The White Mouse

#41

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

After collecting lots of bits, I dropped off my head, block, crank and a two large boxes of bits in September to the engine builder. The engine in all it's clingwrap glory is now back, and waiting on me to get get started on reattaching things.

I am hoping for mid 400's at the wheels from this engine and an EFR6758.

I am hoping for mid 400's at the wheels from this engine and an EFR6758.

#43

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

I've been working on getting this car back together and it is now 90% ready for first start.

This was before the engine went in, showing the various lines attached.

I decided to use an Os Giken twin plate to manage the planned torque output. Getting this aligned was a pain until I was able to borrow a steel tool.

The engine back in the car, the next several jobs involved making intercooler pipes, mounting things and making up the last of the fuel lines. These pipes are using TSE's recommended pathway - I don't have that much experience with a TIG, but I'm happy with how these turned out.

This was before the engine went in, showing the various lines attached.

I decided to use an Os Giken twin plate to manage the planned torque output. Getting this aligned was a pain until I was able to borrow a steel tool.

The engine back in the car, the next several jobs involved making intercooler pipes, mounting things and making up the last of the fuel lines. These pipes are using TSE's recommended pathway - I don't have that much experience with a TIG, but I'm happy with how these turned out.

#44

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

I paid a shop to put this together for me, but I want to make the next exhaust I need (I will have regular access to a hoist soon). It's 3"from dump to tip, has a 100 cell cat, resonator and muffler. V-band connections, except for the bottom of the dump which is a two bolt flange.

[/url]

[/url]

[/url]

[/url]

#45

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

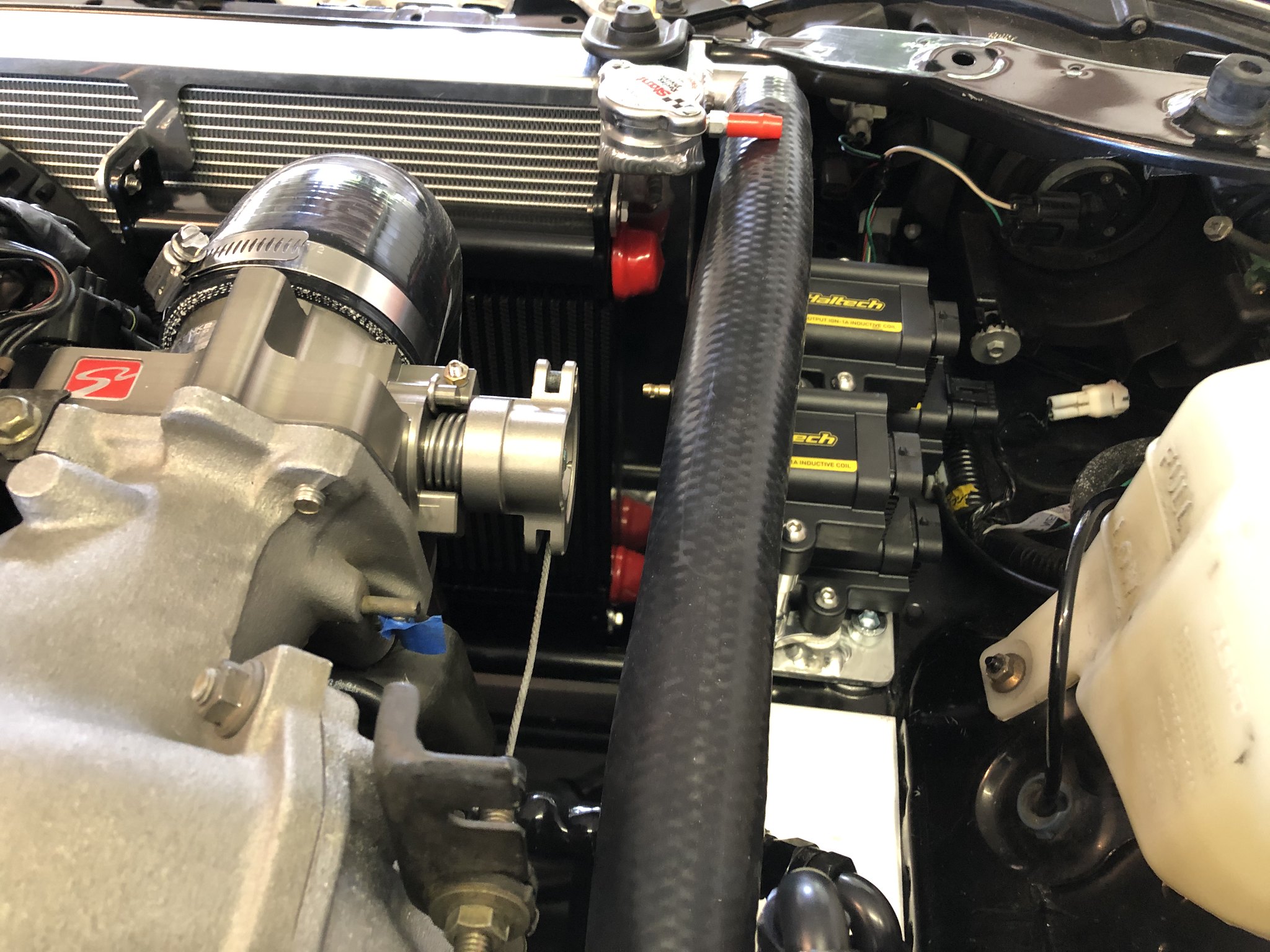

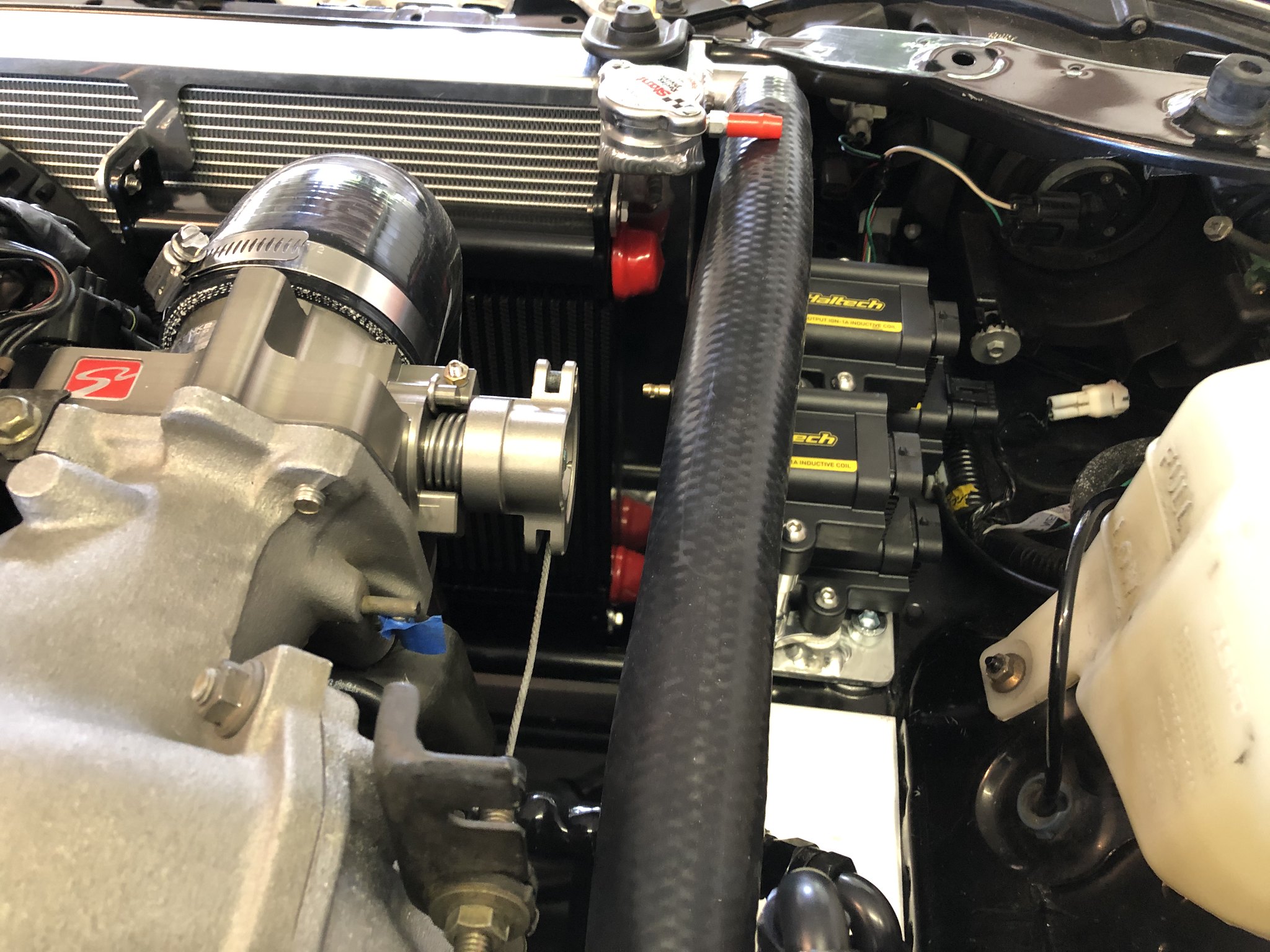

This side of the bay is getting very crowded now, with remote mounted coils, FPR, fuel composition sensor, coolant reroute lines, remote mounted oil filter and (soon) lines for the oil cooler. The offset inlet for the radiator has worked out nicely with a straight shot down the side of the engine.

#46

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

I had a first attempt at making a catch can today. It's not finished yet, and I still need to weld in the baffling, attach the inlets and a vent, and figure out a drain (yes, nowhere near done!) but the overall shape and fit is fairly sorted.

This is where it fits in the engine bay. It shares a bolt with the power steering reservoir, and there will be a second bolt and nutsert underneath the intake pipe.

In terms of total capacity, it is about 1.6 quarts.

In terms of baffling, I am hoping to keep it fairly simple and allow the air to slow and turn back on itself a few times. The inlets will be located just above the little leg with the hole for the powersteering reservoir bolt, and the outlet will be in the top at the farther end. Any thoughts on the baffling?

The drain will probably be through a port on the bottom which I think should pass comfortably through the sheet metal into the same area where the intake filter sits: Empty catch can, clean and reoil filter perhaps?

This is where it fits in the engine bay. It shares a bolt with the power steering reservoir, and there will be a second bolt and nutsert underneath the intake pipe.

In terms of total capacity, it is about 1.6 quarts.

In terms of baffling, I am hoping to keep it fairly simple and allow the air to slow and turn back on itself a few times. The inlets will be located just above the little leg with the hole for the powersteering reservoir bolt, and the outlet will be in the top at the farther end. Any thoughts on the baffling?

The drain will probably be through a port on the bottom which I think should pass comfortably through the sheet metal into the same area where the intake filter sits: Empty catch can, clean and reoil filter perhaps?

#48

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

My 2003 is nearly ready for first start, run-in and tune.

Iím bracing myself for a dyno result (hopefully not a disappointment) and am interested in feedback on what Iíve put together and where it might fall over in the quest for mid 400ís.

The engine itself is VVT, has forged H beams and 9:1 forged pistons, ACL race series bearings, ARP main and head studs, Supertech +1 intake SS and +1 exhaust (Iconel) valves with ST heavy double springs, BE pump with two shims and standard cams. The lifters are converted to shim under bucket (probably not needed). The head is not modified other than was required to fit the larger valves.

The fuel system is a return set up with -6 lines to and from the tank which has a W460 pump and TSE wiring. Fuel goes into the rail at the rear and out at the front. After the rail, a boost referenced FPR and fuel composition sensor are plumbed. Thereís a referenced pulse damper mounted on the rail itself. The injectors are id1050x.

The hot side is a TSE manifold, 3Ē exhaust and EFR6758 with a medium spring in a two port actuator and a four port solenoid.

Cold side is a flattop manifold and a skunk2 with the spring hole mod. The intercooler is a PWR 19x11x2.75.

Spark is by remote mounted IGN-1a coils wired for sequential fire.

The clutch is an Os Giken twin (ts2b) and so should have plenty of capacity.

Iím bracing myself for a dyno result (hopefully not a disappointment) and am interested in feedback on what Iíve put together and where it might fall over in the quest for mid 400ís.

The engine itself is VVT, has forged H beams and 9:1 forged pistons, ACL race series bearings, ARP main and head studs, Supertech +1 intake SS and +1 exhaust (Iconel) valves with ST heavy double springs, BE pump with two shims and standard cams. The lifters are converted to shim under bucket (probably not needed). The head is not modified other than was required to fit the larger valves.

The fuel system is a return set up with -6 lines to and from the tank which has a W460 pump and TSE wiring. Fuel goes into the rail at the rear and out at the front. After the rail, a boost referenced FPR and fuel composition sensor are plumbed. Thereís a referenced pulse damper mounted on the rail itself. The injectors are id1050x.

The hot side is a TSE manifold, 3Ē exhaust and EFR6758 with a medium spring in a two port actuator and a four port solenoid.

Cold side is a flattop manifold and a skunk2 with the spring hole mod. The intercooler is a PWR 19x11x2.75.

Spark is by remote mounted IGN-1a coils wired for sequential fire.

The clutch is an Os Giken twin (ts2b) and so should have plenty of capacity.

#49

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

I should know what the set up is good for by mid next month. Will be nice to have the thing moving under own steam again after what will have been 11 1/2 months in bits

#50

Sounds ace. My Turbosmart 2 port wastegate wore the bore of the brass bushing which the main shaft runs through. There must be some angulation in my setup. This means the bottom chamber leaks and so the available boost suddenly dropped off.

Worth checking you have your actuator alignment bang on through the full range of wastegate movement. As a quick fix I'm using the top port only with no issue or leaks. I may get another brass bushing and try to re align and go back to 2 port operation or may just leave it as is as boost control is currently very good and meets my range requirements.

Worth checking you have your actuator alignment bang on through the full range of wastegate movement. As a quick fix I'm using the top port only with no issue or leaks. I may get another brass bushing and try to re align and go back to 2 port operation or may just leave it as is as boost control is currently very good and meets my range requirements.

#52

It's physically impossible for the rod to not pivot while it's doing it's thing, and the way the turbosmart is designed doesn't allow any. It might be made better with a much fatter o-ring seat, so that it doesn't bottom out and actually allows some flex. Then the rod won't slowly machine the never-seal into a nice gaper, although I doubt it.

I think the much better solution is putting a ball joint on the rod, which is what turbosmart eventually did. They don't sell parts to upgrade the junk one, and they wouldn't sell me a replacement brass bushing either.

I think the much better solution is putting a ball joint on the rod, which is what turbosmart eventually did. They don't sell parts to upgrade the junk one, and they wouldn't sell me a replacement brass bushing either.

#54

I think mine sealed for c.2000miles before being gaped. I notices very fine brass powder on a hose under it. The arc of operation of my turbo wastegate lever is far from optimum so the arc is twice the relative distance it needs to be if it was set up right with a neutral mid point. I will be adjusting the turbo in the future to optimise this but rushed to get it on and start enjoying it.

A thicker o-ring may provide a little more flex.

#56

Holy cow - that is fantastic! Congratulations, you must be very happy. You have also made me quite excited - I am transitioning from a Nitro Dann (!) twistmount to a Kraken topmount. Our builds are pretty much identical except I have a GTX II 2867R, so I'm not expecting quite as much as what you have found, but even 450 at anything under 30 would make me happy.

Can I please enquire who your tuner was? Even with such a stellar parts list, they must know their stuff... Top form

Can I please enquire who your tuner was? Even with such a stellar parts list, they must know their stuff... Top form

#58

Spotted the coolant reroute - what did you do for headgasket and sealing on the VVT?

Standard cams peaked at 6700 NA on mine so its a hard sell to try changing them out unless wishing to rev to the moon which is not really needed with a balanced turbo. V interested to see the graphs once you have them.

#59

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

Holy cow - that is fantastic! Congratulations, you must be very happy. You have also made me quite excited - I am transitioning from a Nitro Dann (!) twistmount to a Kraken topmount. Our builds are pretty much identical except I have a GTX II 2867R, so I'm not expecting quite as much as what you have found, but even 450 at anything under 30 would make me happy.

Can I please enquire who your tuner was? Even with such a stellar parts list, they must know their stuff... Top form

Can I please enquire who your tuner was? Even with such a stellar parts list, they must know their stuff... Top form

Ace work - at the wheels?

Spotted the coolant reroute - what did you do for headgasket and sealing on the VVT?

Standard cams peaked at 6700 NA on mine so its a hard sell to try changing them out unless wishing to rev to the moon which is not really needed with a balanced turbo. V interested to see the graphs once you have them.

Spotted the coolant reroute - what did you do for headgasket and sealing on the VVT?

Standard cams peaked at 6700 NA on mine so its a hard sell to try changing them out unless wishing to rev to the moon which is not really needed with a balanced turbo. V interested to see the graphs once you have them.

The headgasket is the 99-00 from Cometic.

Green lines are HP and boost pressure on 98/premium. Red lines are e85. The runs were done in 5th gear which is 1:1 and the car has a 3.63 diff. The handwritten numbers are RPM (added in by me).

#60

Thanks for the straight answers: 400+ torque = handful for you and the drivetrain!

With the meat from just before 4,500rpm - should be able to keep that on the boil with a 6 speed and 3.6 rear on track.

Looks like the tuner was playing with ramp rates - possibly controlling temperature/wheel slip. The 130 kph HP blip looks like a DD smoothing error - swear they use excel graph for smoothing and it looks like total error between the actual recorded points at 127 and 134.

Looking forward to videos once you get this back on the hill.

With the meat from just before 4,500rpm - should be able to keep that on the boil with a 6 speed and 3.6 rear on track.

Looks like the tuner was playing with ramp rates - possibly controlling temperature/wheel slip. The 130 kph HP blip looks like a DD smoothing error - swear they use excel graph for smoothing and it looks like total error between the actual recorded points at 127 and 134.

Looking forward to videos once you get this back on the hill.