Boost by Gear

#1

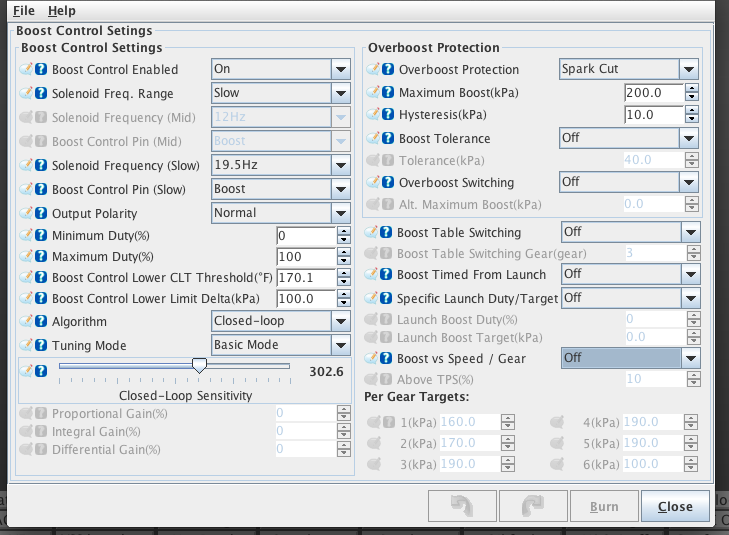

Running a MS3 built by the master, Dimitris, I have vehicle speed, dead accurate now, gear algorithm is working perfectly. Boost by gear has no effect at all, I tried 5 kpa and was hitting the 13 psi (190kpa) then switched it to 190kpa, and hit the exact same kpa, much testing the same results, boost by gear was totally inoperable. I have verified speed sensor working great, gear algorithm working great, closed loop boost working great. Is there something I'm missing, or is this boost by gear just a foolish waste of time anyway? Has anyone actually got this working? What's the secret?

#7

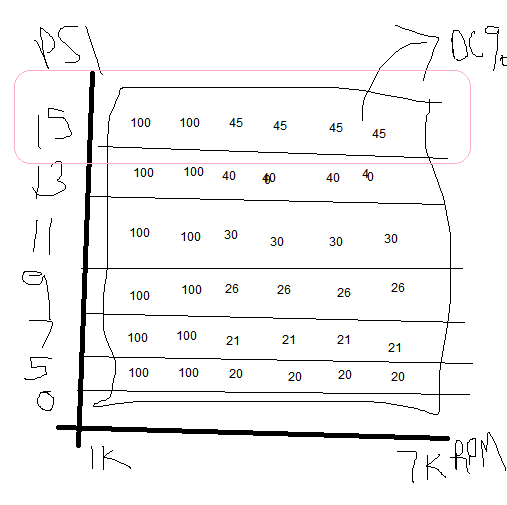

Yes sir, because it does not work, but you can see a few of the targets I tried, along with 5 kpa, 190 kpa in 3rd gear, which made no difference whatsoever. I also tried the closed loop in basic mode, advanced mode, and the slider between 200 and 450 (PID algorithm, with no effect whatsoever.)

#10

Closed loop is working great, just turned off the boost by gear and spent some more time tuning closed loop, and it's hitting the desired 190kpa very quickly and very stable. I guess I think boost by gear is a waste of time now, but it bugs me that it didn't work.

I tried setting kpa to 5!! (which should have just returned it to my 8 psi wastegate) in 1st, 2nd and 3rd gears, it still hit the 190 kpa target from closed loop, like it ignored the boost by gear numbers completely. I tried 5kpa, 100kpa, 160kpa it just kept hitting the 190kpa target from closed loop.

I tried it in basic mode and advanced mode and it made no difference to the boost by gear, it just kept ignoring those values. I tried power cycling the car and tunerstudio multiple times.

I discovered that basic mode of closed loop worked better for me, though, because I didn't need to set any PID numbers at all, just moved the little slider to 300 and it's perfect, hits the 190 kpa target and stays there, and my overboost is set to 200 and it doesn't overboost either.

I did set up my boost duty table quite aggressively, keeping the solenoid wide open, as long as possible to get the boost up to pressure quickly and then tapering my values off, the same way I did on my open loop table (which also works really, really well,) and I wondered if that could make boost by gear not work because it is following my duty values? Are you supposed to use a soft duty map to make boost by gear work maybe?

You can see this in the tune I posted, I'm sure. If you have any ideas of things to try, I'd be interested to hear them. I have a new motor with forged internals almost finished, so I figured this is the time to learn to tune boost, as all that is at risk are some cheap chinese pistons that will soon be done their duty in my car.

I tried setting kpa to 5!! (which should have just returned it to my 8 psi wastegate) in 1st, 2nd and 3rd gears, it still hit the 190 kpa target from closed loop, like it ignored the boost by gear numbers completely. I tried 5kpa, 100kpa, 160kpa it just kept hitting the 190kpa target from closed loop.

I tried it in basic mode and advanced mode and it made no difference to the boost by gear, it just kept ignoring those values. I tried power cycling the car and tunerstudio multiple times.

I discovered that basic mode of closed loop worked better for me, though, because I didn't need to set any PID numbers at all, just moved the little slider to 300 and it's perfect, hits the 190 kpa target and stays there, and my overboost is set to 200 and it doesn't overboost either.

I did set up my boost duty table quite aggressively, keeping the solenoid wide open, as long as possible to get the boost up to pressure quickly and then tapering my values off, the same way I did on my open loop table (which also works really, really well,) and I wondered if that could make boost by gear not work because it is following my duty values? Are you supposed to use a soft duty map to make boost by gear work maybe?

You can see this in the tune I posted, I'm sure. If you have any ideas of things to try, I'd be interested to hear them. I have a new motor with forged internals almost finished, so I figured this is the time to learn to tune boost, as all that is at risk are some cheap chinese pistons that will soon be done their duty in my car.

#12

I believe I could set the closed loop to whatever I want to be at, I assumed the only reason I was seeing 190kpa was because I set that as the target. I could try telling closed loop to see 100 kpa in all the cells and see if it only sees wastegate pressure, I think it would, I know when I put all zeros into my duty table, as a test, it dropped to wastegate pressure, and when I pasted my duty numbers back in, it was instantly back. You think I should try the same thing with my closed loop targets? I'm curious where you're going with this?

#15

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

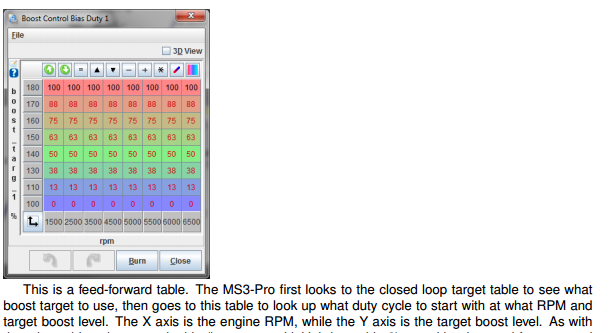

There is a bias duty table. It is different. It is what the closed loop equation is based off of, but it won't follow those duty cycles exactly. They are just taken into account in the equation.

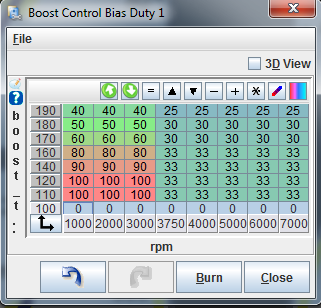

Just looked at your tune again. You are tuning the bias duty table wrong.

The way the bias duty table works is its almost like a "suggestion" for the closed loop boost equation. Take a look at it again. The Y axis is target boost. So Right now you are actually trying to use a higher duty cycle for a lower boost pressure, so completely backwards.

If you want to hit 100kpa with closed loop then you want your EBC solenoid at 0 duty cycle, so your bias table would look like this:

Retune your bias table and it will work again.

Just looked at your tune again. You are tuning the bias duty table wrong.

The way the bias duty table works is its almost like a "suggestion" for the closed loop boost equation. Take a look at it again. The Y axis is target boost. So Right now you are actually trying to use a higher duty cycle for a lower boost pressure, so completely backwards.

If you want to hit 100kpa with closed loop then you want your EBC solenoid at 0 duty cycle, so your bias table would look like this:

Retune your bias table and it will work again.

#16

Ok, I was intentionally keeping the solenoid wide open (100% duty) bleeding as much air as possible, as long as possible, to build as much boost, and obviously by putting high duty in the bottom row, building boost as early as possible too. It seemed to work very well, like open loop duty tables, but you're saying I've got this backwards, and it sounds like I was applying open loop duty table ideas, and I should really just start at 0 at the bottom and end up with 100 on the top row? Will it really build boost as quickly, I wonder? Gonna have to try this out and see! Thanks for the responses, aidandj!

Found this in the MS3pro manual

#17

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

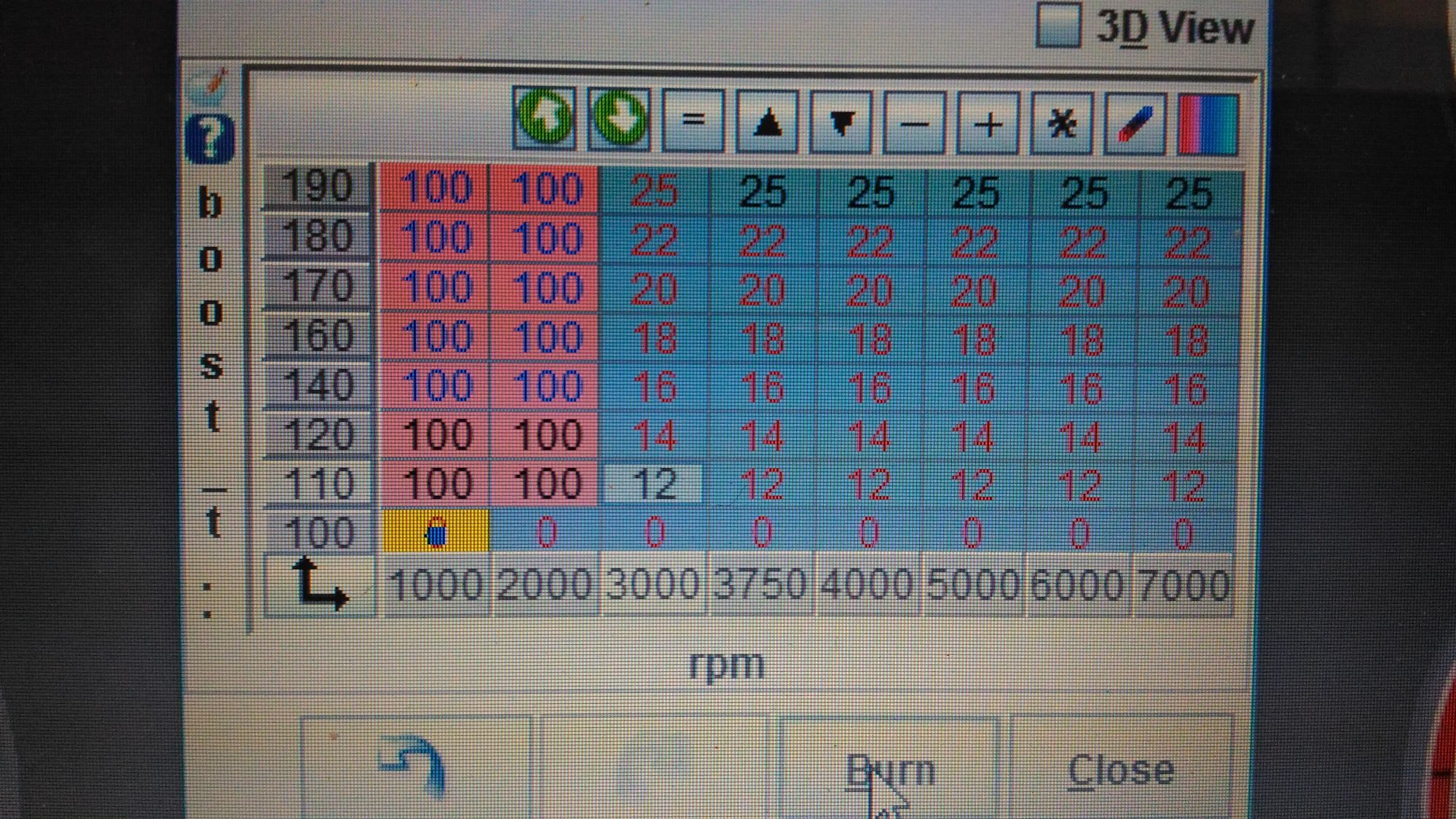

You are still not understanding the table. The Y axis is boost target.

Left to right will start at 100 and go to whatever you need. But up and down are unrelated.

Also closed loop wont even drop from the max value until you are inside the boost delta. So if your delta is set to 20kpa and your target is 190kpa then the solenoid will stay at max until 170kpa.

Also, tune the min and max for your solenoid. Its never 0-100. That just makes it harder to tune. Do some pulls starting at 100% open loop, and lower the duty cycle by 5% until spool is affected. Do the same starting at 0%. Then fine tune. You will have a min and max. Mine is like 20%-60%

Left to right will start at 100 and go to whatever you need. But up and down are unrelated.

Also closed loop wont even drop from the max value until you are inside the boost delta. So if your delta is set to 20kpa and your target is 190kpa then the solenoid will stay at max until 170kpa.

Also, tune the min and max for your solenoid. Its never 0-100. That just makes it harder to tune. Do some pulls starting at 100% open loop, and lower the duty cycle by 5% until spool is affected. Do the same starting at 0%. Then fine tune. You will have a min and max. Mine is like 20%-60%

#19

Ok, so I guess the only row I had tuned somewhat correctly was the top row, because that's where I was getting the boost numbers I wanted to see, at 25% duty cycle with a target of 190 kpa, from 3750 rpm all the way up to 7000rpm (which I was getting exactly) but all of the rows below that, where I was trying to run the highest duty cycle I could, is just wrong. I will try this, and also I think I will look at my log from open loop and see exactly what kpas I was getting at various duty cycles, to see if that information will help.

#20

<br >

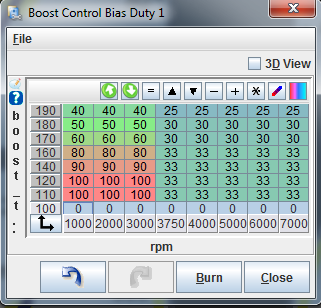

<br >Ok, given that I know the top row was giving me the expected target of 190 kpa, I've gone from there and lowered each row below that as a starting point, and left the first two columns as 100s as in Brain's example. I also added the row of zeros at 100 kpa as per aidandj's example.

I do not know where to set my delta, as aidandj mentioned setting it to 20% for example. Is the theory that my duty cycles were so high in lower cells that it was preventing me specifying the kpa in boost by gear? As I now test and datalog, should I be checking each target kpa cell and adjusting the duty cycle until I get the target and result to match, always in the same gear for now?