321 sch5 manifold

#1

Finally got the time to play with all that material I bought! Built a manifold for a 76' Lancia Scorpion, and also my 95'. First one is of the Lancia Manifold.

For a 76' Lancia

Also the 76'

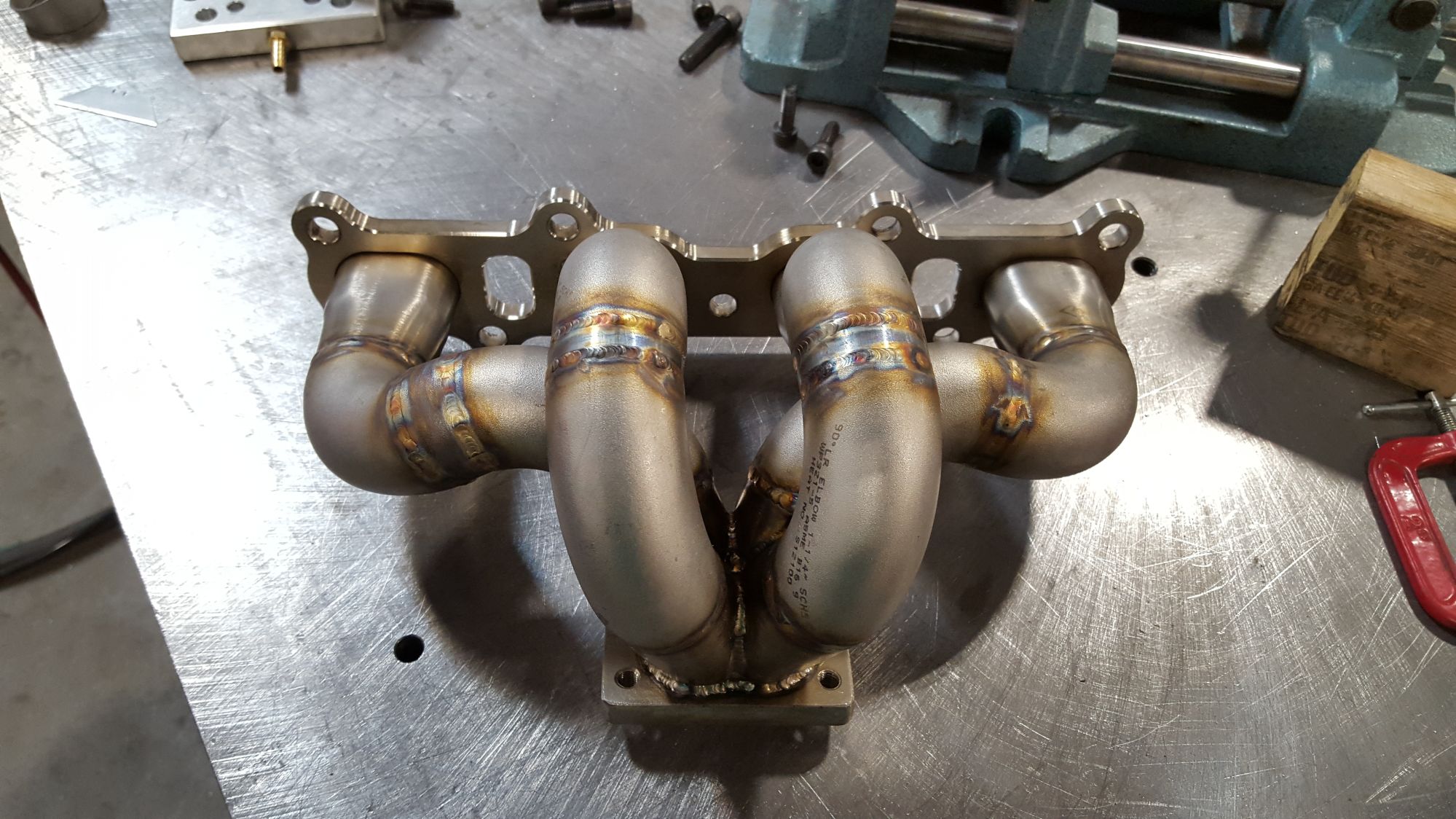

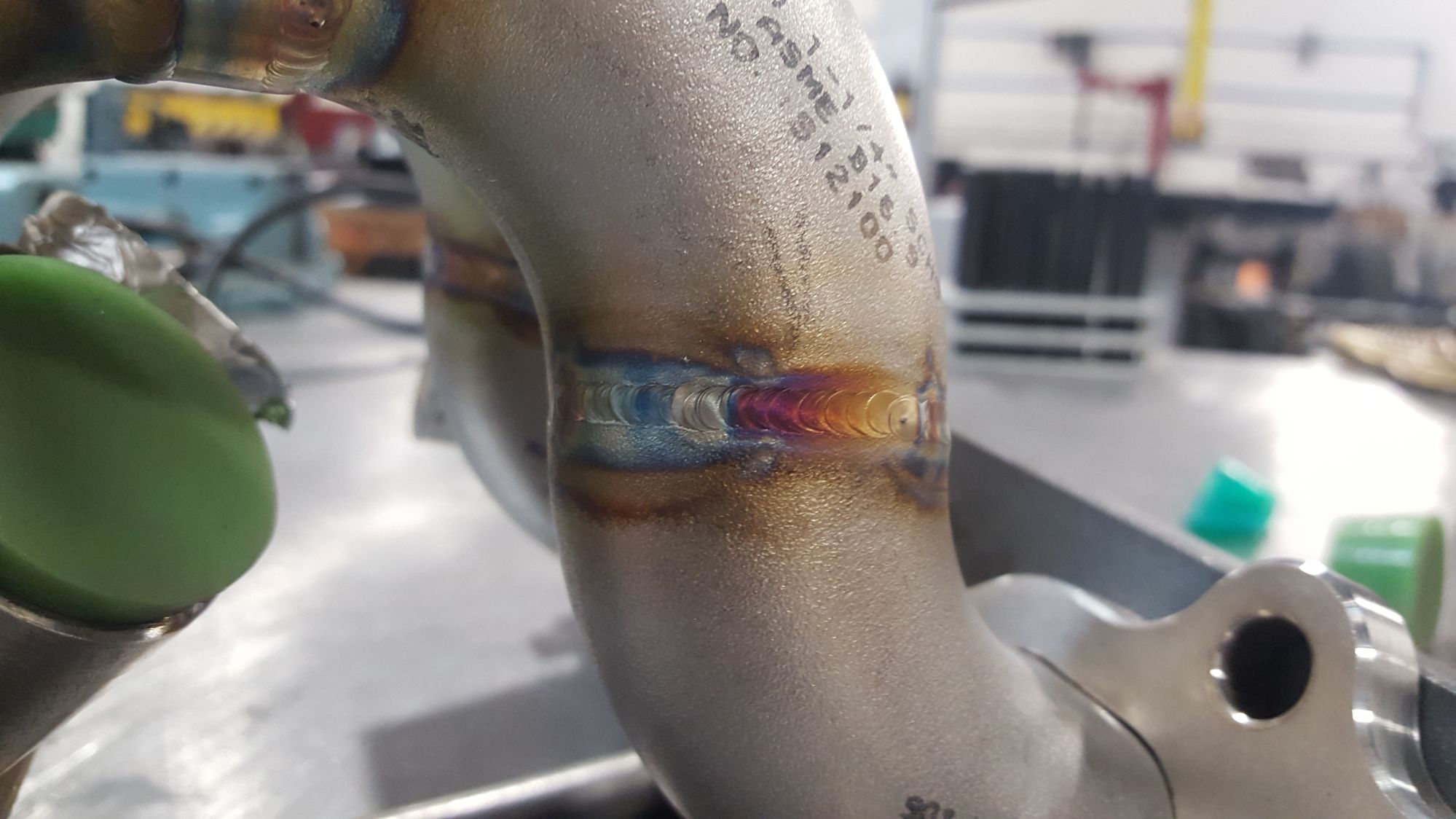

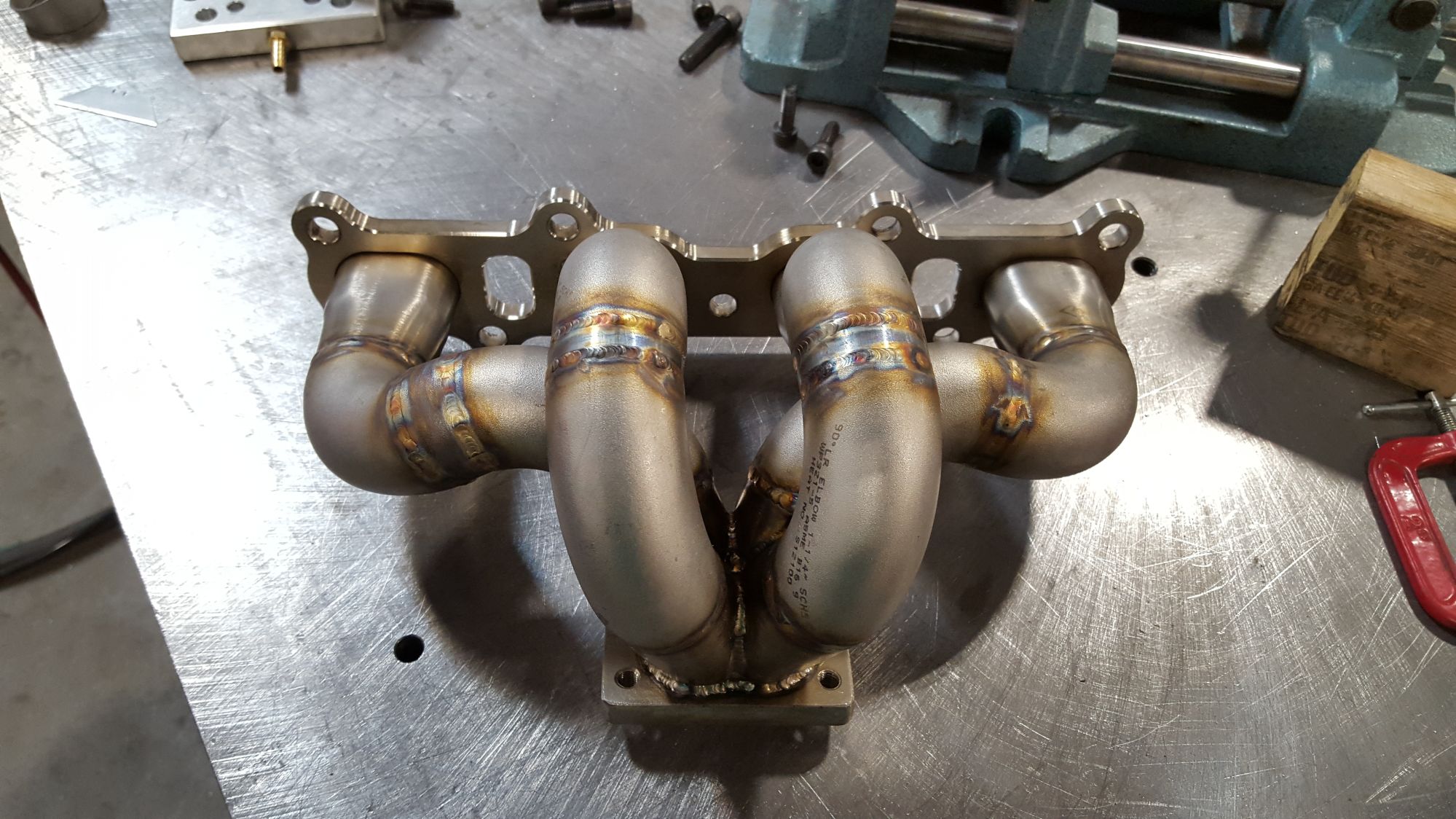

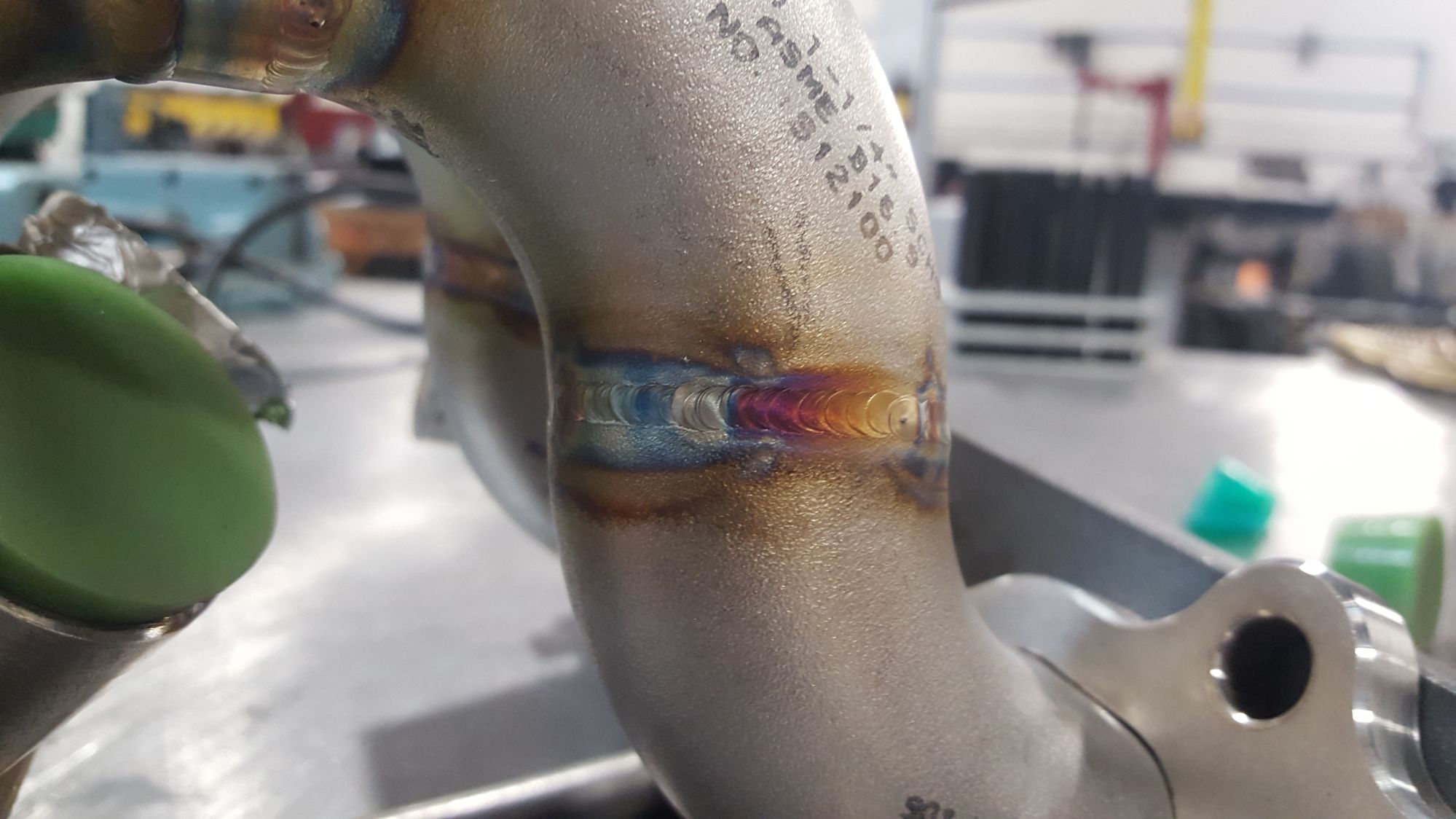

Here's a few shots of the mani I made for my car.

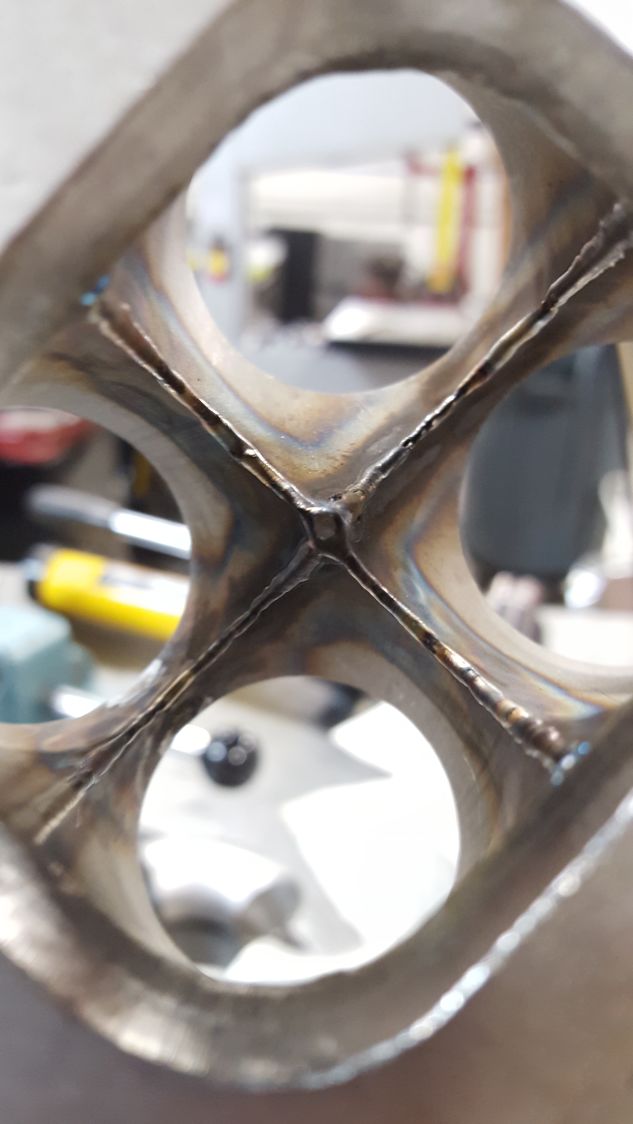

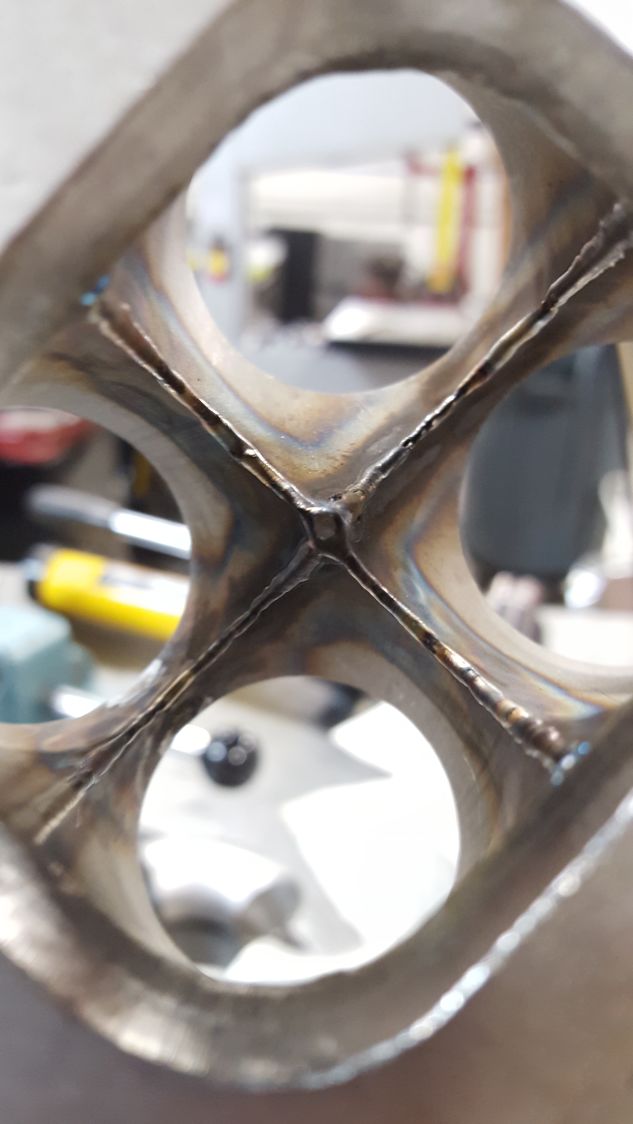

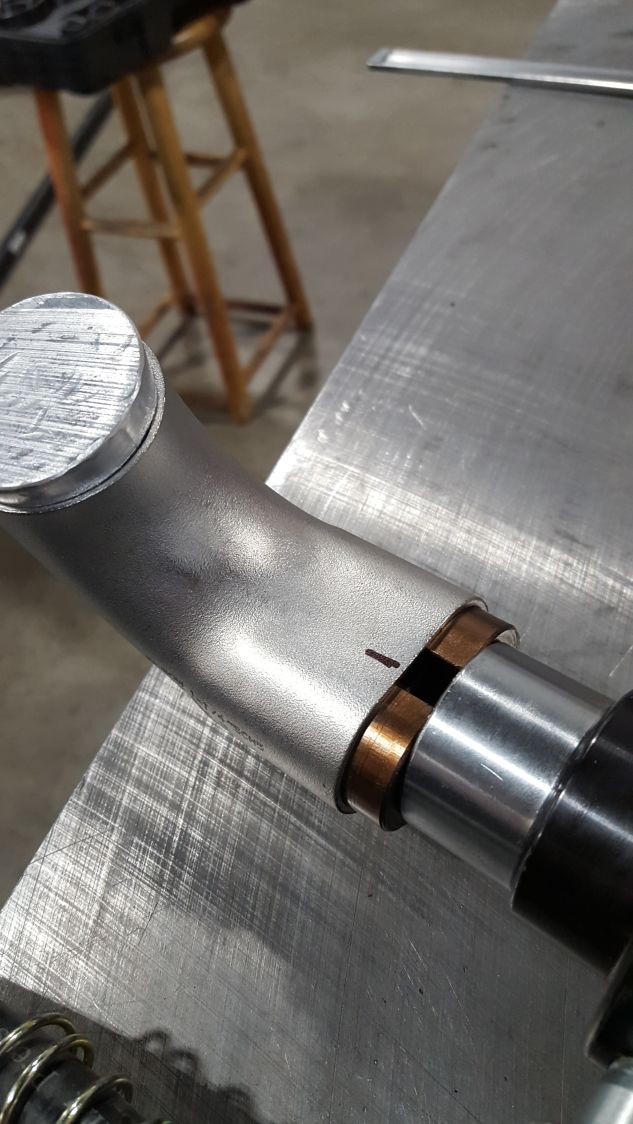

I'm pretty happy with way it turned out. This was the first time I tried welding the collector on the inside and it went really well. To fit the runners I side the flange I designed and machined my own expansion tooling that I use in conjuction with a Harbor Frieght knockout punch cylinder.

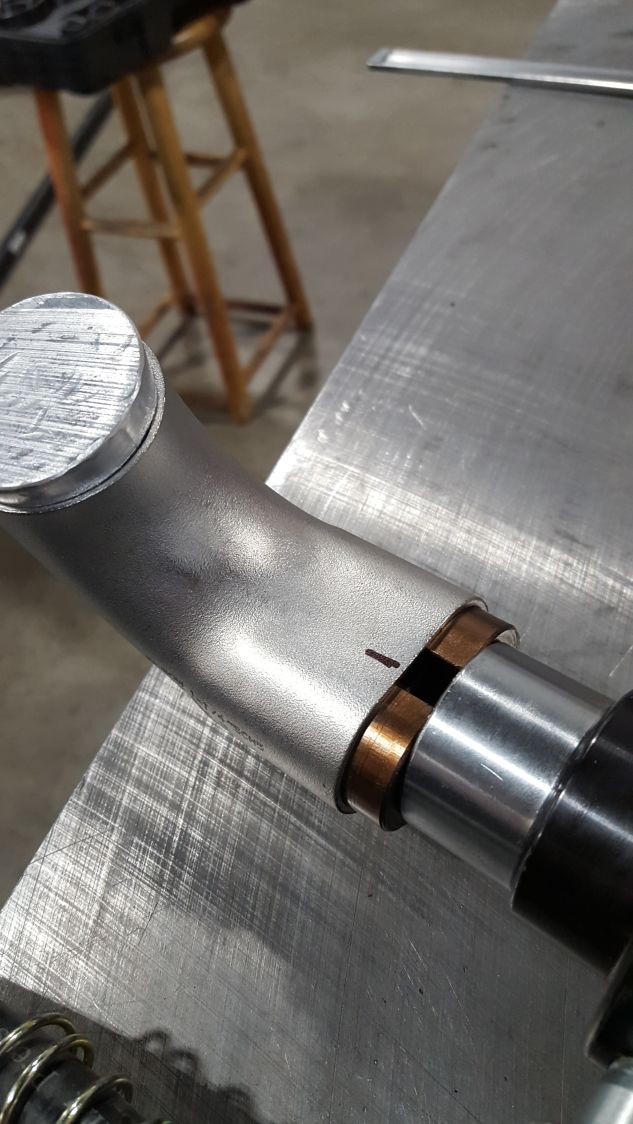

Made from some S7 we had lying around.

My thinking with fitting the runners in the flange is that when you see a hot manifold it's always the runners glowing while the head flange is still dark and cool. Runners are trying to expand and the flange is staying put. When the pipe is placed on the flange and fillet welded all this expansion force is focused on the weld. I'm thinking my way will take a lot of stress off the weld. I'm excited to see how it holds up. I will of course be bracing the turbo.

For a 76' Lancia

Also the 76'

Here's a few shots of the mani I made for my car.

I'm pretty happy with way it turned out. This was the first time I tried welding the collector on the inside and it went really well. To fit the runners I side the flange I designed and machined my own expansion tooling that I use in conjuction with a Harbor Frieght knockout punch cylinder.

Made from some S7 we had lying around.

My thinking with fitting the runners in the flange is that when you see a hot manifold it's always the runners glowing while the head flange is still dark and cool. Runners are trying to expand and the flange is staying put. When the pipe is placed on the flange and fillet welded all this expansion force is focused on the weld. I'm thinking my way will take a lot of stress off the weld. I'm excited to see how it holds up. I will of course be bracing the turbo.

#11

No this will not be a dedicated street car. It will most certainly be on road america with the north woods Shelby club. This year? Idk. Like I said I am as curious as anyone about the durability. I would be very open to the idea of shipping this to someone who can get it on the track and beat the poop out of it!

#12

Here is how it positions the turbo. My goal was to have it put the turbo in a place that would make the downpipe as straight as possible. A manifold like this will certainly need a good brace and that is next up on my list. I will design a support that keeps the turbo vibrating the same way the engine does so the manifold isnt trying to take that up. And also in a way that allows for thermal expansion. Prolly something like two plates clamped together with a Belleville spring.