Turbo water line routing, quick question

#1

Thread Starter

Junior Member

iTrader: (2)

Joined: Mar 2013

Posts: 138

Total Cats: -18

From: Livermore, CA

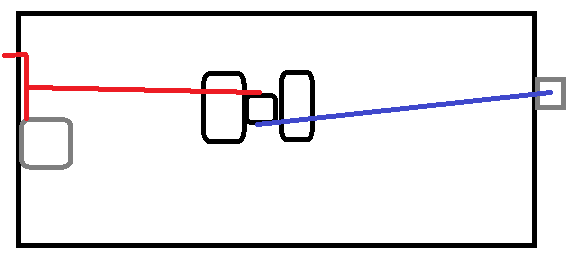

So I'm upgrading my turbo to one that is now water cooled and I'm trying to figure out how to run my lines. This picture shows how my routing currently is with the exceptions that the thermostat housing is blocked off with a freeze plug and I bypassed the throttle body, so basically the one hose goes directly from oil cooler outlet to the mixing manifold.

I was thinking of running the feed hose from one of the available ports in the BEGi reroute spacer, and then Tee-ing into the hose just before the mixing manifold for the return. Would this be ok or can y'all recommend a better way? Block is from a 96-97 btw

I was thinking of running the feed hose from one of the available ports in the BEGi reroute spacer, and then Tee-ing into the hose just before the mixing manifold for the return. Would this be ok or can y'all recommend a better way? Block is from a 96-97 btw

#4

Thread Starter

Junior Member

iTrader: (2)

Joined: Mar 2013

Posts: 138

Total Cats: -18

From: Livermore, CA

https://turbobygarrett.com/turbobyga...er_Cooling.pdf

"It is true that during normal engine operation water flows through the turbocharger mostly due to pressure created by the engine’s water pump. However, an additional phenomenon known as “thermal siphoning” pulls water through the turbo’s center housing if the water lines are properly routed, even after the engine is shut off and the water pump is no longer pumping. Heat in the center housing is transferred to the water via conduction, like the cooling effect that occurs inside a typical water-cooled engine (with a water jacket surrounding each cylinder and running through the cylinder head). If the water running through a turbocharger is allowed to escape freely after absorbing heat, it will rise through the cooling system pulling cooler water into the turbocharger along with it. In this way the intense heat that has soaked back into the turbo after engine shutdown is wicked away from the bearings and seals, and prevented from causing serious damage without assistance from the engine’s water pump."

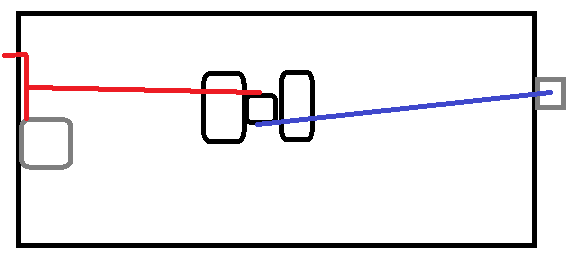

It's hard for me to determine which is the cooler water source, since both take coolant from the back of the head, but the line running into the mixing manifold has also run through the oil cooler. I think that once it's all plumbed in the two sources will be of similar elevation. Like this is how I was planning:

Now I am thinking I should go back to my original plan, which I abandoned in favor of something that was easier to do, of welding a -6an fitting to the center metal section of the lower radiator hose for the feed line, then I could send the return to my Tee location going back into the mixing manifold from the oil cooler output like I have it in the diagram.

"It is true that during normal engine operation water flows through the turbocharger mostly due to pressure created by the engine’s water pump. However, an additional phenomenon known as “thermal siphoning” pulls water through the turbo’s center housing if the water lines are properly routed, even after the engine is shut off and the water pump is no longer pumping. Heat in the center housing is transferred to the water via conduction, like the cooling effect that occurs inside a typical water-cooled engine (with a water jacket surrounding each cylinder and running through the cylinder head). If the water running through a turbocharger is allowed to escape freely after absorbing heat, it will rise through the cooling system pulling cooler water into the turbocharger along with it. In this way the intense heat that has soaked back into the turbo after engine shutdown is wicked away from the bearings and seals, and prevented from causing serious damage without assistance from the engine’s water pump."

It's hard for me to determine which is the cooler water source, since both take coolant from the back of the head, but the line running into the mixing manifold has also run through the oil cooler. I think that once it's all plumbed in the two sources will be of similar elevation. Like this is how I was planning:

Now I am thinking I should go back to my original plan, which I abandoned in favor of something that was easier to do, of welding a -6an fitting to the center metal section of the lower radiator hose for the feed line, then I could send the return to my Tee location going back into the mixing manifold from the oil cooler output like I have it in the diagram.

#5

Thread Starter

Junior Member

iTrader: (2)

Joined: Mar 2013

Posts: 138

Total Cats: -18

From: Livermore, CA

After doing some more reading I think that Tee-ing into stuff is less than ideal due to waters nature to run through the path of least resistance. I've decided that perhaps my best course of action is just to do it like in the picture I posted in the first post running the turbo in line with the oil cooler and mixing manifold. Now, it looks like they have the feed come from the oil cooler, and drains into the mixing manifold, but I'm wondering if it wouldn't be better the other way around since the mixing manifold is at a lower point than the oil cooler. So that when the engine is running, coolant will run through the turbo top-bottom, then after shutoff it can run bottom-top. Would that be better? Or am I overthinking this?

Thread

Thread Starter

Forum

Replies

Last Post

nigelt

DIY Turbo Discussion

27

05-07-2018 03:43 PM