Gauging interest in a 304SS or a 316SS Head Flange

#1

Thread Starter

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

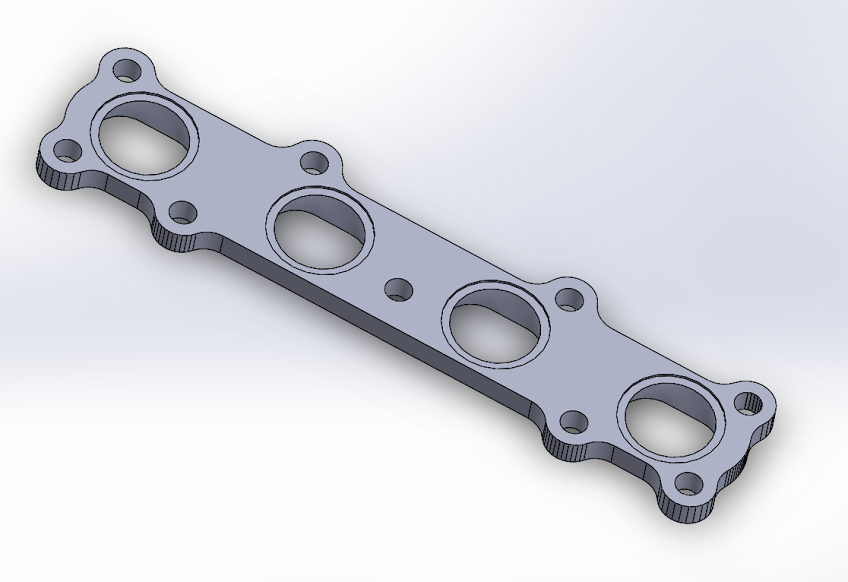

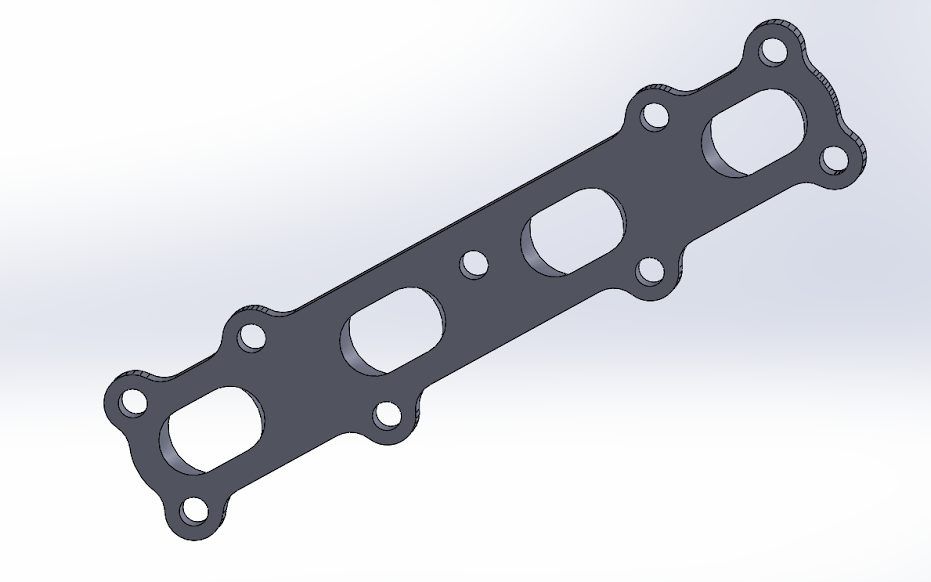

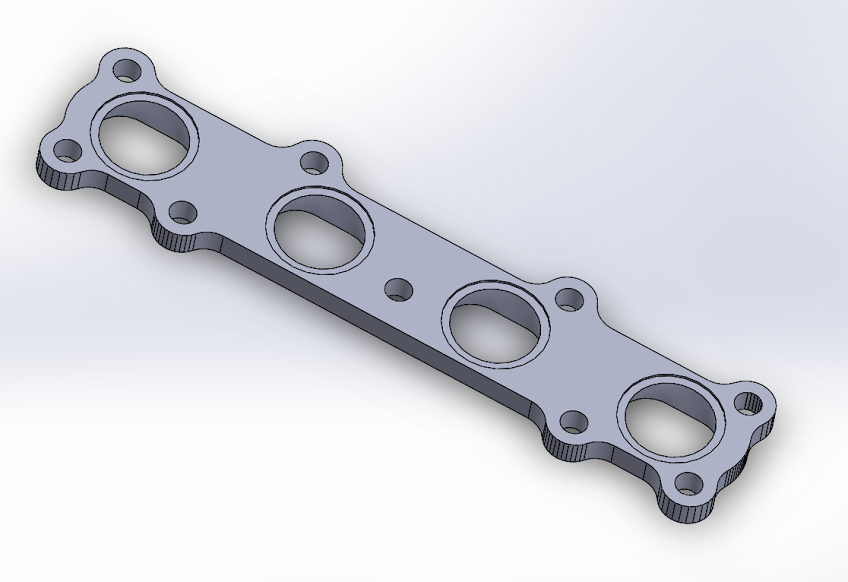

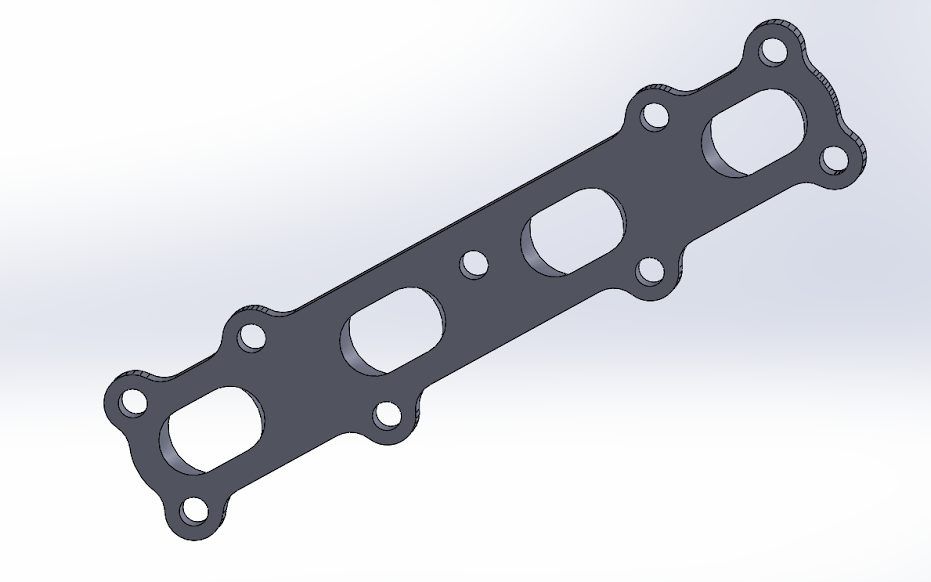

Getting one of these made for my project in either 304SS or 316SS. Have a couple other people interested and wanted to gauge interest and see if I should get more than a few cut.

It will be built for Schedule 40 1-1/2" pipe, with a port match to the head ports.

No idea on price yet.

Post here with how many you would want, and how much you would pay for one. I will be getting quotes this week.

Also will get getting T2 flanges out of the same material.

It will be built for Schedule 40 1-1/2" pipe, with a port match to the head ports.

No idea on price yet.

Post here with how many you would want, and how much you would pay for one. I will be getting quotes this week.

Also will get getting T2 flanges out of the same material.

#2

I was just wondering about where to source a stainless version of this as I model my manifold plans. PRL sells a steel version but only stainless weld els.. Not sure unlike metals is going to cause any problems other than corrosion. I can get steel weld els elsewhere, but they are actually more $ (from McMaster) than the SS ones.

How thick will these be?

How thick will these be?

#3

I was just wondering about where to source a stainless version of this as I model my manifold plans. PRL sells a steel version but only stainless weld els.. Not sure unlike metals is going to cause any problems other than corrosion. I can get steel weld els elsewhere, but they are actually more $ (from McMaster) than the SS ones.

How thick will these be?

How thick will these be?

#7

Thread Starter

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

Here is the flange drawing. It has not been tested, so don't assume its complete.

http://sadfab.com/opensource.html#headflange

http://sadfab.com/opensource.html#headflange

#9

I say 5/8" if possible. Go big or go home. That way the first milling after it's welded brings the flange thickness down to 1/2". Maybe straighten the taper a little at the end so the ports don't get smaller as you mill the head flange down to nothing. Not that I'm worried about warping or anything...

Also, I'm down for one if Aidan build's me a manifold with it. Aidan, I'll assemble your short block?

Also, I'm down for one if Aidan build's me a manifold with it. Aidan, I'll assemble your short block?

#10

Thread Starter

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

I'm going to be building the manifold on the spare head. Hopefully should help keep it from warping. Unless I can get this giant piece of steel I've been eyeing in a corner of the machine shop at work.

I think 5/8 is overkill. 3/8 used to be acceptable. Thats how thick my flange is.

A little exhaust leak is fine. Nothin like a bit of carbon monoxide to make you tired before track days.

I think 5/8 is overkill. 3/8 used to be acceptable. Thats how thick my flange is.

A little exhaust leak is fine. Nothin like a bit of carbon monoxide to make you tired before track days.

#11

Here is the flange drawing. It has not been tested, so don't assume its complete.

http://sadfab.com/opensource.html#headflange

http://sadfab.com/opensource.html#headflange