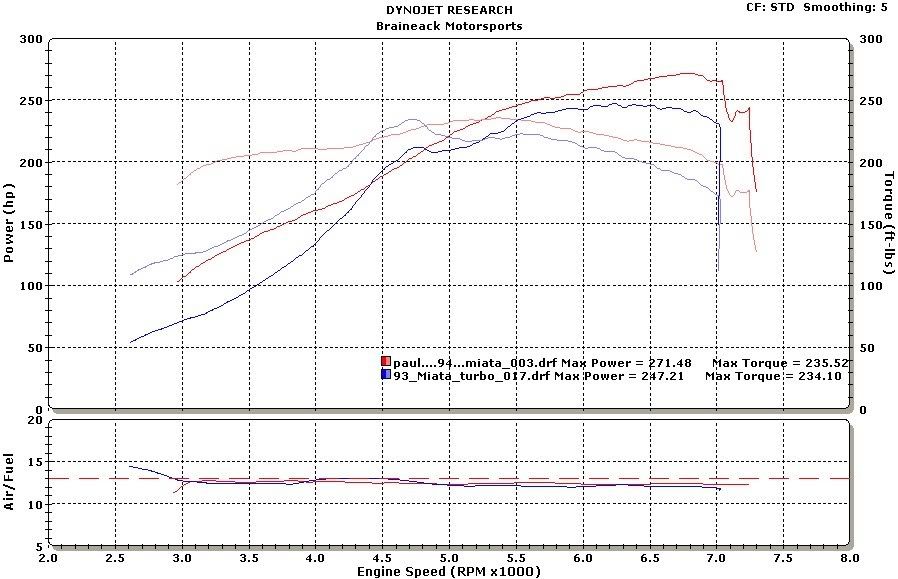

Dyno graphs from NE Dyno Day 11/15/08

#25

It looks like the 2560 has no problem making 300whp on a '99 with some goodies to help it flow. Paul, I would love to see you expiriment with an exhintake and adjustable cam-gear. My build-sheet is looking almost identical to the Machine except for the intake manifold. I won't have the budget for one, but if the guys playing with gutted VICS setups get the data to prove it's worth it, I'll definitely go there. If not, I'll be looking for a spare head and getting intimate with my Demel.

So, coming back to the real-world, and considering that 95% of the time, I'll be running wastegate at around 10psi for whatever that gives me... probably in the 220-230whp range... and knowing that the 2560 will give me 300whp with the hardware to let it flow good, that's my snail.

So, coming back to the real-world, and considering that 95% of the time, I'll be running wastegate at around 10psi for whatever that gives me... probably in the 220-230whp range... and knowing that the 2560 will give me 300whp with the hardware to let it flow good, that's my snail.

#26

It looks like the 2560 has no problem making 300whp on a '99 with some goodies to help it flow. Paul, I would love to see you expiriment with an exhintake and adjustable cam-gear. My build-sheet is looking almost identical to the Machine except for the intake manifold. I won't have the budget for one, but if the guys playing with gutted VICS setups get the data to prove it's worth it, I'll definitely go there. If not, I'll be looking for a spare head and getting intimate with my Demel.

So, coming back to the real-world, and considering that 95% of the time, I'll be running wastegate at around 10psi for whatever that gives me... probably in the 220-230whp range... and knowing that the 2560 will give me 300whp with the hardware to let it flow good, that's my snail.

So, coming back to the real-world, and considering that 95% of the time, I'll be running wastegate at around 10psi for whatever that gives me... probably in the 220-230whp range... and knowing that the 2560 will give me 300whp with the hardware to let it flow good, that's my snail.

Here's what FM did with a N/A car. The first run is VICS unplugged, then active, then last it's locked in the low position.

http://www.flyinmiata.com/tech/dyno_runs/99_050400.pdf

I have adjustable gears for my new 99. The intake cam even already has a little nub added to it to for the CAS sensor.

I will not be doing exh-intake but am considering the MSM intake cam. It's pretty inexpensive, but I fear that it may loose all ***** up top.

Anyone know the projected price point of BEGi's new manifold?

#29

Thread Starter

Elite Member

iTrader: (21)

Joined: Jun 2006

Posts: 2,957

Total Cats: 2

From: Point Pleasant, NJ

I'm really concerned about what would happen below 3500rpm. I'd hate to give up too much of that power down low. I need to test one of these things out. who wants to loan me a gt2871r?

#31

I'm not trying to beat on the horse, but I'm not convinced yet that the stock manifold with gutted VICS is better than a stock manifold with functional VICS. Unfortunately I have no evidence one way or the other.

Here's what FM did with a N/A car. The first run is VICS unplugged, then active, then last it's locked in the low position.

http://www.flyinmiata.com/tech/dyno_runs/99_050400.pdf

I have adjustable gears for my new 99. The intake cam even already has a little nub added to it to for the CAS sensor.

I will not be doing exh-intake but am considering the MSM intake cam. It's pretty inexpensive, but I fear that it may loose all ***** up top.

Anyone know the projected price point of BEGi's new manifold?

Here's what FM did with a N/A car. The first run is VICS unplugged, then active, then last it's locked in the low position.

http://www.flyinmiata.com/tech/dyno_runs/99_050400.pdf

I have adjustable gears for my new 99. The intake cam even already has a little nub added to it to for the CAS sensor.

I will not be doing exh-intake but am considering the MSM intake cam. It's pretty inexpensive, but I fear that it may loose all ***** up top.

Anyone know the projected price point of BEGi's new manifold?

I think paul is too obsessed with "spool". If you want more power, then you need a bigger turbo. Period. You want it to spool like your 2560 or better, then you need some head work to increase the VE of the engine.

#37

The cheap basic kit is on and off. The progressive kit has it's own controller and MS isn't currently (easily) capable of controlling a high speed valve. We went over this real hot and heavy for a while. All the info is still here. The HSVs are expensive as heck, unless someone came out with one in the past couple months.

#39

Buy an ebay kit for WI. Get a few different nozzle sizes when I order it so I can play with different amounts of water. Use a pressure switch to trigger a relay that turns on the pump. Really simple to wire up. Magna doesn't even use a relay, but I will.

I'm gonna do it one stage at first, with the WI nozzle being sized for about 10% of the amount of fuel I'll be burning at peak duty cycle for the sum of all my fuel injectors. So If I'm burning 2K cc of fuel at peak power, I'll get a 200cc nozzle. Then I'll add a second stage down the road, as it's cheap and not hard to do. And it's a lot cheaper than a 'real' progressive setup.

#40

So if the primary purpose of WI is to lower intake temps... AND NOTHING MORE...right? Does it do anything else? Then wouldn't you want to feed the WI controller with an IAT reading before and after the nozzle. The program would sense the ramp-up of IAT's and inject water accordingly. Are there "progressive" pumps that aren't simply on/off, but can supply different pressure... that would alleviate the need for stages.

You could put one sensor just after the intercooler, WI nozzle on the coldside, and second sensor just before the TB... that way, the controller could see pre-and-post injection temps, and give just enough water to maintain a specific temperature.

As the first sensor saw temps climbing through say 90*, it would start injecting water, giving just enough to stabilize in the 95* area at the second sensor. I'm talking out my *** here since I know nothing about water injection or ideal intake temps (other than colder is better)

I would say though before doing all the work on that, you'd want an efficient turbo, good cooling system, proper air-filter placement to minimize intake air temps, good engine compartment heat-shielding, properly sized intercooler getting good airflow. Make sure you're not using WI as a band-aid for inefficiencies in your build. I'm not speaking to anybody in particular, just generalities.

You could put one sensor just after the intercooler, WI nozzle on the coldside, and second sensor just before the TB... that way, the controller could see pre-and-post injection temps, and give just enough water to maintain a specific temperature.

As the first sensor saw temps climbing through say 90*, it would start injecting water, giving just enough to stabilize in the 95* area at the second sensor. I'm talking out my *** here since I know nothing about water injection or ideal intake temps (other than colder is better)

I would say though before doing all the work on that, you'd want an efficient turbo, good cooling system, proper air-filter placement to minimize intake air temps, good engine compartment heat-shielding, properly sized intercooler getting good airflow. Make sure you're not using WI as a band-aid for inefficiencies in your build. I'm not speaking to anybody in particular, just generalities.