Over The Radiator Intercooler Setup 99 NB

#1

Thread Starter

Elite Member

iTrader: (16)

Joined: Aug 2007

Posts: 9,352

Total Cats: 524

From: Houston, TX

I'm trying to decide how I'm going to design my intercooler setup for my supercharger setup. I want to do an over the radiator setup, very similar to Track Dog Racing's. The questions are what size intercooler will fit and what size is best for the over the radiator setup.

Track dog racing uses a top discharge intercooler. It has a core size of 16" wide, 8" height, and 3" thick. Overall dimensions are about 22" wide, 8" height, and 3" core. It has 2.5" inlet and outlets. There setup requires 'bending' the A/C receiver for clearance, relocating the power steering cooler, relocating the horn, and lowering the radiator and tilting the top of it toward the engine. They advertise its' efficiency at 80-85%.

I found an intercooler similar to TDR's on Ebay that I would like to use. It has a core size of 18" wide, 11" height, and 3" thick. Overall dimensions are 24" wide, 11" height, and 3" thick. Also has 2.5 inch inlet and outlets. In comparison, it's 2" wider and 3" taller than the intercooler TDR uses.

Here's a link to the intercooler on Ebay: http://cgi.ebay.com/ebaymotors/FMIC-...spagenameZWD1V

The question is, will this larger intercooler fit? From what I can tell, it will, but I'll have to move the A/C receiver over about 3.5" to get it out of the way for the larger IC. I don't think it can be bent that much without breaking a hard line on it. That not a problem though, I can remove the receiver and make lines to move it over or maybe even relocate it, getting it out of the way completely.

The measurement from the center of the throttle body to the center of the discharge port on the supercharger is 19". The measurement between the center of the inlet and outlet on the Ebay intercooler is 21". That's only a two inch difference, so I don't see that being a problem. The discharge pipes will still have a fairly straight shot with minimal bends.

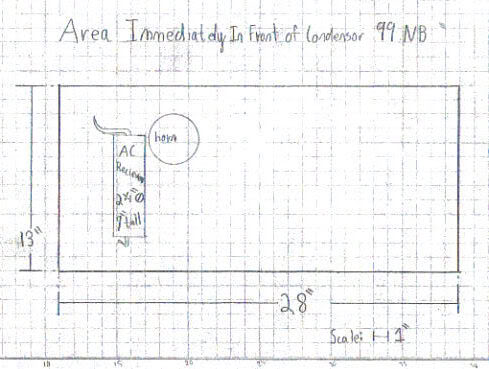

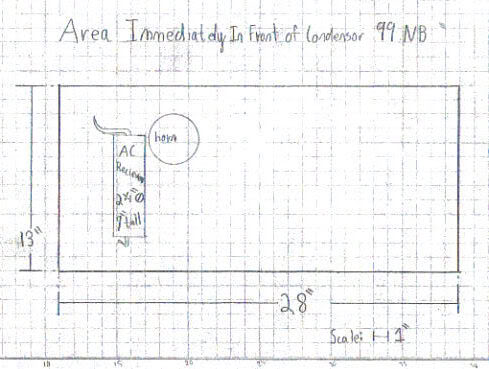

Here's a diagram I made of the area in front of the A/C condensor. In this picture, bending the A/C reciever over about 1" will give enough clearance for the TDR intercooler.

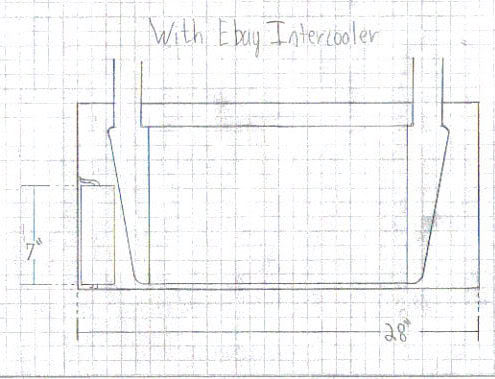

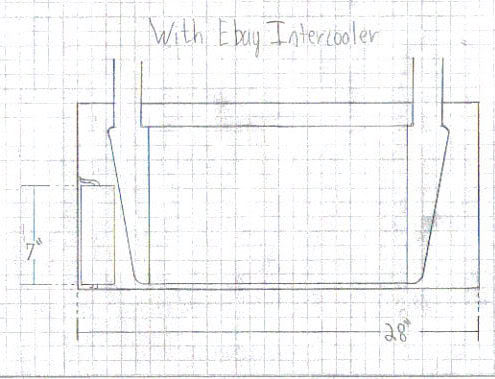

Here's a picture of the intercooler I'm considering using, if it will fit.

Here's a diagram with the Ebay intercooler in front of the A/C condensor area. The reciever has been moved, but could just as easily be relocated to allow more airflow and more clearance.

Track dog racing uses a top discharge intercooler. It has a core size of 16" wide, 8" height, and 3" thick. Overall dimensions are about 22" wide, 8" height, and 3" core. It has 2.5" inlet and outlets. There setup requires 'bending' the A/C receiver for clearance, relocating the power steering cooler, relocating the horn, and lowering the radiator and tilting the top of it toward the engine. They advertise its' efficiency at 80-85%.

I found an intercooler similar to TDR's on Ebay that I would like to use. It has a core size of 18" wide, 11" height, and 3" thick. Overall dimensions are 24" wide, 11" height, and 3" thick. Also has 2.5 inch inlet and outlets. In comparison, it's 2" wider and 3" taller than the intercooler TDR uses.

Here's a link to the intercooler on Ebay: http://cgi.ebay.com/ebaymotors/FMIC-...spagenameZWD1V

The question is, will this larger intercooler fit? From what I can tell, it will, but I'll have to move the A/C receiver over about 3.5" to get it out of the way for the larger IC. I don't think it can be bent that much without breaking a hard line on it. That not a problem though, I can remove the receiver and make lines to move it over or maybe even relocate it, getting it out of the way completely.

The measurement from the center of the throttle body to the center of the discharge port on the supercharger is 19". The measurement between the center of the inlet and outlet on the Ebay intercooler is 21". That's only a two inch difference, so I don't see that being a problem. The discharge pipes will still have a fairly straight shot with minimal bends.

Here's a diagram I made of the area in front of the A/C condensor. In this picture, bending the A/C reciever over about 1" will give enough clearance for the TDR intercooler.

Here's a picture of the intercooler I'm considering using, if it will fit.

Here's a diagram with the Ebay intercooler in front of the A/C condensor area. The reciever has been moved, but could just as easily be relocated to allow more airflow and more clearance.

Last edited by patsmx5; 11-11-2007 at 02:12 AM.

#2

I'd think it would fit ok if, like you said, you bent the ac reciever out of the way. I just fit a 28x7x2.5 one in mine and definitely could have went taller. Unless you have your heart set on going over the top, there's a hell of a lot of room in the front of the wheel well and behind the fog lights to run piping. Over the top probably would look nicer and use less piping though.

#3

Thread Starter

Elite Member

iTrader: (16)

Joined: Aug 2007

Posts: 9,352

Total Cats: 524

From: Houston, TX

I can get the intercooler for $190.00 shipped. I'll need two or three bends and four 2.5" couplers, and 8 clamps. There will be the cost of having to relocate the A/C receiver if necessary. I do my own A/C work so that cost will only be Freon, some aluminum tubing to relocate the A/C receiver, and maybe a couple fittings. Looks like the IC setup can be built for <$300.00.

TDR's setup uses large radius stainless steel bends, but they are not 90* bends. They're more like 70* bends. I think they mount the intercooler leaning, probably to match the radiator and condenser, but I'm not sure. My pipes will be aluminum as it will conduct heat better and aid in cooling the air. I may insulate the outlets pipe to keep it from being heated.

I'm making the discharge port that bolts to the top of the SC, so I'll make sure it's pointing square and straight to the center of the IC pipes inlet to eliminate having an extra bend like TDR's. That means I should be able have one 70-90* bend between the blower and the inlet of the IC, and one between the outlet of the IC and the TB. That should make for less than 180* total bends for the IC piping.

TDR's setup uses large radius stainless steel bends, but they are not 90* bends. They're more like 70* bends. I think they mount the intercooler leaning, probably to match the radiator and condenser, but I'm not sure. My pipes will be aluminum as it will conduct heat better and aid in cooling the air. I may insulate the outlets pipe to keep it from being heated.

I'm making the discharge port that bolts to the top of the SC, so I'll make sure it's pointing square and straight to the center of the IC pipes inlet to eliminate having an extra bend like TDR's. That means I should be able have one 70-90* bend between the blower and the inlet of the IC, and one between the outlet of the IC and the TB. That should make for less than 180* total bends for the IC piping.

#4

Thread Starter

Elite Member

iTrader: (16)

Joined: Aug 2007

Posts: 9,352

Total Cats: 524

From: Houston, TX

Does anyone know of a valve that looks at boost to determine when to vent to atmosphere? Basically a pop off vavle I suppose. I need something that's adjustable that will vent to atmosphere at say 20PSI. MY SC setup will not be using the recircualting valve and will be running unthrottled, so I need something that will VTA. I understand that BOV's look at vacuum, not boost.

I'm wanting something that will stay closed at idle. I will have boost on the other side of the TB at idle, but the valve will open if pressure exceeds say 20 PSI, so I don't break belts and pop hoses.

I'm wanting something that will stay closed at idle. I will have boost on the other side of the TB at idle, but the valve will open if pressure exceeds say 20 PSI, so I don't break belts and pop hoses.

#6

Thread Starter

Elite Member

iTrader: (16)

Joined: Aug 2007

Posts: 9,352

Total Cats: 524

From: Houston, TX

I don't know. It may, and that's what I'm trying to find out. I went on Wikipedia and looked up BOV and it says a BOV opens when it's given a source of vacuum. If they also open like your saying at a certain PSI, then that would work. Wiki say a dump valve is what looks soley at pressure. If there's a BOV that opens at 20PSI without vacuum applied that will work.

EDIT: the reason I was doing an over the radiator setup is to minimize the flow losses and whatnot from all the bends. I figure it will be less weight and more efficient. If I upgrade radiators I may have to get slimmer fans for clearance. We shall see.

EDIT: the reason I was doing an over the radiator setup is to minimize the flow losses and whatnot from all the bends. I figure it will be less weight and more efficient. If I upgrade radiators I may have to get slimmer fans for clearance. We shall see.

#9

I like that intercooler.

I have a custom setup with 2.5" lines going over the top of the rad.

I ended up keeping the stock rad position, but lowered it. (this caused me to have to add a expansion tank for the rad, as the rad fill point, became slightly lower than the head)

getting the tubing to clear the rad, but still line up to the appropriate locations in the engine bay will be a pita, but worth it in the end imo.

I have a custom setup with 2.5" lines going over the top of the rad.

I ended up keeping the stock rad position, but lowered it. (this caused me to have to add a expansion tank for the rad, as the rad fill point, became slightly lower than the head)

getting the tubing to clear the rad, but still line up to the appropriate locations in the engine bay will be a pita, but worth it in the end imo.

#10

Someone on CR.net did a great over-the-rad. kit... said it was pretty easy.

http://clubroadster.net/forum/viewtopic.php?t=13007

[/quote]

[/quote]

http://clubroadster.net/forum/viewtopic.php?t=13007

Originally Posted by darkmx5 @ Wed Oct 31, 2007 1:17 am

This is my old set-up for my 2000 miata I made a custom I/C set-up, for my JRSC it is a VW I/C out of a 1.8T. finished it may 2006

I made a bracket to fasten the I/C to the subframe (like TRD does), the rad was moved back and down(as TRD does). I bought some mandel bent piping and couplers from a local performance shop.. my total cost was abit over $200

I/C $50

couplers/reducer/clams $100

aluminum for fabrication $15

piping 2 90's 1 45 (2.25 OD) $60

total $225 Canadian

Why a VW 1.8T I/C, well after talking doing some research and talking to VW guys these are good little I/C's and alot of VW guy runs alot more boost in them then my set-up will ever see, plus I wanted to keep the I/C small to reduce lag.

The I/C install was easy, the P/S cooling line was not cut just moved over abit, the RAD hoses were trimmed abit. Easy so far.. my biggest problems were I was destroying belts very quickly I needed a BRP idler pulley and making a rad sheild/support. The set-up I had was a 2000 miata, JRSC, 62.5 BRP pulley, crank pulley overlay, custom I/C, jrsc timming control, JR powercard. The car runs very strong drive just like a basic JRSC set-up (no lag) except much quicker, and awsome sound!

But I keep eating belts, well the crank overlay slightly changes the location of the belt, the edge of the belt is close to the bolts on the water pump and does rub at times, I have changed the OEM bolts to a round head allan key style, but it still rubs abit and wears down the belt. I have heard the BRP idler pulley will help with this !!But I never got around to getting one.

Now I am sure some will say why do all that work for a M45, well I bought my car with the M45 on it, I couldn't justify ripping it out selling it then getting a M62. When I purchased the car had the DFMM on it and the 62.5 pulley, while it was quick, I upgraded to a powercard as the DFMM is poo. I got deal on a used crank pulley overlay.. and figured I'd try it ( see TRD did the same setup on some customer cars [m45, powercard, crank overlay and 62.5pulley]) with success.. PLUS I like the challenge of do this myself..and figuring new ways to mod my car.

I do know this is as far as I would take the car and thats fine with me.

I had to take off the crank pulley overlay for now boost down to ~4.8-5psi from ~7.8-8psi with the overlay yah I lost 3 psi for now..

I hope this post will help someone who wants to do there own A:A I/C set up on a M45 or other project.. it really was not hard, just took abit of time.. but then again, my car was in the garage all winter, so I had no down time with it . feel free to ask me any questions about it..

here are a few pics, While it is not a perfect install, doesn't look to bad.

I made a bracket to fasten the I/C to the subframe (like TRD does), the rad was moved back and down(as TRD does). I bought some mandel bent piping and couplers from a local performance shop.. my total cost was abit over $200

I/C $50

couplers/reducer/clams $100

aluminum for fabrication $15

piping 2 90's 1 45 (2.25 OD) $60

total $225 Canadian

Why a VW 1.8T I/C, well after talking doing some research and talking to VW guys these are good little I/C's and alot of VW guy runs alot more boost in them then my set-up will ever see, plus I wanted to keep the I/C small to reduce lag.

The I/C install was easy, the P/S cooling line was not cut just moved over abit, the RAD hoses were trimmed abit. Easy so far.. my biggest problems were I was destroying belts very quickly I needed a BRP idler pulley and making a rad sheild/support. The set-up I had was a 2000 miata, JRSC, 62.5 BRP pulley, crank pulley overlay, custom I/C, jrsc timming control, JR powercard. The car runs very strong drive just like a basic JRSC set-up (no lag) except much quicker, and awsome sound!

But I keep eating belts, well the crank overlay slightly changes the location of the belt, the edge of the belt is close to the bolts on the water pump and does rub at times, I have changed the OEM bolts to a round head allan key style, but it still rubs abit and wears down the belt. I have heard the BRP idler pulley will help with this !!But I never got around to getting one.

Now I am sure some will say why do all that work for a M45, well I bought my car with the M45 on it, I couldn't justify ripping it out selling it then getting a M62. When I purchased the car had the DFMM on it and the 62.5 pulley, while it was quick, I upgraded to a powercard as the DFMM is poo. I got deal on a used crank pulley overlay.. and figured I'd try it ( see TRD did the same setup on some customer cars [m45, powercard, crank overlay and 62.5pulley]) with success.. PLUS I like the challenge of do this myself..and figuring new ways to mod my car.

I do know this is as far as I would take the car and thats fine with me.

I had to take off the crank pulley overlay for now boost down to ~4.8-5psi from ~7.8-8psi with the overlay yah I lost 3 psi for now..

I hope this post will help someone who wants to do there own A:A I/C set up on a M45 or other project.. it really was not hard, just took abit of time.. but then again, my car was in the garage all winter, so I had no down time with it . feel free to ask me any questions about it..

here are a few pics, While it is not a perfect install, doesn't look to bad.

[/quote]

[/quote]

#11

I really don't think the over-the-top pipes benefit a turbo miata any noticeable amount. If you look at the multitude of turbo systems out their, most of them have pipe sections as long if not longer than just about any turbo Miata. IMO take the "accepted" around-the-rad approach and focus your engineering and work hours on another part of the system. I'm speaking from experience- I put some work hours in for my shorter pipes and see no difference compared to other kits with an extra 2ft of tubing. The only reason I'd resort to over-the-rad is there was just no room pass any pipes another route.

As far as the a/c drier- Lazzer went to an a/c shop and asked them to put it in the engine bay for him and they did. It's a matter of cutting the drier lines and brazing in some new tubes routed to the new location. I was going to do this, but managed to work my drier far enough out of the way to fit a 3x12x27 fmic in. The end tanks are shaped similar to the track dog, except it's got inlet/outlet near the fat part of the tank and is mount upside down. The issue with sticking that sized IC with the end tank fat end up, is that the front end frame gussets get in the way- cutting into the useable space. -rob

As far as the a/c drier- Lazzer went to an a/c shop and asked them to put it in the engine bay for him and they did. It's a matter of cutting the drier lines and brazing in some new tubes routed to the new location. I was going to do this, but managed to work my drier far enough out of the way to fit a 3x12x27 fmic in. The end tanks are shaped similar to the track dog, except it's got inlet/outlet near the fat part of the tank and is mount upside down. The issue with sticking that sized IC with the end tank fat end up, is that the front end frame gussets get in the way- cutting into the useable space. -rob

#13

two reasons to like over the rad.

A) safer for tubing, really nothing exposed to road hazards (cept for the IC but thats always the case)

B) less connections, mine is 4 couplings total (yes you can do it around the rad, but its harder longer)

C) more effcient, less pressure loss

D) less likely to absorb heat from engine

A) safer for tubing, really nothing exposed to road hazards (cept for the IC but thats always the case)

B) less connections, mine is 4 couplings total (yes you can do it around the rad, but its harder longer)

C) more effcient, less pressure loss

D) less likely to absorb heat from engine

#14

Does anyone know of a valve that looks at boost to determine when to vent to atmosphere? Basically a pop off vavle I suppose. I need something that's adjustable that will vent to atmosphere at say 20PSI. MY SC setup will not be using the recircualting valve and will be running unthrottled, so I need something that will VTA. I understand that BOV's look at vacuum, not boost.

I'm wanting something that will stay closed at idle. I will have boost on the other side of the TB at idle, but the valve will open if pressure exceeds say 20 PSI, so I don't break belts and pop hoses.

I'm wanting something that will stay closed at idle. I will have boost on the other side of the TB at idle, but the valve will open if pressure exceeds say 20 PSI, so I don't break belts and pop hoses.

BOV and DVs look at pressure differentials. If the cracking pressure of the spring in your valve is ~3psi there will need to be a 3 psi difference between between the pressure beneath the piston/diaphragm and the reference to the top. They can open while seeing positive pressure on both sides if the differential is great enough...

#16

Thread Starter

Elite Member

iTrader: (16)

Joined: Aug 2007

Posts: 9,352

Total Cats: 524

From: Houston, TX

Yea I know it goes against popular wisdom on this site to go over the radiator with IC pipes. I think it will be worth it in the end. I need it to be as efficient as possible, because I'm going to be pushing the limits of the SC.

Loki had 4 good letered points in his 2 reasons to go over the rad. He's right, and that's basically why I'm doing it that way. Moving the radiator isn't a problem, and I can make the stock fans fit, and if I need aftermarket fans, no problem.

He's right, and that's basically why I'm doing it that way. Moving the radiator isn't a problem, and I can make the stock fans fit, and if I need aftermarket fans, no problem.

Loki had 4 good letered points in his 2 reasons to go over the rad.

He's right, and that's basically why I'm doing it that way. Moving the radiator isn't a problem, and I can make the stock fans fit, and if I need aftermarket fans, no problem.

He's right, and that's basically why I'm doing it that way. Moving the radiator isn't a problem, and I can make the stock fans fit, and if I need aftermarket fans, no problem.

#17

Just because I like to show this off:http://us.share.geocities.com/deadlytrap/miataic.JPG

http://www.geocities.com/deadlytrap/miataic2.JPG

http://www.geocities.com/deadlytrap/miataic2.JPG

#20

Yea I know it goes against popular wisdom on this site to go over the radiator with IC pipes. I think it will be worth it in the end. I need it to be as efficient as possible, because I'm going to be pushing the limits of the SC.

Loki had 4 good letered points in his 2 reasons to go over the rad. He's right, and that's basically why I'm doing it that way. Moving the radiator isn't a problem, and I can make the stock fans fit, and if I need aftermarket fans, no problem.

He's right, and that's basically why I'm doing it that way. Moving the radiator isn't a problem, and I can make the stock fans fit, and if I need aftermarket fans, no problem.

Loki had 4 good letered points in his 2 reasons to go over the rad.

He's right, and that's basically why I'm doing it that way. Moving the radiator isn't a problem, and I can make the stock fans fit, and if I need aftermarket fans, no problem.

He's right, and that's basically why I'm doing it that way. Moving the radiator isn't a problem, and I can make the stock fans fit, and if I need aftermarket fans, no problem.Im lucky that the 4 letered points for my 2 reasons at least resembled english