Turbo Manifold For A GT3271

#1

Thread Starter

Elite Member

iTrader: (16)

Joined: Aug 2007

Posts: 9,352

Total Cats: 524

From: Houston, TX

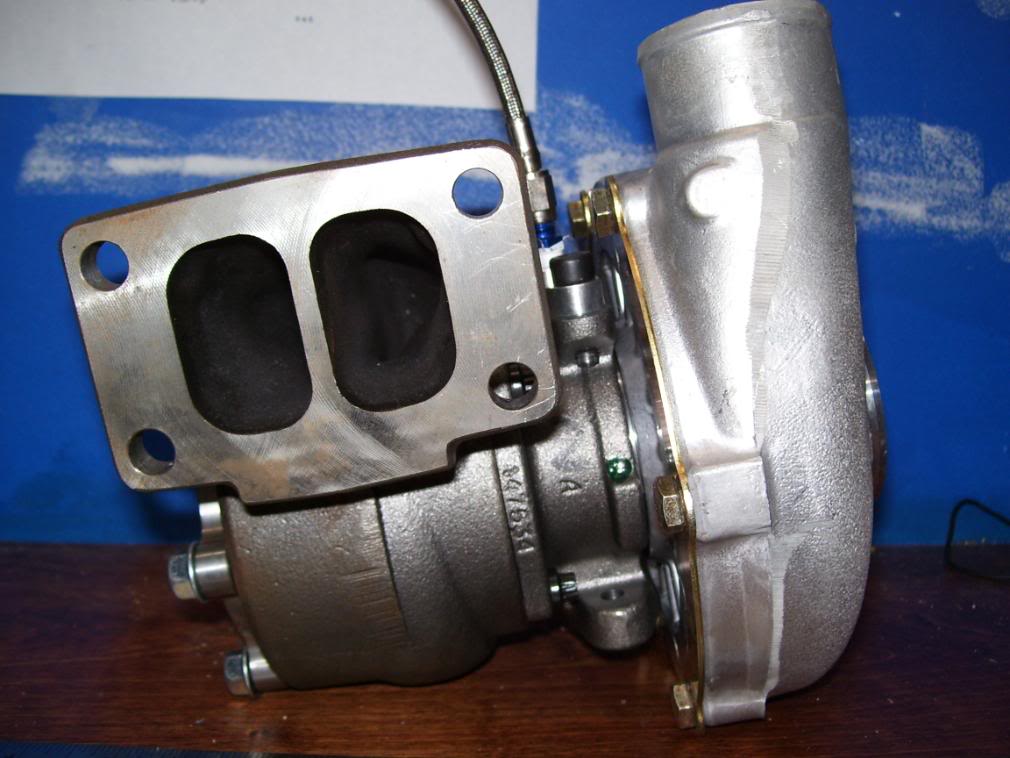

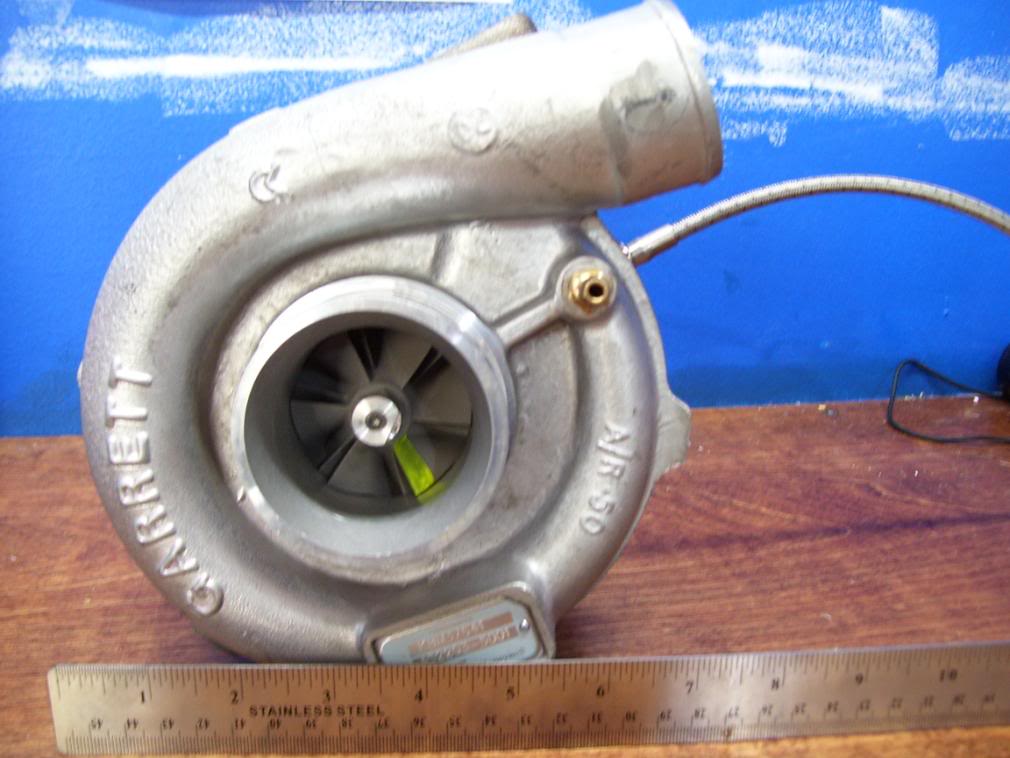

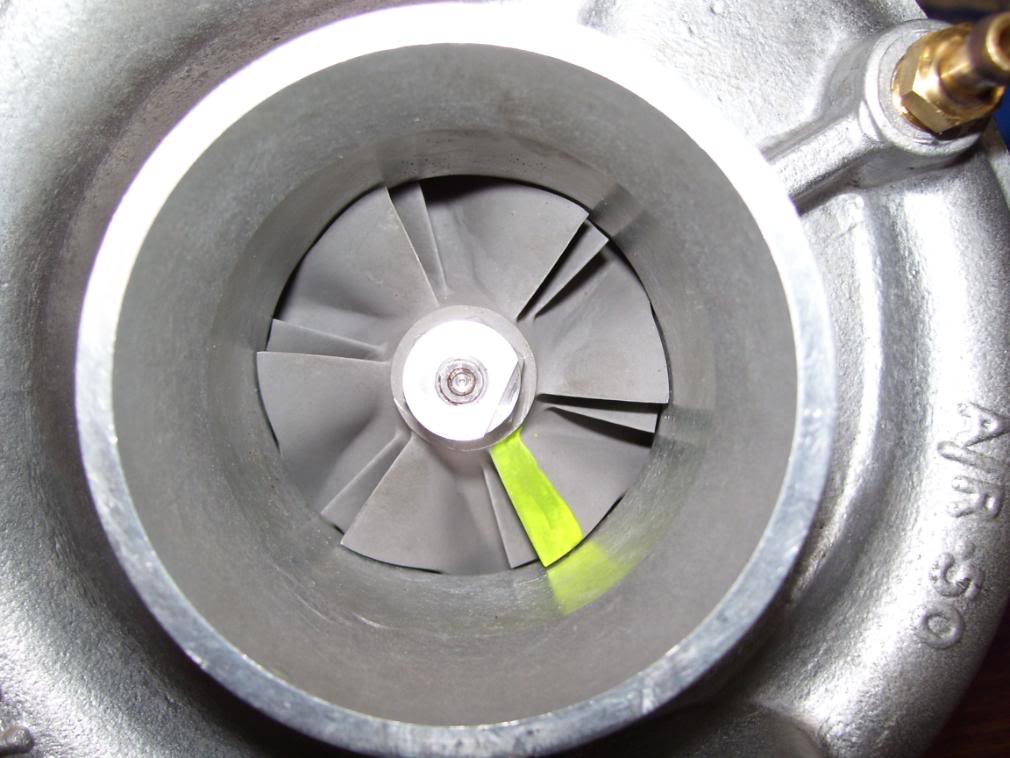

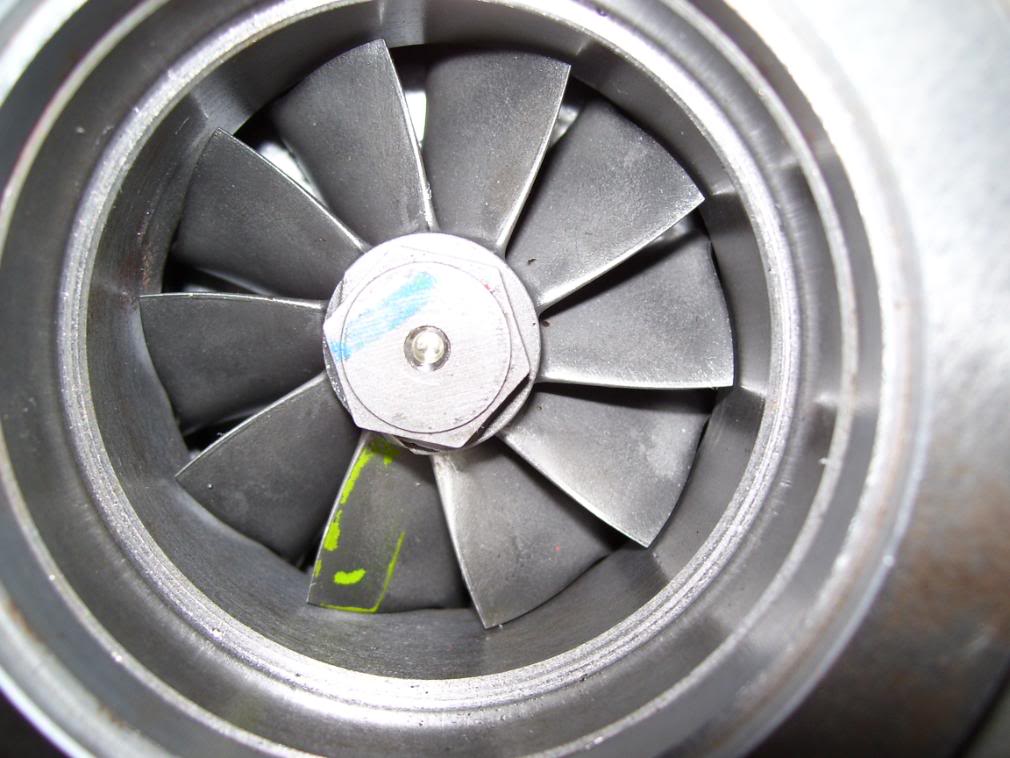

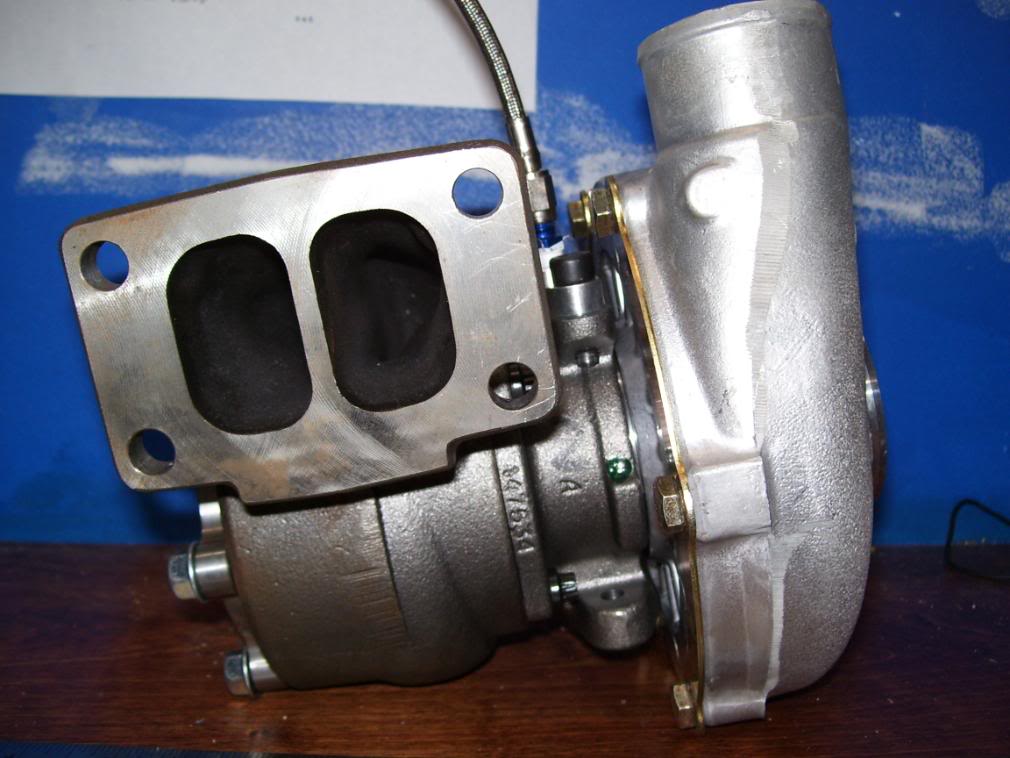

So I just bought a new Garrett GT3271 from Nick on the forum. I haven't even got it yet, but I'm beginning to consider different manifold options. Here's the SPECS on the turbo. It's a T3 divided gases turbine and setup for external wastegate.

I have several options I'm considering. Unfortunately, each is a trade off in some regards. Before I bought this turbo, I was planning on buying a BEGI S5 manifold and bolting it up as it seems to be a good piece. I still could, but the begi pieces is money, and it does not accommodate the divided gases turbine. It would work, but I would not see the benefits of the divided turbine.

Or, I could build a manifold. This is probably what will happen, in some form or fashion. Mind you I am keeping P/S and A/C. I don't want to build a POS manifold that might work for a while. I want to build one that will be super reliable. I want to do it right the first time, and not have it cracking and warping on me as this is my DD and only car at college. Reliability first and performance a very close second.

I am considering building a manifold that DOES accommodate the divided turbine housing. It seems this will increase spool which would be great. However, the miata's engine bay is small so I have little room to get carried away meeting optimal design criteria. The turbo is setup for external wastegate. From my research, some put two wastegates. That's not for me. Others run a pipe from each side of the divided gases flange to one wastegate, and the pipes combine right before the wastegate. Sounds like a plan to me.

Optimally, the manifold would start out as four 1 1/2" weld ells. They would be up swept and somehow 1&4 would combine into one pipe right before the flange. So would 2&3. But that's easier said than done. A bit easier would be combining 1&4 and 2&3 somewhat early, and then just have two pipes that go into the divided gases flange that the turbo would bolt to. (would look like this http://i47.photobucket.com/albums/f1...a/DSC00551.jpg )

So does this sound reasonable? Will building a divided gases manifold for this turbo make much difference? Are weld ells the best material to use? (That's what I've read and been told, mild steel weld ells are the best) Anyone here ever work with weld ells or build their own manifold and want to share their experience? I have a Lincoln 220 AC/DC stick welder. I can weld ok, but not great. Also I have a lot of the stuff I'd need to fabricate with like a 14" abrasive chop saw, compound miter saw w/ 10" abrasive disk, welding machine, grinders, oxy propane torch, etc. But I don't have a TIG. :( But a friend does.

I have several options I'm considering. Unfortunately, each is a trade off in some regards. Before I bought this turbo, I was planning on buying a BEGI S5 manifold and bolting it up as it seems to be a good piece. I still could, but the begi pieces is money, and it does not accommodate the divided gases turbine. It would work, but I would not see the benefits of the divided turbine.

Or, I could build a manifold. This is probably what will happen, in some form or fashion. Mind you I am keeping P/S and A/C. I don't want to build a POS manifold that might work for a while. I want to build one that will be super reliable. I want to do it right the first time, and not have it cracking and warping on me as this is my DD and only car at college. Reliability first and performance a very close second.

I am considering building a manifold that DOES accommodate the divided turbine housing. It seems this will increase spool which would be great. However, the miata's engine bay is small so I have little room to get carried away meeting optimal design criteria. The turbo is setup for external wastegate. From my research, some put two wastegates. That's not for me. Others run a pipe from each side of the divided gases flange to one wastegate, and the pipes combine right before the wastegate. Sounds like a plan to me.

Optimally, the manifold would start out as four 1 1/2" weld ells. They would be up swept and somehow 1&4 would combine into one pipe right before the flange. So would 2&3. But that's easier said than done. A bit easier would be combining 1&4 and 2&3 somewhat early, and then just have two pipes that go into the divided gases flange that the turbo would bolt to. (would look like this http://i47.photobucket.com/albums/f1...a/DSC00551.jpg )

So does this sound reasonable? Will building a divided gases manifold for this turbo make much difference? Are weld ells the best material to use? (That's what I've read and been told, mild steel weld ells are the best) Anyone here ever work with weld ells or build their own manifold and want to share their experience? I have a Lincoln 220 AC/DC stick welder. I can weld ok, but not great. Also I have a lot of the stuff I'd need to fabricate with like a 14" abrasive chop saw, compound miter saw w/ 10" abrasive disk, welding machine, grinders, oxy propane torch, etc. But I don't have a TIG. :( But a friend does.

#4

Thread Starter

Elite Member

iTrader: (16)

Joined: Aug 2007

Posts: 9,352

Total Cats: 524

From: Houston, TX

Marc I was thinking about that. Just tacking it up and then getting it professionally welded out. I know if I preheated the manifold and welded it out with 3/16 7018's it would probably be ok, but I'm not 100%. I've built and welded out my 3" exhaust and so far, so good, but it doesn't get as hot as the turbo manifold would.

#11

Thread Starter

Elite Member

iTrader: (16)

Joined: Aug 2007

Posts: 9,352

Total Cats: 524

From: Houston, TX

Meh, I'm not too impressed with ETD's ideas on how to sell their products. From their website on the shorty manifold for the miata:

First, that's a fragment. Second, I don't buy this anyway. Maybe something along the lines of, "Each runner points to the collector where each cylinder can direct its energy to the turbine." That's a lot more believable to me and probably more accurate. It's also a selling point to most buyers that their manifold doesn't direct cylinders 1&4 right at each other. Yet they make no mention of it in their ad...

Grammar check:

That's better (though still wordy), but does this really need to be in the ad in the first place? Maybe just, "The waste gate connects near the collector, below the turbo." They could also show a few more pics of the manifold, like one with and one without the wastegate flange.

Try this: "Available with or without a waste gate flange."

WITHOUT HITTING! This isn't an ebay ad from some tacotacochinaJDM

It seriously looks like a 5th grader and Boostinboy got together and wrote wrote the ad. Reading things like that shys me away from ETD.

Besides, I'm pretty much dead set on building a manifold now. I don't see any available that are divided gases. Once I get the turbo here I'll figure out the best placement for it, and from their decide which type of manifold will be best.

Short runner design to deliver the exhaust to the turbocharger as quickly as possible for fastest spool.

Waste gate placement from the collector hidden below the turbo so people who know what their looking for can see it, those who don't have no idea.

Waste gate placement, from the collector, is hidden below the turbo so people who know what they are looking for can see it. Those who don't have no idea.

Available without a waste gate spot or from the bottom of the collector

Gives excellent clearance for your down pipe and easily fits a T3/T4 turbo under the hood with no hitting.

It seriously looks like a 5th grader and Boostinboy got together and wrote wrote the ad. Reading things like that shys me away from ETD.

Besides, I'm pretty much dead set on building a manifold now. I don't see any available that are divided gases. Once I get the turbo here I'll figure out the best placement for it, and from their decide which type of manifold will be best.

#12

If you only knew how many DIY'ers and manifold builders had this issue in the past. I've been around for 12 years playing with Miatas and it is funny how many make nice manifolds which need a hole cut in the hood

I'm a numbers guy, not an English major. However I don't write the pages. You have some VERY smart people at ETD, but an English Degree is not what makes them smart. The products are great and work! Nuff said...

However I don't write the pages. You have some VERY smart people at ETD, but an English Degree is not what makes them smart. The products are great and work! Nuff said...

I'm a numbers guy, not an English major.

However I don't write the pages. You have some VERY smart people at ETD, but an English Degree is not what makes them smart. The products are great and work! Nuff said...

However I don't write the pages. You have some VERY smart people at ETD, but an English Degree is not what makes them smart. The products are great and work! Nuff said...

#13

Thread Starter

Elite Member

iTrader: (16)

Joined: Aug 2007

Posts: 9,352

Total Cats: 524

From: Houston, TX

If you only knew how many DIY'ers and manifold builders had this issue in the past. I've been around for 12 years playing with Miatas and it is funny how many make nice manifolds which need a hole cut in the hood

I'm a numbers guy, not an English major. However I don't write the pages. You have some VERY smart people at ETD, but an English Degree is not what makes them smart. The products are great and work! Nuff said...

However I don't write the pages. You have some VERY smart people at ETD, but an English Degree is not what makes them smart. The products are great and work! Nuff said...

I'm a numbers guy, not an English major.

However I don't write the pages. You have some VERY smart people at ETD, but an English Degree is not what makes them smart. The products are great and work! Nuff said...

However I don't write the pages. You have some VERY smart people at ETD, but an English Degree is not what makes them smart. The products are great and work! Nuff said...And yeah I've heard quite a few horror stories of people buying "new" parts that don't fit as advertised.

#14

I have a better idea. Put 2 superchargers off the millenia on there. That'd be badass.

Build a divided manifold with a single EWG fed by both sides of the manifold. I have no idea about the strength of your welds, so yeah I guess you should farm it out to a TIG guy if that's what others with more experience with stick say. If you get tired, then make a more simple manifold. If you get tired still, buy the ETD and write everything else off as experience.

All I use for my manifolds is a 14 abrasive chop saw, dremel, die grinder, bench grinder, Lincoln TIG185.

Build a divided manifold with a single EWG fed by both sides of the manifold. I have no idea about the strength of your welds, so yeah I guess you should farm it out to a TIG guy if that's what others with more experience with stick say. If you get tired, then make a more simple manifold. If you get tired still, buy the ETD and write everything else off as experience.

All I use for my manifolds is a 14 abrasive chop saw, dremel, die grinder, bench grinder, Lincoln TIG185.

#15

Thread Starter

Elite Member

iTrader: (16)

Joined: Aug 2007

Posts: 9,352

Total Cats: 524

From: Houston, TX

Two SC's, hmm, there's a thought... I need another miata to put the SC's on.

I have 50-60 hours of stick welding under my belt. I know I can weld "decent", but it seems perfect is what's needed for a crack free manifold. All the manifolds I see are TIG'd, though I'm unsure if that's for aesthetics or for integrity. If a solid stick weld is just as good as a solid TIG weld, I'll get my dad to weld it. He's an awesome stick welder (like 20,000 hours stick welding) I'll at least tack it up if TIG is the way to go.

I have 50-60 hours of stick welding under my belt. I know I can weld "decent", but it seems perfect is what's needed for a crack free manifold. All the manifolds I see are TIG'd, though I'm unsure if that's for aesthetics or for integrity. If a solid stick weld is just as good as a solid TIG weld, I'll get my dad to weld it. He's an awesome stick welder (like 20,000 hours stick welding) I'll at least tack it up if TIG is the way to go.

#17

That's understandable. But it doesn't excuse the problem. There is some percentage of people who judge the product they are considering buying by the ad on the website alone. They have words and pictures to go by. If it were me, I would have a short and concise overview of the product on the page that shows it listed, with a small picture of it. Click on it and the new page has a through, grammatically correct, concise, and well organized description of the product and several clear pictures that get bigger when I click them.

And yeah I've heard quite a few horror stories of people buying "new" parts that don't fit as advertised.

And yeah I've heard quite a few horror stories of people buying "new" parts that don't fit as advertised.

#18

Thread Starter

Elite Member

iTrader: (16)

Joined: Aug 2007

Posts: 9,352

Total Cats: 524

From: Houston, TX

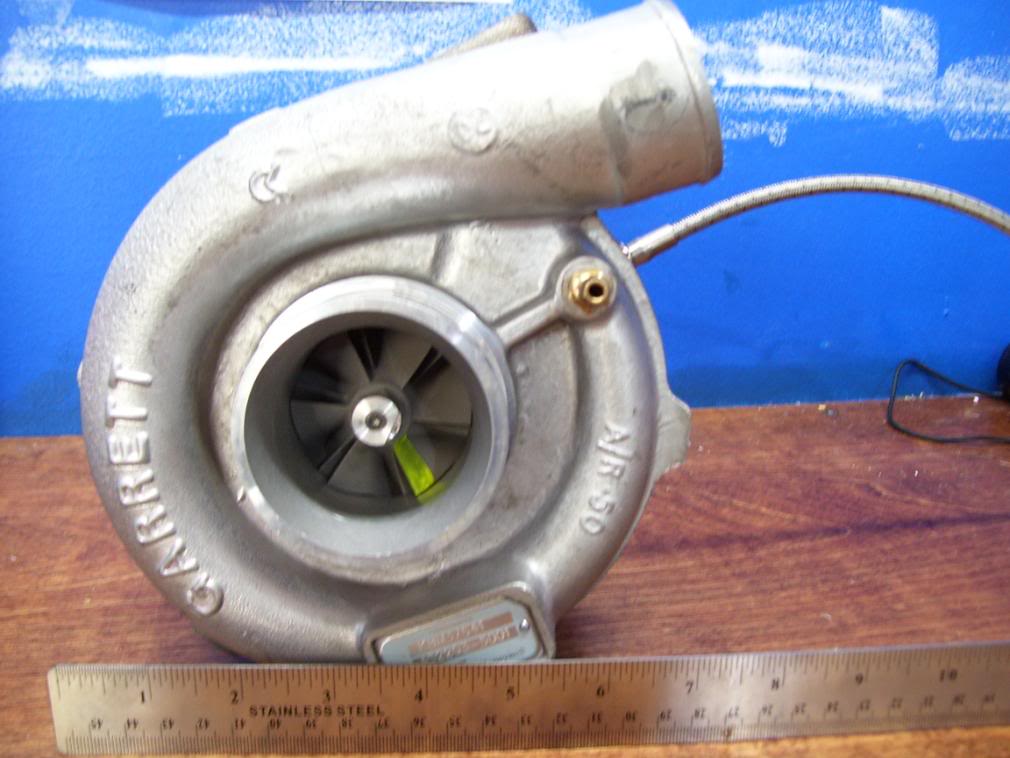

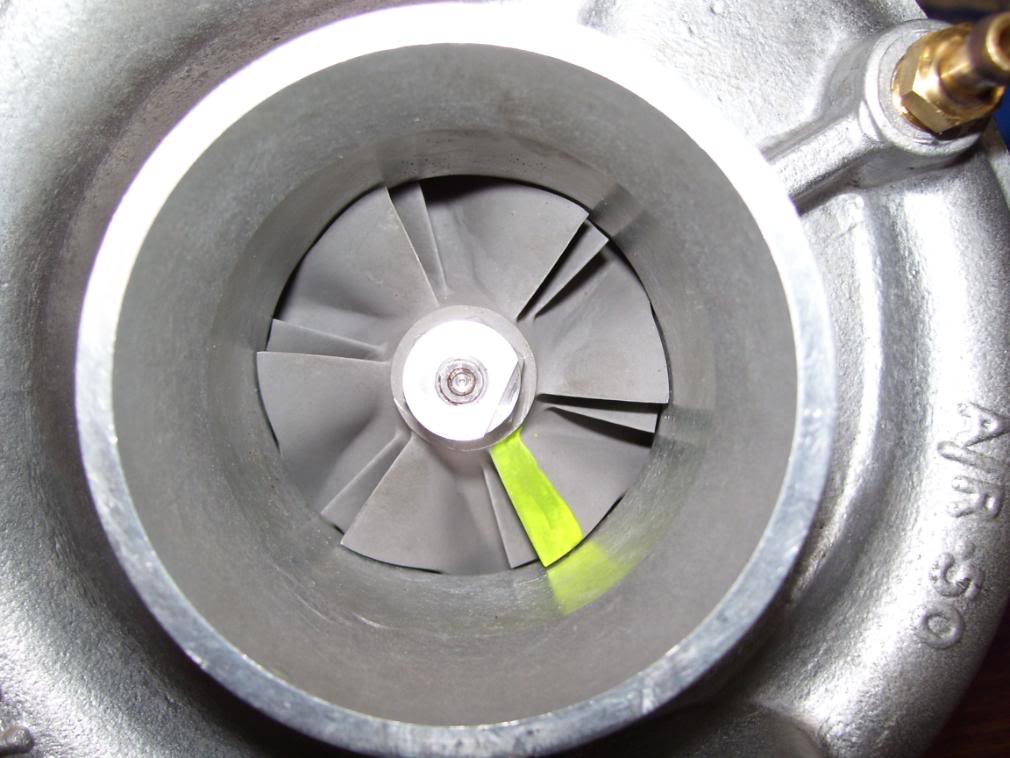

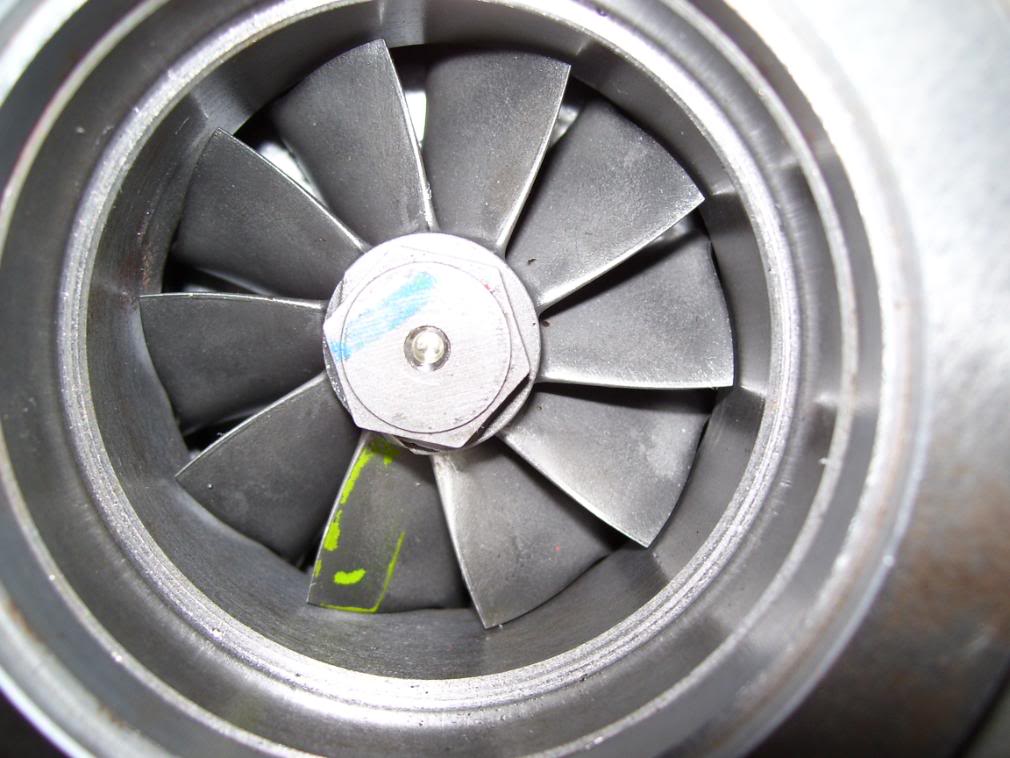

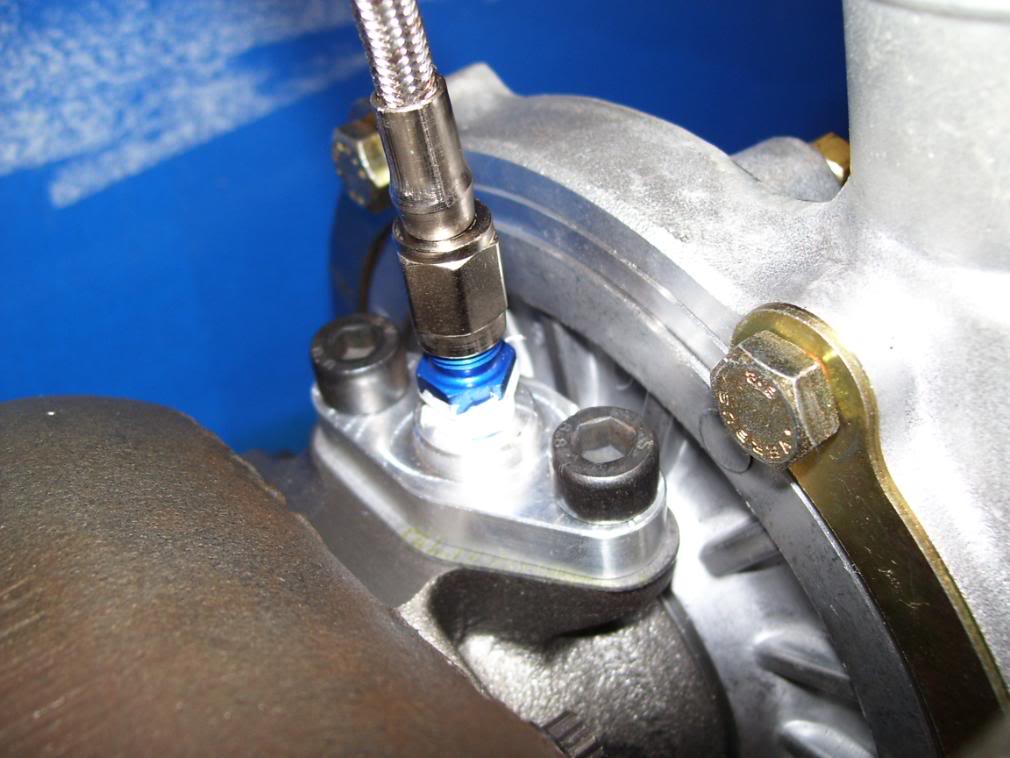

Pics of what UPS delivered today:

Thing looks small to me. Thought it would be bigger. Oh well. It's new and it's what I have, so this is what's going on it. Now I just need to build a manifold for it.

Thing looks small to me. Thought it would be bigger. Oh well. It's new and it's what I have, so this is what's going on it. Now I just need to build a manifold for it.

#20

Thread Starter

Elite Member

iTrader: (16)

Joined: Aug 2007

Posts: 9,352

Total Cats: 524

From: Houston, TX

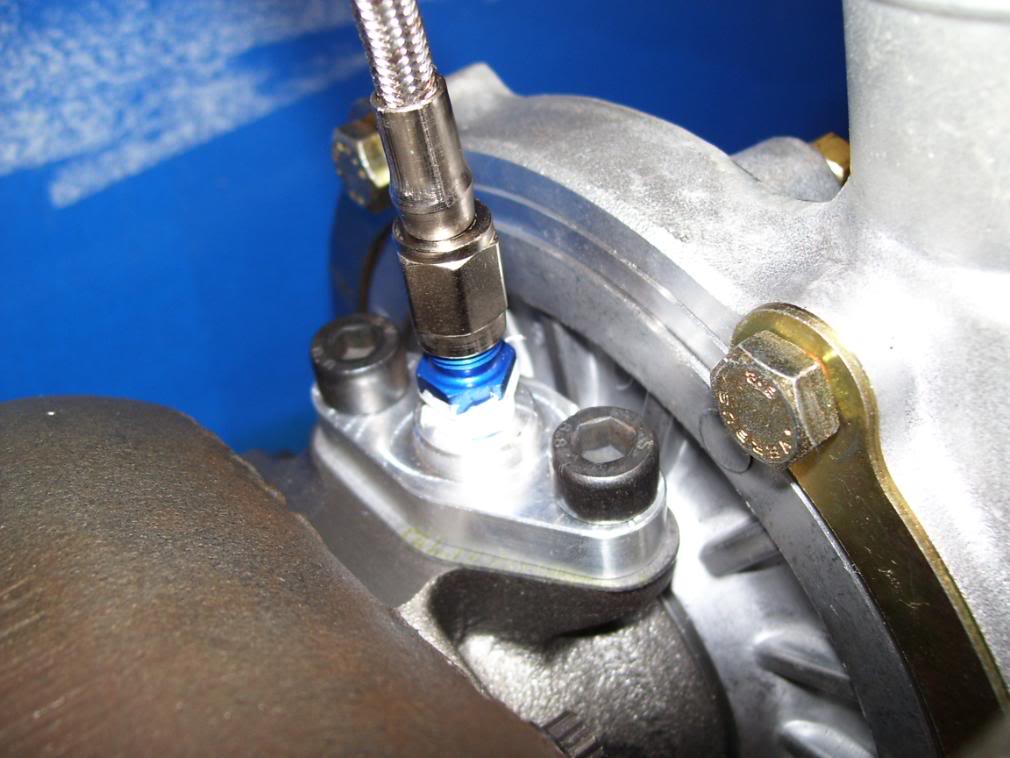

Yeah I'm going to redo that fitting for sure. I'm gonna end up tearing it down and going over it completely before I ever use it. You never know, the bearings could be contaminated with artificial diamond and ceramic debris. Won't know for sure unless I check. Plus I'll have to clock it anyways so it's coming apart.

Well good news is one of these will probably fit! Damn these turbo things are tiny compared to superchargers.

Well good news is one of these will probably fit! Damn these turbo things are tiny compared to superchargers.