sean's cheap thrills, 90 1.6 with subaru td04

#162

Thread Starter

Joined: Sep 2012

Posts: 4,560

Total Cats: 1,142

From: your mom's house phoenix, AZ

there is an autobody/paint supply place near me though that sells the same stuff, its very good quality. hell it could have some from there. find a body place near you that sells weatherstripping and other auto related rubber products on large rolls, and theyre bound to have something decent.

#163

Thread Starter

Joined: Sep 2012

Posts: 4,560

Total Cats: 1,142

From: your mom's house phoenix, AZ

after more research i have decided 9" wheels wont play nice with offset upper control arm bushings. im going to do an offset bushing in the lower control arm front position only

todays progress

i made the drivers side fender brace. i found the sheet metal is different on each side. the spot where the cable comes through is about 1.5" closer to the firewall on the drivers side. the flat spot i used on the pass side isnt as big on the drivers side. you can see how the front landing ended up right next to the cable in an effort to keep the braces similar length on each side; for no particular reason other than it would have bothered me if they werent.

i was using up some of my old rattle cans and neon green by chance was one of the first i grabbed. i ran out before it was done and did the back in black. this left some of the sides speckled, so it speckled the rest to match and because i was feeling gay.

the pass side was going to be ford blue until that rattle can clogged up, so now its satin black.

rear cannon brace is next and i should get my wheels tomorrow!

todays progress

i made the drivers side fender brace. i found the sheet metal is different on each side. the spot where the cable comes through is about 1.5" closer to the firewall on the drivers side. the flat spot i used on the pass side isnt as big on the drivers side. you can see how the front landing ended up right next to the cable in an effort to keep the braces similar length on each side; for no particular reason other than it would have bothered me if they werent.

i was using up some of my old rattle cans and neon green by chance was one of the first i grabbed. i ran out before it was done and did the back in black. this left some of the sides speckled, so it speckled the rest to match and because i was feeling gay.

the pass side was going to be ford blue until that rattle can clogged up, so now its satin black.

rear cannon brace is next and i should get my wheels tomorrow!

Last edited by hi_im_sean; 08-28-2018 at 01:46 AM.

#164

Joined: Apr 2014

Posts: 18,642

Total Cats: 1,866

From: Beaverton, USA

after more research i have decided 9" wheels wont play nice with offset upper control arm bushings. im going to take emilios advice and do an offset bushing in the lower control arm front position only

Miata Race alignment

todays progress

i made the drivers side fender brace. i found the sheet metal is different on each side. the spot where the cable comes through is about 1.5" closer to the firewall on the drivers side. the flat spot i used on the pass side isnt as big on the drivers side. you can see how the front landing ended up right next to the cable in an effort to keep the braces similar length on each side; for no particular reason other than it would have bothered me if they werent.

i was using up some of my old rattle cans and neon green by chance was one of the first i grabbed. i ran out before it was done and did the back in black. this left some of the sides speckled, so it speckled the rest to match and because i was feeling gay.

the pass side was going to be ford blue until that rattle can clogged up, so now its satin black.

rear cannon brace is next and i should get my wheels tomorrow!

Miata Race alignment

todays progress

i made the drivers side fender brace. i found the sheet metal is different on each side. the spot where the cable comes through is about 1.5" closer to the firewall on the drivers side. the flat spot i used on the pass side isnt as big on the drivers side. you can see how the front landing ended up right next to the cable in an effort to keep the braces similar length on each side; for no particular reason other than it would have bothered me if they werent.

i was using up some of my old rattle cans and neon green by chance was one of the first i grabbed. i ran out before it was done and did the back in black. this left some of the sides speckled, so it speckled the rest to match and because i was feeling gay.

the pass side was going to be ford blue until that rattle can clogged up, so now its satin black.

rear cannon brace is next and i should get my wheels tomorrow!

#166

Thread Starter

Joined: Sep 2012

Posts: 4,560

Total Cats: 1,142

From: your mom's house phoenix, AZ

installed, i also scrubbed everything clean

i went with the "space" theme on the drivers side

you can see the spacer in the pocket there

tubing is 1" 11ga. (.120) steel square, mounts are 1/8" plate, and 1" angle iron btw

most of the bolts holding the fender that go into the bottom of the car behind the rear wheel broke off in the car. can i drill these to the next size up, anyone know if there is enough meat? i vaguely recall this in someone elses thread but i cant remember whos.

i went with the "space" theme on the drivers side

you can see the spacer in the pocket there

tubing is 1" 11ga. (.120) steel square, mounts are 1/8" plate, and 1" angle iron btw

most of the bolts holding the fender that go into the bottom of the car behind the rear wheel broke off in the car. can i drill these to the next size up, anyone know if there is enough meat? i vaguely recall this in someone elses thread but i cant remember whos.

Last edited by hi_im_sean; 12-28-2014 at 11:18 PM.

#168

Thread Starter

Joined: Sep 2012

Posts: 4,560

Total Cats: 1,142

From: your mom's house phoenix, AZ

i dont think so, but im not an ME. its not really a load path for the purpose the brace is serving as far as i can tell; and it would be redundant as the car itself completes the triangle with the structure between the hinges.

#169

Thread Starter

Joined: Sep 2012

Posts: 4,560

Total Cats: 1,142

From: your mom's house phoenix, AZ

3 of the 4 lower fender bolts broke upon removal

the 1 that didnt

i was able to drill them out and retap to M6

i got the headlamp frame straightened out, the headlamp "cover" pounded back flat (those things are surprisingly strong and heavy), and the new fender mounted.

the new fender sucks. its the cheapest china one that was on ebay, so i dont know what i was expecting. one day i will find a clean used OEM replacement.

it isnt bent right at the top and has a huge gap between the hood and headlamp

it need to go in another 1/8" or so, and heres where it sits

i also had to pull the fender out near the door as it wouldn't open, although i did get that gap nice eventually.

the corner bend is shitty

the lower bumper skin to fender bolt doesnt pull tight because the front edge is bent wrong, but it really isnt bad

decent 20ft paint match for a rattle can.

my dial ins came in tuesday

15x9

offset delrin LCA front bushing

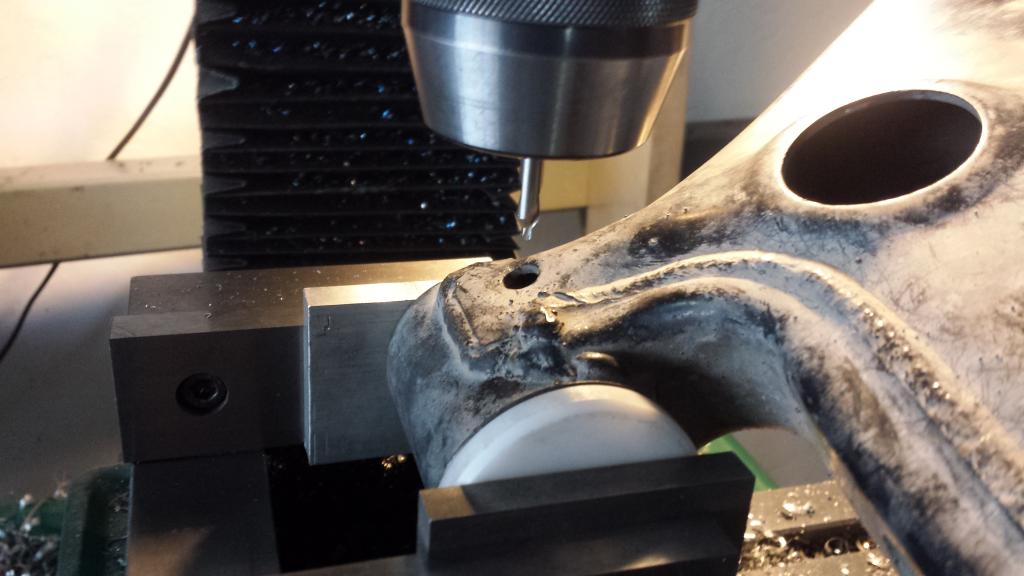

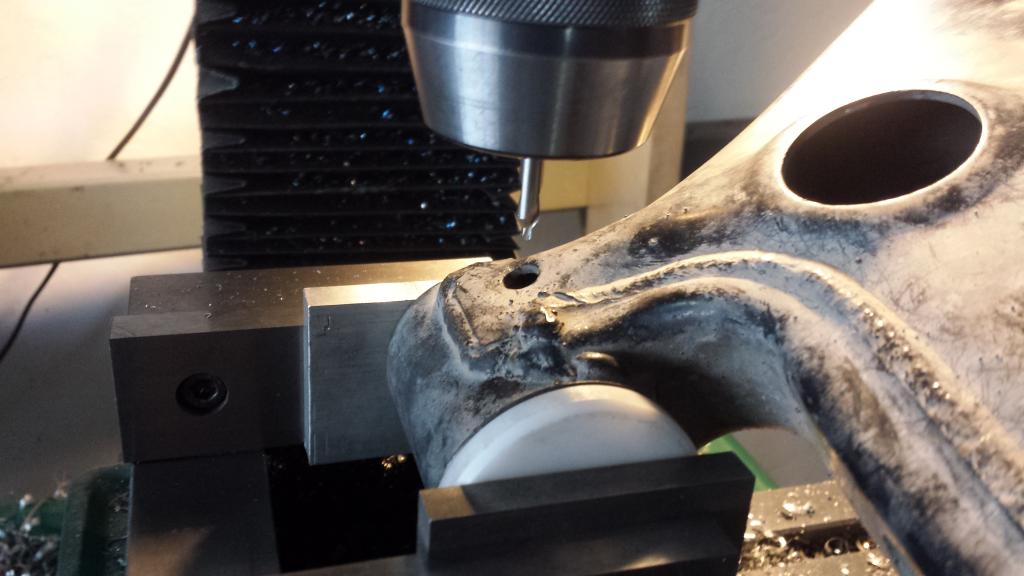

i used a piece of 1/4" scrap under one of the jaws to establish the offset. i started with 5/16" (pictured), but it left about 0.001" wall thickness at the thin point of the offset hole.

i have no idea how much camber this is good for. one can do the math, but its purely academic so i didnt bother.

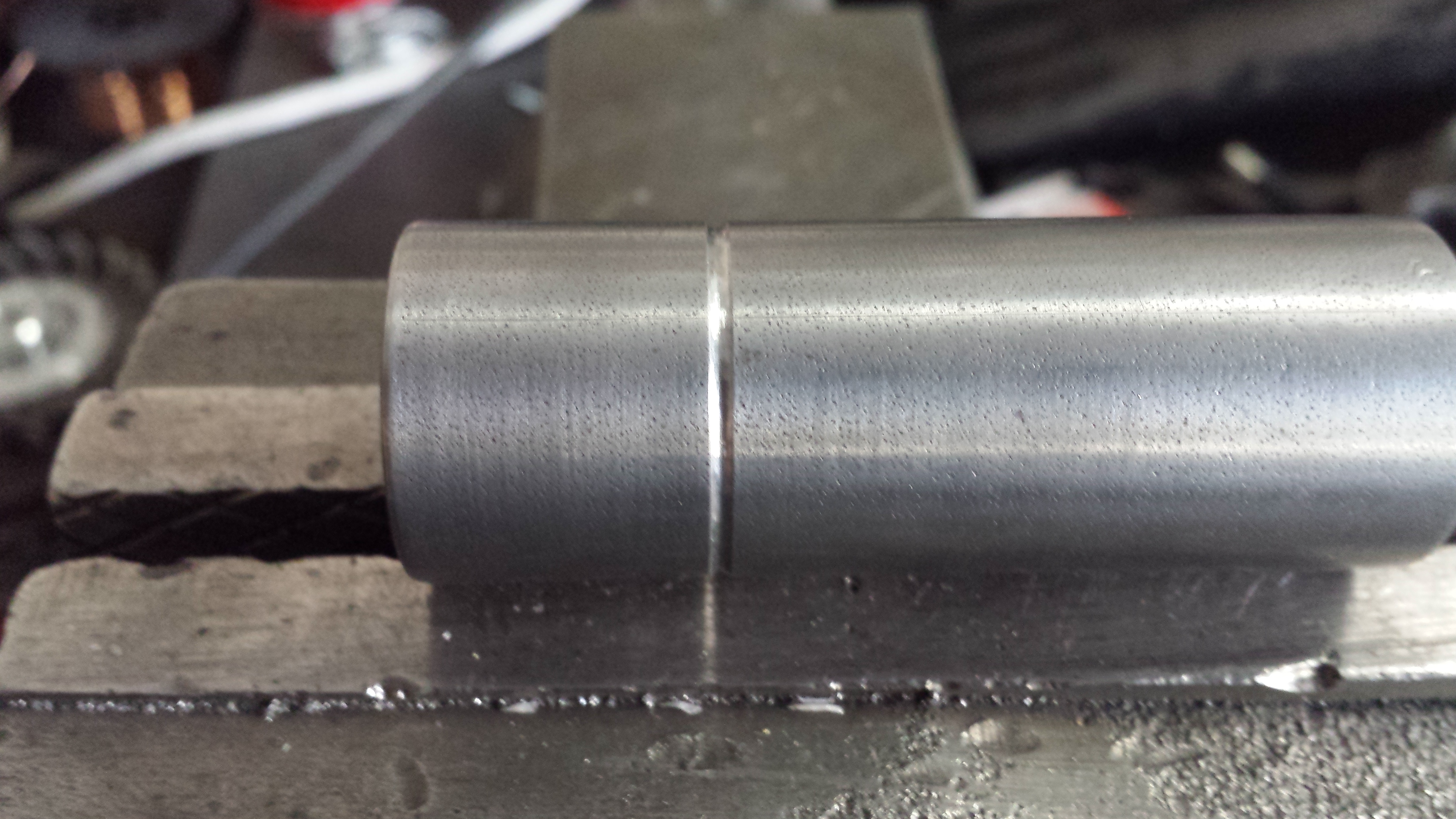

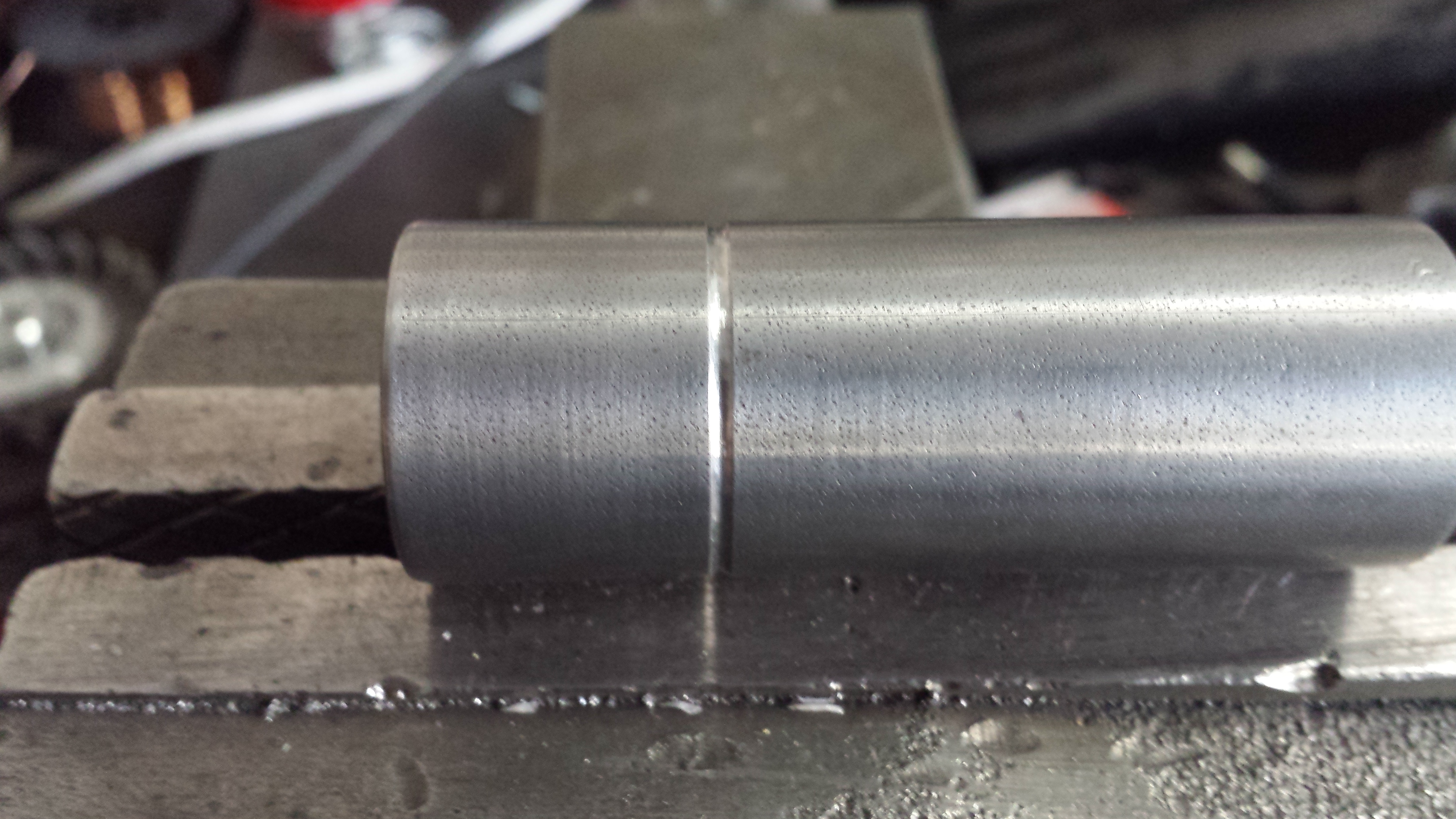

a 1.5" weld T work perfect to press the bushing out

i used 1" round stock for the sleeve. i had to ream the hole out in the bushing with the drill bit post installation as the delrin crushes a little.

grease groove

i drilled through this hole for 1/4"-28 grease fitting

the hardware store is closed today so i couldnt get an extended legth fitting, i only have the short ones.

i found this wonderful publication by dupont on how to properly implement derin as a bushing

http://plastics.dupont.com/plastics/...n/L12565_7.pdf

"A bearing surface should always be provided with interruptions

to allow wear debris to be picked up and, as

much as possible to be removed from the rubbing surface.

This can be achieved by means of longitudinal slots

or simply by radial holes depending on the design

possibilities.

Extensive tests have proven beyond any doubt that maintenance

of a clean rubbing surface increases service life

considerably (Fig. 7.01, curve 5). Axial grooves shown

in Fig. 7.03 may constitute the single most useful design

improvement to a plastic bushing or bearing. "

so to that end i made a sort of broach to slot the bushings

one side is 0.030" depth, the other is 0.060". use the 30, then flip the insert and go to 60.

i should probably do one more slot there somewhere

the 1 that didnt

i was able to drill them out and retap to M6

i got the headlamp frame straightened out, the headlamp "cover" pounded back flat (those things are surprisingly strong and heavy), and the new fender mounted.

the new fender sucks. its the cheapest china one that was on ebay, so i dont know what i was expecting. one day i will find a clean used OEM replacement.

it isnt bent right at the top and has a huge gap between the hood and headlamp

it need to go in another 1/8" or so, and heres where it sits

i also had to pull the fender out near the door as it wouldn't open, although i did get that gap nice eventually.

the corner bend is shitty

the lower bumper skin to fender bolt doesnt pull tight because the front edge is bent wrong, but it really isnt bad

decent 20ft paint match for a rattle can.

my dial ins came in tuesday

15x9

offset delrin LCA front bushing

i used a piece of 1/4" scrap under one of the jaws to establish the offset. i started with 5/16" (pictured), but it left about 0.001" wall thickness at the thin point of the offset hole.

i have no idea how much camber this is good for. one can do the math, but its purely academic so i didnt bother.

a 1.5" weld T work perfect to press the bushing out

i used 1" round stock for the sleeve. i had to ream the hole out in the bushing with the drill bit post installation as the delrin crushes a little.

grease groove

i drilled through this hole for 1/4"-28 grease fitting

the hardware store is closed today so i couldnt get an extended legth fitting, i only have the short ones.

i found this wonderful publication by dupont on how to properly implement derin as a bushing

http://plastics.dupont.com/plastics/...n/L12565_7.pdf

"A bearing surface should always be provided with interruptions

to allow wear debris to be picked up and, as

much as possible to be removed from the rubbing surface.

This can be achieved by means of longitudinal slots

or simply by radial holes depending on the design

possibilities.

Extensive tests have proven beyond any doubt that maintenance

of a clean rubbing surface increases service life

considerably (Fig. 7.01, curve 5). Axial grooves shown

in Fig. 7.03 may constitute the single most useful design

improvement to a plastic bushing or bearing. "

so to that end i made a sort of broach to slot the bushings

one side is 0.030" depth, the other is 0.060". use the 30, then flip the insert and go to 60.

i should probably do one more slot there somewhere

Last edited by hi_im_sean; 01-02-2015 at 10:55 AM.

#171

Thread Starter

Joined: Sep 2012

Posts: 4,560

Total Cats: 1,142

From: your mom's house phoenix, AZ

thanks porkchop.

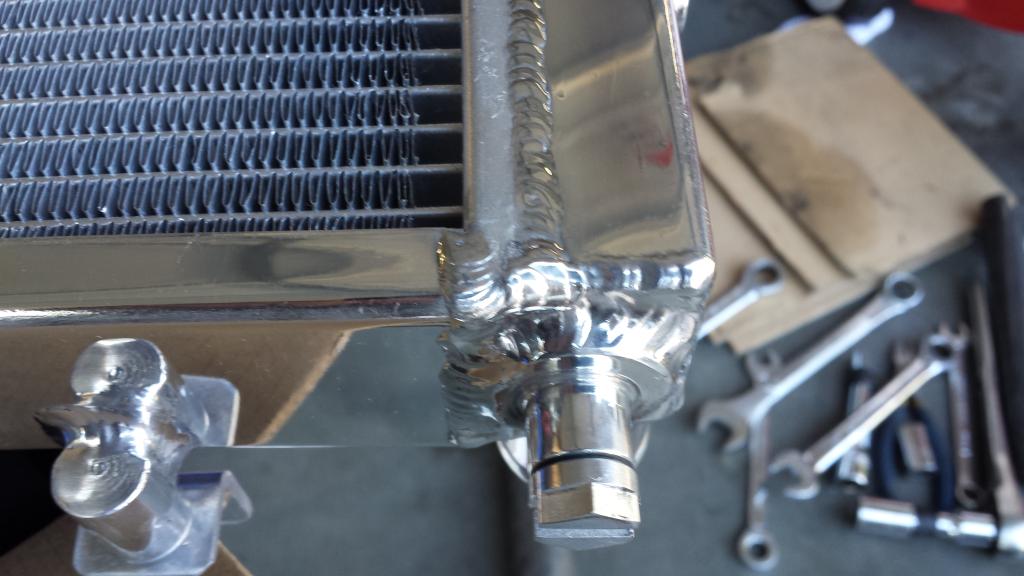

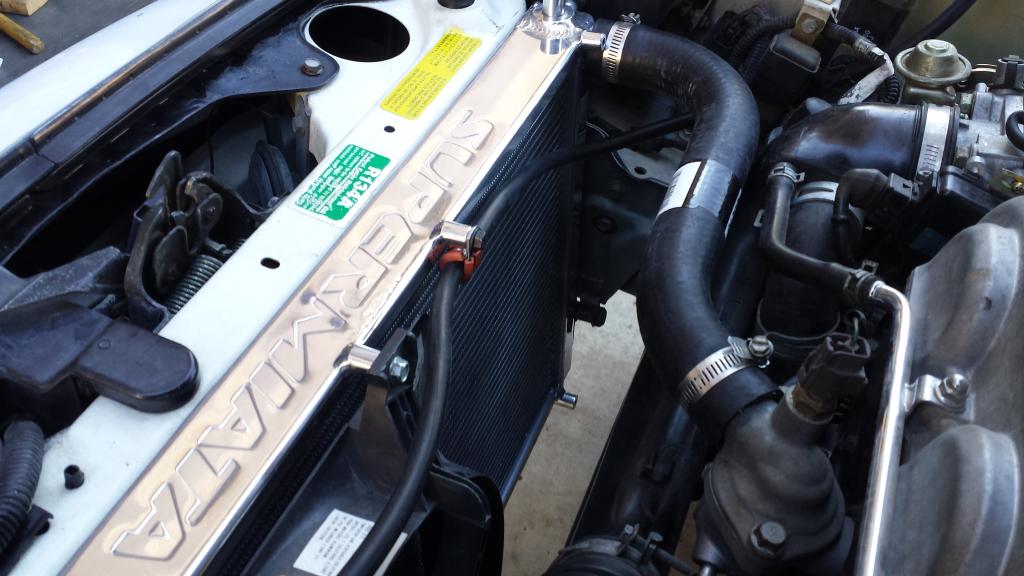

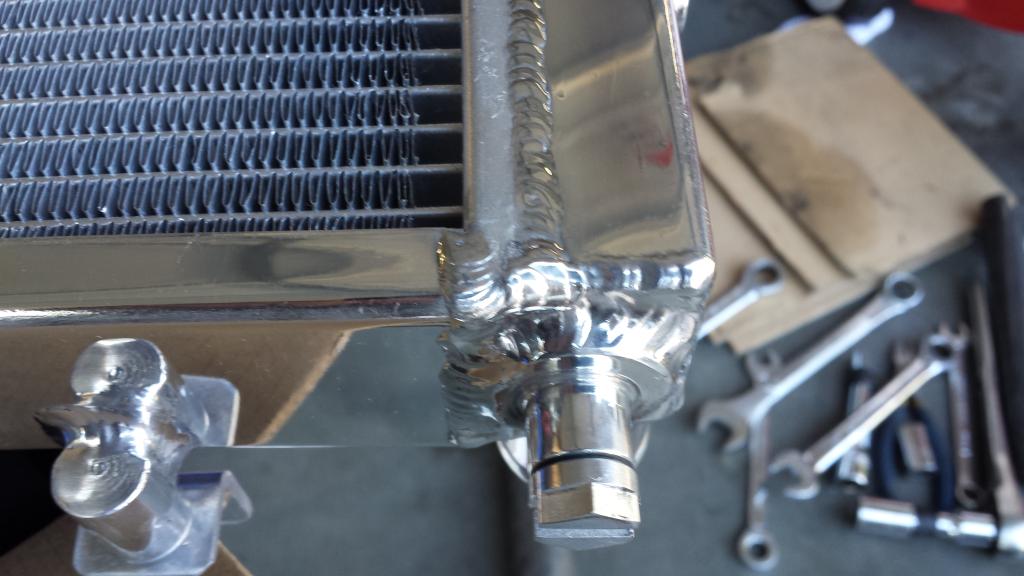

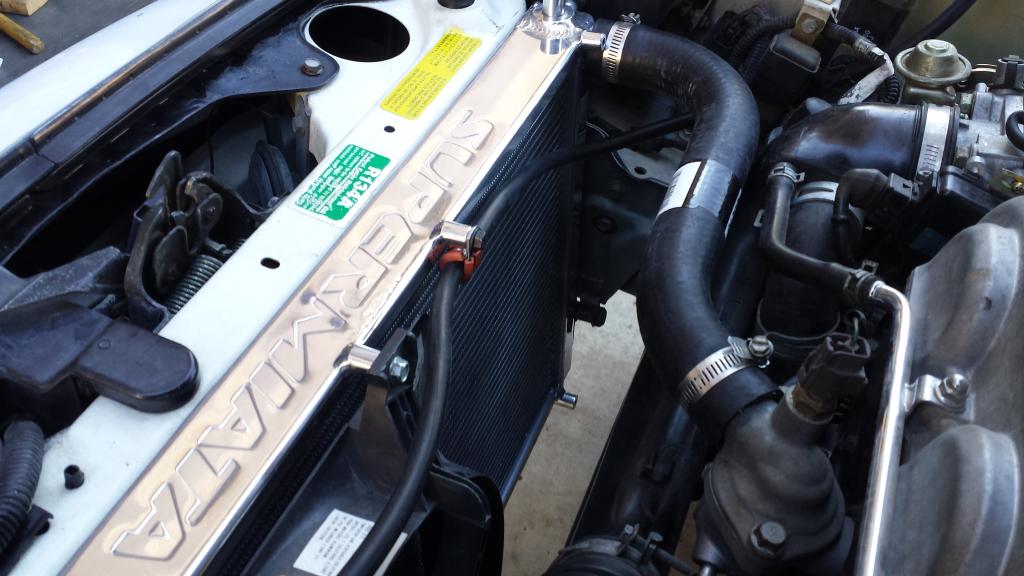

i got my 949 crossflow radiator. i did a garden hose flush, and tried to fix some minor leaks ive had on the lower hoses.

one of my pet peeves is when people slide the hose clamp all the way back to the end of the hose away from the lip of the nipple. this car has had every coolant connection "fastened" in that way. this is why you dont do that:

this was the 2nd best of the 3 i "cleaned" today.

1/8"+ thick goo and rust

all scraped off

heres the other end of the same pipe after i cleaned it. a lot of it is corroded away, i had to file the edges down because the were sharp from the corrosion.

new rad

its pretty

fan trimming

new vs old hose. i didnt realize 949 sold one for a non reroute car, so i matched one up at oriely. its for a hyundai.

overflow line

i got my 949 crossflow radiator. i did a garden hose flush, and tried to fix some minor leaks ive had on the lower hoses.

one of my pet peeves is when people slide the hose clamp all the way back to the end of the hose away from the lip of the nipple. this car has had every coolant connection "fastened" in that way. this is why you dont do that:

this was the 2nd best of the 3 i "cleaned" today.

1/8"+ thick goo and rust

all scraped off

heres the other end of the same pipe after i cleaned it. a lot of it is corroded away, i had to file the edges down because the were sharp from the corrosion.

new rad

its pretty

fan trimming

new vs old hose. i didnt realize 949 sold one for a non reroute car, so i matched one up at oriely. its for a hyundai.

overflow line

#174

Thread Starter

Joined: Sep 2012

Posts: 4,560

Total Cats: 1,142

From: your mom's house phoenix, AZ

thanks nigelt

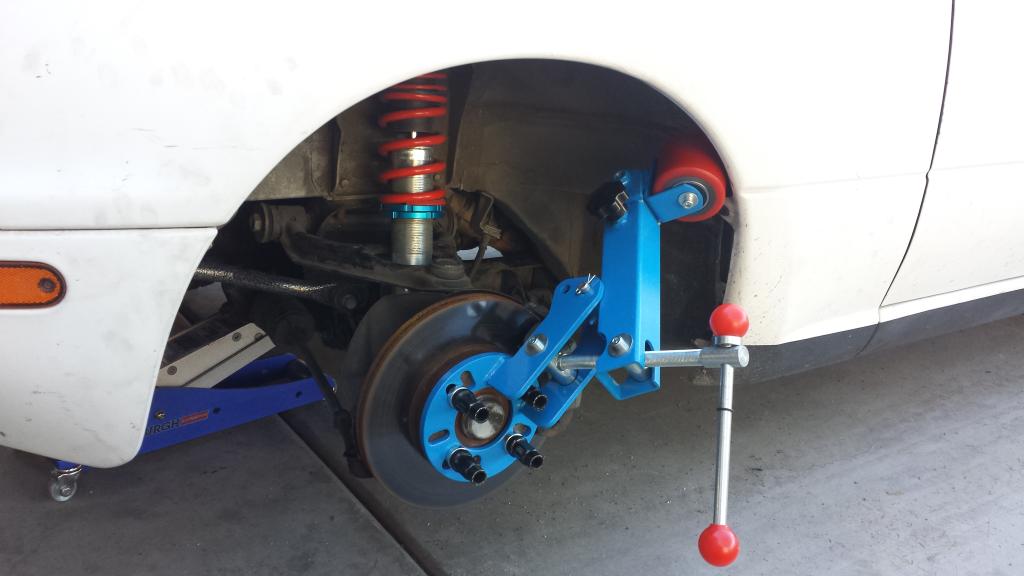

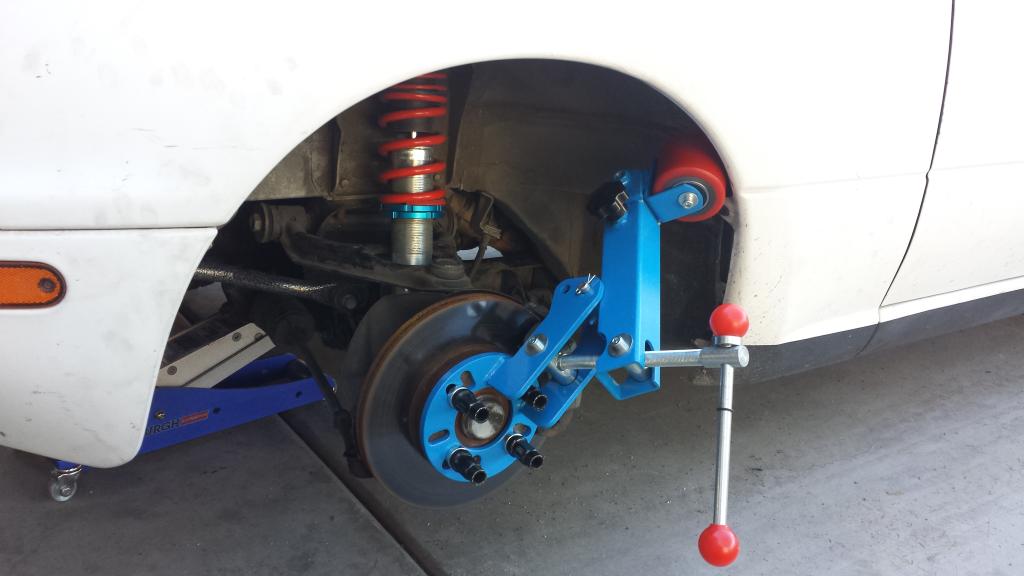

i got my tires stretched... i mean installed onto the rims...

i dont like, cant wait until these wear so i can get 225s

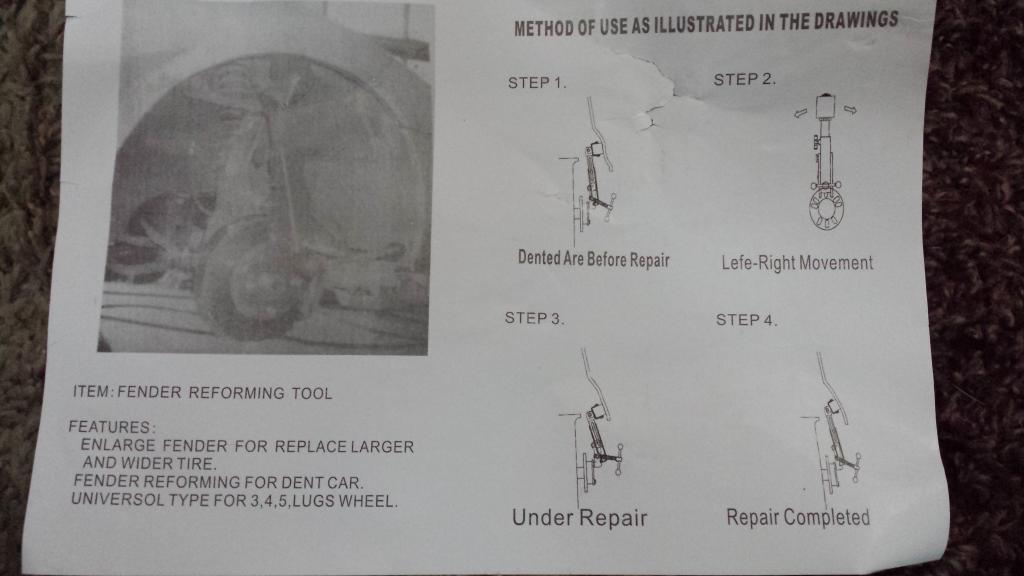

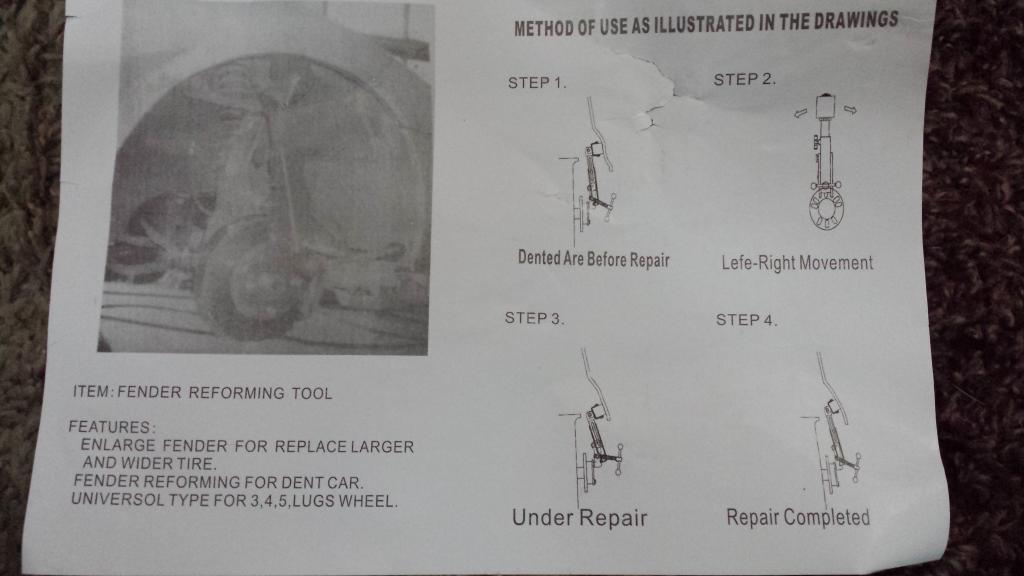

got the $65 ebay fender roller. i cant believe they can make a profit on these at $65, im quite impressed with it for what it is.

the engrish is great

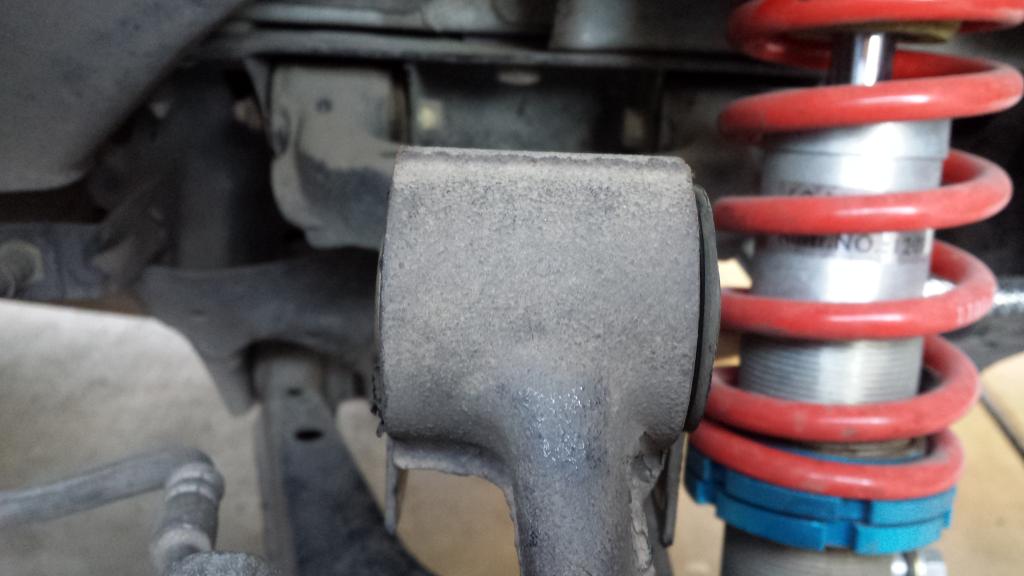

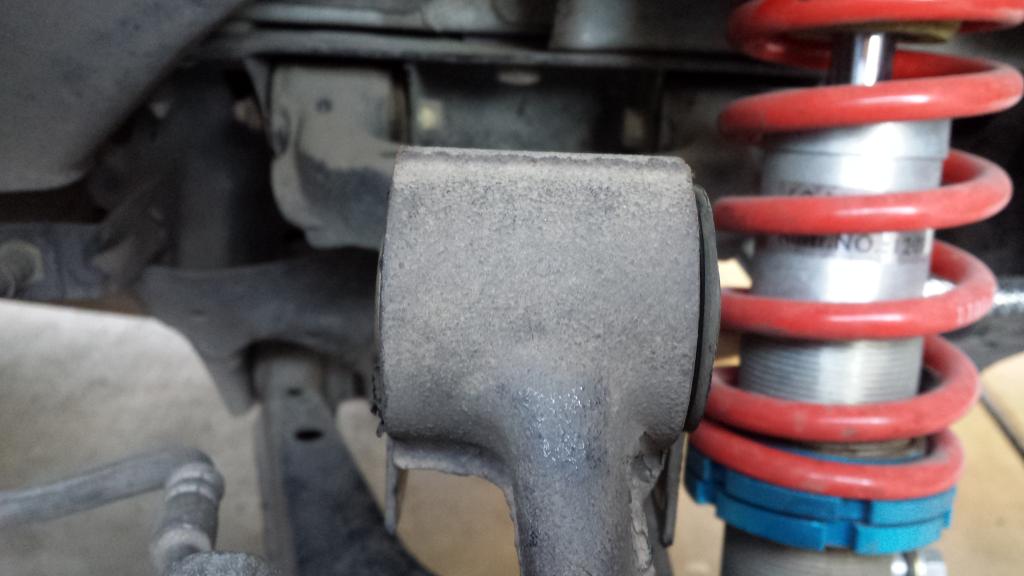

i did my rear knuckle uppers

before

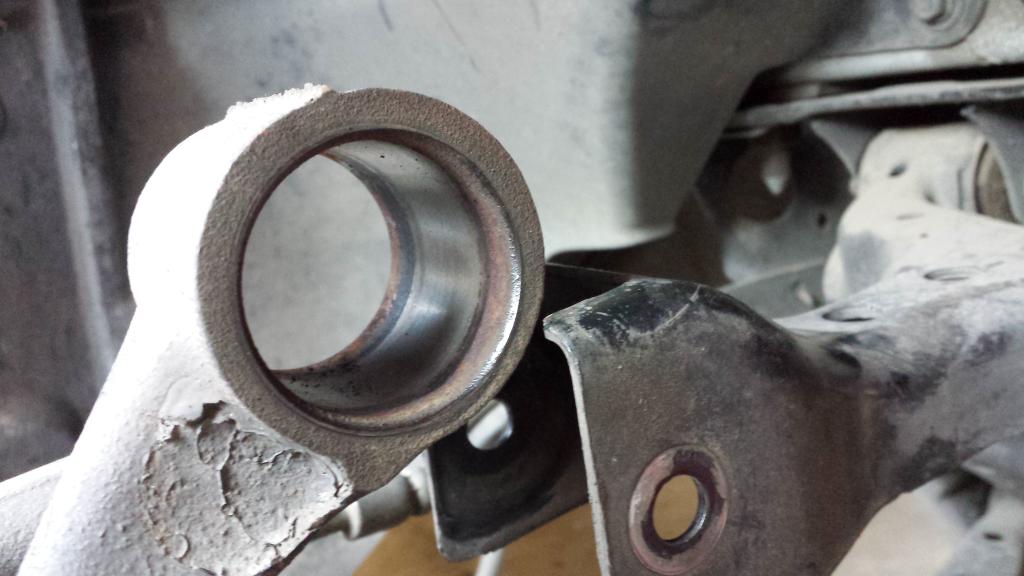

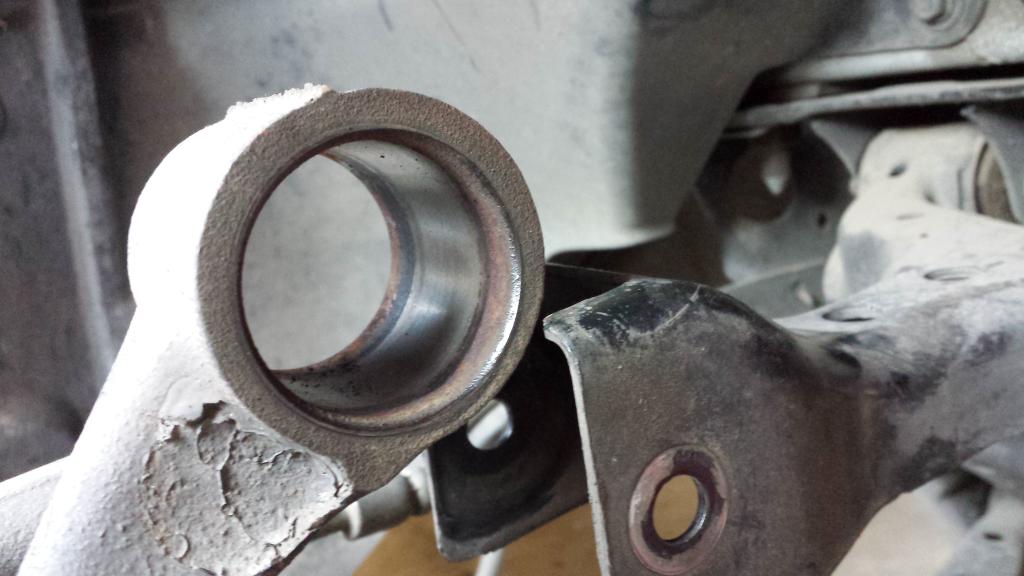

pushed out by hand, easily

after cleaning with sand paper

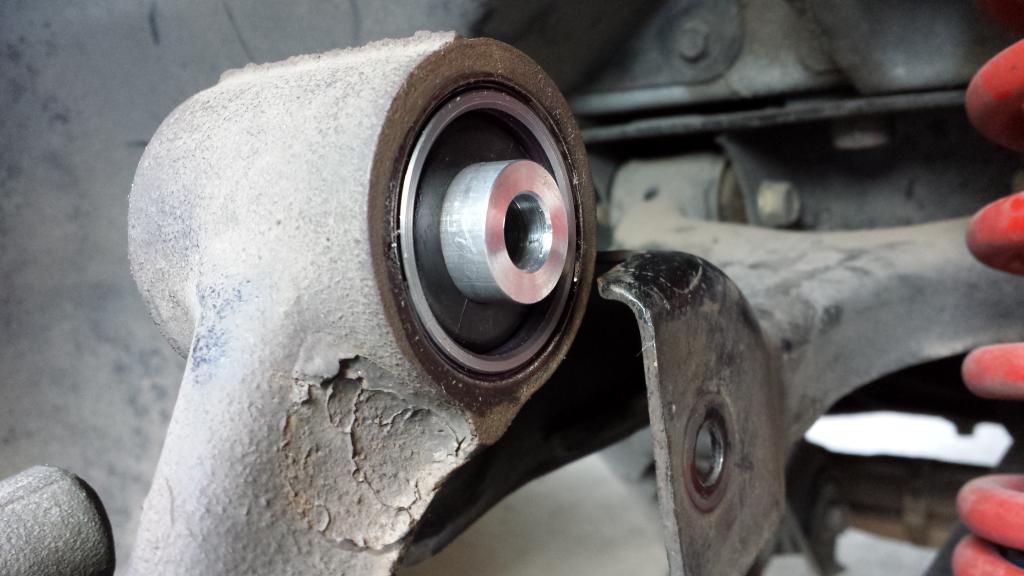

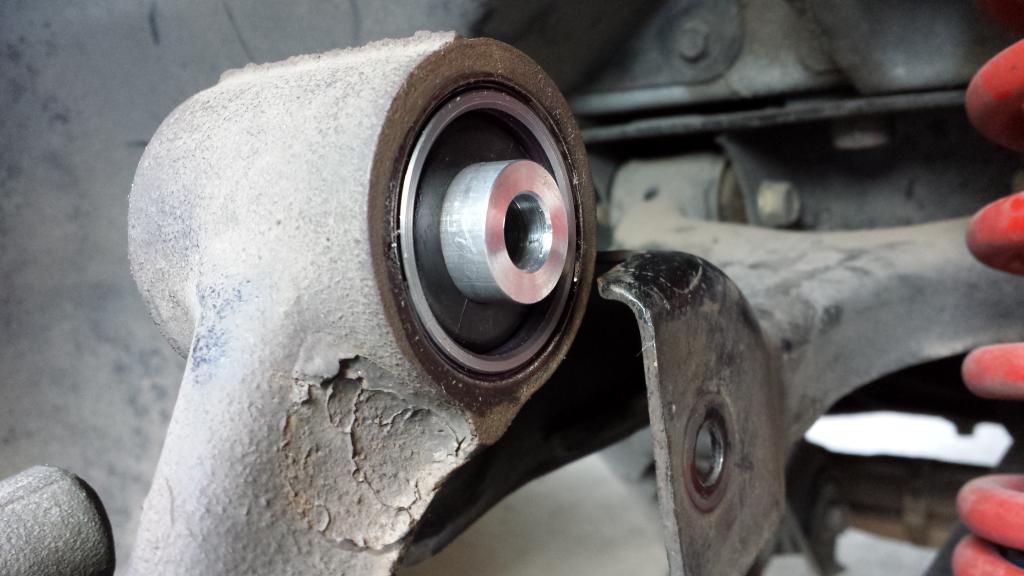

my replacement sleeve, spherical assembly with harbor freight grommet seals

greased

"loctited" in

clamped and dried overnight

assembled this morning

so now its alignment time and id like some input

-205 bfg rivals on 15x9, will be going to 225 after these wear out

-504/336lb srpings on vmaxx

-FM sways

-4.75" front, 5" rear ride height

-track only alignment. although i do drive it to events and on the street occasionally, im not concerned with street wear.

i was thinking

front:

-3 camber

5 ish caster

0 toe

rear:

-2.6 camber

0-1/6" toe

i got my tires stretched... i mean installed onto the rims...

i dont like, cant wait until these wear so i can get 225s

got the $65 ebay fender roller. i cant believe they can make a profit on these at $65, im quite impressed with it for what it is.

the engrish is great

i did my rear knuckle uppers

before

pushed out by hand, easily

after cleaning with sand paper

my replacement sleeve, spherical assembly with harbor freight grommet seals

greased

"loctited" in

clamped and dried overnight

assembled this morning

so now its alignment time and id like some input

-205 bfg rivals on 15x9, will be going to 225 after these wear out

-504/336lb srpings on vmaxx

-FM sways

-4.75" front, 5" rear ride height

-track only alignment. although i do drive it to events and on the street occasionally, im not concerned with street wear.

i was thinking

front:

-3 camber

5 ish caster

0 toe

rear:

-2.6 camber

0-1/6" toe

#176

Thread Starter

Joined: Sep 2012

Posts: 4,560

Total Cats: 1,142

From: your mom's house phoenix, AZ

i got the fenders rolled and the tires mounted. clearance with 9" wheels is better than i expected. we probably didnt even have to roll the front with these 205s, but did anyway. the rears needed a little more clearance, so we rolled the lip back all the way, and i think mike got a little ambitious and even pulled the quater panels out a little.

china fender roller is awesome with the caveat that the nylock nut on the main adjusting screw kept backing off. loctite or a pin will fix that.

i gave it a bath after this pic, you can see out greasy hand prints all over the car. these wheels look great on this car.

i havnt messed with or checked the ride heights since a week or 2 after i installed the vmaxxs. i figured now would be a good time after all the screwing around with suspension, and because i found the passenger side upper control bushing bound from someone tightening the bolt with the wheel off the ground. the measurements were all over the place. so i fixed them and ended up with 4.5"/4.75" F/R pinch heights.

while i was doing that i discovered the pass side wheel had toe slop. traced it down to the inner tie rod. got all new inners and outers, and installed them on monday. i was about to go get an alignment when i noticed the drivers side hub is going bad. its a timken with about 1000 track miles and maybe 500 street miles. at this point my dumbass finally lifted every wheel on the car and wiggled them in every direction to make sure nothing else was going bad. i have a track day saturday, so i didnt want to risk waiting on a replacement hub from amazon/rockauto/ebay etc. none of the auto parts chains could get me a brand name in any reasonable amount of time. i guess the master warehouse was out of stock with no eta.... so i got a dura international for $44 from what used to be BAP and is now parts authority.

i was going to attempt "blue printing" this timken until i found this.

i havnt had a chance to wipe the races clean to see how they look, but im sure with this spalled ball, they arnt going to be useable.

so now i have an alignment scheduled at the last minute on friday. i took the car for a spin and first impressions are good. its the first time ive driven it since offset delrin bushings, rear upper spherical, 15x9s with new rivals, and fender braces. its not even aligned and turn in and response are much improved.

china fender roller is awesome with the caveat that the nylock nut on the main adjusting screw kept backing off. loctite or a pin will fix that.

i gave it a bath after this pic, you can see out greasy hand prints all over the car. these wheels look great on this car.

i havnt messed with or checked the ride heights since a week or 2 after i installed the vmaxxs. i figured now would be a good time after all the screwing around with suspension, and because i found the passenger side upper control bushing bound from someone tightening the bolt with the wheel off the ground. the measurements were all over the place. so i fixed them and ended up with 4.5"/4.75" F/R pinch heights.

while i was doing that i discovered the pass side wheel had toe slop. traced it down to the inner tie rod. got all new inners and outers, and installed them on monday. i was about to go get an alignment when i noticed the drivers side hub is going bad. its a timken with about 1000 track miles and maybe 500 street miles. at this point my dumbass finally lifted every wheel on the car and wiggled them in every direction to make sure nothing else was going bad. i have a track day saturday, so i didnt want to risk waiting on a replacement hub from amazon/rockauto/ebay etc. none of the auto parts chains could get me a brand name in any reasonable amount of time. i guess the master warehouse was out of stock with no eta.... so i got a dura international for $44 from what used to be BAP and is now parts authority.

i was going to attempt "blue printing" this timken until i found this.

i havnt had a chance to wipe the races clean to see how they look, but im sure with this spalled ball, they arnt going to be useable.

so now i have an alignment scheduled at the last minute on friday. i took the car for a spin and first impressions are good. its the first time ive driven it since offset delrin bushings, rear upper spherical, 15x9s with new rivals, and fender braces. its not even aligned and turn in and response are much improved.

#178

Thread Starter

Joined: Sep 2012

Posts: 4,560

Total Cats: 1,142

From: your mom's house phoenix, AZ

thanks!

nope.

it went up $10! it was $64.99 when i bought mine about 2 weeks ago.

4x100 4x114 Fender Roller Inner Lip Forming Rolling Tool Kit Stance 4 Lug | eBay

other options

A Fender Panel Roller Tool Auto Body Shop Extending Extend Tool | eBay

New Wheel Arch Roller Tool Flaring Heavy Duty | eBay

#180

Thread Starter

Joined: Sep 2012

Posts: 4,560

Total Cats: 1,142

From: your mom's house phoenix, AZ

thanks aidan

got my alignment done today, just in time for tomorrow. the alignment shop was able to reach all of my alignment goals. i ended up with:

front

camber: -3

caster: 4.5 (thats the most they could get and keep each side equal and not sacrifice camber, im happy with it)

toe: 0

rear

camber: -2.7

toe: 1/16" in

i did an A/B test and drove the 205 kumho XS on 6.5"s combo and then the 205 rivals on 15x9s combo back to back to see how much of the improvements the wheel is responsible for. the difference is staggering. i used to think the car was so much tighter when i swapped between the daisies with 195s, and the kumho/6.5" combo, and now the 6.5" feels floppy and ridiculous to me. im so glad i went with 9s as i almost got 8s instead.

can i get a tire pressure recommendation for the 15x9/205 rival combo? i was thinking of starting at 28 psi, maybe less? we were running the kumhos at 32-33 cold

got my alignment done today, just in time for tomorrow. the alignment shop was able to reach all of my alignment goals. i ended up with:

front

camber: -3

caster: 4.5 (thats the most they could get and keep each side equal and not sacrifice camber, im happy with it)

toe: 0

rear

camber: -2.7

toe: 1/16" in

i did an A/B test and drove the 205 kumho XS on 6.5"s combo and then the 205 rivals on 15x9s combo back to back to see how much of the improvements the wheel is responsible for. the difference is staggering. i used to think the car was so much tighter when i swapped between the daisies with 195s, and the kumho/6.5" combo, and now the 6.5" feels floppy and ridiculous to me. im so glad i went with 9s as i almost got 8s instead.

can i get a tire pressure recommendation for the 15x9/205 rival combo? i was thinking of starting at 28 psi, maybe less? we were running the kumhos at 32-33 cold