Fab9 EFR NA/NB owners.

#1

If anyone has a Fab9 EFR setup on an NA/NB I'd like see how they ran the supporting lines (Oil/Water, Exhaust, Hot/Cold pipes) I'm currently having difficulty finding many who have actually installed a kit with a majority of them still waiting to do the install. Is there anything I need to pay special attention to? NB specific information would be especially helpful.

#5

https://www.miataturbo.net/build-thr...0/#post1354718

http://www.full-race.com/articles/efrturbotechbrief.pdf

pg37-39 for oil/coolant connections

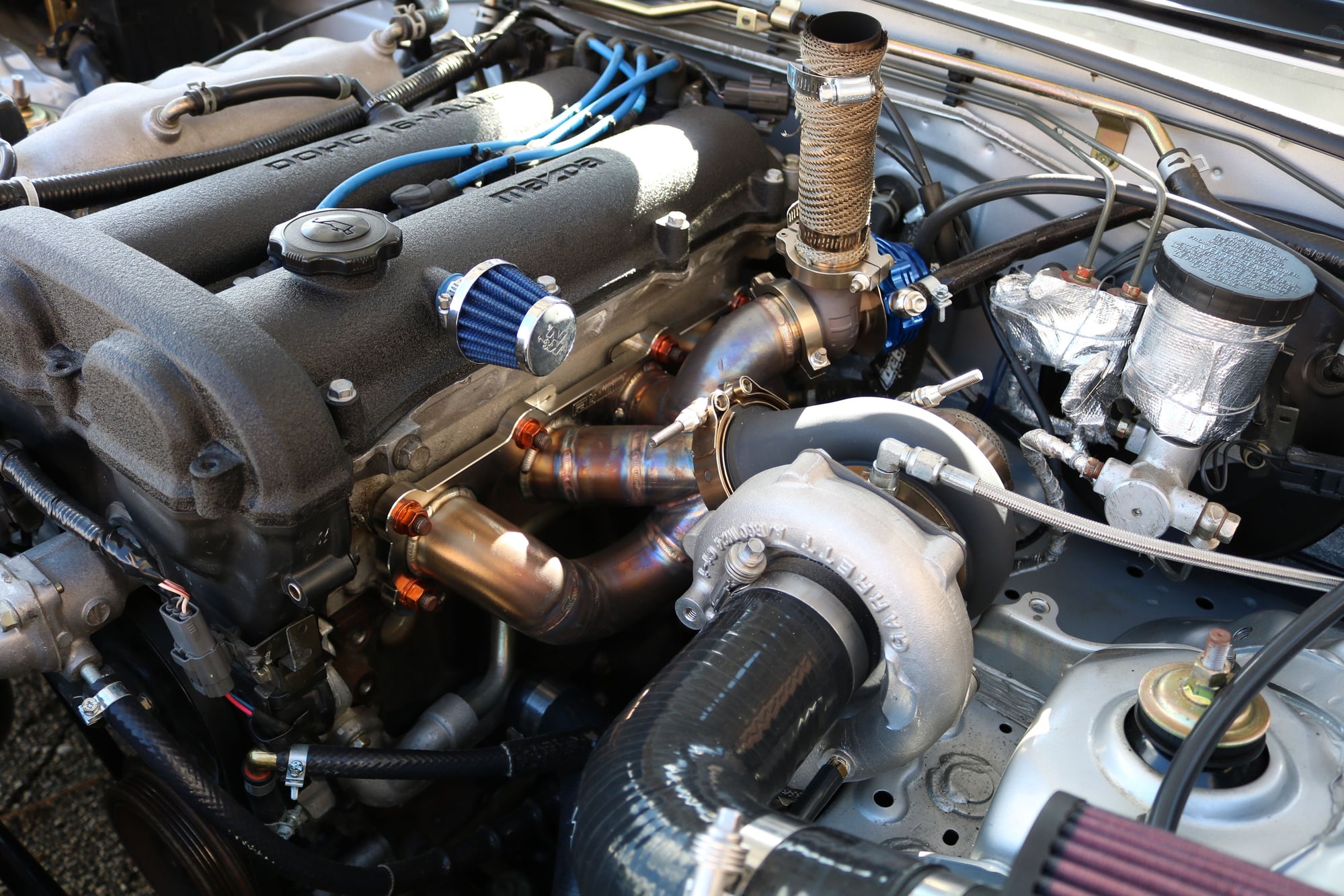

I initially purchased the oil/ coolant line from Bryan and personally did not like the fittings nor the line it came with, more so personal preference. I just finished my lines and it was relatively simple. In that post I listed all the parts with the exception of the banjo bolt i purchased for the oil/coolant lines. Pushlock fittings are the way to go in my opinion. I got the feed from the exhaust side of the block where there is already a pre tapped location for oil feed, drained down to the oil pan where i drilled and welded a bung on for a 1/2npt fitting for the drain. I then picked up coolant feed from the re route housing on the back of the head, (949 coolant reroute kit) and then drained/returned the coolant to the nipple on the mixing manifold. Keep in mind that on the EFR, the coolant lines have to run diagonal across the CHRA, meaning the feed on one side has to be the bottom port, and the return on the opposite side has to be the return. Which side of the turbo does not matter, but the bottom HAS to be the feed, and the top has to be the drain. If you have any questions about the turbo fittings, you can look at the EFR technical document that I also listed above.

http://www.full-race.com/articles/efrturbotechbrief.pdf

pg37-39 for oil/coolant connections

I initially purchased the oil/ coolant line from Bryan and personally did not like the fittings nor the line it came with, more so personal preference. I just finished my lines and it was relatively simple. In that post I listed all the parts with the exception of the banjo bolt i purchased for the oil/coolant lines. Pushlock fittings are the way to go in my opinion. I got the feed from the exhaust side of the block where there is already a pre tapped location for oil feed, drained down to the oil pan where i drilled and welded a bung on for a 1/2npt fitting for the drain. I then picked up coolant feed from the re route housing on the back of the head, (949 coolant reroute kit) and then drained/returned the coolant to the nipple on the mixing manifold. Keep in mind that on the EFR, the coolant lines have to run diagonal across the CHRA, meaning the feed on one side has to be the bottom port, and the return on the opposite side has to be the return. Which side of the turbo does not matter, but the bottom HAS to be the feed, and the top has to be the drain. If you have any questions about the turbo fittings, you can look at the EFR technical document that I also listed above.

#8

Bryan asked me to deal directly with John, since John didn't sell me the parts I didn't think that was an appropriate method of taking care of business. I was a customer who had spent over $6k in parts through Fab9 and there was always an excuse.

The whole time Bryan insisted I was the only person having issues, later I found out other NB users had fitment problems with the pie cut downpipes hitting the body and steering rod. I have since gotten a V2 downpipe and it hits the engine block, a wack with a hammer next time it is off should allow some clearance. I am currently stuck trying to figure out how to deluge the coolant (heater core) lines so they don't sit directly on the downpipe. The kit was designed to fit an NA and assumed it would work well on NB as well.

The whole time Bryan insisted I was the only person having issues, later I found out other NB users had fitment problems with the pie cut downpipes hitting the body and steering rod. I have since gotten a V2 downpipe and it hits the engine block, a wack with a hammer next time it is off should allow some clearance. I am currently stuck trying to figure out how to deluge the coolant (heater core) lines so they don't sit directly on the downpipe. The kit was designed to fit an NA and assumed it would work well on NB as well.

#9

My manifold and dp came with the wrong flanges welded on. Even after i sent the specific measurements (in mm) of all the ID and ODs. I went through hell and back with bryan to get it fixed. The best thing was just dealing directly with john. His customer service is phenomenal. Imo he shoukd ditch fab9 and sell them himself.

Bryan offered me a discount "on a future purchase" for my troubles. He will never get another dime from me

Bryan offered me a discount "on a future purchase" for my troubles. He will never get another dime from me

#10

The manifold puts the turbo too far rearward and needs a better wastegate location, or ideally utilized the EFR internal gate.

What are are you doing to keep the heat off of your brake components? I've tried to fit a shield but nothing is working out and use a blanket and wrapped downpipe.

What are are you doing to keep the heat off of your brake components? I've tried to fit a shield but nothing is working out and use a blanket and wrapped downpipe.

#11

The manifold puts the turbo too far rearward and needs a better wastegate location, or ideally utilized the EFR internal gate.

What are are you doing to keep the heat off of your brake components? I've tried to fit a shield but nothing is working out and use a blanket and wrapped downpipe.

What are are you doing to keep the heat off of your brake components? I've tried to fit a shield but nothing is working out and use a blanket and wrapped downpipe.

not the best pic but i wrapped most of the brake components in an adhesive backed shield. Wrapped DP and screamer pipe with dei wrap. and slid the water lines through some DEI fire sleeve. also put some fire sleeve around a few vacuum lines.

I dont track the car. I just drive like a dumbass on the streets and nothing has melted yet...

#15

EFR 6258

Fab9 Mani/DP

Stock Bottom BP4W

MSM Intake Cam

ST Dual Springs

Flat Top IM

250hp 205tq @ 9-10 PSI

I hit my HP/TQ goal but I expected to have more TQ earlier in the powerband, like 200 ft lbs 1500-2000 RPM sooner. I was warned about the .85ar prior to purchase but didn't expect such a shift.

Going to look for a boost leak, hoping it's something rather simple. Probably another 5-10 left on the table with more timing but I was not looking to stress things any more. (The last 2 deg of timing I added gave me another 5hp/5ft lbs still conservative)

Fab9 Mani/DP

Stock Bottom BP4W

MSM Intake Cam

ST Dual Springs

Flat Top IM

250hp 205tq @ 9-10 PSI

I hit my HP/TQ goal but I expected to have more TQ earlier in the powerband, like 200 ft lbs 1500-2000 RPM sooner. I was warned about the .85ar prior to purchase but didn't expect such a shift.

Going to look for a boost leak, hoping it's something rather simple. Probably another 5-10 left on the table with more timing but I was not looking to stress things any more. (The last 2 deg of timing I added gave me another 5hp/5ft lbs still conservative)