the case, and barely worked at all unless the car was moving. The first true PCV systems were just improvements on this idea, and used vacuum in the intake to pull the vapors into the air/fuel stream and burn them, rather than dumping them to the atmosphere. Very little has changed since then.

In this article, we’ll start off by examining the factory PCV setup on turbo 4G63s and how to improve it for daily driver and part-time track cars, and then move on to other alternatives for more demanding situations.

DISCLAIMER: An improperly functioning PCV system, or one that has been modified improperly, can lead to emmisions violations or even damage to the vehicle. As always, any modifications to your car should be done at your own risk.

Why it’s needed, and how it works

An engine produces power by burning an air/fuel mixture in the cylinders under extremely high pressure (bet you already knew that huh?). As the gases burn and expand, the released energy is used to push the pistons downward and rotate the crank, and the combustion leftovers are then sent out the exhaust. The job of the piston rings is to seal the cylinder so pressure can be built up, prevent oil from getting up into the cylinders, and prevent the air/fuel mix from getting down into the oil.

Note: We’ll just ignore the valve seals and the fact the oil is flowing around in the head for this discussion.

In a perfect world, air and fuel would stay on top of the pistons, and oil would stay below them. But of course it’s not a perfect world. Because of the high cylinder pressures, some of the expanding gases are forced past the piston rings and find their way into the lower crankcase. These gases (commonly referred to as blow-by) consist of fuel vapor, partially burnt hydrocarbons, water vapor, and other nasty by-products of the combustion process. If these gases are not vented from the crankcase, they will eventually be absorbed into the oil and cause damage to bearings and other internal parts of the engine.

The goal of the PCV system is to provide a way to get these gases out of the engine’s crankcase and recycle them into the air/fuel mix, thus cutting down on emissions and preventing the oil from becoming contaminated. It does this by “sucking” the vapors out of the crankcase through a port in the valve cover, and routing them to the intake manifold (IM) where they are mixed with the incoming air and burned. As the harmful gases are pulled from the crankcase, fresh air is pulled in and circulated…thus the term “ventilation”.

At the heart of the system is a special valve called (oddly enough) the PCV valve. In one sense it is a simple check valve; it only allows air to flow towards the IM and closes completely when air tries to flow the other way. But it is also an airflow-metering device. Under maximum intake vacuum (such as when idling or decelerating) the amount of blow by in the engine is at it’s minimum, and the PCV valve is mostly closed. As the engine load increases and intake vacuum decreases, blow by increases and the PCV valve opens proportionally to allow more airflow. It is this metering function that keeps the airflow between the IM and crankcase balanced under all load conditions.

The Stock 4G63T PCV System

So far we’ve mostly talked about the PCV system as it applies to naturally aspirated gas engines. These same principles apply to our turbo DSM’s, with a twist. In a turbocharged engine, the IM can see positive pressure as well as vacuum, so the PCV system takes on another role. Not only is it responsible for ventilating the crankcase with fresh air while the IM is in vacuum, it also has to relieve the crankcase of excessive pressure buildup during boost. Because of this, parts of the system must allow air to flow in two directions while preventing it from flowing in a certain direction under different operating conditions.

Important point #1: The PCV system has two functions:

• To ventilate the crankcase with fresh air while operating under vacuum conditions, and

• To relieve the crankcase of excess pressure during high engine loads

Important point #2: Parts of the system must allow air to flow in two directions.

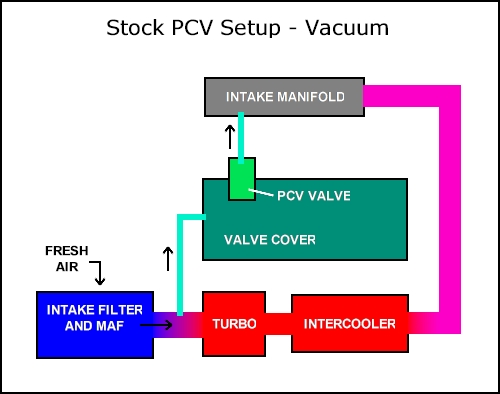

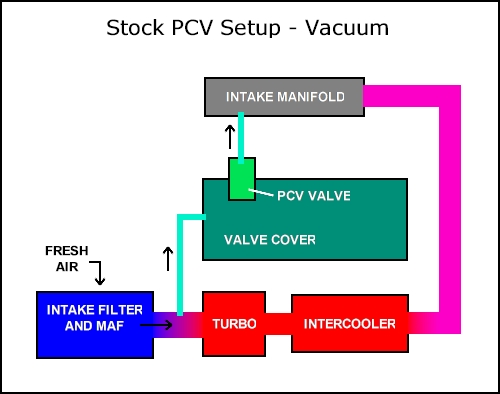

The diagram below shows how the factory PCV system on a turbo 4G63 motor works while operating in vacuum conditions. Crankcase vapors are drawn out through the PCV valve, which is located on the valve cover. As vacuum in the IM increases and decreases, the PCV valve opens and closes proportionally to meter the amount of crankcase air that enters the IM. At the same time, fresh air is pulled from the air inlet to replenish the air that was drawn out.

Notice that the air used to replenish the crankcase is pulled in after the mass airflow sensor (MAF), and has therefore been measured and reported to the ECU. If the air were pulled before the MAF, the ECU would think less air is entering the IM than there really is and the car would run lean. This is important to remember; we’ll talk about it again a little later on.

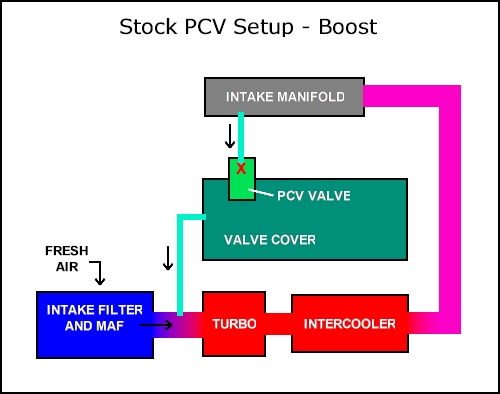

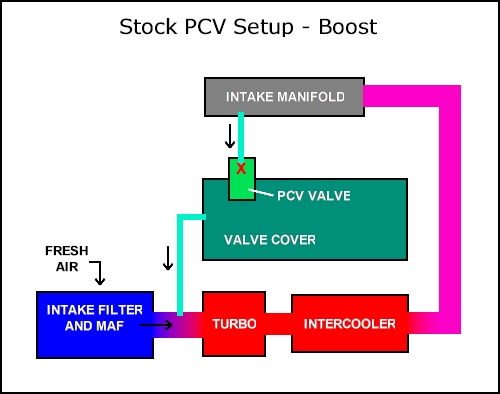

When the engine is running under boost, the PCV valve closes to prevent positive pressure in the IM from entering the crankcase. At the same time, excess pressure is drawn out through the VC breather port and into the turbo inlet, where it eventually finds it’s way back to the IM and into the cylinders to be burned off. When under boost, the high speed of the turbo's compressor creates a vacuum that helps to overcome the resistance of the lines and fittings, and pull out the excess crankcase vapors. In an ideal world the crankcase should never see positive pressure... and providing suction to it ensures this is the case.

The larger the turbo and the more boost being created, the more of a vacuum affect that will be felt at the turbo inlet.

Important point #3: The turbo inlet creates a vacuum that helps pull out the excess crankcase vapors.

You may be wondering why the crankcase is vented at the top of the engine off of the VC when the gases are being forced down past the rings into the lower crankcase. It’s quite simple actually; anywhere there is oil, there are crankcase gases. The hot gases will rise to the top of the engine through the oil passages in the head, and by tapping into the VC there is less chance of liquid oil being sucked into the IM or turbo inlet.

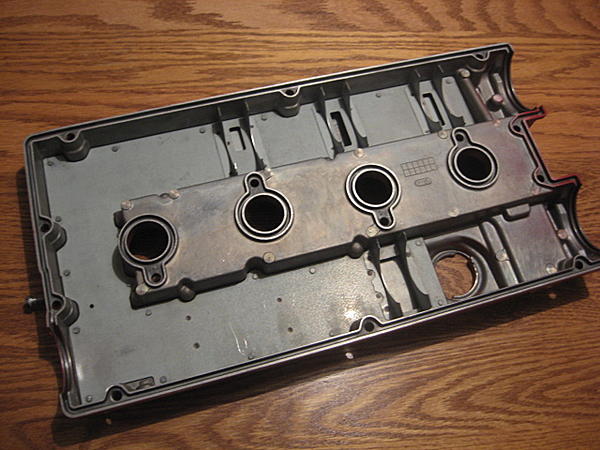

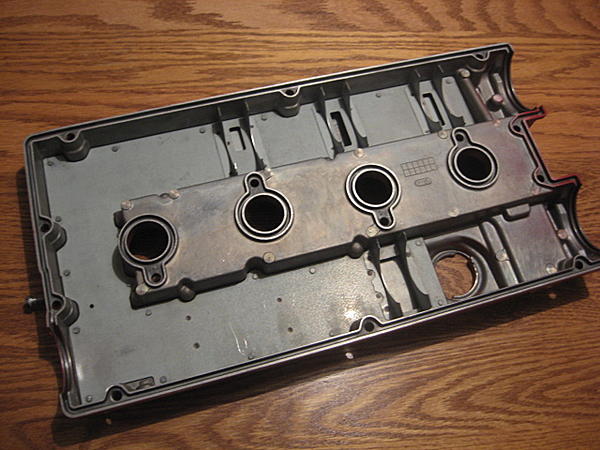

If you look at the underside of the VC, you’ll see a series of plates and baffles. These baffles separate the liquid oil splashing around the valve train from the PCV ports, and provide an area for the crankcase vapors to collect and be pulled out.

Important point #4: Unless you have a good reason not to, leave your VC baffles in place.

You’ll also notice that the PCV valve itself has a tube extending from the end that screws into the VC. This is there to prevent any oil that does find it’s way past the baffles from getting into the PCV valve. Regardless of this and the baffling, oil still collects in the PCV valve and the lines that connect the entire PCV system. Needless to say, it can make for a pretty messy intake tract.

When things go bad…

If the PCV system isn’t functioning properly, several not so pleasant things can happen. Probably the worst of these is that crankcase pressure can build up and cause the dipstick to pop out (especially if it’s old and worn out), potentially covering everything in oil. In a worst-case scenario this could cause an engine fire. Not fun.

Note: Clamping the dipstick down to prevent it from blowing out is not a fix for a poorly operating PCV system. If your dipstick still pops out even after replacing it with a new one, fix your PCV issues!

Excessive crankcase pressure can also wreak havoc on seals, cause accelerated bearing wear, and in some cases hinder the proper draining of oil from the turbo back into the oil pan.

A dirty or clogged PCV valve can also affect performance and fuel economy. If it’s stuck open, boost from the IM can enter the crankcase, causing a slight drop in power due to pumping losses… if the dipstick doesn’t pop out first. It can also cause drivability issues due to fluctuations in IM vacuum, since it has lost the ability to properly meter the air as described above. If it’s stuck closed or completely clogged, oil contamination can become a serious issue and your bearings will start to suffer.

So what’s wrong with the factory PCV system?

The short answer is… nothing; as long as the car is stock and everything is properly maintained. But if you are running anything more than stock boost or would prefer to not have oily residue in your intake, read on.

Since the PCV valve is the heart of the system, let’s start there. This thing is notorious for not being able to completely close to prevent boost from entering the VC, even when brand new. Add a few thousand miles worth of crud flowing back and forth through it and it gets worse. And the more boost you run, the greater the problem becomes.

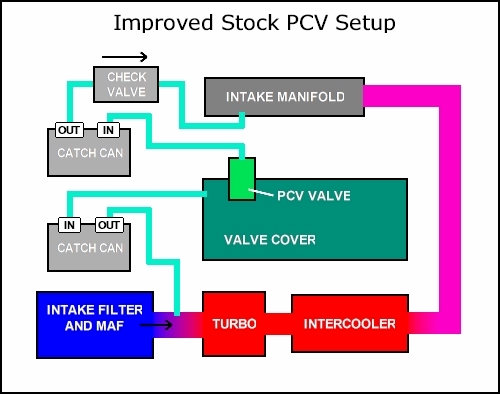

A simple solution to this problem is to add an additional check valve between the IM and PCV valve. This check valve needs to be tough and chemical resistant, and have a fairly low crack pressure so that normal flow isn’t impeded. Fortunately for us, US Plastics sells one that is both ideal and inexpensive. (I think Romeen was the first to find these and test them. We owe him a big thanks, as they are extremely useful for many applications under the hood.)

3/8” Kynar Standard Check Valves

Although shipping is a bit much for a part that cost $1.49, you can probably get them to throw a couple in an envelope and mail it to you over the phone. Or, buy several and sell them to other DSM’ers at a small profit.

Note: If you look closely at these check valves, one side of the larger diameter body is angled. This angled side points in the direction of flow.

Another problem with the stock PCV valve (and this is just my opinion) is the way in which it sits in the VC. The stock arrangement makes getting to the TPS a real pain, so I modified the stock PCV valve to make things a little more accessible.

A tech article describing how it was done can be found here, and more pictures and information on how I routed everything can be found here.

Even with a perfectly maintained engine, oil is still going to find its’ way into your intake manifold and intercooler piping with the factory setup. By adding an inline catch can to each side of the VC, you can greatly cut down on the amount of oil that collects in the intake tract.

There is a fair amount in common between the two engines also, I felt this article whould have some valid use here, mainly how a PCV system works, and setting a catch can up for use on a turbo engine.

This was written and posted on DSMTuners.com By Calan

DSM Forums - View Profile: Calan

The 4G63T PCV System - DSM Forums

The 4G63T PCV System

________________________________________

Introduction

With very few exceptions, no topic generates more debate than the PCV system used on our turbo DSMs. I think it is mostly because of the huge amount of confusing and sometimes misleading information that has been posted in the forums over the years. It is for this reason that I decided to write this article, with the goal of clarifying a few things and providing answers to the most commonly asked questions.

Note: PCV stands for Positive Crankcase Ventilation. Don’t confuse this with PVC, which stands for Poly Vinyl Chloride and is a type of plastic commonly found in home plumbing.

Also, the term “positive” doesn’t refer to any particular direction of flow or pressure value (like positive/negative); it is simply meant to imply a definite flow, rather than a passive system that may or may not be ventilating anything.

Also, the term “positive” doesn’t refer to any particular direction of flow or pressure value (like positive/negative); it is simply meant to imply a definite flow, rather than a passive system that may or may not be ventilating anything.PCV systems were first used on automobiles starting in the 1960s, when crankcase emissions were discovered to be a source of pollution. Before that, most vehicles used a simple draft tube hanging off the engine, in which crankcase vapors were vented off under the car. The idea was that air flowing over the tube would create a low-pressure area and help pull the vapors from the crankcase, while fresh air was drawn in through a breather vent. But this wasn’t always the case, and barely worked at all unless the car was moving. The first true PCV systems were just improvements on this idea, and used vacuum in the intake to pull the vapors into the air/fuel stream and burn them, rather than dumping them to the atmosphere. Very little has changed since then.

In this article, we’ll start off by examining the factory PCV setup on turbo 4G63s and how to improve it for daily driver and part-time track cars, and then move on to other alternatives for more demanding situations.

DISCLAIMER: An improperly functioning PCV system, or one that has been modified improperly, can lead to emmisions violations or even damage to the vehicle. As always, any modifications to your car should be done at your own risk.

Why it’s needed, and how it works

An engine produces power by burning an air/fuel mixture in the cylinders under extremely high pressure (bet you already knew that huh?). As the gases burn and expand, the released energy is used to push the pistons downward and rotate the crank, and the combustion leftovers are then sent out the exhaust. The job of the piston rings is to seal the cylinder so pressure can be built up, prevent oil from getting up into the cylinders, and prevent the air/fuel mix from getting down into the oil.

Note: We’ll just ignore the valve seals and the fact the oil is flowing around in the head for this discussion.

In a perfect world, air and fuel would stay on top of the pistons, and oil would stay below them. But of course it’s not a perfect world. Because of the high cylinder pressures, some of the expanding gases are forced past the piston rings and find their way into the lower crankcase. These gases (commonly referred to as blow-by) consist of fuel vapor, partially burnt hydrocarbons, water vapor, and other nasty by-products of the combustion process. If these gases are not vented from the crankcase, they will eventually be absorbed into the oil and cause damage to bearings and other internal parts of the engine.

The goal of the PCV system is to provide a way to get these gases out of the engine’s crankcase and recycle them into the air/fuel mix, thus cutting down on emissions and preventing the oil from becoming contaminated. It does this by “sucking” the vapors out of the crankcase through a port in the valve cover, and routing them to the intake manifold (IM) where they are mixed with the incoming air and burned. As the harmful gases are pulled from the crankcase, fresh air is pulled in and circulated…thus the term “ventilation”.

At the heart of the system is a special valve called (oddly enough) the PCV valve. In one sense it is a simple check valve; it only allows air to flow towards the IM and closes completely when air tries to flow the other way. But it is also an airflow-metering device. Under maximum intake vacuum (such as when idling or decelerating) the amount of blow by in the engine is at it’s minimum, and the PCV valve is mostly closed. As the engine load increases and intake vacuum decreases, blow by increases and the PCV valve opens proportionally to allow more airflow. It is this metering function that keeps the airflow between the IM and crankcase balanced under all load conditions.

The Stock 4G63T PCV System

So far we’ve mostly talked about the PCV system as it applies to naturally aspirated gas engines. These same principles apply to our turbo DSM’s, with a twist. In a turbocharged engine, the IM can see positive pressure as well as vacuum, so the PCV system takes on another role. Not only is it responsible for ventilating the crankcase with fresh air while the IM is in vacuum, it also has to relieve the crankcase of excessive pressure buildup during boost. Because of this, parts of the system must allow air to flow in two directions while preventing it from flowing in a certain direction under different operating conditions.

Important point #1: The PCV system has two functions:

• To ventilate the crankcase with fresh air while operating under vacuum conditions, and

• To relieve the crankcase of excess pressure during high engine loads

Important point #2: Parts of the system must allow air to flow in two directions.

The diagram below shows how the factory PCV system on a turbo 4G63 motor works while operating in vacuum conditions. Crankcase vapors are drawn out through the PCV valve, which is located on the valve cover. As vacuum in the IM increases and decreases, the PCV valve opens and closes proportionally to meter the amount of crankcase air that enters the IM. At the same time, fresh air is pulled from the air inlet to replenish the air that was drawn out.

Notice that the air used to replenish the crankcase is pulled in after the mass airflow sensor (MAF), and has therefore been measured and reported to the ECU. If the air were pulled before the MAF, the ECU would think less air is entering the IM than there really is and the car would run lean. This is important to remember; we’ll talk about it again a little later on.

When the engine is running under boost, the PCV valve closes to prevent positive pressure in the IM from entering the crankcase. At the same time, excess pressure is drawn out through the VC breather port and into the turbo inlet, where it eventually finds it’s way back to the IM and into the cylinders to be burned off. When under boost, the high speed of the turbo's compressor creates a vacuum that helps to overcome the resistance of the lines and fittings, and pull out the excess crankcase vapors. In an ideal world the crankcase should never see positive pressure... and providing suction to it ensures this is the case.

The larger the turbo and the more boost being created, the more of a vacuum affect that will be felt at the turbo inlet.

Important point #3: The turbo inlet creates a vacuum that helps pull out the excess crankcase vapors.

You may be wondering why the crankcase is vented at the top of the engine off of the VC when the gases are being forced down past the rings into the lower crankcase. It’s quite simple actually; anywhere there is oil, there are crankcase gases. The hot gases will rise to the top of the engine through the oil passages in the head, and by tapping into the VC there is less chance of liquid oil being sucked into the IM or turbo inlet.

If you look at the underside of the VC, you’ll see a series of plates and baffles. These baffles separate the liquid oil splashing around the valve train from the PCV ports, and provide an area for the crankcase vapors to collect and be pulled out.

Important point #4: Unless you have a good reason not to, leave your VC baffles in place.

You’ll also notice that the PCV valve itself has a tube extending from the end that screws into the VC. This is there to prevent any oil that does find it’s way past the baffles from getting into the PCV valve. Regardless of this and the baffling, oil still collects in the PCV valve and the lines that connect the entire PCV system. Needless to say, it can make for a pretty messy intake tract.

When things go bad…

If the PCV system isn’t functioning properly, several not so pleasant things can happen. Probably the worst of these is that crankcase pressure can build up and cause the dipstick to pop out (especially if it’s old and worn out), potentially covering everything in oil. In a worst-case scenario this could cause an engine fire. Not fun.

Note: Clamping the dipstick down to prevent it from blowing out is not a fix for a poorly operating PCV system. If your dipstick still pops out even after replacing it with a new one, fix your PCV issues!

Excessive crankcase pressure can also wreak havoc on seals, cause accelerated bearing wear, and in some cases hinder the proper draining of oil from the turbo back into the oil pan.

A dirty or clogged PCV valve can also affect performance and fuel economy. If it’s stuck open, boost from the IM can enter the crankcase, causing a slight drop in power due to pumping losses… if the dipstick doesn’t pop out first. It can also cause drivability issues due to fluctuations in IM vacuum, since it has lost the ability to properly meter the air as described above. If it’s stuck closed or completely clogged, oil contamination can become a serious issue and your bearings will start to suffer.

So what’s wrong with the factory PCV system?

The short answer is… nothing; as long as the car is stock and everything is properly maintained. But if you are running anything more than stock boost or would prefer to not have oily residue in your intake, read on.

Since the PCV valve is the heart of the system, let’s start there. This thing is notorious for not being able to completely close to prevent boost from entering the VC, even when brand new. Add a few thousand miles worth of crud flowing back and forth through it and it gets worse. And the more boost you run, the greater the problem becomes.

A simple solution to this problem is to add an additional check valve between the IM and PCV valve. This check valve needs to be tough and chemical resistant, and have a fairly low crack pressure so that normal flow isn’t impeded. Fortunately for us, US Plastics sells one that is both ideal and inexpensive. (I think Romeen was the first to find these and test them. We owe him a big thanks, as they are extremely useful for many applications under the hood.)

3/8” Kynar Standard Check Valves

Although shipping is a bit much for a part that cost $1.49, you can probably get them to throw a couple in an envelope and mail it to you over the phone. Or, buy several and sell them to other DSM’ers at a small profit.

Note: If you look closely at these check valves, one side of the larger diameter body is angled. This angled side points in the direction of flow.

Another problem with the stock PCV valve (and this is just my opinion) is the way in which it sits in the VC. The stock arrangement makes getting to the TPS a real pain, so I modified the stock PCV valve to make things a little more accessible.

A tech article describing how it was done can be found here, and more pictures and information on how I routed everything can be found here.

Even with a perfectly maintained engine, oil is still going to find its’ way into your intake manifold and intercooler piping with the factory setup. By adding an inline catch can to each side of the VC, you can greatly cut down on the amount of oil that collects in the intake tract.

#2

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

There are countless different catch cans available, but here are a few things to keep in mind when selecting the right ones:

1. Empty cans like the ones commonly found on eBay for dirt cheap are going to do very little, if anything. There needs to be some type of filtering media in the can; preferably something that can remove sub-micron particles. Stuffing the cans with coarse media such as steel wool helps, but only to a point.

2. Home Depot style air compressor filters aren’t the best choice for a number of reasons. Besides having the wrong type of filter for this application, they are usually made from polycarbonate, which doesn’t like any of the chemicals found in an engine bay. They typically don’t last very long and will usually hurt airflow due to the large pressure drop.

3. Regardless of which type of cans are used, they should be sealed rather than open to the atmosphere. The inlet of the can should be connected to a line facing the VC, and the outlet should be connected to a vacuum source to help pull air through the can.

4. The cans must not have a large pressure drop that limits the flow of air through them.

5. If only one can is to be used, put it between the VC and turbo inlet. There is much more oil and hydrocarbon vapor being pushed out of the VC while under boost than there is being drawn into the IM while under vacuum.

Important point #5: Catch cans should always be connected to a vacuum source to help pull air through them, rather than vented to atmospheric pressure.

When choosing a catch can, think about where and how you will mount it, and make sure the drain will be accessible. For the can between my VC and turbo inlet, I ran a line from the drain down to a bracket and valve mounted on the lower frame. This allowed me to mount the can to the factory clutch line bracket and still clear the tranny, and makes draining it very easy.

In most cases, the factory hoses will be adequate, but you may consider upgrading the lines on the turbo side to –6AN or –8AN. This will provide slightly more airflow, and they will hold up much better. (Not to mention they look purdy!).

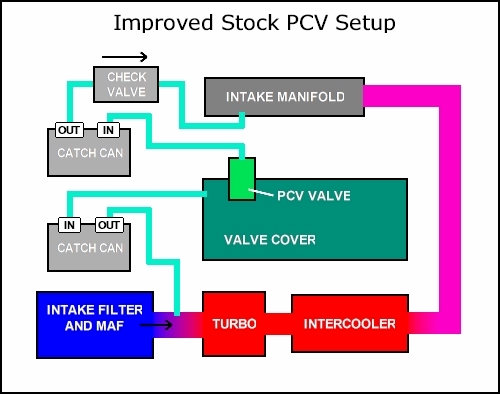

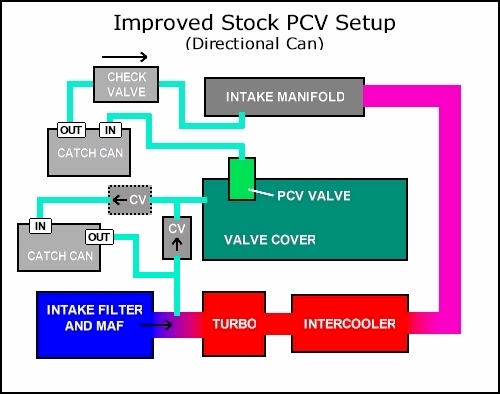

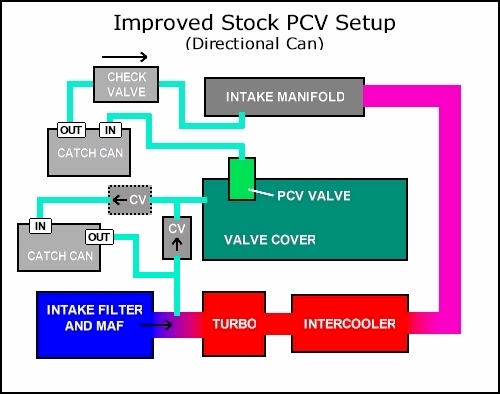

PCV Setup #1 – The Improved Factory Setup

The diagram below shows this improved version of the factory PCV system. This arrangement is the ideal setup for most street and part-time track DSMs.

Note: Be sure to pay close attention to the check valve orientation. It should be positioned so that air can flow towards the IM, but not away from it. Also make sure that it goes between the catch can and IM, so that the can doesn’t become pressurized during boost.

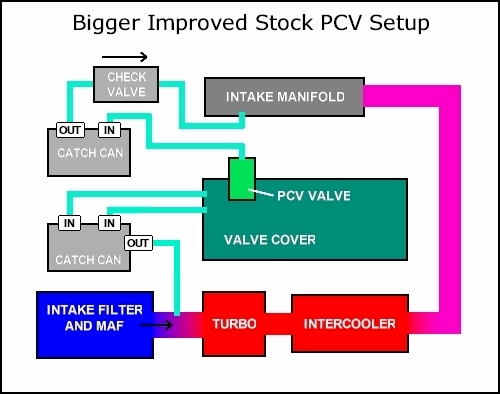

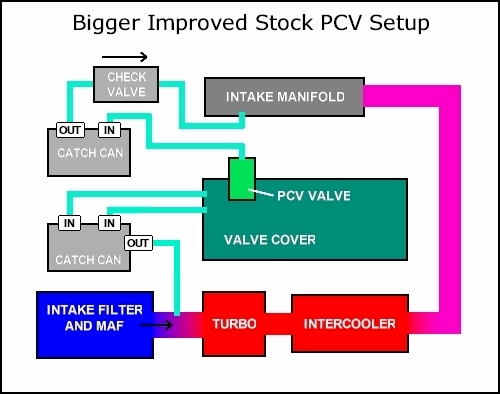

PCV Setup #2 – The Bigger Improved Factory Setup

To provide more pressure relief while still keeping the stock PCV valve for ventilation purposes, extra and/or larger lines can be tapped off of the VC and routed to a dual inlet catch can. This would provide more flow from the VC, and a lower pressure drop across the can inlet.

The drawing below is the same as above, with the addition of an extra VC line and dual inlet can.

When the factory setup isn’t enough…

In certain cases, even the improved factory arrangement with larger lines may not be adequate for relieving crankcase pressure. In this case it may be desirable to disregard the ventilation aspect of the PCV system altogether and concentrate solely on relieving the excess pressure. This usually involves deleting the PCV valve, blocking the IM port, and running extra and/or larger lines from the VC to the turbo inlet. Before deciding to do this, I would highly recommend that you make sure this is the best choice for your situation. Some factors to consider are:

1. The oil must be changed often and religiously, so that hydrocarbon contamination doesn’t become an issue.

2. Is crankcase pressure really high enough to warrant bypassing the PCV valve and running extra VC lines? Measure it!

3. Is the excess pressure the result of an engine problem that needs to be fixed? For example, if the rings are worn enough to cause excessively high blow by, it would be wise to replace the rings, rather than worrying about the PCV system.

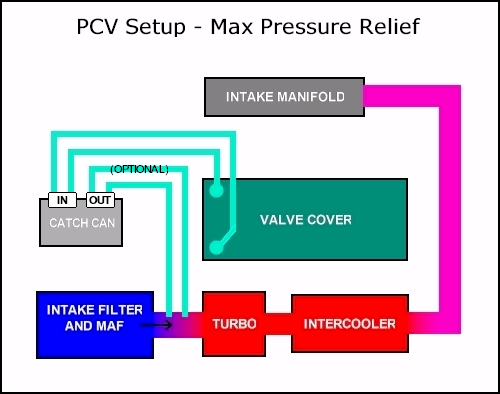

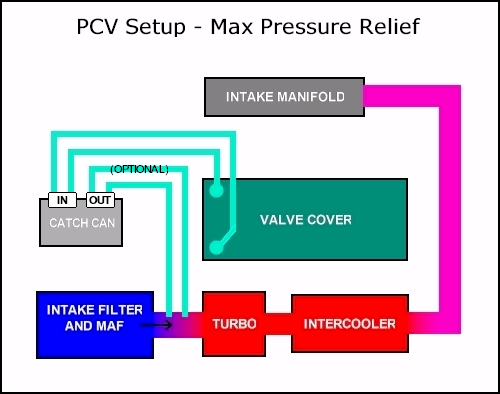

PCV Setup #3 – Maximum Pressure Relief

The following diagram shows one possible arrangement for providing maximum pressure relief. The most common arrangement would be 2 lines coming off the VC and a single line going from the catch can to the turbo inlet, although the number and size of lines will vary from car to car. If you are going this route, you should already know how much pressure you are seeing in the crankcase under varying conditions, and should be able to design the proper setup for your situation.

Note: Regardless of the number and size of lines exiting the VC, they should still lead to the intake snorkel for the vacuum assistance that the turbo provides, rather than just venting to atmosphere.

Alternative PCV Systems

Although outside the scope of this article, other types of PCV systems have been around for years and are sometimes considered alternatives for turbo DSMs. One example is the exhaust scavenging system, in which one or more hoses are connected between the VC and the exhaust system through a check valve. The exhaust flow creates a scavenging effect similar to the old draft tube idea, and pulls crankcase gases out and into the exhaust stream. One possible disadvantage of this system is that it may increase harmful emissions, but there is no data available that I’m aware of to prove or disprove this. Also, this is a pressure relief setup only, and does nothing for ventilating the crankcase during normal driving to prevent oil contamination. There is also some evidence that the exhaust doesn't provide much draw on the crankcase at all (compared to the turbo inlet), and is much less effective.

Another similar alternative is the vacuum pump. Rather than relying on the engine or exhaust to provide vacuum, a separate pump is used to draw out the crankcase gases. The downside to this approach is the added cost and weight of the additional pump, along with any power or voltage drain that it may cause.

Measuring Crankcase Pressure

There are several ways you can measure crankcase pressure, but I’ve found the easiest way is to tap into the VC breather port. Since I am running a –6AN line from the VC to the catch can, I used a fuel pressure take-off fitting from Summit Racing. I attached a 90* brass barb fitting, and ran a hose to a boost sensor so that the pressure could be logged with DSMLink. If you are running the stock rubber hoses, you can simply tee into the line between the VC and turbo inlet with a standard hose barb “T” fitting.

Note: At full vacuum, I see about –1.1 in/hg, and at 20 psi of boost the most I’ve seen is 0.6 psi of positive pressure. (This is on a 2.3l stroker with 8.8:1 CR). Although this isn't a problem...I'll probably change to a -8AN line, (or possibly run an aditional line) just for peace of mind, and to keep the CC in vacuum while running more boost on this higher compression motor.

You could also use a standard boost/vac gauge rather than a boost sensor, and tap it off of other places such as a hole in an old oil cap, etc. It’s also useful to measure the pressure at the turbo inlet, to get an idea of how much vacuum your turbo can pull. By comparing the values at the VC and turbo inlet, you can also determine how much of a pressure drop is occurring across the catch can.

EDIT:

My original thought was that since no air is actually flowing through the line going to the boost gauge/sensor, and since there is a constant draw on the outlet of the can's filter...you should see an accurate reading by tapping directly into the line between the VC outlet and catch can. In other words, the pressure on the VC side of the catch can should be fairly equalized no matter where you measure it. But after talking with a couple of respected members and thinking about this a bit more, I'm not convinced that measuring it as I described above is the best method. The measurement may be affected by pressure fluctuations across the can's inlet, or due to a venturi effect as air flows past the sensor tap. (I have not yet verified this, but it does make sense). In any case, the most accurate way would be to tap into the VC or crankcase at an isolated location, such as the oil filler cap or a dedicated port on the VC.

Some common questions…

Here are some common questions I see asked a lot in the forums, along with my thoughts on them.

Quote:

Why can’t I just recirculate the oil in my catch can back to the oil pan?

There’s a very good reason why this is a bad idea on a street car.

That liquid that has collected in the can isn't just oil; it also contains all sorts of combustion by-products that have made it past the piston rings, as well as liquid water which condenses as the hot gases hit the relatively cool can. So now sitting in the bottom of the catch can is a mix of hydrocarbons (raw fuel and other nasty things), water, and oil. Do you really want this to be dumped back into your engine's clean oil supply?

Quote:

Can I just use one catch can and tie both the PCV valve and VC lines into it?

Not if you want to keep the PCV valve functionality. Remember that air has to travel in two directions between the turbo inlet and VC, while the path between the IM and VC must remain isolated between vacuum and boost.

If you must run only one catch can, put it between the valve cover vent and turbo inlet.

Quote:

What is the recommended setup if I’m running a GM MAF in blow-through?

This one has been beaten to death and unfortunately there still isn’t a good answer. The problem comes from the fact that when operating in vacuum, fresh air needs to come after the MAF so that the ECU accounts for it and maintains the proper AFR. With a GM MAF in blow-through, the only place this would be possible is between the MAF and throttle body. But this point is pressurized during boost, so you would have no pressure relief; the boost in the UICP would be trying to push air into the VC rather than pull it out. Adding a check valve won’t help because that would cut off the source of fresh air during ventilation.

The best answer is to run one of the modified factory setups, and compensate for the unmetered air with tuning or just don’t worry about it. Once above a certain engine load, it isn’t really a major factor.

Quote:

How do I test my PCV valve?

The PCV valve should allow air to pass through in one direction but not the other, and the internal spring and ball should move freely (if you shake it, you should be able to hear it rattle). To check it's ability to seal under boost, apply about 5 psi more than the amount of boost you plan to run to the hose nipple, opposite the threaded end. There should not be any air escaping from the threaded end.

Since even new PCV valves can (and usually do) leak, adding an external check valve is always a good idea.

Summary

The PCV system on the turbo 4G63 engine seems complicated; but as long as you understand how air flows through it under different operating conditions, it isn’t hard to understand. Although several different arrangements have been tried over the years, there are only a handful that are proven to work well. With the addition of an inexpensive check valve and a couple of catch cans, the factory setup can be made to be very effective and hassle free for the majority of daily drivers and part-time track cars.

1. Empty cans like the ones commonly found on eBay for dirt cheap are going to do very little, if anything. There needs to be some type of filtering media in the can; preferably something that can remove sub-micron particles. Stuffing the cans with coarse media such as steel wool helps, but only to a point.

2. Home Depot style air compressor filters aren’t the best choice for a number of reasons. Besides having the wrong type of filter for this application, they are usually made from polycarbonate, which doesn’t like any of the chemicals found in an engine bay. They typically don’t last very long and will usually hurt airflow due to the large pressure drop.

3. Regardless of which type of cans are used, they should be sealed rather than open to the atmosphere. The inlet of the can should be connected to a line facing the VC, and the outlet should be connected to a vacuum source to help pull air through the can.

4. The cans must not have a large pressure drop that limits the flow of air through them.

5. If only one can is to be used, put it between the VC and turbo inlet. There is much more oil and hydrocarbon vapor being pushed out of the VC while under boost than there is being drawn into the IM while under vacuum.

Important point #5: Catch cans should always be connected to a vacuum source to help pull air through them, rather than vented to atmospheric pressure.

When choosing a catch can, think about where and how you will mount it, and make sure the drain will be accessible. For the can between my VC and turbo inlet, I ran a line from the drain down to a bracket and valve mounted on the lower frame. This allowed me to mount the can to the factory clutch line bracket and still clear the tranny, and makes draining it very easy.

In most cases, the factory hoses will be adequate, but you may consider upgrading the lines on the turbo side to –6AN or –8AN. This will provide slightly more airflow, and they will hold up much better. (Not to mention they look purdy!).

PCV Setup #1 – The Improved Factory Setup

The diagram below shows this improved version of the factory PCV system. This arrangement is the ideal setup for most street and part-time track DSMs.

Note: Be sure to pay close attention to the check valve orientation. It should be positioned so that air can flow towards the IM, but not away from it. Also make sure that it goes between the catch can and IM, so that the can doesn’t become pressurized during boost.

PCV Setup #2 – The Bigger Improved Factory Setup

To provide more pressure relief while still keeping the stock PCV valve for ventilation purposes, extra and/or larger lines can be tapped off of the VC and routed to a dual inlet catch can. This would provide more flow from the VC, and a lower pressure drop across the can inlet.

The drawing below is the same as above, with the addition of an extra VC line and dual inlet can.

When the factory setup isn’t enough…

In certain cases, even the improved factory arrangement with larger lines may not be adequate for relieving crankcase pressure. In this case it may be desirable to disregard the ventilation aspect of the PCV system altogether and concentrate solely on relieving the excess pressure. This usually involves deleting the PCV valve, blocking the IM port, and running extra and/or larger lines from the VC to the turbo inlet. Before deciding to do this, I would highly recommend that you make sure this is the best choice for your situation. Some factors to consider are:

1. The oil must be changed often and religiously, so that hydrocarbon contamination doesn’t become an issue.

2. Is crankcase pressure really high enough to warrant bypassing the PCV valve and running extra VC lines? Measure it!

3. Is the excess pressure the result of an engine problem that needs to be fixed? For example, if the rings are worn enough to cause excessively high blow by, it would be wise to replace the rings, rather than worrying about the PCV system.

PCV Setup #3 – Maximum Pressure Relief

The following diagram shows one possible arrangement for providing maximum pressure relief. The most common arrangement would be 2 lines coming off the VC and a single line going from the catch can to the turbo inlet, although the number and size of lines will vary from car to car. If you are going this route, you should already know how much pressure you are seeing in the crankcase under varying conditions, and should be able to design the proper setup for your situation.

Note: Regardless of the number and size of lines exiting the VC, they should still lead to the intake snorkel for the vacuum assistance that the turbo provides, rather than just venting to atmosphere.

Alternative PCV Systems

Although outside the scope of this article, other types of PCV systems have been around for years and are sometimes considered alternatives for turbo DSMs. One example is the exhaust scavenging system, in which one or more hoses are connected between the VC and the exhaust system through a check valve. The exhaust flow creates a scavenging effect similar to the old draft tube idea, and pulls crankcase gases out and into the exhaust stream. One possible disadvantage of this system is that it may increase harmful emissions, but there is no data available that I’m aware of to prove or disprove this. Also, this is a pressure relief setup only, and does nothing for ventilating the crankcase during normal driving to prevent oil contamination. There is also some evidence that the exhaust doesn't provide much draw on the crankcase at all (compared to the turbo inlet), and is much less effective.

Another similar alternative is the vacuum pump. Rather than relying on the engine or exhaust to provide vacuum, a separate pump is used to draw out the crankcase gases. The downside to this approach is the added cost and weight of the additional pump, along with any power or voltage drain that it may cause.

Measuring Crankcase Pressure

There are several ways you can measure crankcase pressure, but I’ve found the easiest way is to tap into the VC breather port. Since I am running a –6AN line from the VC to the catch can, I used a fuel pressure take-off fitting from Summit Racing. I attached a 90* brass barb fitting, and ran a hose to a boost sensor so that the pressure could be logged with DSMLink. If you are running the stock rubber hoses, you can simply tee into the line between the VC and turbo inlet with a standard hose barb “T” fitting.

Note: At full vacuum, I see about –1.1 in/hg, and at 20 psi of boost the most I’ve seen is 0.6 psi of positive pressure. (This is on a 2.3l stroker with 8.8:1 CR). Although this isn't a problem...I'll probably change to a -8AN line, (or possibly run an aditional line) just for peace of mind, and to keep the CC in vacuum while running more boost on this higher compression motor.

You could also use a standard boost/vac gauge rather than a boost sensor, and tap it off of other places such as a hole in an old oil cap, etc. It’s also useful to measure the pressure at the turbo inlet, to get an idea of how much vacuum your turbo can pull. By comparing the values at the VC and turbo inlet, you can also determine how much of a pressure drop is occurring across the catch can.

EDIT:

My original thought was that since no air is actually flowing through the line going to the boost gauge/sensor, and since there is a constant draw on the outlet of the can's filter...you should see an accurate reading by tapping directly into the line between the VC outlet and catch can. In other words, the pressure on the VC side of the catch can should be fairly equalized no matter where you measure it. But after talking with a couple of respected members and thinking about this a bit more, I'm not convinced that measuring it as I described above is the best method. The measurement may be affected by pressure fluctuations across the can's inlet, or due to a venturi effect as air flows past the sensor tap. (I have not yet verified this, but it does make sense). In any case, the most accurate way would be to tap into the VC or crankcase at an isolated location, such as the oil filler cap or a dedicated port on the VC.

Some common questions…

Here are some common questions I see asked a lot in the forums, along with my thoughts on them.

Quote:

Why can’t I just recirculate the oil in my catch can back to the oil pan?

There’s a very good reason why this is a bad idea on a street car.

That liquid that has collected in the can isn't just oil; it also contains all sorts of combustion by-products that have made it past the piston rings, as well as liquid water which condenses as the hot gases hit the relatively cool can. So now sitting in the bottom of the catch can is a mix of hydrocarbons (raw fuel and other nasty things), water, and oil. Do you really want this to be dumped back into your engine's clean oil supply?

Quote:

Can I just use one catch can and tie both the PCV valve and VC lines into it?

Not if you want to keep the PCV valve functionality. Remember that air has to travel in two directions between the turbo inlet and VC, while the path between the IM and VC must remain isolated between vacuum and boost.

If you must run only one catch can, put it between the valve cover vent and turbo inlet.

Quote:

What is the recommended setup if I’m running a GM MAF in blow-through?

This one has been beaten to death and unfortunately there still isn’t a good answer. The problem comes from the fact that when operating in vacuum, fresh air needs to come after the MAF so that the ECU accounts for it and maintains the proper AFR. With a GM MAF in blow-through, the only place this would be possible is between the MAF and throttle body. But this point is pressurized during boost, so you would have no pressure relief; the boost in the UICP would be trying to push air into the VC rather than pull it out. Adding a check valve won’t help because that would cut off the source of fresh air during ventilation.

The best answer is to run one of the modified factory setups, and compensate for the unmetered air with tuning or just don’t worry about it. Once above a certain engine load, it isn’t really a major factor.

Quote:

How do I test my PCV valve?

The PCV valve should allow air to pass through in one direction but not the other, and the internal spring and ball should move freely (if you shake it, you should be able to hear it rattle). To check it's ability to seal under boost, apply about 5 psi more than the amount of boost you plan to run to the hose nipple, opposite the threaded end. There should not be any air escaping from the threaded end.

Since even new PCV valves can (and usually do) leak, adding an external check valve is always a good idea.

Summary

The PCV system on the turbo 4G63 engine seems complicated; but as long as you understand how air flows through it under different operating conditions, it isn’t hard to understand. Although several different arrangements have been tried over the years, there are only a handful that are proven to work well. With the addition of an inexpensive check valve and a couple of catch cans, the factory setup can be made to be very effective and hassle free for the majority of daily drivers and part-time track cars.

#3

Thread Starter

Senior Member

iTrader: (1)

Joined: Mar 2012

Posts: 588

Total Cats: 203

From: Pensacola Fla.

Directional Catch Cans

One other thing to consider when hooking up catch cans, is whether or not they are bi-directional. Most are, but some of the cheaper Husky type filters (which aren't the best choice anyway as described above) only flow in one direction. Even the cans that do flow in both directions may be optimized for better filtering or airflow in one direction. Because of this, it may be necessary to add an additional line from the VC to the turbo inlet, and use one or two additional check valves to control the flow.

This is the same as the improved stock setup shown above, with the addition of check valves and an extra hose between the can and turbo inlet. If the can between the VC and turbo inlet only flows in one direction, then there would be no source of fresh air when the engine is running in vacuum. By adding the extra line and check valves, the VC gets fresh air straight from the inlet, bypassing the catch can. When under boost, that line closes and excess pressure is routed through the catch can to filter out the oil and hydrocarbon aerosols.

Another thing to consider is whether or not a catch can has "loose" filtering material on the inlet side. If it does, adding the check valve(s) would definitely be a good idea; you probably don't want strands of steel wool or Scotch pads getting sucked into your engine when the crank case is under vacuum.

The check valve on the left (shown with a dotted outline) may not be necessary, depending on which type of filter or can is used. If the can is open or bi-directional, adding the extra valve may help prevent excess oil vapor from being sucked back out of the can and into the VC. If the can has an internal valve or completely blocks reverse airflow, this valve wouldn't be needed.

Things To Look Out For

Any time you change the PCV system, you need to be sure that you still have proper pressure relief. Catch cans and check valves may cause a slight increase in resistance to airflow, so it's always a good idea to check the amount of pressure you see at the VC after making any changes. If your car is prone to blowing out the dipstick or leaking oil from the filler cap, take steps to protect against these issues before really pushing the new system for the first time.

If you measure the pressure after installing catch can(s) and or check valves and it is higher than before, there may be a problem with how things are hooked up, or you may just need more pressure relief. One fact of life is that the better a catch can is at removing blowby, the more resistance to airflow that it will present. An empty can has very little (if any) resistance to airflow; it also does very little to remove suspended particles and aerosols. A can filled with "steel wool" is somewhat better at blowby removal, and coincidently has a bit more resistance to airflow.

The trick is to find a setup that provides as little resistance to airflow as possible, while still removing the most blowby. If you use cans that are very good at removing small particles, make sure that the pressure drop across their inputs is low enough to provide enough pressure relief. This may require more can inputs, an extra can, or in extreme cases...even switching to cans that aren't quite as good at small particle removal but have a lower pressure drop.

Like everything else, it's always a compromise.

Full Race Setups With No Air Inlet Pipes

On full race setups with no inlet pipe, crankcase evacuation options are obviously limited. Since there is no suction being applied to the crankcase, pressure will not be relieved until it exceeds atmospheric pressure plus any drops across the catch can(s), lines, and any filters. Because of this, you will want to run the largest-sized lines possible for the pressure to escape through, and use a large empty can with low-restriction filters open to the atmosphere.

It is always advisable to apply suction to the crankcase... but if this simply isn't an option, make sure to allow as much cross sectional area as possible for air to escape through. Be sure to check the can's filters often for oil saturation and replace as necessary.

Should I delete my PCV valve?

I get asked this a lot, so I decided to add something here about it. The short answer is, I have no freakin' idea; you'll have to decide for yourself. But I can give you a few things to consider when making that decision.

But I can give you a few things to consider when making that decision.

The PCV valve is mostly used to provide ventilation (air circulation) while the car is operating in vacuum and things are fairly calm in the crankcase. This is important because it helps keep the concentrations of combustion by-products lower, leading to longer oil life...at least in theory. Whether or not it actually has an impact is a good question; I've never found a way to accurately test it and find out, and I wouldn't want to run my oil until it breaks down to prove the point one way or the other. So I would rather err on the side of caution and accept what seems to make sense.

From this standpoint, if you are under the hood a lot and change your oil often, removing the PCV valve probably won't make a bit of difference. If you are a drive-it-and-forget-it kind of person though, it may be beneficial to keep it "just because".

There is something else to consider though. While you are driving around at low loads, there is very little pressure differential between the VC breather port and the turbo inlet. In fact, in a stock system the vacuum in the IM overcomes the suction at the turbo inlet, which is what allows the air to flow into the crankcase and out through the PCV valve to the IM. The net effect of this, is that air flowing through the crankcase switches directions smoothly as the lower pressure source swings between the IM and turbo inlet as you cross into and out of boost. With me so far?

If you remove the PCV valve, you now have a small window of opportunity where crankcase pressure can build up. It's not much, but when you consider a BOV dumping back into the turbo inlet and so forth, you can have momentary situations where air is restricted from getting out of the crankcase since there is no PCV valve there to allow a rapid change of airflow direction. This can show up as small spikes of positive crankcase pressure, maybe up to 1 psi or so.

It's completely dependent on the setup and catch can configuration, and how much of a restriction you have between the VC and turbo. If you are running big lines into a very low restriction can, CC pressure may barely get above zero as you drop out of boost. On the other hand, if you are running small lines and/or have a can with a large pressure drop across it, CC pressure may rise to over 1 or 2 psi momentarily.

There's also the obvious benefit of removing the PCV valve to consider; no chance of oil in the IM. This is hard to argue with, as burning oil causes all kinds of issues with performance, including an increased chance of detonation and difficulty in tuning. Although this problem can be greatly reduced (or virtually eliminated) by using a good catch can design, it's still something to consider.

The only way to know for sure what effect removing the PCV valve will have is to try it and log the CC pressure. If it stays low enough to tolerate and you take care of your oil, you're probably fine. If you see positive CC spikes in and around the area that you drop in and out of boost, or you don't change your oil often, you may be better off leaving it....but take steps to keep as much oil out of the IM as possible if you do.

One other thing to consider when hooking up catch cans, is whether or not they are bi-directional. Most are, but some of the cheaper Husky type filters (which aren't the best choice anyway as described above) only flow in one direction. Even the cans that do flow in both directions may be optimized for better filtering or airflow in one direction. Because of this, it may be necessary to add an additional line from the VC to the turbo inlet, and use one or two additional check valves to control the flow.

This is the same as the improved stock setup shown above, with the addition of check valves and an extra hose between the can and turbo inlet. If the can between the VC and turbo inlet only flows in one direction, then there would be no source of fresh air when the engine is running in vacuum. By adding the extra line and check valves, the VC gets fresh air straight from the inlet, bypassing the catch can. When under boost, that line closes and excess pressure is routed through the catch can to filter out the oil and hydrocarbon aerosols.

Another thing to consider is whether or not a catch can has "loose" filtering material on the inlet side. If it does, adding the check valve(s) would definitely be a good idea; you probably don't want strands of steel wool or Scotch pads getting sucked into your engine when the crank case is under vacuum.

The check valve on the left (shown with a dotted outline) may not be necessary, depending on which type of filter or can is used. If the can is open or bi-directional, adding the extra valve may help prevent excess oil vapor from being sucked back out of the can and into the VC. If the can has an internal valve or completely blocks reverse airflow, this valve wouldn't be needed.

Things To Look Out For

Any time you change the PCV system, you need to be sure that you still have proper pressure relief. Catch cans and check valves may cause a slight increase in resistance to airflow, so it's always a good idea to check the amount of pressure you see at the VC after making any changes. If your car is prone to blowing out the dipstick or leaking oil from the filler cap, take steps to protect against these issues before really pushing the new system for the first time.

If you measure the pressure after installing catch can(s) and or check valves and it is higher than before, there may be a problem with how things are hooked up, or you may just need more pressure relief. One fact of life is that the better a catch can is at removing blowby, the more resistance to airflow that it will present. An empty can has very little (if any) resistance to airflow; it also does very little to remove suspended particles and aerosols. A can filled with "steel wool" is somewhat better at blowby removal, and coincidently has a bit more resistance to airflow.

The trick is to find a setup that provides as little resistance to airflow as possible, while still removing the most blowby. If you use cans that are very good at removing small particles, make sure that the pressure drop across their inputs is low enough to provide enough pressure relief. This may require more can inputs, an extra can, or in extreme cases...even switching to cans that aren't quite as good at small particle removal but have a lower pressure drop.

Like everything else, it's always a compromise.

Full Race Setups With No Air Inlet Pipes

On full race setups with no inlet pipe, crankcase evacuation options are obviously limited. Since there is no suction being applied to the crankcase, pressure will not be relieved until it exceeds atmospheric pressure plus any drops across the catch can(s), lines, and any filters. Because of this, you will want to run the largest-sized lines possible for the pressure to escape through, and use a large empty can with low-restriction filters open to the atmosphere.

It is always advisable to apply suction to the crankcase... but if this simply isn't an option, make sure to allow as much cross sectional area as possible for air to escape through. Be sure to check the can's filters often for oil saturation and replace as necessary.

Should I delete my PCV valve?

I get asked this a lot, so I decided to add something here about it. The short answer is, I have no freakin' idea; you'll have to decide for yourself.

But I can give you a few things to consider when making that decision.

But I can give you a few things to consider when making that decision.The PCV valve is mostly used to provide ventilation (air circulation) while the car is operating in vacuum and things are fairly calm in the crankcase. This is important because it helps keep the concentrations of combustion by-products lower, leading to longer oil life...at least in theory. Whether or not it actually has an impact is a good question; I've never found a way to accurately test it and find out, and I wouldn't want to run my oil until it breaks down to prove the point one way or the other. So I would rather err on the side of caution and accept what seems to make sense.

From this standpoint, if you are under the hood a lot and change your oil often, removing the PCV valve probably won't make a bit of difference. If you are a drive-it-and-forget-it kind of person though, it may be beneficial to keep it "just because".

There is something else to consider though. While you are driving around at low loads, there is very little pressure differential between the VC breather port and the turbo inlet. In fact, in a stock system the vacuum in the IM overcomes the suction at the turbo inlet, which is what allows the air to flow into the crankcase and out through the PCV valve to the IM. The net effect of this, is that air flowing through the crankcase switches directions smoothly as the lower pressure source swings between the IM and turbo inlet as you cross into and out of boost. With me so far?

If you remove the PCV valve, you now have a small window of opportunity where crankcase pressure can build up. It's not much, but when you consider a BOV dumping back into the turbo inlet and so forth, you can have momentary situations where air is restricted from getting out of the crankcase since there is no PCV valve there to allow a rapid change of airflow direction. This can show up as small spikes of positive crankcase pressure, maybe up to 1 psi or so.

It's completely dependent on the setup and catch can configuration, and how much of a restriction you have between the VC and turbo. If you are running big lines into a very low restriction can, CC pressure may barely get above zero as you drop out of boost. On the other hand, if you are running small lines and/or have a can with a large pressure drop across it, CC pressure may rise to over 1 or 2 psi momentarily.

There's also the obvious benefit of removing the PCV valve to consider; no chance of oil in the IM. This is hard to argue with, as burning oil causes all kinds of issues with performance, including an increased chance of detonation and difficulty in tuning. Although this problem can be greatly reduced (or virtually eliminated) by using a good catch can design, it's still something to consider.

The only way to know for sure what effect removing the PCV valve will have is to try it and log the CC pressure. If it stays low enough to tolerate and you take care of your oil, you're probably fine. If you see positive CC spikes in and around the area that you drop in and out of boost, or you don't change your oil often, you may be better off leaving it....but take steps to keep as much oil out of the IM as possible if you do.

Last edited by BogusSVO; 01-09-2013 at 01:19 PM.

#5

Bogus,

Do you have any recommendations on catch cans? Most of the ones I seem to be able to find, you describe as not ideal.

Edit: I like this guy, seems legit.

http://www.jcsautomation.com/vs%20catch%20cans.html

Do you have any recommendations on catch cans? Most of the ones I seem to be able to find, you describe as not ideal.

Edit: I like this guy, seems legit.

http://www.jcsautomation.com/vs%20catch%20cans.html

#10

Nice writeup.

I use Stef's catch cans. Cheap & pretty hand fabricated jobbies. And they will put whatever fittings you want on there, whereever you want them. Helps that they are local.

EDIT: Except they use cheapass ugly stamped 2cent caps. I weld on my own billet caps from Meziere or whomever.

http://www.stefsperformance.net/stef...breather-tanks

I use Stef's catch cans. Cheap & pretty hand fabricated jobbies. And they will put whatever fittings you want on there, whereever you want them. Helps that they are local.

EDIT: Except they use cheapass ugly stamped 2cent caps. I weld on my own billet caps from Meziere or whomever.

http://www.stefsperformance.net/stef...breather-tanks

#11

I am planning on basically doing the "max pressure relief" diagram, except running it to a vented to atm catch can. I don't really see a benefit to running that hose to the intake for 'vacuum source'. IIRC, guy on Honda Tech did some measurements, and on his turbo Honda, he saw a max of .5psi vaccum from it...basically nothing.

Other solution I was considering was same as above, except run a sealed CC and you exhaust slashcut as vacuum source. I think I've read you'll only see a psi or two from that...doesn't quite seem worth the extra effort.

Other solution I was considering was same as above, except run a sealed CC and you exhaust slashcut as vacuum source. I think I've read you'll only see a psi or two from that...doesn't quite seem worth the extra effort.

#15

Maybe I should just hook up a cheap vacuum pump, OEM part on from a Ford Excursion, and call it a day?

2005 Ford Excursion Vacuum Pump F81Z 2A451 BA

2005 Ford Excursion Vacuum Pump F81Z 2A451 BA

#16

Maybe I should just hook up a cheap vacuum pump, OEM part on from a Ford Excursion, and call it a day?

2005 Ford Excursion Vacuum Pump F81Z 2A451 BA

2005 Ford Excursion Vacuum Pump F81Z 2A451 BA

#17

I have a question in regards to connecting the PCV valve and VC port directly to a sealed catch can. I just installed this setup and would like to know the possible benefits or shortcomings of having it like this.

Everyone is always stating how excess crankcase pressure is bad due to blowing seals, etc., but wouldn't it be a good thing to have more negative pressure? I understand this really eliminates the "fresh air" aspect of the system, but wouldn't the increase in vacuum be a good thing?

I have a Saikou Michi sealed can with the PCV and VC ports (added check valve to VC port line) connected to the inlet, and the outlet port connected to my IM. I understand there is potential for quite a bit of vacuum under the VC like this, but will it hurt anything?

I'm running NA at the moment, and I can see how it could be a bad setup if adding boost...

http://www.saikoumichi.com/OCC_page.htm

Quote:

"Can I just use one catch can and tie both the PCV valve and VC lines into it?

Not if you want to keep the PCV valve functionality. Remember that air has to travel in two directions between the turbo inlet and VC, while the path between the IM and VC must remain isolated between vacuum and boost."

-Ryan

Everyone is always stating how excess crankcase pressure is bad due to blowing seals, etc., but wouldn't it be a good thing to have more negative pressure? I understand this really eliminates the "fresh air" aspect of the system, but wouldn't the increase in vacuum be a good thing?

I have a Saikou Michi sealed can with the PCV and VC ports (added check valve to VC port line) connected to the inlet, and the outlet port connected to my IM. I understand there is potential for quite a bit of vacuum under the VC like this, but will it hurt anything?

I'm running NA at the moment, and I can see how it could be a bad setup if adding boost...

http://www.saikoumichi.com/OCC_page.htm

Quote:

"Can I just use one catch can and tie both the PCV valve and VC lines into it?

Not if you want to keep the PCV valve functionality. Remember that air has to travel in two directions between the turbo inlet and VC, while the path between the IM and VC must remain isolated between vacuum and boost."

-Ryan

Last edited by RyanLewo; 01-10-2013 at 07:56 PM. Reason: More data!