Petrolmed's basic Artech build

#81

Thanks Wes. I was using that advice and being gentle on the rubber hose clamp while tightening, but it appears the leak is coming from the core itself and not the pipe connections. It's leaking much more now and smells like raw coolant. Gonna flush the system with water to it's not so messy and while the car is down begin my saga of biking to work haha.

Anyone ever done an NB heater box/Al core upgrade? Looks more robust and mobile with two proper hard hose clamps. Seems preferable to the single long hose on NA units.

Anyone ever done an NB heater box/Al core upgrade? Looks more robust and mobile with two proper hard hose clamps. Seems preferable to the single long hose on NA units.

#82

So I've sourced a replacement unit and in preparation for the removal I flushed the system with straight water. Drove it a bit and now it doesn't leak even after a good bit of romping. The mixture before might not have been cooling enough, resulting in high pressures which pushed through whatever minor gap there is in my heater. I'll still replace it but now its just not as urgent.

Before it leaked after a 2 mile limping trip to pick up DI water. I just drove around town hard with plenty of boost and no leakage

Before it leaked after a 2 mile limping trip to pick up DI water. I just drove around town hard with plenty of boost and no leakage

#85

Hells yeah! So, details: I got my hands on some gen 2s with 550/350 springs. I've got a pretty good grasp of them now that my ride height and alignments are settled. Though this is a huge upgrade for me, I think I can be objective about what they bring to the table. This is on 195 S. Drives, ~4.75", and dual duty alignment btw.

What impresses me most is their range of damping adjustability. At full soft (20 clicks, CCW) they are pretty floppy which has its pros and cons. Bumps are smoothly mitigated but it doesn't feel stabilized enough when you're on respectable surfaces and can allow a good bit of movement from sudden transitions, especially on/off throttle rocking. The lowest I go now is 2 or 3 from full soft, which have about as much comfort but don't let the suspension move so much with speed bumps, sudden braking, etc.

I keep it at 4 clicks from full soft unless I'm expecting crap roads. That is a good setting for my sporty DDing, retaining a large fraction the comfort component and the awesome handling characteristics which is what you should be buying these for

. On ramps that I would take between 40-50 with limited confidence are now doable at about 60. My click settings will likely move further from soft for more high performance tires which I really want now. I'll report on that in the spring.

. On ramps that I would take between 40-50 with limited confidence are now doable at about 60. My click settings will likely move further from soft for more high performance tires which I really want now. I'll report on that in the spring. The highest I've bothered with is 10 clicks from full soft. It didn't seem to bring any more handling to the table than 6-7 did for my grip levels. It brought more harshness from road imperfections obviously but it is crazy how level the car stays under braking or steering transitions at stiffer settings. Also, that front to back throttle on/off rocking is virtually nonexistent even when trying to force it.

Overall I love them and don't have to worry about buyers guilt on whether I've correctly compromised comfort vs performance. I can just go twist le **** to get one or the other

In other news Seefo took me out for ride along in his HPDE 3 group at VIR last weekend. He is a good driver and knows the track well, so it was an exhilarating first time on a track. It's kinda crazy to see how high the limits are on a properly sorted track car. Now I am excited to get out there and try it for myself. For now I'll settle with the late fall autocrosses, a great perk of being in the south!

#88

Thanks guys, it's growing up to be the build I always knew it could be if it just stayed in school and stopped messing around with the law.

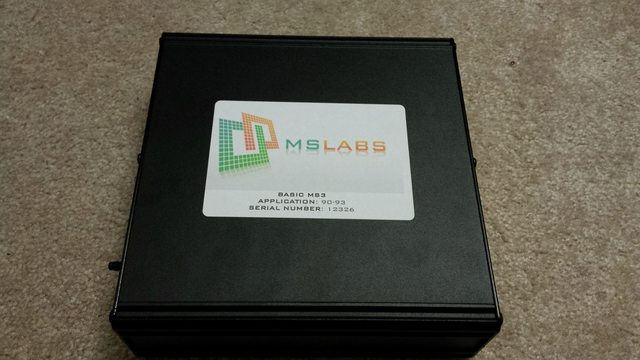

I cleaned a bunch of grime off the head and block and want to finally break it down in the coming weeks. Semi-building it over the winter and MS3 are possibilities on the horizon. And maybe 15x8s to go with the stickier 205s that I will be getting to replace my worn S. drives in the spring. Oh crystal ball and lottery, why are you not at my command?

I cleaned a bunch of grime off the head and block and want to finally break it down in the coming weeks. Semi-building it over the winter and MS3 are possibilities on the horizon. And maybe 15x8s to go with the stickier 205s that I will be getting to replace my worn S. drives in the spring. Oh crystal ball and lottery, why are you not at my command?

#89

Had my first reliability issue in 3 years or so crop up the other day. I drive home from work and as soon as I shut the motor off, steam starts billowing out the back of the head area. Fuuuuuuuuuuuuuuuu! The reservoir is empty and radiator needs a half gallon of water. After prodding around and not finding anything, I attempt a short drive and the same happened on a lesser scale. Refill. It's a slow leak from somewhere.

I basically thought my 1.6 had rage-quit since I saw coolant pooling at the rear corner of the head-block mating surface and thought I'd blew the head gasket externally. Anyway after much searching I notice where the tiny leak is coming from.

It was very hard to see exactly where the drip was coming from to eliminate common culprits of heater hose, neck gasket, vs this damn plug. I replaced the cursed plug with a generic one since it doesn't need to last too long. The motor will be coming out anyway. Crisis averted!

I basically thought my 1.6 had rage-quit since I saw coolant pooling at the rear corner of the head-block mating surface and thought I'd blew the head gasket externally. Anyway after much searching I notice where the tiny leak is coming from.

It was very hard to see exactly where the drip was coming from to eliminate common culprits of heater hose, neck gasket, vs this damn plug. I replaced the cursed plug with a generic one since it doesn't need to last too long. The motor will be coming out anyway. Crisis averted!

#90

I did a thing! I was forced to learn how to set mechanical timing over the weekend, due to a rather unique circumstance, and am now over my hesitancy to mess with timing belt stuff.

Reliability issue #2 is also coolant related! I missed most of the winter storm that hit NC last week with a trip down to SC so I didn't encounter any issues until I returned on Thursday night which saw temperatures of 1* F. This is about 20 less than we had been seeing so far. I go outside Friday morning and 'crank' the car to go to work (aka it turns over extremely laboriously with a unique mechanical sound after each revolution. Then it subsequently stops entirely as if bound in place. This was followed up by a much quicker and free spinning crank than usual). The car wont start even thought the starter's spinning with ease. I can hear puffs of what I imagine is compression with almost ignition going out the tailpipe. I guess now that timing is off? How?

Pop the hood- see pool of partially frozen coolant below the crank pulley with more all over the timing belt and gears. Uncap radiator- hello lemon lime slushie! From my prior coolant issues I ended up not bringing the coolant:water ratio high enough and had a partial freeze at least in the radiator and I imagine less so in the block. My hypothesis is that the water pump was unable to spin easily making the cold start even harder than usual. This coupled with the timing belt having coolant on it (from water neck drip I believe) the belt skipped multiple teeth. Or some weird combination of factors.

Anyway at TDC, both cams were off by at least 15*. So I break it down, loosen the belt, and get everything aligned right. Success, it starts! No leaks from water pump or anything else. Crisis averted.

But wait! The timing marks on my pulley are off by like 70* ATDC. I double check everything, which is fine, and the car is running like normal. Then I read that it's possible to have the timing marks on the pulley move. After verifying TDC, I mark the pulley with that location and then the timing light is dead on. Possibly the marks moved due to me yanking on the pulley while removing it or from the bound up water pump resisting the crank pulley movement during the initial start attempts.

At least I got the opportunity to clean up the front of the engine which was satisfying. Hope it all holds up until I get the new one in.

Reliability issue #2 is also coolant related! I missed most of the winter storm that hit NC last week with a trip down to SC so I didn't encounter any issues until I returned on Thursday night which saw temperatures of 1* F. This is about 20 less than we had been seeing so far. I go outside Friday morning and 'crank' the car to go to work (aka it turns over extremely laboriously with a unique mechanical sound after each revolution. Then it subsequently stops entirely as if bound in place. This was followed up by a much quicker and free spinning crank than usual). The car wont start even thought the starter's spinning with ease. I can hear puffs of what I imagine is compression with almost ignition going out the tailpipe. I guess now that timing is off? How?

Pop the hood- see pool of partially frozen coolant below the crank pulley with more all over the timing belt and gears. Uncap radiator- hello lemon lime slushie! From my prior coolant issues I ended up not bringing the coolant:water ratio high enough and had a partial freeze at least in the radiator and I imagine less so in the block. My hypothesis is that the water pump was unable to spin easily making the cold start even harder than usual. This coupled with the timing belt having coolant on it (from water neck drip I believe) the belt skipped multiple teeth. Or some weird combination of factors.

Anyway at TDC, both cams were off by at least 15*. So I break it down, loosen the belt, and get everything aligned right. Success, it starts! No leaks from water pump or anything else. Crisis averted.

But wait! The timing marks on my pulley are off by like 70* ATDC. I double check everything, which is fine, and the car is running like normal. Then I read that it's possible to have the timing marks on the pulley move. After verifying TDC, I mark the pulley with that location and then the timing light is dead on. Possibly the marks moved due to me yanking on the pulley while removing it or from the bound up water pump resisting the crank pulley movement during the initial start attempts.

At least I got the opportunity to clean up the front of the engine which was satisfying. Hope it all holds up until I get the new one in.

#92

But wait! The timing marks on my pulley are off by like 70* ATDC. I double check everything, which is fine, and the car is running like normal. Then I read that it's possible to have the timing marks on the pulley move. After verifying TDC, I mark the pulley with that location and then the timing light is dead on. Possibly the marks moved due to me yanking on the pulley while removing it or from the bound up water pump resisting the crank pulley movement during the initial start attempts.

At least I got the opportunity to clean up the front of the engine which was satisfying. Hope it all holds up until I get the new one in.

At least I got the opportunity to clean up the front of the engine which was satisfying. Hope it all holds up until I get the new one in.

#93

Yeah, apparently it is a thing that the runner with the timing marks can move independently on the crank pulley since it is mounted with some sort of rubber membrane. Mechanical timing will always be OK, but the indicators can be off. It seems to have happened to me so I just make my own correct timing marks while I could see everything.

Things have been running perfectly since then and the finer tune of the MS3 is coming along nicely.

Things have been running perfectly since then and the finer tune of the MS3 is coming along nicely.

#94

Have I really not updated this in almost a year?

Well I've been dailying it regularly with a couple hiccups due to the 225k miles that I've accumulated, almost 40k boosted. Had an almost seized and very noisy water pump I rushed to replace one Sunday afternoon in a thunderstorm before work. Also the fuel pump nearly died, taking the FP relay down with it. Replaced the relay and FP with a DW200. Now, in boost AFRs are much more stable. I should have done that swap long ago. Finally, driveshaft u-joints were on their way out, squeaking with every rotation. Other than that its been quite the joy as usual.

and FP with a DW200. Now, in boost AFRs are much more stable. I should have done that swap long ago. Finally, driveshaft u-joints were on their way out, squeaking with every rotation. Other than that its been quite the joy as usual.

Got some new wheels and tires earlier in the year, 15x8 with ZII star specs. Grip is phenomenal. AutoX and on ramps are the shiz.

I plan on finally tackling some 1.8 rebuild action, having picked up a bunch of parts and acquiring a second car to rely on!

Well I've been dailying it regularly with a couple hiccups due to the 225k miles that I've accumulated, almost 40k boosted. Had an almost seized and very noisy water pump I rushed to replace one Sunday afternoon in a thunderstorm before work. Also the fuel pump nearly died, taking the FP relay down with it. Replaced the relay

and FP with a DW200. Now, in boost AFRs are much more stable. I should have done that swap long ago. Finally, driveshaft u-joints were on their way out, squeaking with every rotation. Other than that its been quite the joy as usual.

and FP with a DW200. Now, in boost AFRs are much more stable. I should have done that swap long ago. Finally, driveshaft u-joints were on their way out, squeaking with every rotation. Other than that its been quite the joy as usual. Got some new wheels and tires earlier in the year, 15x8 with ZII star specs. Grip is phenomenal. AutoX and on ramps are the shiz.

I plan on finally tackling some 1.8 rebuild action, having picked up a bunch of parts and acquiring a second car to rely on!

Last edited by petrolmed; 12-15-2015 at 01:39 AM.

#98

Looks like almost another year with no update. Car still going strong? I have the same fitment issues with my downpipe that you have. It's resting right on the bell housing. Did you have any issues with this later on? I am not very concerned about it yet, but once things start to heat up I see the stress getting a bit higher on the exhaust and I would hate to crank a weld.

#99

Looks like almost another year with no update. Car still going strong? I have the same fitment issues with my downpipe that you have. It's resting right on the bell housing. Did you have any issues with this later on? I am not very concerned about it yet, but once things start to heat up I see the stress getting a bit higher on the exhaust and I would hate to crank a weld.

#100

Ha, things are good. The previous update post was from last month. But yes, things are chugging along as usual! The bell housing contact has not been a big issue, it mostly has caused things to shake more than usual which did lead to one of three muffler hangers breaking off at the weld. The alignment of the exhaust being a bit off contributed to that as well. I plan on correcting this when 1.8 goes in.

Shuiend is right, 1.8ness shall be springtime project. I can sense the 1.6's tiredness.

Shuiend is right, 1.8ness shall be springtime project. I can sense the 1.6's tiredness.