Pat's Ebay Turbo Compound Boost Build

#1641

When I was researching it seemed like the off road crowd was one of the biggest markets for a controller like this. If you intend to sell it I think they would like to see an option to disable the fan with a toggle switch for water crossings. I guess they could just interrupt the ignition signal with a toggle. I think that's something a lot of people would want to see advertised though.

#1642

Pat, don't run the condenser fan all of the time when the ac is on. It will actually reduce cooling above 30-40 mph.

Better to have it come on at 200 psi and off at 175 psi

If you can change fan speed at will have it ramp up (60%) at 225 and at max (100%) at 250.

Running down the road above 30 mph your high side should be below 200 and probably closer to 150.

Running the fan any time the AC is on puts a big load on the charging system that is not needed and can restrict airflow.

Better to figure out a way to have the fan and its shroud "disappear" past 30 mph (or anytime pressures are below 200).

This is impossible but you might find a work around...

A lot of the American cars don't turn the fans on until high side is 225 and don't go full speed until 275.

The Japanese tend to do the same at 175/225 and the AC compressors last twice as long.

Japanese AC also runs 10 degrees cooler at the vents than the American stuff but this has to do with evap temp cutoffs and not usually cooling fans.

Another AC improvement would be spraying the drain water produced by the evaporator at the condenser above 225 psi. Wetting the condenser usually has a 50 psi drop effect on the high side.

Only draw back is corrosion/rust on everything around the condenser...

Better to have it come on at 200 psi and off at 175 psi

If you can change fan speed at will have it ramp up (60%) at 225 and at max (100%) at 250.

Running down the road above 30 mph your high side should be below 200 and probably closer to 150.

Running the fan any time the AC is on puts a big load on the charging system that is not needed and can restrict airflow.

Better to figure out a way to have the fan and its shroud "disappear" past 30 mph (or anytime pressures are below 200).

This is impossible but you might find a work around...

A lot of the American cars don't turn the fans on until high side is 225 and don't go full speed until 275.

The Japanese tend to do the same at 175/225 and the AC compressors last twice as long.

Japanese AC also runs 10 degrees cooler at the vents than the American stuff but this has to do with evap temp cutoffs and not usually cooling fans.

Another AC improvement would be spraying the drain water produced by the evaporator at the condenser above 225 psi. Wetting the condenser usually has a 50 psi drop effect on the high side.

Only draw back is corrosion/rust on everything around the condenser...

#1643

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,339

Total Cats: 519

When I was researching it seemed like the off road crowd was one of the biggest markets for a controller like this. If you intend to sell it I think they would like to see an option to disable the fan with a toggle switch for water crossings. I guess they could just interrupt the ignition signal with a toggle. I think that's something a lot of people would want to see advertised though.

Pat, don't run the condenser fan all of the time when the ac is on. It will actually reduce cooling above 30-40 mph.

Better to have it come on at 200 psi and off at 175 psi

If you can change fan speed at will have it ramp up (60%) at 225 and at max (100%) at 250.

Running down the road above 30 mph your high side should be below 200 and probably closer to 150.

Running the fan any time the AC is on puts a big load on the charging system that is not needed and can restrict airflow.

Better to figure out a way to have the fan and its shroud "disappear" past 30 mph (or anytime pressures are below 200).

This is impossible but you might find a work around...

A lot of the American cars don't turn the fans on until high side is 225 and don't go full speed until 275.

The Japanese tend to do the same at 175/225 and the AC compressors last twice as long.

Japanese AC also runs 10 degrees cooler at the vents than the American stuff but this has to do with evap temp cutoffs and not usually cooling fans.

Another AC improvement would be spraying the drain water produced by the evaporator at the condenser above 225 psi. Wetting the condenser usually has a 50 psi drop effect on the high side.

Only draw back is corrosion/rust on everything around the condenser...

Better to have it come on at 200 psi and off at 175 psi

If you can change fan speed at will have it ramp up (60%) at 225 and at max (100%) at 250.

Running down the road above 30 mph your high side should be below 200 and probably closer to 150.

Running the fan any time the AC is on puts a big load on the charging system that is not needed and can restrict airflow.

Better to figure out a way to have the fan and its shroud "disappear" past 30 mph (or anytime pressures are below 200).

This is impossible but you might find a work around...

A lot of the American cars don't turn the fans on until high side is 225 and don't go full speed until 275.

The Japanese tend to do the same at 175/225 and the AC compressors last twice as long.

Japanese AC also runs 10 degrees cooler at the vents than the American stuff but this has to do with evap temp cutoffs and not usually cooling fans.

Another AC improvement would be spraying the drain water produced by the evaporator at the condenser above 225 psi. Wetting the condenser usually has a 50 psi drop effect on the high side.

Only draw back is corrosion/rust on everything around the condenser...

For my car, I'll probably use the MS to send a signal to disable after 30-40 mph as suggested. I can't remember if the VSS goes to the MS right now, but I can set that up if it doesn't.

#1645

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,339

Total Cats: 519

Small update...

I haz a TIG! It finally came in. Had some shipping problems but finally got it. Also picked up a 200CF Argon tank. Most of the welding things I bought I have. Got a bunch of 304 stainless coupons to practice welding with. A little bit of filler in 3 different sizes. Once I know what size works best, I'll order a few pounds of that size. Got a couple new stainless wire brushes. Got a fancy gas cup for stainless that's supposed to be good. And a couple diff types of tungsten for stainless. Probably some other stuff too. A 220 to 220 adapter to convert my house plug to the welder plug is also on the way. So hopefully in the next week, test welding will begin! Possibly tomorrow...

Still need some acetone for cleaning, some gloves, maybe a nicer welding helmet but gonna try the one I got first.

Super excited to be able to do higher quality welding in the near future. Hoping my exhaust system will be my first upgrade and turn out looking much better than my previous work.

Haven't worked on fan controller since last post, but plan to get back to that this weekend.

I haz a TIG! It finally came in. Had some shipping problems but finally got it. Also picked up a 200CF Argon tank. Most of the welding things I bought I have. Got a bunch of 304 stainless coupons to practice welding with. A little bit of filler in 3 different sizes. Once I know what size works best, I'll order a few pounds of that size. Got a couple new stainless wire brushes. Got a fancy gas cup for stainless that's supposed to be good. And a couple diff types of tungsten for stainless. Probably some other stuff too. A 220 to 220 adapter to convert my house plug to the welder plug is also on the way. So hopefully in the next week, test welding will begin! Possibly tomorrow...

Still need some acetone for cleaning, some gloves, maybe a nicer welding helmet but gonna try the one I got first.

Super excited to be able to do higher quality welding in the near future. Hoping my exhaust system will be my first upgrade and turn out looking much better than my previous work.

Haven't worked on fan controller since last post, but plan to get back to that this weekend.

#1647

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,339

Total Cats: 519

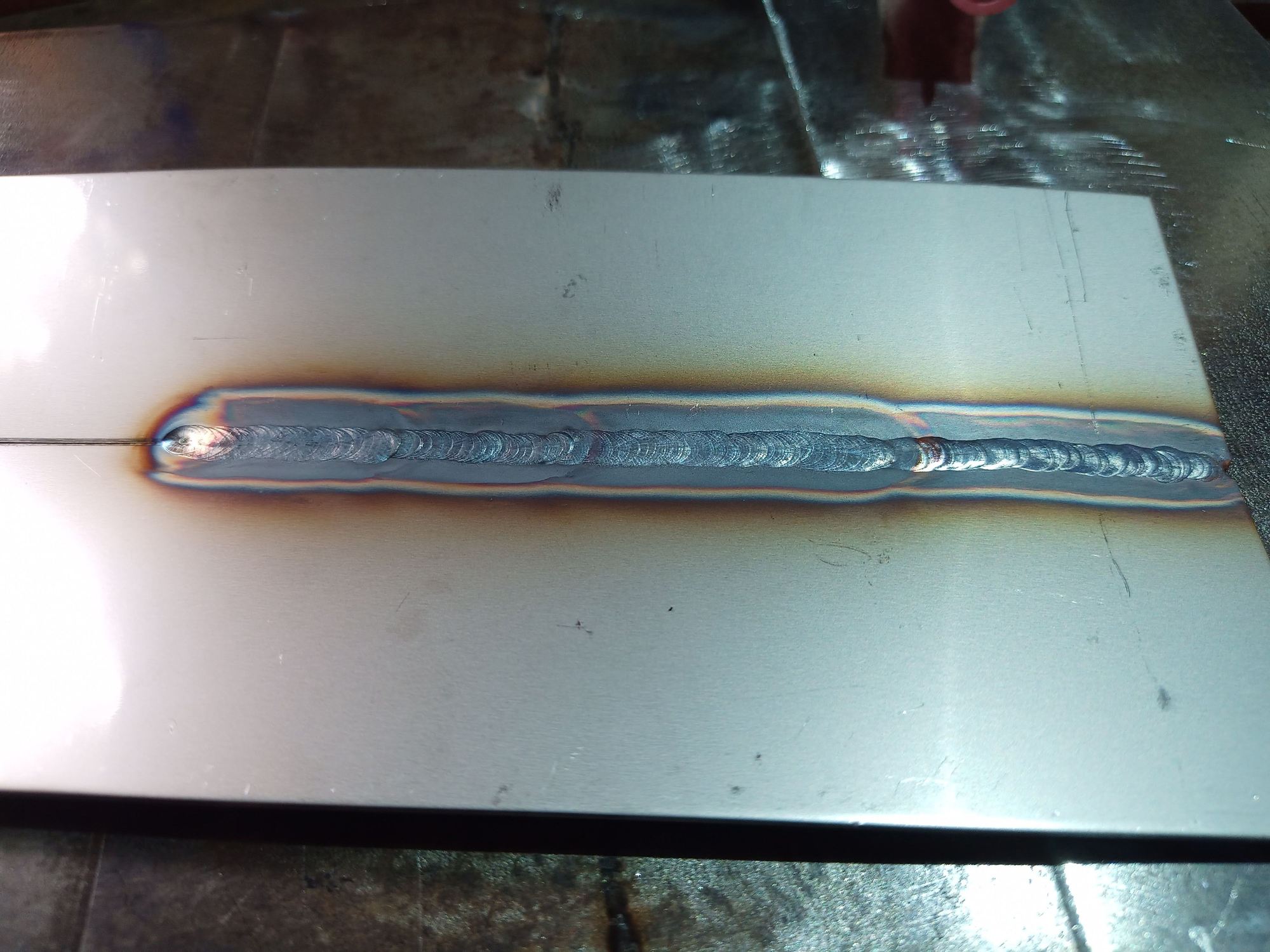

Update, got some first welds done today! Just practice. Last time I used a TIG was 3-4 years ago when I did my C4 auto conversion, welding the aluminum bell housing.

I'm definitely going to have to practice, but that is the plan. I was using a small cup, need to buy a bigger one. I had mixed results with different techniques. I will practice more and hopefully improve. Now I'm thinking next weekend I begin making the exhaust system.

Fusion welded 3 pieces together to make a make-shift welding table, and then welded a few pieces of 304 .065 stainless.

Pics!

#1648

If you don't mine me asking, where did you buy your Stainless Steel coupons? I'm a Houston resident (SW area) so if you have a local supplier that would be nice to know.

Regarding the solar flux, ya.....I built my entire dump tube with stainless steel tubing without backpurging or solarflux. Too cheap to buy a dual airline line set-up and wasn't aware of solar flux at the time... The inside looks horrid w/ the sugaring but hopefully it last long enough for me to break the car in + dyno time. I started to learn how to TIG a few months back so i'm basically new.

Regarding the solar flux, ya.....I built my entire dump tube with stainless steel tubing without backpurging or solarflux. Too cheap to buy a dual airline line set-up and wasn't aware of solar flux at the time... The inside looks horrid w/ the sugaring but hopefully it last long enough for me to break the car in + dyno time. I started to learn how to TIG a few months back so i'm basically new.

#1649

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,339

Total Cats: 519

https://weldmetalsonline.com/collect...l-flat-coupons

Currently sold out unfortunately. Don't know who bought all their stock.....

Not local, I didn't think to try that. I priced the metal through some online outlets, and buying the coupons was cheaper.

My plan is to do more test welding, and then more when I get the solar flux. If the solar flux works well, I'll use that. If it doesn't, and I can't get it to work, then I'll buy the stuff to backpurge, but really hoping the solar flux does it!

Currently sold out unfortunately. Don't know who bought all their stock.....

Not local, I didn't think to try that. I priced the metal through some online outlets, and buying the coupons was cheaper.

My plan is to do more test welding, and then more when I get the solar flux. If the solar flux works well, I'll use that. If it doesn't, and I can't get it to work, then I'll buy the stuff to backpurge, but really hoping the solar flux does it!

#1650

Don't be afraid to tig with mild steel and paint it (especially when prototyping). It's quite a bit cheaper and more forgiving (no back purging, easier to bridge gaps, much easier to cut). It's the one thing that I wish I had realized when I got my tig. Not everything needs to be stainless if it isn't a requirement.

#1651

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,339

Total Cats: 519

Got a good update!

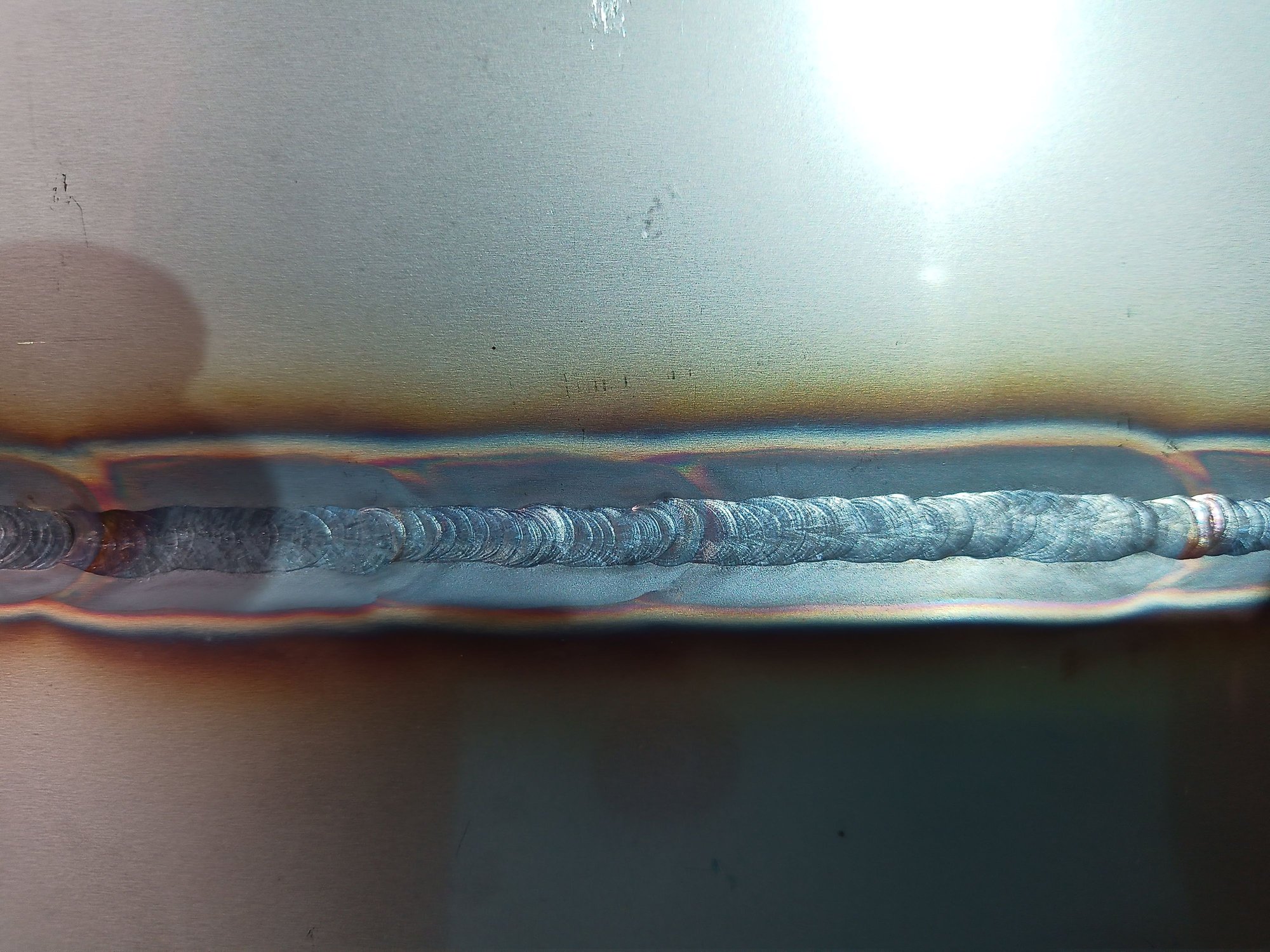

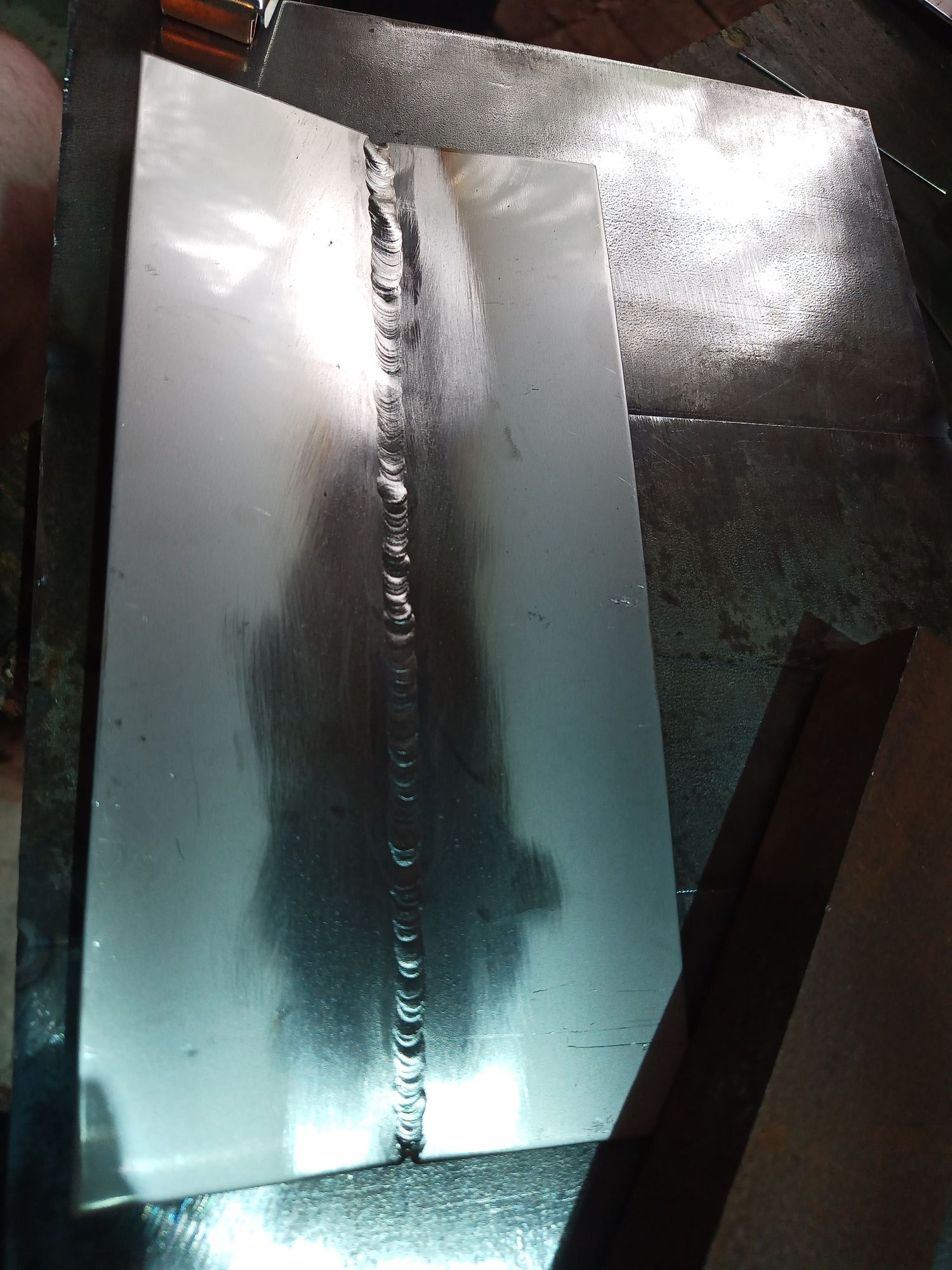

Solar flux came in. I tried it out. It works, but I think I need to practice how I'm using it. I stopped using it at one point so I could get back to working on other things.

Anyway! Welding is getting much better. I'm happy enough with where I'm at now to start building my exhaust. Wont' win any awards, but it looks solid to me.

Also bought a harbor freight thing for sharpening saw blades, but it has a diamond wheel, and I used that to sharpen my tungsten. Last time I tried to weld, I could tell something besides my skill was wrong, and some internet searching showed that sharpening it with a very coarse grinding wheel was the problem. I couldn't get a sharp tip before. I can now!

Even tried two different angles. And I tried experimenting with pulse. Still not sure how I should set that up, but seems it could be useful.

And did a bit of fusion welding, that is easy.

I tried several different techniques. I'll explain below with the pics!

Started with this tungsten angle.

One on left is first one today, other is second weld.

Then tried this tungsten angle.

2nd from left is 5 daps, then 5 sec cooldown. Next is fusion weld with pulse, then last is fusion pulse with more amps. The last one welded through on about 2/3's of the plate so a bit more heat would have been perfect.

5 dabs/5sec cooldown

Fusion 60A pulse

Fusion 90A pulse

Last piece. Very happy with this quality.

Solar flux came in. I tried it out. It works, but I think I need to practice how I'm using it. I stopped using it at one point so I could get back to working on other things.

Anyway! Welding is getting much better. I'm happy enough with where I'm at now to start building my exhaust. Wont' win any awards, but it looks solid to me.

Also bought a harbor freight thing for sharpening saw blades, but it has a diamond wheel, and I used that to sharpen my tungsten. Last time I tried to weld, I could tell something besides my skill was wrong, and some internet searching showed that sharpening it with a very coarse grinding wheel was the problem. I couldn't get a sharp tip before. I can now!

Even tried two different angles. And I tried experimenting with pulse. Still not sure how I should set that up, but seems it could be useful.

And did a bit of fusion welding, that is easy.

I tried several different techniques. I'll explain below with the pics!

Started with this tungsten angle.

One on left is first one today, other is second weld.

Then tried this tungsten angle.

2nd from left is 5 daps, then 5 sec cooldown. Next is fusion weld with pulse, then last is fusion pulse with more amps. The last one welded through on about 2/3's of the plate so a bit more heat would have been perfect.

5 dabs/5sec cooldown

Fusion 60A pulse

Fusion 90A pulse

Last piece. Very happy with this quality.

#1652

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,188

Total Cats: 1,684

Long term a dedicated tungsten grinder is worth its weight in gold if you are welding a ton. It is one of those things with a high up front cost, and not a seemingly quick ROI. But after using grinding stones and then switching to a proper grinder. I will never go back. It was sort of like going from 1ply industrial TP to 3 ply Charmin.

#1653

Long term a dedicated tungsten grinder is worth its weight in gold if you are welding a ton. It is one of those things with a high up front cost, and not a seemingly quick ROI. But after using grinding stones and then switching to a proper grinder. I will never go back. It was sort of like going from 1ply industrial TP to 3 ply Charmin.

#1655

Elite Member

iTrader: (9)

Join Date: Jun 2006

Location: Chesterfield, NJ

Posts: 6,914

Total Cats: 402

And here I have always grinded my tungstens on whatever grinder wheel is closest. I go very sharp/shallow angle, more like a sewing needle. I never tried anything else. I also use 'wrong' tungstens on aluminum because they work better. And turn off the auto balance on aluminum, bias way towards penetration baby.

#1656

mkturbo.com

iTrader: (24)

Join Date: May 2006

Location: Charleston SC

Posts: 15,188

Total Cats: 1,684

Those types work fine. If I was buying new again I would go that route instead of my expensive HTP Weld one. But I will still swear by them being nice and worth the money. No matter what type you get.

#1657

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,339

Total Cats: 519

Friend today told me about the new 275/35/15 tire that just came out. I'm thinking about buying those when they are available, and some appropriate wheels, and coilovers of some flavor so they fit, and whatever else I need to make them fit and work. Suggestions? Would like all the grip.

#1658

Friend today told me about the new 275/35/15 tire that just came out. I'm thinking about buying those when they are available, and some appropriate wheels, and coilovers of some flavor so they fit, and whatever else I need to make them fit and work. Suggestions? Would like all the grip.

A pair of the tires in link above, a big hammer and strong arm to swing said hammer will get you in business.

#1660

Elite Member

Thread Starter

iTrader: (16)

Join Date: Aug 2007

Location: Houston, TX

Posts: 9,339

Total Cats: 519

Small update!

Been looking into wheels/tires. Seems a 10" wheel and 245, there are a couple wheel options in stock, and a few tire options from 200 and 100 tread wear, and I think a couple 40 treadwear options.

I'm wondering, is going to an 11" and 275 worth it? I ask, because it will cost a lot more. I can't find any 15x11 wheels for one. And I'd have to wait for the new 275 tire that's supposed to be coming soon.

In other news, I have made a small amount of progress on my fan controller. Well, sort of. I'm developing a different part for a friends car, and while it's not a fan controller, it does have the high power electronics on it that I may use for my fan controller if they prove reliable in that environment.

I ran it doing about 4kHz PWM, sweeping from 0% to 100% and back to 0% in a 30second loop, running a large SPAL fan that pulls about 22A in free air and it seems to do that OK. Also wired in a large DC motor for an electric power steering pump and a 12V headlight bulb to add some extra load and that went ok. (about 35A and two inductive loads)

Just ordered another SPAL fan and will do more testing having it drive a pair of large spal fans, and an electric motor and headlight bulb. My goal is to get it to drive a 50A load without issue.

So far the biggest hurdle seems to be the edge speed going to my mosfet. I have what I thought was a very beefy gate driver, but still seeing slower than hoped for V/ns on the input of the FET.

Also need to buy a large amp meter, and a larger power supply for further testing. I fried this 30A supply once already and repaired it, need a bigger one.

Been looking into wheels/tires. Seems a 10" wheel and 245, there are a couple wheel options in stock, and a few tire options from 200 and 100 tread wear, and I think a couple 40 treadwear options.

I'm wondering, is going to an 11" and 275 worth it? I ask, because it will cost a lot more. I can't find any 15x11 wheels for one. And I'd have to wait for the new 275 tire that's supposed to be coming soon.

In other news, I have made a small amount of progress on my fan controller. Well, sort of. I'm developing a different part for a friends car, and while it's not a fan controller, it does have the high power electronics on it that I may use for my fan controller if they prove reliable in that environment.

I ran it doing about 4kHz PWM, sweeping from 0% to 100% and back to 0% in a 30second loop, running a large SPAL fan that pulls about 22A in free air and it seems to do that OK. Also wired in a large DC motor for an electric power steering pump and a 12V headlight bulb to add some extra load and that went ok. (about 35A and two inductive loads)

Just ordered another SPAL fan and will do more testing having it drive a pair of large spal fans, and an electric motor and headlight bulb. My goal is to get it to drive a 50A load without issue.

So far the biggest hurdle seems to be the edge speed going to my mosfet. I have what I thought was a very beefy gate driver, but still seeing slower than hoped for V/ns on the input of the FET.

Also need to buy a large amp meter, and a larger power supply for further testing. I fried this 30A supply once already and repaired it, need a bigger one.