Sixshooter loses another CHRA but doesn't know why

#1

Thread Starter

Joined: Nov 2008

Posts: 21,117

Total Cats: 3,142

From: Tampa, Florida

I noticed power and spool was down on the GTX2867R and so I checked the internal wastegate to make sure it was closing and checked the preload. All good. Bosch BOV was still good (need to upgrade). I pulled the air cleaner for an inspection of the spinny bits and found quite a bit more play in the wheels than it had when I was new. I am disappoint. But thankfully no wheel contact when I push and pull and twist.

I pulled the oil feed line and restrictor from the CHRA and dropped the end into an empty jug to see if the oil supply was blocked. In the 15 or so seconds I ran the engine, it pissed a very powerful stream and put about 1/4 quart into the bottle. Seems plenty good.

The water lines for the CHRA banjo fittings come from the front of the head and go to the mixing manifold. Should be good on coolant flow.

I went through a couple of chinese journal bearing turbos prior to dropping in the Garrett, blaming the first failure on plastic dipstick pieces getting in the feed line. The second I attributed to very high temperatures due to using a turbo blanket.

I'm very cautious with cooling down prior to shutting off the engine, so I don't suspect hot shutdowns killed it.

Engine temps and oil temps (has oil temp gauge) never crest 215/245

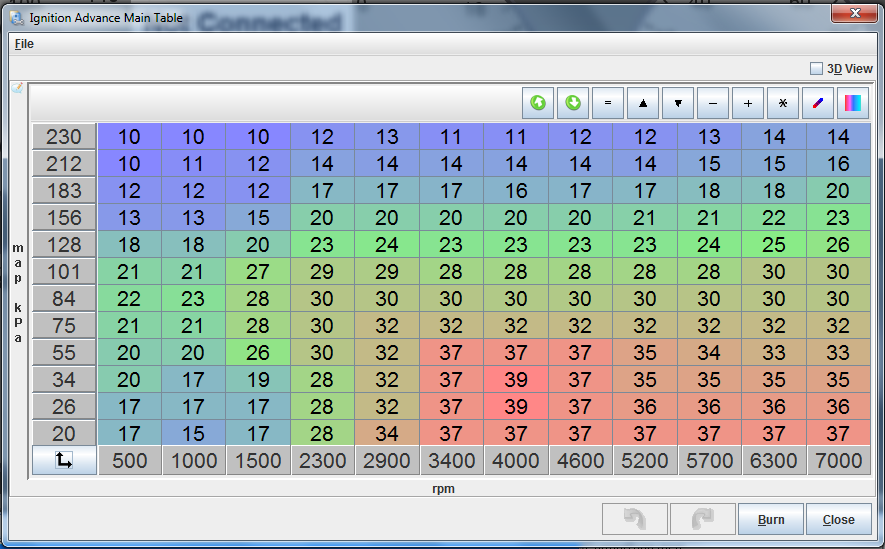

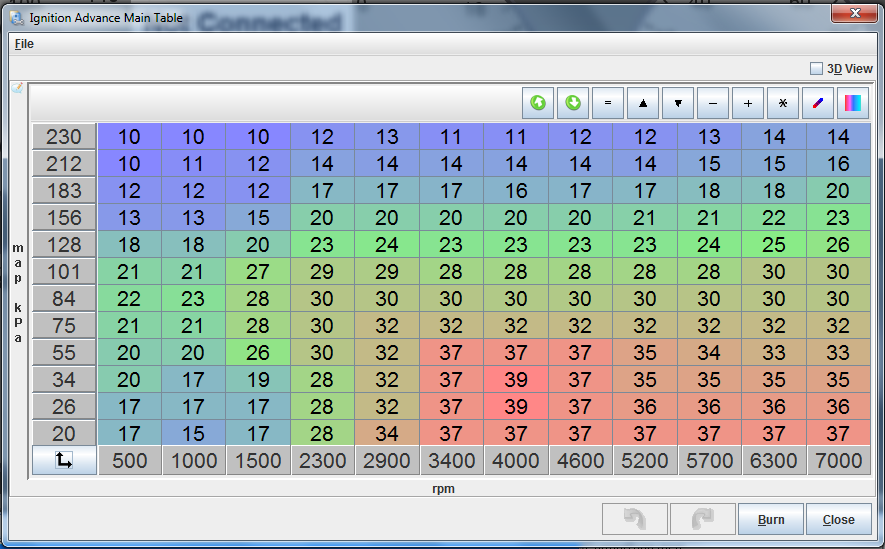

I'm wondering if my tune has too much retard in the boosted cells, thereby making more heat than normal in the turbo? Running 8.4cr Supertechs and Crower rods, 1.8na stock cams, pump 93, boundary non-vvt oil pump assembly. About 14-15psi max. I'll attach a timing map.

I'm also wondering about the oiling and whether it truly is enough. I only get about 40-45psi hot at higher RPMs due to my engine builder building the bottom end a bit loose (because racecar engine builder?) Maybe I should have a larger opening in my restrictor to compensate? But, damn, it sure seems like plenty of oil at cold idle.

I am going to send the CHRA to get rebuilt/exchanged but don't want to do this again next year.

Please offer ideas / direction / something I missed.

I pulled the oil feed line and restrictor from the CHRA and dropped the end into an empty jug to see if the oil supply was blocked. In the 15 or so seconds I ran the engine, it pissed a very powerful stream and put about 1/4 quart into the bottle. Seems plenty good.

The water lines for the CHRA banjo fittings come from the front of the head and go to the mixing manifold. Should be good on coolant flow.

I went through a couple of chinese journal bearing turbos prior to dropping in the Garrett, blaming the first failure on plastic dipstick pieces getting in the feed line. The second I attributed to very high temperatures due to using a turbo blanket.

I'm very cautious with cooling down prior to shutting off the engine, so I don't suspect hot shutdowns killed it.

Engine temps and oil temps (has oil temp gauge) never crest 215/245

I'm wondering if my tune has too much retard in the boosted cells, thereby making more heat than normal in the turbo? Running 8.4cr Supertechs and Crower rods, 1.8na stock cams, pump 93, boundary non-vvt oil pump assembly. About 14-15psi max. I'll attach a timing map.

I'm also wondering about the oiling and whether it truly is enough. I only get about 40-45psi hot at higher RPMs due to my engine builder building the bottom end a bit loose (because racecar engine builder?) Maybe I should have a larger opening in my restrictor to compensate? But, damn, it sure seems like plenty of oil at cold idle.

I am going to send the CHRA to get rebuilt/exchanged but don't want to do this again next year.

Please offer ideas / direction / something I missed.

#2

What size oil feed line? What size restrictor? What size oil drain and does it have any sharp bends? What viscocity and type of oil do you run?

Almost a guarantee these repeated failures are a lubrication problem. You're not even pushing the turbo that hard with only 15 PSI. It should last a longggggg time.

Your timing map looks ok to me.

If it were me I'd make sure my oil drain was large and free of sharp bends, and it dumps into the oil pan ABOVE the oil level. Then I'd run a 4AN oil line to the turbo with no restrictor. And run it. If it proves to push oil past the turbine seals, and I was CERTAIN my oil drain was an well-designed as I could make it, then I'd start with a large restrictor and find the largest one that makes the oil burning go away.

Almost a guarantee these repeated failures are a lubrication problem. You're not even pushing the turbo that hard with only 15 PSI. It should last a longggggg time.

Your timing map looks ok to me.

If it were me I'd make sure my oil drain was large and free of sharp bends, and it dumps into the oil pan ABOVE the oil level. Then I'd run a 4AN oil line to the turbo with no restrictor. And run it. If it proves to push oil past the turbine seals, and I was CERTAIN my oil drain was an well-designed as I could make it, then I'd start with a large restrictor and find the largest one that makes the oil burning go away.

#3

Joined: Oct 2007

Posts: 6,028

Total Cats: 304

From: The coal ridden hills of Pennsylvania

I'm having severe déjà vu right now with this thread. I swear I almost read this word for word a few months ago. Feels like I stepped into a time warp, mind is blown.

Do you think it's bearing failure due to oil starvation? Or is the oil simply not circulating fast enough and getting way too hot?

Do you think it's bearing failure due to oil starvation? Or is the oil simply not circulating fast enough and getting way too hot?

#4

I'm having severe déjà vu right now with this thread. I swear I almost read this word for word a few months ago. Feels like I stepped into a time warp, mind is blown.

Do you think it's bearing failure due to oil starvation? Or is the oil simply not circulating fast enough and getting way too hot?

Do you think it's bearing failure due to oil starvation? Or is the oil simply not circulating fast enough and getting way too hot?

#6

Oil lubricates and cools. Both functions are important. A compromise in the feed or drain will reduce both. A smaller drain line can cause oil to back up into the turbo, forcing you to run a restrictor to prevent the backup causing smoke. Of course less oil means less cooling, and less lubrication, so bearing life will decrease. The right fix is to fix the drain. Miata people commonly run small drains. I ran a 12AN drain on my Garrett journal bearing and had no sharp bends, it worked great.

#9

Thread Starter

Joined: Nov 2008

Posts: 21,117

Total Cats: 3,142

From: Tampa, Florida

I use Rotella cut 50/50 with Valvoline VR1 50wt to keep the pressure up since the rebuild is so loose. The feed line is large 1/8" but the restrictor is the small hole recommended for ball bearings. The drainis 1/2" with no tight bends. It empties at the front corner of the oil pan beneath the a/c compressor.

The mobile app doesn't let me refer back to the posts while typing so I'll have to make another post but I really appreciate everyone's questions and advice.

The mobile app doesn't let me refer back to the posts while typing so I'll have to make another post but I really appreciate everyone's questions and advice.

#11

I use Rotella cut 50/50 with Valvoline VR1 50wt to keep the pressure up since the rebuild is so loose. The feed line is large 1/8" but the restrictor is the small hole recommended for ball bearings. The drainis 1/2" with no tight bends. It empties at the front corner of the oil pan beneath the a/c compressor.

The mobile app doesn't let me refer back to the posts while typing so I'll have to make another post but I really appreciate everyone's questions and advice.

The mobile app doesn't let me refer back to the posts while typing so I'll have to make another post but I really appreciate everyone's questions and advice.

Also, is that a typo or do you really have a 1/8" ID oil feed line? Cause that's tiny. A 1/4" hose would be more common and certainly better since you already have low oil pressure to start with.

What size is the restrictor?

If you are going to run that high of viscosity, I would completely remove the oil restrictor.

Also if you can easily run a larger diameter hose for your drain, that would be a good idea too since running without a restrictor will make it more likely to backup without a large drain.

#13

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

<p>https://www.turbobygarrett.com/turbo...oil_restrictor</p><p>Sounds like ball bearing turbos want 40-45. So your restrictor might have made that lower.</p>

#14

Thread Starter

Joined: Nov 2008

Posts: 21,117

Total Cats: 3,142

From: Tampa, Florida

https://www.turbobygarrett.com/turbo...oil_restrictor

Sounds like ball bearing turbos want 40-45. So your restrictor might have made that lower.

Sounds like ball bearing turbos want 40-45. So your restrictor might have made that lower.

Restrictor size will always depend on how much oil pressure your engine is generating-there is no single restrictor size suited for all engines. Ball-bearing turbochargers can benefit from the addition of an oil restrictor, as most engines deliver more pressure than a ball bearing turbo requires. The benefit is seen in improved boost response due to less windage of oil in the bearing. In addition, lower oil flow further reduces the risk of oil leakage compared to journal-bearing turbochargers. Oil pressure entering a ball-bearing turbocharger needs to be between 40 psi and 45 psi at the maximum engine operating speed. For many common passenger vehicle engines, this generally translates into a restrictor with a minimum of 0.040" diameter orifice upstream of the oil inlet on the turbocharger center section. Again, it is imperative that the restrictor be sized according to the oil pressure characteristics of the engine to which the turbo is attached.

#19

I would urge you drop the restrictor and change to a 20/50 oil.

When using a restrictor, it's good to check oil p after the restrictor. Takes a little work.

You suggest heavier wt oil due to loose clearances, but were these bearings of which you talk? I doubt it.

Pistons don't give a hoot what oil you use.

Corky

When using a restrictor, it's good to check oil p after the restrictor. Takes a little work.

You suggest heavier wt oil due to loose clearances, but were these bearings of which you talk? I doubt it.

Pistons don't give a hoot what oil you use.

Corky

#20

Thread Starter

Joined: Nov 2008

Posts: 21,117

Total Cats: 3,142

From: Tampa, Florida

I'll probably run straight 50wt in the summer from here out. The rod bearings are the biggest reason I use heavier oil to keep the film strength up.