Flow Force injector help

#42

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

Normally the vendor provides that data

Or so the warning says.

Joking aside that looks like something to counter pulsewodths changing when they get small. Or "non-linear"

Normally this isn't a huge issue until you get into much bigger injectors. I can't find a link about it right now. Just Google small pulsewidth nonlinearity.

Basically huge injectors don't act the same when they are run at low pulsewodths. Say at 5ms PW it injects 50ccs of fuel (fake number) and at 4ms, 40ccs,..etc. But then at 2ms it injects 25ccs, 1ms, 17ccs.

Or so is my understanding.

Or so the warning says.

Joking aside that looks like something to counter pulsewodths changing when they get small. Or "non-linear"

Normally this isn't a huge issue until you get into much bigger injectors. I can't find a link about it right now. Just Google small pulsewidth nonlinearity.

Basically huge injectors don't act the same when they are run at low pulsewodths. Say at 5ms PW it injects 50ccs of fuel (fake number) and at 4ms, 40ccs,..etc. But then at 2ms it injects 25ccs, 1ms, 17ccs.

Or so is my understanding.

#43

My ****'s not that primitive. Doubt I could idle 14.7 batch, that'd be two 1.0ms pulses...

All injectors have non-linear areas near the deadtime value, weather or not they are consistently inconstant enough to tune out is a whole nother' deal.

I agree it's not much an issue for these injectors, nearly all miata setups should idle well into the linear range on these things.

#45

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

Who did what?

My ****'s not that primitive. Doubt I could idle 14.7 batch, that'd be two 1.0ms pulses...

All injectors have non-linear areas near the deadtime value, weather or not they are consistently inconstant enough to tune out is a whole nother' deal.

I agree it's not much an issue for these injectors, nearly all miata setups should idle well into the linear range on these things.

My ****'s not that primitive. Doubt I could idle 14.7 batch, that'd be two 1.0ms pulses...

All injectors have non-linear areas near the deadtime value, weather or not they are consistently inconstant enough to tune out is a whole nother' deal.

I agree it's not much an issue for these injectors, nearly all miata setups should idle well into the linear range on these things.

#46

Yes, batch spark but seq fuel. I can run sequential spark, but then I'd loose ECU fan control, ac idle-up if I still had it. I only have 4 outputs fast enough to do fuel and spark, at least as I understand it, those are in addition to the two stock spark and fuel channels.

I'm not too bent out of shape on the batch spark thing, pretty sure my miata turns slow enough for it to not matter.

There's only like 4 things from MS3 I want, idle VE, non-linear deadtime correction, and better fuel/timing resolution. USB/sd would be tight, too. Maybe the boost by gear stuff. Waiting on you to figure out fuel blending for me, then maybe that too.

I'm not too bent out of shape on the batch spark thing, pretty sure my miata turns slow enough for it to not matter.

There's only like 4 things from MS3 I want, idle VE, non-linear deadtime correction, and better fuel/timing resolution. USB/sd would be tight, too. Maybe the boost by gear stuff. Waiting on you to figure out fuel blending for me, then maybe that too.

#48

In my very limited experience it seems like manufacturers' deadtimes are from clearing the seat and not from a point of appreciable flow, or enough fuel to make a difference. I found it useful to add a little deadtime to the manufacturer's spec. Try adding .2ms and see if it gets more manageable at idle.

#49

Joined: Jan 2013

Posts: 5,012

Total Cats: 859

From: Seneca, SC

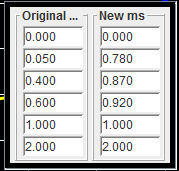

I have been using non-linear small pulse widths with the Yellow RX8 injectors. Dead time set at 0.8mS at 13.2, which may be a little short because the Reverant battery control keeps things at 14.0 unless RPM gets to about 600.

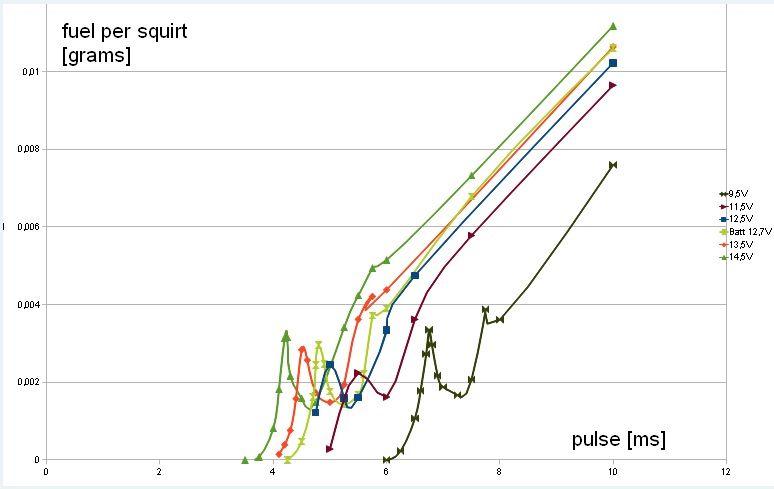

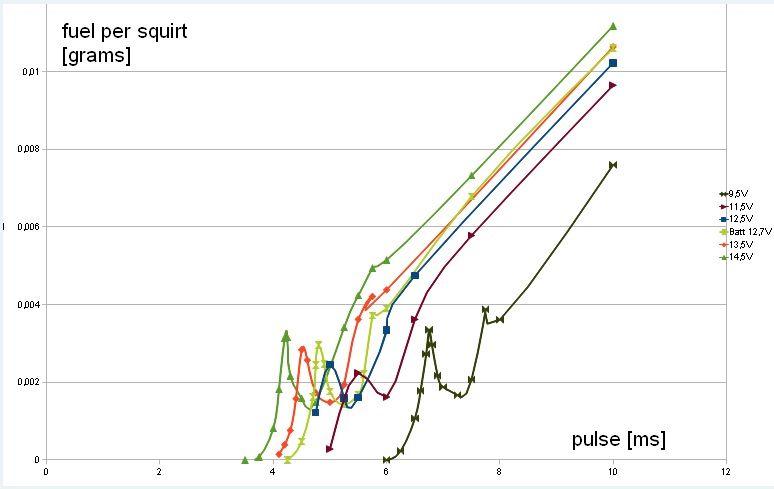

1) I found this set of curves (I cannot find where I found them, either on here or on MS forum)

2) All my data logs would show any time total (actual) pulse was around 15.5mS, I would go full lean. But below that, say about 14.8mS would get some fuel back.

3) Lead me to conclude that true pulse output at 15.5 was virtually zilch.

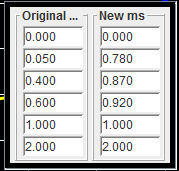

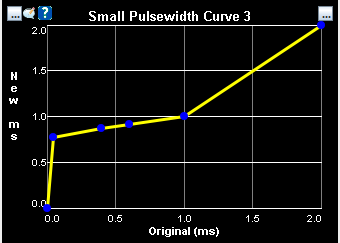

4) I made a very aggressive NL curve that basically prevents ever going to 15.5mS. I'm treating it as zero.

5) By the way, my table will show that I'm abiding by the (0.0) and (2,2), but I have also ignored it and had the same results. I set up (0,.75) on the top row, so that, before deadtime was added, the minimum pulse width would be .75, and all worked out fine. During fuel cut, PW still went to ZERO.

6) It appears that this correction is made just before deadtime is added and final, actual PW is sent.

7) I idle at about 17.8mS and 30kPa, so this table really takes effect only on less than about 25kPa (lifted throttle, before fuel cut happens).

So, in other words, I'm ignoring, and never sending commands below the right-most major dip (ignoring the re-rising).

This is not perfect, but now instead of swings of 10 to 17 AFR upon throttle lift, it is more like 13-16.

As you can see, my curve is pretty radical, so small corrections due to MAT and hot restart will move things around a bit, but it is now much better than it was.

No further progress due to REAL failure of the exhaust manifold, and I have worked on the car 2 nights in the last 4 weeks.

1) I found this set of curves (I cannot find where I found them, either on here or on MS forum)

2) All my data logs would show any time total (actual) pulse was around 15.5mS, I would go full lean. But below that, say about 14.8mS would get some fuel back.

3) Lead me to conclude that true pulse output at 15.5 was virtually zilch.

4) I made a very aggressive NL curve that basically prevents ever going to 15.5mS. I'm treating it as zero.

5) By the way, my table will show that I'm abiding by the (0.0) and (2,2), but I have also ignored it and had the same results. I set up (0,.75) on the top row, so that, before deadtime was added, the minimum pulse width would be .75, and all worked out fine. During fuel cut, PW still went to ZERO.

6) It appears that this correction is made just before deadtime is added and final, actual PW is sent.

7) I idle at about 17.8mS and 30kPa, so this table really takes effect only on less than about 25kPa (lifted throttle, before fuel cut happens).

So, in other words, I'm ignoring, and never sending commands below the right-most major dip (ignoring the re-rising).

This is not perfect, but now instead of swings of 10 to 17 AFR upon throttle lift, it is more like 13-16.

As you can see, my curve is pretty radical, so small corrections due to MAT and hot restart will move things around a bit, but it is now much better than it was.

No further progress due to REAL failure of the exhaust manifold, and I have worked on the car 2 nights in the last 4 weeks.

#50

For example rolling up to a stop light, depress the clutch and the car will stall. Stop and go traffic the car will stall.

@Savington any chance we could have a look at your VE tables you are using with the FF610 units. It may help us dial it in.

Here is my datalog during the stalls: https://s3-us-west-2.amazonaws.com/t...8_16.12.19.msl

I sent the datalog over to DIYAUTOTUNE and the reply I received from Russ was pretty helpful regarding what to try next:

Check that your alternator control is set to "high speed feedback field control". This will likely need a power cycle after you click burn if you have to change the setting.

Comment:

Alternator was setup this way already.

Next have a look at this screenshot from your log and let me show you what I see. Top graph white line is RPM and I have on screen one time where the engine cut out after what looks like coasting to a stop. Next graph down, white is fuel PW and red is your AFR from the wideband.

As RPM is on the down swing passing where it should idle it looks like the AFR is on an upswing, getting leaner and leaner. It seems on rev-down there is an area in the VE table near idle that needs a fuel increase. It may be that the fuel table needs to be set for rev down and then activate "idle VE" to have a separate small fuel table just for idle once it stabilizes .

Comment:

So perhaps the next step would be a small idle VE table?

I will be handing the car off to Curly Monday and he will continue the tune.

Looking forward to getting this dialed in.

I will share my MSQ file once the car operates properly in daily driving conditions, with the hope that it will give other MSM and boosted NB drivers additional help with the FF610 injectors.

#51

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

Could you post your MSQ that goes along with that log? That log is different than what I've been seeing. You have a 0% duty cycle For a significant period of time. When it probably shouldn't be.

What are your overrun settings? It also looks like you are stuck in PID idle like the entire time. Post MSQ Plz

This is really screwy right here:

What are your overrun settings? It also looks like you are stuck in PID idle like the entire time. Post MSQ Plz

This is really screwy right here:

#52

Any updates on these injectors going lean on deceleration? I am working on tuning my exocet and have run into the same problem. My car doesn't stall, its just strange that my AFR goes lean right as I let off the gas.

95 1.8 turbo exocet

Garrett 2560, FM Manifold

DIYPNP Sequential injection

95 1.8 turbo exocet

Garrett 2560, FM Manifold

DIYPNP Sequential injection

#53

They will go lean on decel if your fuel map is tuned for ****. You could use the small pulsewidth features on MS3, or you can make the low map cells high VE so you actually get a reliable clean squirt of fuel.

I have a shitty fuel pump and can tell that ~1.3-1.6ms pulsewidths are not at all linear especially in high vac. Sometimes decel will be around 15.0, other times around 17.5. That's pretty much the definition of non-linear. Tune overrun well and forget about it, that's what I did.

I have a shitty fuel pump and can tell that ~1.3-1.6ms pulsewidths are not at all linear especially in high vac. Sometimes decel will be around 15.0, other times around 17.5. That's pretty much the definition of non-linear. Tune overrun well and forget about it, that's what I did.

#56

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

Megasquirt Support Forum (MSEXTRA) ? Verifying my dead time calculation. (View topic)

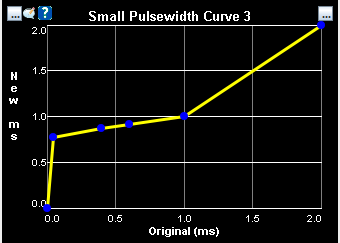

Just found this test. Which may be applicable to us. @deezums is going to test it out.

This points to a deadtime of more like .9-1ms at 13.6 volts. On the MS2 voltage correction curve.

Just found this test. Which may be applicable to us. @deezums is going to test it out.

This points to a deadtime of more like .9-1ms at 13.6 volts. On the MS2 voltage correction curve.

#58

Joined: Aug 2014

Posts: 1,461

Total Cats: 388

From: Bainbridge Island, WA

I've just sent an injector off for linearity and latency testing at a different shop, so it will be interesting to see whether the results differ from the dead times we've been working from.

I also did some of my own testing and the results confound me. Maybe one of you can help interpret this in a useful or meaningful way? The test process was to run 1500 RPM at different pulse widths starting at 5ms and going down until nothing squirts out. Around 2ms the steps are 0.1 ms apart for a decent amount of precision. The machine was running at 12V.

If you do a regression of the linear section, it intercepts at pretty darn close to x=0, which makes no sense at all.

I also did some of my own testing and the results confound me. Maybe one of you can help interpret this in a useful or meaningful way? The test process was to run 1500 RPM at different pulse widths starting at 5ms and going down until nothing squirts out. Around 2ms the steps are 0.1 ms apart for a decent amount of precision. The machine was running at 12V.

If you do a regression of the linear section, it intercepts at pretty darn close to x=0, which makes no sense at all.

__________________

#60

So they pretty much shut off around 1.7ms, no more fuel? That kinda meshes with my tuning, I try and avoid anything that small. I thought I hand changed to .75 for a deadtime, but I am still running .63@13.2V. Easy comparison to everyone else that way.

Was that run at 43psi? Can you test higher or lower rail pressure as well, to see if the shape changes drastically?

It looks like there might be two slopes going on, I wonder what the intersection on the steeper line is? If you average those few non linear points it looks like it might be around 1.0ms? Deadtime is a smaller percentage of a 5.0ms pulse compared to 2.0, a whole lot less, might make tuning easier?

Was that run at 43psi? Can you test higher or lower rail pressure as well, to see if the shape changes drastically?

It looks like there might be two slopes going on, I wonder what the intersection on the steeper line is? If you average those few non linear points it looks like it might be around 1.0ms? Deadtime is a smaller percentage of a 5.0ms pulse compared to 2.0, a whole lot less, might make tuning easier?