The White Mouse

#22

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

The Torsen 2 went to a new home and the OG Superlock is in the shop getting set up with a set of 3.63 gears. I should have it back in the car by the end of the weekend.

After a long break, I'm entered in two hillclimbs in the next two months: Bulahdelah Hillclimb and the Noosa Hillclimb.

After a long break, I'm entered in two hillclimbs in the next two months: Bulahdelah Hillclimb and the Noosa Hillclimb.

#23

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

I took the Os Giken diff for a second drive this afternoon.

Once the diff 'grips' under light load it seems to hold itself partly clamped (unless there's been some firm engine braking), which seems to lead to some chatter if you happen to do a u-turn or tight low speed turn, but otherwise it's mostly invisible. Tight figure-8's don't create chatter until there's some moderate torque in play. Push it a little more than part throttle and it starts to lock and spin the inside wheel to keep pace with the outside.

The inside wheelspin of the Torsen in steep, tight uphill corners is gone - it feels like just grips, and I didn't notice anything that felt like it wanted to 'push'. I'm looking forward to trying it at the Noosa Hillclimb in November.

I think I will have to do another motorkhana with this diff!

Clutch pack diffs are a new experience for me. I was happy with the Mazda Torsen that I thought I had until it became a single spinner. When I pulled it out, I discovered it was an aftermarket 'OBX' helical (essentially a torsen style diff). After I replaced the after market helical with a Mazda Torsen, I researched the failure. I found that the OBX helical diff is known to fail as a result of poor quality Bellville washers that provide preload to the gears that limit the slip. The OBX is also rebuildable. I also read that Mazda torsens used in spec miata racing are known to lose effectiveness for essentially the same reason that my aftermarket unit had failed, and are not so easily rebuilt.

Persistent inside wheelspin and the spectre of failed Torsen diffs, combined are the reason I decided to sell the Mazda LSD and switch to the current diff.

I still have the OBX helical, and have ordered the parts required to rebuild it. I also have a 3.6 open diff into which the OBX helical will be installed once fixed. This will go in the spare parts stash.

After reading reviews of the OSG diff, I wasn't expecting the chatter this one makes. It is factory S Spec 1.5 way.

Once the diff 'grips' under light load it seems to hold itself partly clamped (unless there's been some firm engine braking), which seems to lead to some chatter if you happen to do a u-turn or tight low speed turn, but otherwise it's mostly invisible. Tight figure-8's don't create chatter until there's some moderate torque in play. Push it a little more than part throttle and it starts to lock and spin the inside wheel to keep pace with the outside.

The inside wheelspin of the Torsen in steep, tight uphill corners is gone - it feels like just grips, and I didn't notice anything that felt like it wanted to 'push'. I'm looking forward to trying it at the Noosa Hillclimb in November.

I think I will have to do another motorkhana with this diff!

Clutch pack diffs are a new experience for me. I was happy with the Mazda Torsen that I thought I had until it became a single spinner. When I pulled it out, I discovered it was an aftermarket 'OBX' helical (essentially a torsen style diff). After I replaced the after market helical with a Mazda Torsen, I researched the failure. I found that the OBX helical diff is known to fail as a result of poor quality Bellville washers that provide preload to the gears that limit the slip. The OBX is also rebuildable. I also read that Mazda torsens used in spec miata racing are known to lose effectiveness for essentially the same reason that my aftermarket unit had failed, and are not so easily rebuilt.

Persistent inside wheelspin and the spectre of failed Torsen diffs, combined are the reason I decided to sell the Mazda LSD and switch to the current diff.

I still have the OBX helical, and have ordered the parts required to rebuild it. I also have a 3.6 open diff into which the OBX helical will be installed once fixed. This will go in the spare parts stash.

After reading reviews of the OSG diff, I wasn't expecting the chatter this one makes. It is factory S Spec 1.5 way.

#25

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

The reason I started down the path towards a clutch-pack diff, was the apparent failure of the 'torsen' that was fitted to my car when I bought it. The diff had begun behaving more like an 'open' and limiting less and less wheelspin. It became most apparent to me that it was 'had it' when a fellow competitor at last year's Noosa Hillclimb sent me this clip of the White Mouse leaving the start line, and doing a very convincing single wheel peal.

On further inspection, it was clear that something inside the diff had come adrift:

As a result it, came out and was replaced with another torsen. At that point I discovered that what I had was actually and OBX helical diff and not a factory Torsen. I also learned that these are prone to failure of the belleville washers and are rebuild-able. The 'slop' visible in the video above seemed likely to be the failure of the bellville washers.

I over the last few weeks, I got around to disassembling the diff center with a view to rebuilding it, with new belleville washers and bolts.

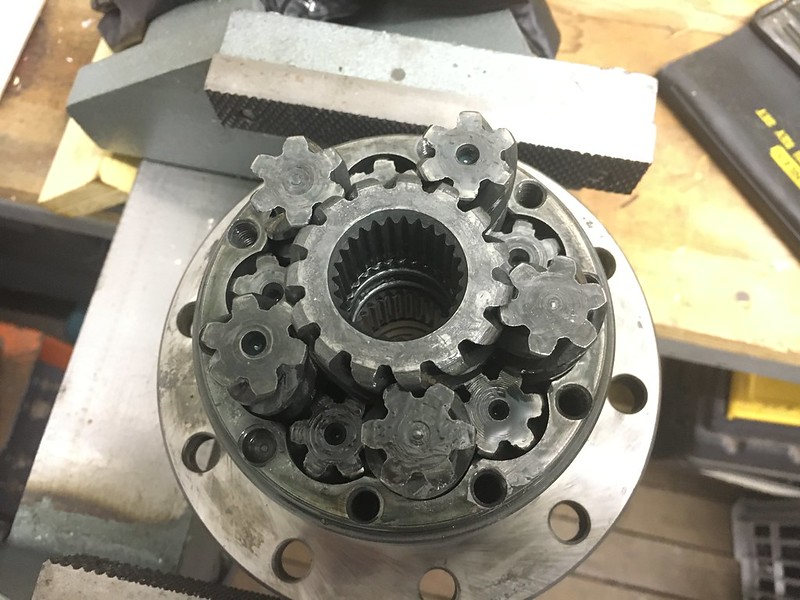

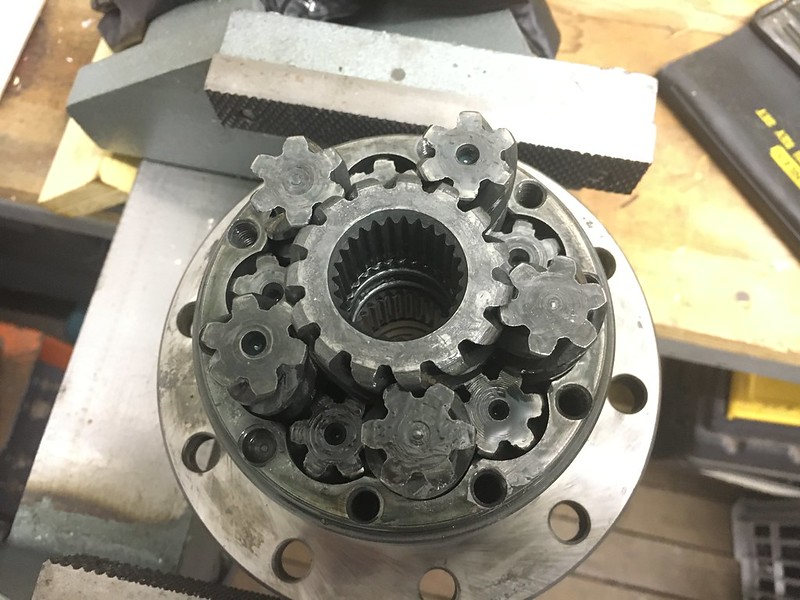

Removing one side of the case reveals a collection of gears:

Between the left hand and right hand center gears, at least 6 washers should be present and be providing preload to the diff: I found only two remaining that looked like this:

The second observation, less obvious, was that the two center gears had been installed in reverse, meaning that under forward load, they would be drawn together rather than being forced into contact with the very stout housing. The result of this is that the belleville washers take the full load and friction of the drive and as a result, fail quickly.

So where did the other 4 washers go to? The got chomped up and powdered:

There is no where for the broken washers to go within the housing except through the gears, and this particular main gear appeared to have done most of the chewing. . I spent a good while cleaning metal powder and flakes of washer out of many places.

. I spent a good while cleaning metal powder and flakes of washer out of many places.

The washers are held within a single case that sits between the central gears, and are sandwiched between two splined washers that are designed to slide in and out of the central case as the washers deflect.

The washers are stacked like so to create the preload spacing that keeps the main gears of the LSD pressed against the housing:

Sitting inside the splined washer, and inside the central housing:

The two halves of the diff go together, located with a single down and clamp on the washers. I used blue Locktight on the bolts and torqued to the recommended 28ft/lbs. Sometime soon, I will get it installed in a spare 3.63 open diff.

On further inspection, it was clear that something inside the diff had come adrift:

As a result it, came out and was replaced with another torsen. At that point I discovered that what I had was actually and OBX helical diff and not a factory Torsen. I also learned that these are prone to failure of the belleville washers and are rebuild-able. The 'slop' visible in the video above seemed likely to be the failure of the bellville washers.

I over the last few weeks, I got around to disassembling the diff center with a view to rebuilding it, with new belleville washers and bolts.

Removing one side of the case reveals a collection of gears:

Between the left hand and right hand center gears, at least 6 washers should be present and be providing preload to the diff: I found only two remaining that looked like this:

The second observation, less obvious, was that the two center gears had been installed in reverse, meaning that under forward load, they would be drawn together rather than being forced into contact with the very stout housing. The result of this is that the belleville washers take the full load and friction of the drive and as a result, fail quickly.

So where did the other 4 washers go to? The got chomped up and powdered:

There is no where for the broken washers to go within the housing except through the gears, and this particular main gear appeared to have done most of the chewing.

. I spent a good while cleaning metal powder and flakes of washer out of many places.

. I spent a good while cleaning metal powder and flakes of washer out of many places.The washers are held within a single case that sits between the central gears, and are sandwiched between two splined washers that are designed to slide in and out of the central case as the washers deflect.

The washers are stacked like so to create the preload spacing that keeps the main gears of the LSD pressed against the housing:

Sitting inside the splined washer, and inside the central housing:

The two halves of the diff go together, located with a single down and clamp on the washers. I used blue Locktight on the bolts and torqued to the recommended 28ft/lbs. Sometime soon, I will get it installed in a spare 3.63 open diff.

#28

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

The White Mouse has had only a few outings this year. My young family and work related travel are taking precedence over play time with the car.

The first adventure for the year was to a regional street sprint event - The Oakey Street Sprints. This event is held on streets in an industrial area, and usually attracts up to 200 competitors. This was my best attempt at the course and it was enough to grab first in the class for the weekend:

Unfortunately, my last run of the weekend ended like this:

Fortunately for me, someone in a Mini had already cleared out a large section of industrial fencing behind the tyre bundle I collected, otherwise the damage would have been more significant. The cause? Driver error ultimately. I missed my braking point and experienced massive brake fade and couldn't slow enough for the corner to get around it.

Fortunately, the damage was superficial. A new guard and mirror were all that was required to get the car back into usable shape for the next event.

Sadly, my fog light oil cooler was a casualty. Amazingly, the lines and cooler did not rupture inspite of being smashed off the car, and then driven over to the point of causing the front wheel to skid on the cooler core.

The next event was the Noosa Hillclimb. It was a bit of a non-event for me. I was way off my previous pace - I think I was still a bit nervous after the last incident.

Between the Noosa Hillclimb and the following event, I changed my coilovers with relatively soft spring rates for a new set at 600/400. I had a bit of fun with the gopro and a timelapse:

The first adventure for the year was to a regional street sprint event - The Oakey Street Sprints. This event is held on streets in an industrial area, and usually attracts up to 200 competitors. This was my best attempt at the course and it was enough to grab first in the class for the weekend:

Unfortunately, my last run of the weekend ended like this:

Fortunately for me, someone in a Mini had already cleared out a large section of industrial fencing behind the tyre bundle I collected, otherwise the damage would have been more significant. The cause? Driver error ultimately. I missed my braking point and experienced massive brake fade and couldn't slow enough for the corner to get around it.

Fortunately, the damage was superficial. A new guard and mirror were all that was required to get the car back into usable shape for the next event.

Sadly, my fog light oil cooler was a casualty. Amazingly, the lines and cooler did not rupture inspite of being smashed off the car, and then driven over to the point of causing the front wheel to skid on the cooler core.

The next event was the Noosa Hillclimb. It was a bit of a non-event for me. I was way off my previous pace - I think I was still a bit nervous after the last incident.

Between the Noosa Hillclimb and the following event, I changed my coilovers with relatively soft spring rates for a new set at 600/400. I had a bit of fun with the gopro and a timelapse:

#29

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

The next event was a brand new hillclimb event on a range crossing in Central Queensland, near a location known for a historical gold rush.

Makeshift pits set up in the middle of nowhere:

Start line:

Passing a spectator point:

This was my best run for the weekend, and enough for 2nd in class:

Finally, last weekend The White Mouse came back from paint - back to better than new

Makeshift pits set up in the middle of nowhere:

Start line:

Passing a spectator point:

This was my best run for the weekend, and enough for 2nd in class:

Finally, last weekend The White Mouse came back from paint - back to better than new

#30

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

Finally the drought is broken!

Took home a second in class (over 3L) behind an LS engined BMW

[youtu]https://youtu.be/-BOi0rNwFPo[/youtu]

Took home a second in class (over 3L) behind an LS engined BMW

[youtu]https://youtu.be/-BOi0rNwFPo[/youtu]

#32

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

Winter is beautiful weather for motorsport (here at least). This was the second running of this even (ever) and it was over two days this year. I was bumped from 4th in my class by an old Alpha Romeo by .001 seconds. It was clear to me by the end of the weekend that I need more time in the car to be competitive/confident enough to make the times need to get closer to the front.

Last edited by The Australian; 07-20-2019 at 07:55 PM.

#37

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

New DSS axles

and SadFab MR2 hubs

and the White Mouse is ready to roll again - will be competing a round in a sprint event on Sunday.

In other news, the White Mouse now now has a slightly scruffy stablemate - the Black Rat - which I am stripping out for a pure track build, starting with a floor drop for my 6'5" frame, and then a weld in 6pt cage.

and SadFab MR2 hubs

and the White Mouse is ready to roll again - will be competing a round in a sprint event on Sunday.

In other news, the White Mouse now now has a slightly scruffy stablemate - the Black Rat - which I am stripping out for a pure track build, starting with a floor drop for my 6'5" frame, and then a weld in 6pt cage.

#38

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

I thought some here might be interested in my take floor lowering. This is not a kit. The containment seats are now fitted to the floor and the car is off having a full cage built.

#39

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

Since completing the floor drop, I have put a full weld-in cage in the car...

...and have stripped the engine down for forged a rebuild

I'm continuing to enjoy the trove of information that is here to make use of.

The new build will use a Trackspeed manifold which I've had sitting in a box for quite a few years, and a BW EFR6758.

...and have stripped the engine down for forged a rebuild

I'm continuing to enjoy the trove of information that is here to make use of.

The new build will use a Trackspeed manifold which I've had sitting in a box for quite a few years, and a BW EFR6758.

#40

Thread Starter

Junior Member

Joined: Dec 2015

Posts: 222

Total Cats: 73

From: Brisbane, Queensland, Australia

I’m in the process of plumbing up a return style fuel system. The referenced FPR and flex sensor are mounted, and the feed and return lines are underway. A Walbro 460 will go in the tank with upgrades wiring courtesy of Trackspeed.

I have not had any luck finding a NB8A return style rail and so I have been looking at the Radium products.

Do I need a pulse damper (OEM’s would suggest ‘yes’)?

Has anyone checked whether the radium direct mount FPDs will fit under the Mazda manifolds (I have a flat top with deleted EGR)?

**edit** Having reviewed the diagram of the rail and the location of the port in relation to the flat top manifold, it looks like a direct fit should be no problem with EGR removed.

I have not had any luck finding a NB8A return style rail and so I have been looking at the Radium products.

Do I need a pulse damper (OEM’s would suggest ‘yes’)?

Has anyone checked whether the radium direct mount FPDs will fit under the Mazda manifolds (I have a flat top with deleted EGR)?

**edit** Having reviewed the diagram of the rail and the location of the port in relation to the flat top manifold, it looks like a direct fit should be no problem with EGR removed.

Last edited by The Australian; 10-20-2020 at 03:48 PM. Reason: Updating the information