My new DIY cold air box/intake heat shield.

#1

Thread Starter

Elite Member

iTrader: (8)

Joined: Aug 2007

Posts: 2,712

Total Cats: 4

From: Bellingham, Wa

The weather is warming up and so are my intake temps. Its time to lose the filter on the compressor laziness and do something better about this. First I just cut a piece of my extra IC piping to move the filter up and behind the headlight. This is my first ever sheet metal project.

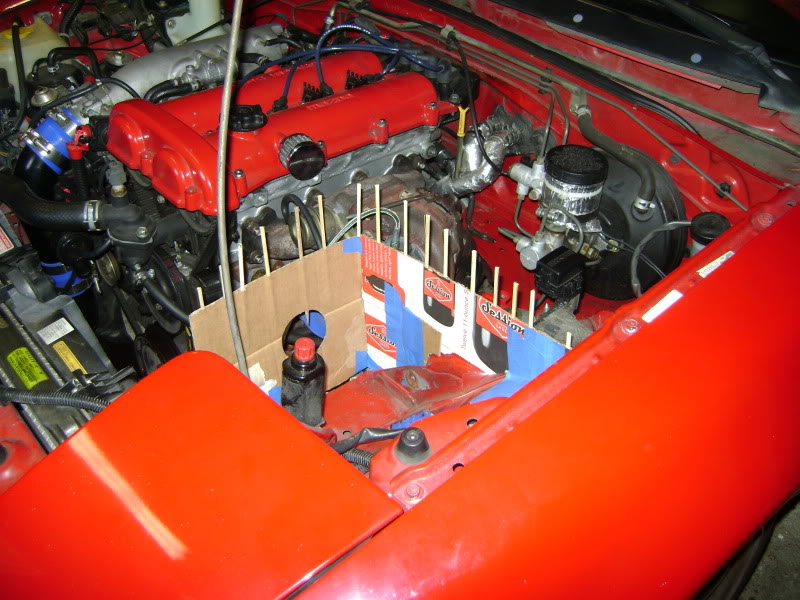

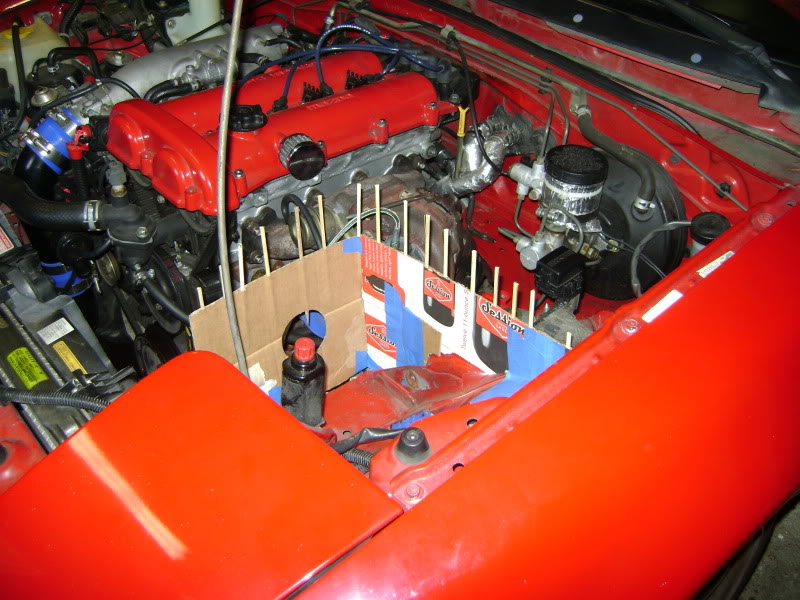

Next I started making the box out of cardboard:

Got my basic shape and stuck some wooden skewers in the cardboard like so:

If you notice, its got the contour of the hood. I stuck those skewers in there and closed the hood on them to get the shape. Learned this from some DSM forum a while back.

Next I took out the cardboard, traced it onto the aluminum sheet I got and busted out the dremel and went to town.

Its not DIY without JBW!

And finally

So for a few dollars, many dremel cutoff wheels and not too much blood (sheet metal is sharp) and you can make one too! Is it pretty? No. Does it work? Probably. I wanted a complete box like the BEGi one, but my filter is too tall and the hood barely closes as it is.

Next up is a heatshield between the mani and the compressor/inlet pipe.

Next I started making the box out of cardboard:

Got my basic shape and stuck some wooden skewers in the cardboard like so:

If you notice, its got the contour of the hood. I stuck those skewers in there and closed the hood on them to get the shape. Learned this from some DSM forum a while back.

Next I took out the cardboard, traced it onto the aluminum sheet I got and busted out the dremel and went to town.

Its not DIY without JBW!

And finally

So for a few dollars, many dremel cutoff wheels and not too much blood (sheet metal is sharp) and you can make one too! Is it pretty? No. Does it work? Probably. I wanted a complete box like the BEGi one, but my filter is too tall and the hood barely closes as it is.

Next up is a heatshield between the mani and the compressor/inlet pipe.

#10

I wouldn't paint it. The aluminum obviously won't rust, and the paint will just flake and chip over time. That's why I love aluminum, it looks pretty bare and won't rust. I'm a big supporter of unpainted valve covers too.

I need to get a smaller filter and do something similar, my filter's right behind the radiator, I hear the air's not very cold there.

I need to get a smaller filter and do something similar, my filter's right behind the radiator, I hear the air's not very cold there.

#13

Thread Starter

Elite Member

iTrader: (8)

Joined: Aug 2007

Posts: 2,712

Total Cats: 4

From: Bellingham, Wa

thanks for the kind words guys.

#18

I used to have that problem. Then I invested in a diamond cutting wheel. Had it for a couple of years now and it's as sharp and strong as day one. I highly recommend this - saves you $$ on standard cutoff wheels and saves lots of hassle!

http://www.dremel.com/en-us/Attachme...l.aspx?pid=545

http://www.dremel.com/en-us/Attachme...l.aspx?pid=545

#19

Thread Starter

Elite Member

iTrader: (8)

Joined: Aug 2007

Posts: 2,712

Total Cats: 4

From: Bellingham, Wa

I used to have that problem. Then I invested in a diamond cutting wheel. Had it for a couple of years now and it's as sharp and strong as day one. I highly recommend this - saves you $$ on standard cutoff wheels and saves lots of hassle!

http://www.dremel.com/en-us/Attachme...l.aspx?pid=545

http://www.dremel.com/en-us/Attachme...l.aspx?pid=545

A word of advice to those doing the skewer trick: my hood isn't closing quite right because I didn't factor in the additional height of the rubber hose. Keep that in mind if/when you build yours. I'm going to have to cut it down a bit, I know exactly where it's too high.

I cant wait to get started on my exhaust heat shielding. I'm still planning it out but I wanna double up the aluminum and put something in the middle.

#20

awesome! looks good. i wish my piping was routed differently so i could do that too. fyi, i cut lots of alum. sheet for all the little projects on my cars. i tried 6 different methods and nothing worked as good as my buddy's band saw at his work. well, i can't always use that so i had to get something for my garage, but didn't want to spend the $$$ on a band saw. my last hope before spending 399.99 on a band saw was a regular old jigsaw from sears. i was able to find 1 pack of alum. cutting blades and took it home to try it. that jigsaw cut through the aluminum sheet like the proverbial ''hot knife through butter'' total cost - $45.00.