Wastegate actuator modification?

#1

Hello,

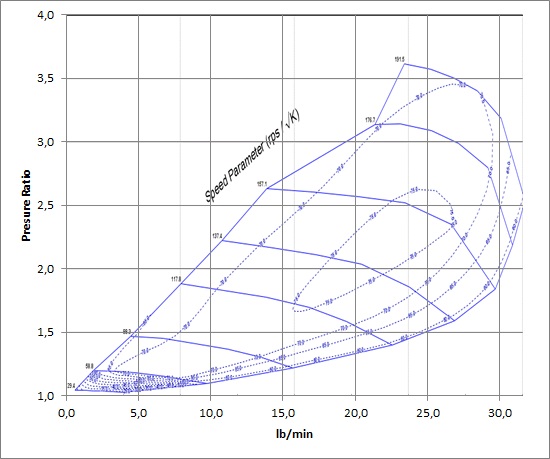

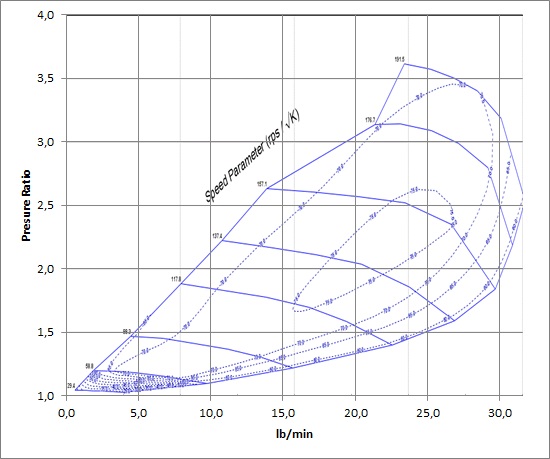

I'm currently building a turbo setup for my car, not a miata but since there is so much turbo knowledge here I'd figure I'd ask here. The car is a toyota glanza 1.3 turbo. I just made a header and downpipe for it, so I could mount a Holset HE200WG Turbo (Awesome little turbo, here is the compressor map of it )

)

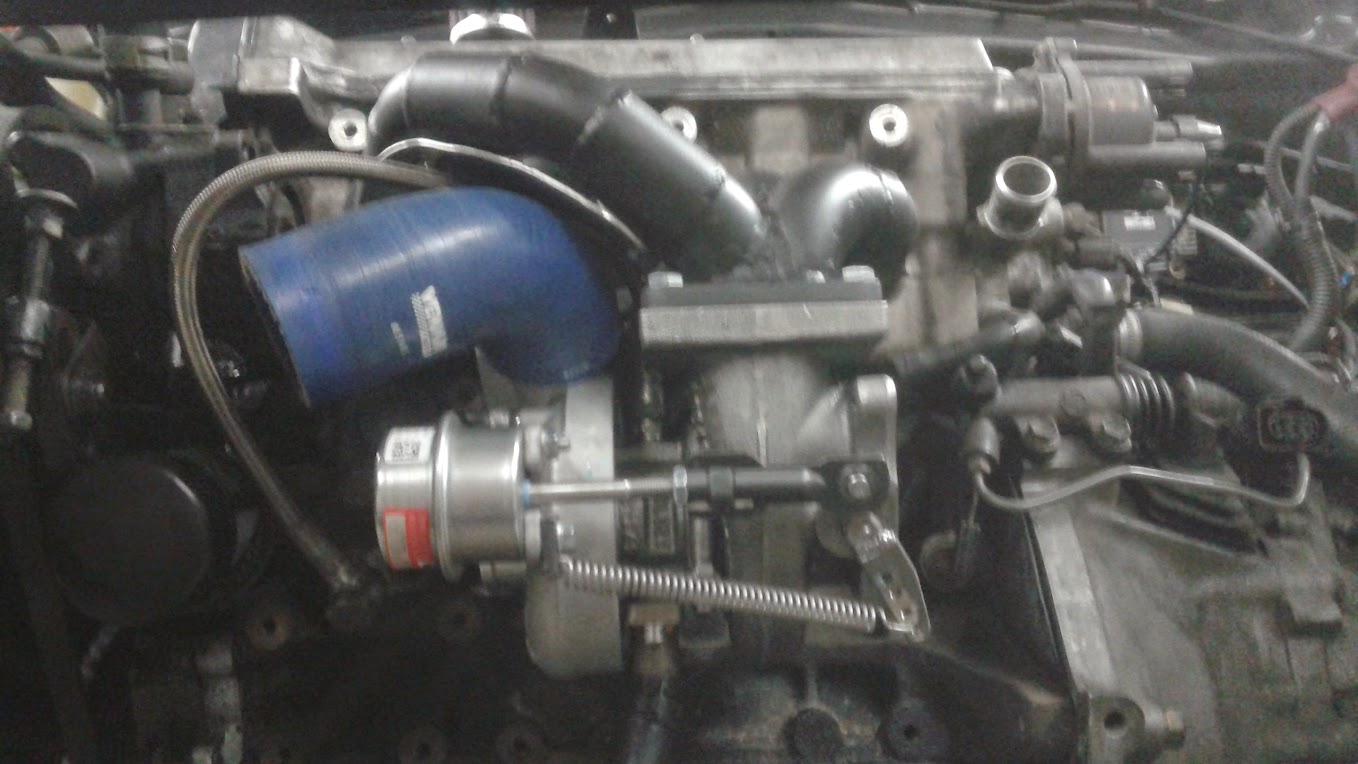

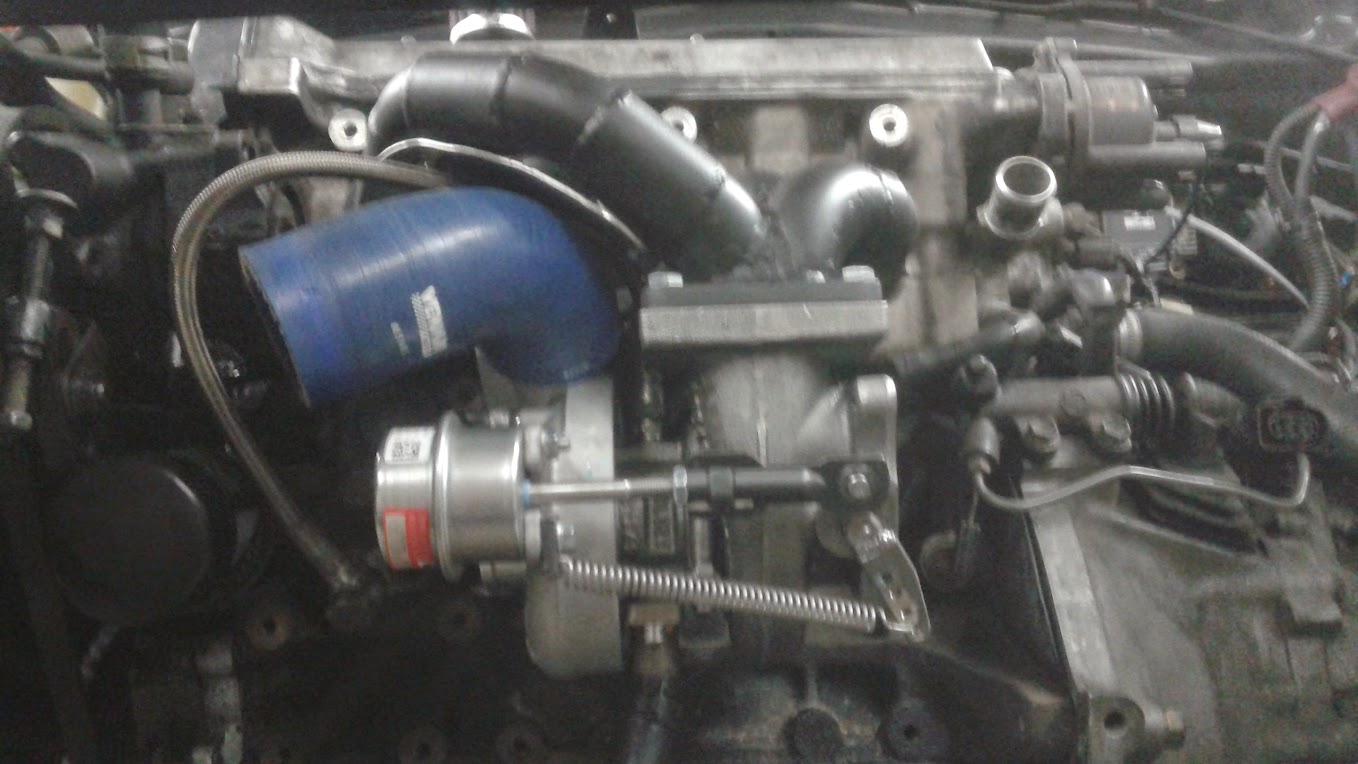

Now, during the assembly I found that the wastegate was too strong for my application, The stock CT9 wastegate had a cracking pressure of about 10 psi, and was fully open at 20 (This does not directly reflect turbo pressure because exhaust backpressure also helps pushing the wastegate flap open). The holset had a wastegate cracking pressure of about 20 psi, and was fully open at 40psi. Now to remedy this I added a spring to the wastegate flapper to reduce the boost pressure:

The problem with this is that this makes the cracking pressure teeny, like 3-5 psi or so, but to fully open it still about 30 psi or so is needed. I ran the car like this to see what it does, and it seems like this hurts spoolup. It's very easy to get into positive boost to about 0,3 - 0,5 bars or so, but there is more lag before it's up to it's maximum boost level of about 1,2 bars than what I'd like.

This brings me to my question, what is preferred for the behaviour of the wastegate? I noticed that with stock diaphram wastegates the cracking pressure is about half of the fully open pressure. But since I have plenty of room near the wastegate actuator what would happen if I machined up a larger piston type actuator which uses a longer spring. I think I can make it so the cracking pressure and fully open pressure to be closer together, which should be good for spoolup, but might cause the pressure to fluctuate more easily. Anyone messed around with this? I ideally would want the turbo pressure only to be regulated with a wastegate actuator while having good spoolup. The car runs on a megasquirt, and I have a MAC boost control valve installed, but I can't seem to get it to work right. The valve acts very non-linear.

I'm currently building a turbo setup for my car, not a miata but since there is so much turbo knowledge here I'd figure I'd ask here. The car is a toyota glanza 1.3 turbo. I just made a header and downpipe for it, so I could mount a Holset HE200WG Turbo (Awesome little turbo, here is the compressor map of it

)

)

Now, during the assembly I found that the wastegate was too strong for my application, The stock CT9 wastegate had a cracking pressure of about 10 psi, and was fully open at 20 (This does not directly reflect turbo pressure because exhaust backpressure also helps pushing the wastegate flap open). The holset had a wastegate cracking pressure of about 20 psi, and was fully open at 40psi. Now to remedy this I added a spring to the wastegate flapper to reduce the boost pressure:

The problem with this is that this makes the cracking pressure teeny, like 3-5 psi or so, but to fully open it still about 30 psi or so is needed. I ran the car like this to see what it does, and it seems like this hurts spoolup. It's very easy to get into positive boost to about 0,3 - 0,5 bars or so, but there is more lag before it's up to it's maximum boost level of about 1,2 bars than what I'd like.

This brings me to my question, what is preferred for the behaviour of the wastegate? I noticed that with stock diaphram wastegates the cracking pressure is about half of the fully open pressure. But since I have plenty of room near the wastegate actuator what would happen if I machined up a larger piston type actuator which uses a longer spring. I think I can make it so the cracking pressure and fully open pressure to be closer together, which should be good for spoolup, but might cause the pressure to fluctuate more easily. Anyone messed around with this? I ideally would want the turbo pressure only to be regulated with a wastegate actuator while having good spoolup. The car runs on a megasquirt, and I have a MAC boost control valve installed, but I can't seem to get it to work right. The valve acts very non-linear.

#3

The MAC valve he mentions is just that. EBC.

How are you controlling that solenoid? What version of Megasquirt do you have? What firmware? This might be better posted on msextra.com or on the msextra facebook page.

I wouldn't by worried about "fully open." I don't think a fully 90 degree open is necessary to release the pressure. How did you test this? Did you pump in 10psi of air into the actuator to see where it ended up, or are you getting these results from spinning the turbo to 30psi? Honestly if I was going to go through the trouble of fabricating up a manifold like that I would have designed it to use an external wastegate, but that's just me.

How are you controlling that solenoid? What version of Megasquirt do you have? What firmware? This might be better posted on msextra.com or on the msextra facebook page.

I wouldn't by worried about "fully open." I don't think a fully 90 degree open is necessary to release the pressure. How did you test this? Did you pump in 10psi of air into the actuator to see where it ended up, or are you getting these results from spinning the turbo to 30psi? Honestly if I was going to go through the trouble of fabricating up a manifold like that I would have designed it to use an external wastegate, but that's just me.

#4

I'm using a microsquirt module which I soldered onto a homemade breakout board which is mounted in a waterproof enclousure, running the latest MSextra firmware.

I agree on the external wastegate, but at the time the owners budget doesn't allow for one. To be honest, the bad result with the mac solenoid was with the stock CT9 turbo spinning at over 1 bars, so huuuge backpressure. After messing around with it for an afternoon I just added a spring and called it a day which worked fine.

To test the working pressure of the wastegate I got the complete turbo on the bench and hooked up a pneumatic reducing / relieving valve with a pressure gauge to the actuator. Checked the pressure at which the wastegate start to go open and checked at what pressure the wastegate is fully open.

Anyway, I will post up a datalog which shows the turbo spooling up later. I also found an actuator in the garage which seems to open at around 10-12 psi. Might be a tad low but it's a fairly large diameter, and maybe I could give the MAC solenoid another go to sort it out.

I agree on the external wastegate, but at the time the owners budget doesn't allow for one. To be honest, the bad result with the mac solenoid was with the stock CT9 turbo spinning at over 1 bars, so huuuge backpressure. After messing around with it for an afternoon I just added a spring and called it a day which worked fine.

To test the working pressure of the wastegate I got the complete turbo on the bench and hooked up a pneumatic reducing / relieving valve with a pressure gauge to the actuator. Checked the pressure at which the wastegate start to go open and checked at what pressure the wastegate is fully open.

Anyway, I will post up a datalog which shows the turbo spooling up later. I also found an actuator in the garage which seems to open at around 10-12 psi. Might be a tad low but it's a fairly large diameter, and maybe I could give the MAC solenoid another go to sort it out.

#6

Ah right, I'll try fitting the lighter actuator then. It's only a single port one though, but I'll see if I can add a second port, or just hook the MAC solenoid up so it relieves.

Anyway, I dug up a datalog, doesn't even look that terrible to me. Full boost is around 4000rpm, Boost level is within 1 psi between 4000 and 7000rpm.

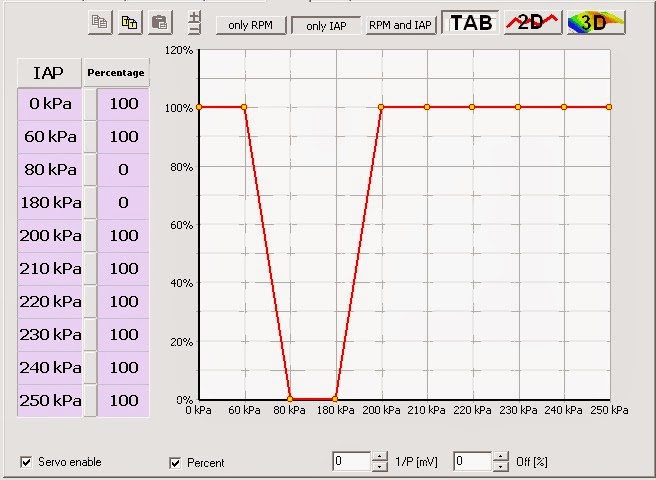

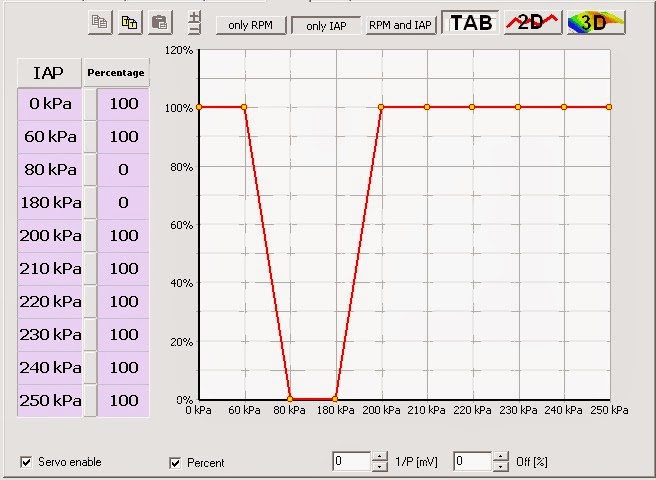

On a side note, I did a test a while ago on my old E30 turbo where I was having a similar issue with a Holset HX35. I ended up going bananas, made up a butterfly valve external wastegate which was hooked up to a servo. The servo then adjusted the wastegate position according to the MAP value.

This worked very very well, I could modify the boost level to any level I wanted. I tested it between 0 and 30psi, I was also able to open the wastegate during cruising levels which I think helped a little with economy. Eventually the fragile butterfly valves failed though, but it worked great while it lasted.

Anyway, I dug up a datalog, doesn't even look that terrible to me. Full boost is around 4000rpm, Boost level is within 1 psi between 4000 and 7000rpm.

On a side note, I did a test a while ago on my old E30 turbo where I was having a similar issue with a Holset HX35. I ended up going bananas, made up a butterfly valve external wastegate which was hooked up to a servo. The servo then adjusted the wastegate position according to the MAP value.

This worked very very well, I could modify the boost level to any level I wanted. I tested it between 0 and 30psi, I was also able to open the wastegate during cruising levels which I think helped a little with economy. Eventually the fragile butterfly valves failed though, but it worked great while it lasted.

#7

Why would the solenoid relieve anything? 2nd port would be ideal, but MANY people run single port wastegate actuator.

What the solenoid does is prevent boost from getting to the actuator until the moment that you want it to, at that point the boost is pulsed which causes the flapper to open to the degree in which the boost should theoretically stop rising (unless you have a poor flowing wastegate airflow path, in which case boost might spike or creep).

What the solenoid does is prevent boost from getting to the actuator until the moment that you want it to, at that point the boost is pulsed which causes the flapper to open to the degree in which the boost should theoretically stop rising (unless you have a poor flowing wastegate airflow path, in which case boost might spike or creep).

#8

I messed with it a bit more last weekend. Had a 0,5 bar actuator that came off an RX-7 lying around so I modified it into having 2 ports and modified it so it fit the holset turbo. For now I just grabbed a pressure regulating valve, which always just puts an X amount of pressure at the spring side. Ended up at about 0,4 bars added to the spring, which gave me about 1 bars of boost pressure. Works pretty good for a manual boost controller! Spools a lot quicker than it did with the spring, full boost at about 3200rpm. Boost level is stable and it's very easy to adjust from about 0,5 bars to whatever is needed.

Thread

Thread Starter

Forum

Replies

Last Post

StratoBlue1109

Miata parts for sale/trade

7

09-24-2015 03:50 PM