How important is oil drain slope? How brittle is the oil pan?

#1

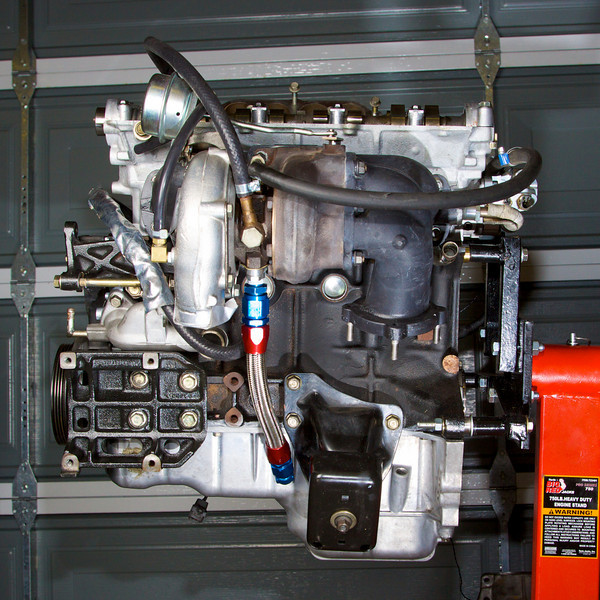

The PO placed the drain line up high on the oil pan, which was never an issue until I tried to re-install the a/c system. It seems my options are-

-Grind out the AC bracket and the casting lugs on the bottom of the compressor so the nipple just barely goes uphill toward the pan (I've read this is a bad idea). But I really don't think it would be enough to create a full trap unless I'm on a long rh sweeper or crankcase positive pressure keeps it from flowing. I may even be able to tap out to a 1/2" npt, offset so the top of the hole is even with the top of the current one, and install a reducer bushing. But this would only give me another 1/16th.

-Install line on front corner of pan. I've seen a few pics of the pan with the baffle and oil pickup line and they seem out of the way in this location but can't tell if the pictures posted are for a 1.6 and if my 1.8 is any different. And i really don't know how brittle the cast alum pan is and if i'm risking cracking it at the corner.

-Plug hole and re-drill in the 7 o'clock position. Again, I'd be concerned with cracking the pan, since the hole would be right near the bottom and I would only have about 1/8" of material between holes.

Opinions from people who have more experience with this oil pan and turbo drain than me?

-Grind out the AC bracket and the casting lugs on the bottom of the compressor so the nipple just barely goes uphill toward the pan (I've read this is a bad idea). But I really don't think it would be enough to create a full trap unless I'm on a long rh sweeper or crankcase positive pressure keeps it from flowing. I may even be able to tap out to a 1/2" npt, offset so the top of the hole is even with the top of the current one, and install a reducer bushing. But this would only give me another 1/16th.

-Install line on front corner of pan. I've seen a few pics of the pan with the baffle and oil pickup line and they seem out of the way in this location but can't tell if the pictures posted are for a 1.6 and if my 1.8 is any different. And i really don't know how brittle the cast alum pan is and if i'm risking cracking it at the corner.

-Plug hole and re-drill in the 7 o'clock position. Again, I'd be concerned with cracking the pan, since the hole would be right near the bottom and I would only have about 1/8" of material between holes.

Opinions from people who have more experience with this oil pan and turbo drain than me?

#2

I'd grind the A/C bracket. It's a bolt on affair if you screw it up or want to change it later. The oil pan isn't fragile, but it's not strong either. I've seen them cracked when threading in a fitting too far.

Definitely wouldn't drill a 2nd hole. You could try that extension, worse case is you smoke a bit and have to re-do it. But if it's already apart, I'd modify the A/C bracket.

Definitely wouldn't drill a 2nd hole. You could try that extension, worse case is you smoke a bit and have to re-do it. But if it's already apart, I'd modify the A/C bracket.

#4

I'd grind the A/C bracket. It's a bolt on affair if you screw it up or want to change it later. The oil pan isn't fragile, but it's not strong either. I've seen them cracked when threading in a fitting too far.

Definitely wouldn't drill a 2nd hole. You could try that extension, worse case is you smoke a bit and have to re-do it. But if it's already apart, I'd modify the A/C bracket.

Definitely wouldn't drill a 2nd hole. You could try that extension, worse case is you smoke a bit and have to re-do it. But if it's already apart, I'd modify the A/C bracket.

Thread

Thread Starter

Forum

Replies

Last Post

StratoBlue1109

Miata parts for sale/trade

21

09-30-2018 02:09 PM

stoves

Suspension, Brakes, Drivetrain

5

04-21-2016 04:00 PM