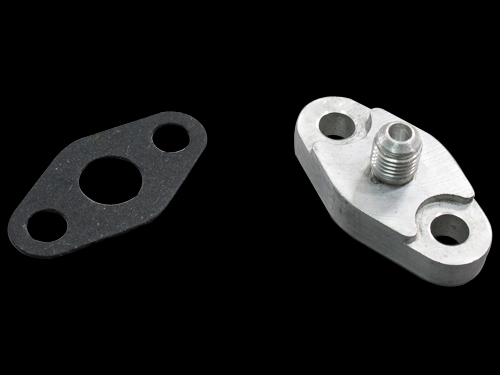

Journal bearing turbo oil restrictor

#1

Hi !

I run a -3 AN line with a .060". I killed my first T25 really quickly but it was a really shady turbocharger so I didn't mind. I bought a second one from my friend that ran perfect on his car (Nissan CA18DET) and now like 1000km later it started smoking.

Internet seems like a debate on wether or not I should use a restrictor. Garrett says that:

"The journal bearing system in a turbo functions very similarly to the rod or crank bearings in an engine. These bearings require enough oil pressure to keep the components separated by a hydrodynamic film. If the oil pressure is too low, the metal components will come in contact causing premature wear and ultimately failure. If the oil pressure is too high, leakage may occur from the turbocharger seals. With that as background, an oil restrictor is generally not needed for a journal-bearing turbocharger except for those applications with oil-pressure-induced seal leakage. Remember to address all other potential causes of leakage first (e.g., inadequate/improper oil drain out of the turbocharger, excessive crankcase pressure, turbocharger past its useful service life, etc.) and use a restrictor as a last resort. Garrett distributors can tell you the recommended range of acceptable oil pressures for your particular turbo. Restrictor size will always depend on how much oil pressure your engine is generating-there is no single restrictor size suited for all engines."

What do you guys use ?

I run a -3 AN line with a .060". I killed my first T25 really quickly but it was a really shady turbocharger so I didn't mind. I bought a second one from my friend that ran perfect on his car (Nissan CA18DET) and now like 1000km later it started smoking.

Internet seems like a debate on wether or not I should use a restrictor. Garrett says that:

"The journal bearing system in a turbo functions very similarly to the rod or crank bearings in an engine. These bearings require enough oil pressure to keep the components separated by a hydrodynamic film. If the oil pressure is too low, the metal components will come in contact causing premature wear and ultimately failure. If the oil pressure is too high, leakage may occur from the turbocharger seals. With that as background, an oil restrictor is generally not needed for a journal-bearing turbocharger except for those applications with oil-pressure-induced seal leakage. Remember to address all other potential causes of leakage first (e.g., inadequate/improper oil drain out of the turbocharger, excessive crankcase pressure, turbocharger past its useful service life, etc.) and use a restrictor as a last resort. Garrett distributors can tell you the recommended range of acceptable oil pressures for your particular turbo. Restrictor size will always depend on how much oil pressure your engine is generating-there is no single restrictor size suited for all engines."

What do you guys use ?

#10

I don't run one on mine. Tried it before and killed a turbo. I suspect it overheated because the shaft was blue when I took it apart. This was on a oil cooled center section though. A water cooled unit may be a different story.

Took it out and I haven't had any problems since. No smoke, no oil in the charge pipe. I'm running a -3 feed line with a -10 drain line.

Took it out and I haven't had any problems since. No smoke, no oil in the charge pipe. I'm running a -3 feed line with a -10 drain line.

#13

Found this later on the garett website in the FAQ by the way.

Does my turbo require an oil restrictor?

Oil requirements depend on the turbo's bearing system type. Garrett has two types of bearing systems; traditional journal bearing; and ball bearing.

The journal bearing system in a turbo functions very similarly to the rod or crank bearings in an engine. These bearings require enough oil pressure to keep the components separated by a hydrodynamic film. If the oil pressure is too low, the metal components will come in contact causing premature wear and ultimately failure. If the oil pressure is too high, leakage may occur from the turbocharger seals. With that as background, an oil restrictor is generally not needed for a journal-bearing turbocharger except for those applications with oil-pressure-induced seal leakage. Remember to address all other potential causes of leakage first (e.g., inadequate/improper oil drain out of the turbocharger, excessive crankcase pressure, turbocharger past its useful service life, etc.) and use a restrictor as a last resort. Garrett distributors can tell you the recommended range of acceptable oil pressures for your particular turbo. Restrictor size will always depend on how much oil pressure your engine is generating-there is no single restrictor size suited for all engines.

Ball-bearing turbochargers can benefit from the addition of an oil restrictor, as most engines deliver more pressure than a ball bearing turbo requires. The benefit is seen in improved boost response due to less windage of oil in the bearing. In addition, lower oil flow further reduces the risk of oil leakage compared to journal-bearing turbochargers. Oil pressure entering a ball-bearing turbocharger needs to be between 40 psi and 45 psi at the maximum engine operating speed. For many common passenger vehicle engines, this generally translates into a restrictor with a minimum of 0.040" diameter orifice upstream of the oil inlet on the turbocharger center section. Again, it is imperative that the restrictor be sized according to the oil pressure characteristics of the engine to which the turbo is attached. Always verify that the appropriate oil pressure is reaching the turbo.

The use of an oil restrictor can (but not always) help ensure that you have the proper oil flow/pressure entering the turbocharger, as well as extract the maximum performance.

Does my turbo require an oil restrictor?

Oil requirements depend on the turbo's bearing system type. Garrett has two types of bearing systems; traditional journal bearing; and ball bearing.

The journal bearing system in a turbo functions very similarly to the rod or crank bearings in an engine. These bearings require enough oil pressure to keep the components separated by a hydrodynamic film. If the oil pressure is too low, the metal components will come in contact causing premature wear and ultimately failure. If the oil pressure is too high, leakage may occur from the turbocharger seals. With that as background, an oil restrictor is generally not needed for a journal-bearing turbocharger except for those applications with oil-pressure-induced seal leakage. Remember to address all other potential causes of leakage first (e.g., inadequate/improper oil drain out of the turbocharger, excessive crankcase pressure, turbocharger past its useful service life, etc.) and use a restrictor as a last resort. Garrett distributors can tell you the recommended range of acceptable oil pressures for your particular turbo. Restrictor size will always depend on how much oil pressure your engine is generating-there is no single restrictor size suited for all engines.

Ball-bearing turbochargers can benefit from the addition of an oil restrictor, as most engines deliver more pressure than a ball bearing turbo requires. The benefit is seen in improved boost response due to less windage of oil in the bearing. In addition, lower oil flow further reduces the risk of oil leakage compared to journal-bearing turbochargers. Oil pressure entering a ball-bearing turbocharger needs to be between 40 psi and 45 psi at the maximum engine operating speed. For many common passenger vehicle engines, this generally translates into a restrictor with a minimum of 0.040" diameter orifice upstream of the oil inlet on the turbocharger center section. Again, it is imperative that the restrictor be sized according to the oil pressure characteristics of the engine to which the turbo is attached. Always verify that the appropriate oil pressure is reaching the turbo.

The use of an oil restrictor can (but not always) help ensure that you have the proper oil flow/pressure entering the turbocharger, as well as extract the maximum performance.

Thread

Thread Starter

Forum

Replies

Last Post